Abstract

In the current scenario most of the industries want to produce superior quality products with less production time and manufacturing cost to full fill the customer needs. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) attain the industry's needs. However, the integration of CAD and CAM is most difficult task and facing lot of challenges. Feature recognition (FR) is the key link between integrate CAD and CAM and overcome the issues present in it. This paper presents a development of complex feature extraction system to extract different features like slant edges, bends, fillets, and chamfers from prismatic parts. A hybrid automatic feature recognition algorithm (HAFRA) combination of milling feature extraction algorithm (MFEA) and cylindrical feature extraction algorithm (CFEA) is proposed to identify the complex features using STEP file and then validation of the algorithm is done through case study. The developed hybrid automatic feature extraction system is well suited to extract the complex features from prismatic parts and thereby improve the downstream applications like process planning, CAPP, CAE, CAM, CAI, etc.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Day by day computer revolution in manufacturing industries rapidly increasing. Most of the manufacturing industries are used computers to design the required products with superior quality, high durability, less manufacturing time with reduced cost and high production throughput. In this manner integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) plays a vital role. However, the integration of CAD and CAM is most difficult task and having lot of issues due to lack of proper interfacing between them. The feature recognition (FR) is a key link to integrate CAD and CAM and also acts as an interface between design and manufacturing activities. Most of the researchers carried out their research on development of automatic feature extraction algorithms to extract various features for downstream applications like computer-aided process planning (CAPP). In this way, an automatic feature extraction system is developed to recognize form features by using logical geometrical rules [1]. In addition, various issues present in feature recognition is clearly addressed and developed a hybrid approach (i.e., combination of hint-based and volume decomposition) to extract intersection features [2]. Moreover, identified different manufactured features by using reverse engineering approach [3]. The extraction process contains three phases feature reconstruction, feature extraction, and feature translation. Furthermore, a novel approach is designed to recognize primitive features in the depressions of a polyhedral machining parts by using graph-based approach [4]. A new approach to identify prismatic part features by using logical rule-based approach [5]. Classification of cylindrical and milling features based on their characteristics and developed a multi-feature extraction system to extract cylindrical and milling features by applying logical rules and concave and convex relations [6].

Furthermore, a novel approach is developed to identify 2.5D prismatic part features based on machining of pre-defined features in the database [7]. A new technique (i.e., light-ray virtual method) is established to recognize machining features [8]. A hybrid approach (combination of graph-based and hint-based) is developed to extract intersecting milling features [9]. Classified free form features like passage, protrusion, slot, and compound features based on their geometrical properties and features are recognized by using attributed adjancy graph (AAG) method [10]. Moreover, some amount of research work has been done on automatic feature recognition of constant thickness metals like sheet metal components. Classified deform features on sheet metal based on their topological properties and features are extracted by using graph-based approach [11]. A new technique (Basic deformation feature graph) is developed to identify deform features like dimple, wall, jog, louver, rib, bead, etc. [12]. Further bit amount of research work has been attempted on extraction of casted features by using automatic feature extraction systems. A new approach is addressed to identify casting and forging part features by using volume decomposition method [13].

However, very limited work has been done on identifying inclined plane features and edge fillet features in matching parts. This paper presents a new algorithm is developed to extract milling and cylindrical features on inclined planes and edge fillets by using combination of logical rules and concave and convex relations. The implementation and validation of algorithm via in house developed JAVA program is used. The rest of the paper is segregated as follows; automatic feature extraction methodology is explained in Sect. 2. Implantation and validation of the algorithm is executed via example in Sect. 3. Discussion and feature construction theory is addressed in Sect. 4. Finally, conclusions are mentioned in Sect. 4.

2 Methodology

The hybrid AFR algorithm is developed to extract various milling features like pocket, blind pocket, through hole, and fillet of a 3D model object created by CATIA software version 5.

The proposed hybrid AFR algorithm is ability to identify the features on inclined plane. Moreover, HAFRA act as a key link between CAD and CAM. In addition, HAFRA minimizes the manufacturing cost as well as stored the product information throughout its life cycle without damage of product attributes data. The milling feature extraction process from 3D modeled object is illustrated in Fig. 1.

2.1 Milling Feature Extraction Algorithm (MFEA) from B-Rep Data

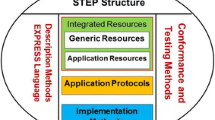

Initially, the required product is created by using CAD software. The product model is transformed into neutral file is known as STEP AP-214 file. Which plays a major role to interface between CAD and CAM. Then after boundary representation (B-rep) data extracted from STEP files by using geometric data extraction algorithm (GDEA) [5]. Further, B-rep data given as an input to MFEA as shown in Fig. 2, to extract milling feature information based on concavity relation approach. The following steps have been adopted to execute the MFEA.

Step 1: Extraction of B-rep data from STEP AP-214 file.

In this step, geometrical entities viz., plane, line, circle, edge, edge loop, inner bound, outer bound, etc. extracted by using geometrical extraction algorithm (GDE) [5] from STEP AP-214 file. Moreover, the B-rep data contains geometrical and topological attributes of the corresponding 3D modeled part.

Step 2: Identify planes, faces, and edges from B-rep data of 3D model part.

This step collects the information like number of faces, edges, and common edges from the planes.

Step 3: Extract edges and common edges between the planes and measure angle between planes.

In this step, extract the common edges from the plane’s nature and measure the angle between two common edges (i.e., angle is 90° or #90° and # 270°).

Step 4: Calculate normal with respect to planes and corresponding edge directions.

The normal of the two planes and corresponding edge direction is calculated in this step.

Step 5: Determine the cross products between the two planes.

This step involves calculate the normality index via cross-product of two normal of the corresponding planes (i.e., ni × nj) and the normal index is denoted by C.

Step 6: Check normal index and direction of the edges.

In this step the normal index and edge direction of the correspond plane is equal then go for next step otherwise repeat the step 3–5.

Step 7: Determine concave and convex between the planes and edges.

The concave and convex relation among the faces is observed based on angle \(180^\circ < \theta < 360^\circ\) and \(0^\circ < \theta < 180^\circ\), respectively. The convex faces between the planes represent (1) and whereas concave faces between the planes indicate (−1) and the data is stored in the database.

2.2 Cylindrical Feature Extraction Algorithm (CFEA) from B-Rep Data

The cylindrical features like holes, bind holes, taper holes, boss, protrusions, etc. are extracted by using CFEA as shown in Fig. 3, based on logical rule-based approach. The following steps have been adopted to extract above listed cylindrical feature information from 3D modeled object.

Step 1: Extraction of B-rep data from STEP AP-214 file.

In this step, geometrical entities viz., cylinders, circle, radius, Cartesian points, vertex points, staring points, ending points, edge loop, inner bound and outer bound, etc. extracted by using geometrical extraction algorithm (GDE) [5] from STEP AP-214 file. Moreover, the B-rep data contains geometrical and topological attributes of the corresponding part.

Step 2: Identify cylinders and circles from the cylinders from B-rep data of 3D model part.

This step collects the information like number of cylinders and corresponding circles with their attributes of the 3D modeled part.

Step 3: Check the number of edges and vertex of the planes and type of surfaces.

In this step, collect the surface details and check the number of edges and circle details of the corresponding plane. Further the nature information either cylindrical surface, conical surface, and toroidal surface with their geometry and correlate with circles information [6].

3 Implementation of HAFRA Via Case Study

3.1 3D Modeling Using CATIA Software

In this study, 3D solid model is developed by using Catia software version 5. The features embedded in the model such as blind hole, blind slot, through pocket, and also features like blind pocket and through slot on inclined plane as shown in Fig. 4.

3.2 B-rep Data from GDE Algorithm

The boundary representation data (B-rep data) as shown in Fig. 5, contains geometrical information, as well as topological information of 3D model, is extracted by using GDE algorithm [5].

3.3 Results and Discussion of HAFRA

The obtained B-rep data from GDE algorithm given as an input to developed HAFRA for extraction of features from inclined plane and edge fillet by using logical rule-based theory and concavity relation. The HAFRA mechanism is the combination of both MFEA and CFEA mechanisms.

3.3.1 Mechanism Involved to Extract Milling Features in MFEA

The milling features like through pocket, rectangular blind pocket, slot and blind slot, respectively. The mechanism involved in MFEA to extract above listed features based on con cavity relations among faces between the planes. The concave and convex relation among the faces is observed based on angle 180° < θ < 360° and 0° < θ < 180°, respectively. The validation of developed MFEA is done via in house developed JAVA program and the corresponding results as depicted in Fig. 6. The following key points have been noted for extraction of milling features mechanism.

-

The B-rep data as shown in Fig. 5, given as input to the MFEA and the corresponding output results of MFEA as shown in Fig. 6.

-

The face relation and corresponding attributes are depicted in Table 1.

Table 1 Attribute relation among the faces -

The attribute relationship among the faces between the planes and feature formation based on relation matrix information is mentioned in Table 2.

Table 2 Attributes relation between the faces based on relation matrix -

From the relationship matrix concave (−1) data applied to production rules, result in corresponding milling features like through pocket, rectangular blind pocket, blind slot and slot are formed as shown in the Table 3a–d, respectively.

Table 3 a–d Feature formation from relation matrix based on production rules

3.3.2 Mechanism Involved to Extract Cylindrical Features in CFEA

The cylindrical feature like blind hole, through hole, taper hole, boss and protrusion fillets, etc. The cylindrical features are extracted by using CFEA based on rule-based approach. The validation of developed CFEA is done via in house developed JAVA program and the corresponding results as shown in Fig. 7. The following mechanism points have been noted to while extracting the cylindrical features as well as edge fillet from the developed 3D model part.

-

The two cylindrical faces 21 and 22 having same geometrical information (radius) and having same center point. Moreover, if the number of edges of the cylinder one side having more than two and other side is equal to two, the obtained feature is blind hole and the information is stored in database.

-

The cylindrical face 27 having same radius and tangent to, and join two surfaces of the corresponding planes, then the obtained plane is toroidal edge fillet and the corresponding data is stored in database for further applications.

-

The inclined plane is Identified based on the cross-product of two planes not equal to 90° and not equal to 270°. The inclined plane details and the corresponding features on inclined plane information is stored in the database.

-

The type of surface either cylindrical surface, conical surface, and toroidal surface and the corresponding direction (negative or positive) of the axis information with their geometry obtained the cylindrical features in the 3D modeled part.

4 Conclusions

This work developed a new HAFR algorithm to recognize milling and cylindrical features like pocket, blind slot, through slot, blind hole, edge fillet by using combination of MFEA and CFEA based on logical rules and concavity relation with relation matrix. The 3D solid model is developed by Catia version 5 software and corresponding data exchange standard STEP AP-214 is to be considered. The new HAFR algorithm is implemented through java program and the embedded features on the solid model are successfully extracted and the corresponding information is stored in the database for further downstream applications like process planning, CNC, and CAM.

References

Abouel Nasr ES, Kamrani AK (2006) A new methodology for extracting manufacturing features from CAD system. Comput Ind Eng 51:389–415

Woo Y, Sakurai H (2002) Recognition of maximal features by volume decomposition. Comput Aided Des 34(3):195–207

Wang M, Chamberlain MA, Joneja A, Chang T (1993) Manufacturing feature extraction and machined volume decomposition in a computer-integrated feature-based design and manufacturing planning environment. Comput Ind 23(1–2):75–86

Marefat M, Kashyap RL (2012) Geometric reasoning for recognition of three-dimensional object features. IEEE Trans Pattern Anal Mach Intell 12(10):949–965

Sreeramulu D, Rao C (2008) A new methodology for recognition of milling features from STEP file. Int J Appl Manage Technol 6(3):172–190

Adapa SK, Sreeramulu D (2021) Jagadish: Classification and automatic feature-based extraction approach for cylindrical and milling parts. Int J Manuf Mater Mech Eng 11(3):55–73

Pedagopu VM, Kumar M (2014) An intelligent feature recognition methodology study for 2.5 D prismatic parts. Int J Comput Eng Technol 5(4):119–125

Ranjan R, Kumar N, Pandey RK, Tiwari MK (2015) Automatic recognition of machining features from a solid model using the 2D feature pattern. Int J Adv Manuf Technol 26:861–869

Rahmani K, Arezoo B (2017) A hybrid hint-based and graph-based framework for recognition of interacting milling features. Comput Ind 58:304–312

Bendjebla S, Cai N, Anwer N, Lavernhe S, Mehdi-Souzani C (2018) Freeform machining features: new concepts and classification. Procedia CIRP 67:482–487

Gupta RK, Gurumoorthy B (2013) Classification, representation, and automatic extraction of deformation features in sheet metal parts. Comput Aided Des 45(11):1469–1484

Sreenu P, Gupta RK (2014) Extraction of process parameters from a sheet metal part model. Appl Mech Mater 592:888–893

Kailash SB, Zhang YF, Fuh JYH (2001) A volume decomposition approach to machining feature extraction of casting and forging components. Comput Aided Des 33(8):605–617

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Meka, S., Sreeramulu, D., Dumpala, L. (2023). Development of Complex Feature Extraction System from Prismatic Parts Using Hybrid Algorithms. In: Dikshit, M.K., Soni, A., Davim, J.P. (eds) Advances in Manufacturing Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-4208-2_6

Download citation

DOI: https://doi.org/10.1007/978-981-19-4208-2_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-4207-5

Online ISBN: 978-981-19-4208-2

eBook Packages: EngineeringEngineering (R0)