Abstract

Water purification, space conditioning, and energy saving are the global necessities. Humidification–dehumidification desalination is a water cycle-based process that includes air humidification and condensation. When compared to a single output device, two or three outputs from a single source result in an overall high energy utilization factor (EUF). In this work, a two-stage humidification and dehumidification (HDH) desalination system has been expanded with the addition of a cooling system. Polygeneration of desalinated water and conditioned air utilizing solar energy fulfills the entire requirement simultaneously. This investigation was done by using two-stage humidification and dehumidification desalination with a vapor compression refrigeration system. The performance is investigated analytically, with the help of mass and energy balance equations and a psychometric chart. The maximum fresh yield water recorded at a particular ambient temperature was approximately 17.24 LPH at 0.1 kg/s of airflow and 0.1 kg/s of hot water flow rate in the humidifier, and the cooling load, energy utilization factor, and gain output ratio obtained from the system are 1.61 kW, 0.59, and 1.2, respectively. The refrigerant used in VCR is R134a.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

When compared to other two-stage systems, the integration of humidification–ehumidification with a vapor compression cycle offers numerous advantages, including compactness. The use of vapor compression cycle with humidification and dehumidification can provide more desalination yield and cooling air, which can be used for space conditioning. During the thermodynamically studies, we observed that energy utilization and cooling loads were high.

The global energy consumption for space cooling is forecast to rise from 2020 TWh in 2016 to 6200 TWh in 2050, based on cooling degree days (CDDs) (International Energy Agency, 2018 [1]). As a result, the severity of urban heat islands may improve as the utilization of air conditioning systems increases. Chiranjeevi et al. [2] demonstrated the novelty of two-stage humidification–dehumidification with a vapor absorption refrigeration system, and using simulation, they concluded that two-stage humidification–dehumidification has a high energy utilization factor. Chiranjeevi et al. [3] experimented on two-stage humidification–dehumidification with a vapor absorption refrigeration system in which they produce 2.2 kg/h of freshwater with a 0.33 plant energy utilization factor. Gholizadeh et al. [4] did a simulation on the humidification–dehumidification desalination unit with an ethane ejector expander transcritical refrigeration cycle. During the simulation, they compared the single-stage HDH and single-stage compression ethane—EETRC—with two-stage HDH unit and single-stage compression ethane—EETRC—with two-stage HDH unit and two-stage compression ethane—EETRC, and they obtained CGOR, cooling load, desalination yield, and exergy efficiency of 6.56, 146.9 kW, 17.3 m3/day, and 17.13%, respectively. Waste heat rejection to the environment from air conditioning is one of the major challenges for human beings which causes the heat island effect. To encounter this problem, Anand et al. [5] did a numerical study on a single-stage HDH desalination system with VCR without changing the original size of the compressor, and they used condenser heat for humidification of air. He obtained a maximum desalination yield and cooling load of 7.35 LPH and 1.89 kW, respectively. The highest GOR, EUF, and COP are 6.18, 8.27, and 2.16, respectively. Lawal et al. [6] developed an experimental model in which an HDH desalination unit is used with a heat pump to increase the freshwater and cooling load. They used refrigerant condensing heat to raise the temperature of the saline water in the humidifier’s condenser and evaporating heat to cool the water in the heat pump’s evaporator for the dehumidifier, and the results indicated that RR, COP, GOR, EUF, freshwater, and cooling load are 4.86%, 4.85, 4.07, 3.04, 287.8 L/day, and 3.07 kW, respectively. Hou et al. [7] built a model for humidified air compression, cooling with seawater, and expansion in a turbine for desalination and air conditioning. They discovered that the planned refrigeration system’s COP is primarily determined by the performance of the compressor and turbine. Zhang et al. [8] the efficiency and cost of a two-stage HDH unit coupled with a vapor compression HPC were experimentally investigated and produced 22.26 kg/h of freshwater for 0.051 $/kg, yielding more appealing results than a basic HDH unit. Zhao et al. [11] investigated a new four-stage solar desalination system for cross-flow humidification and dehumidification (HDH) with direct dehumidifiers. Huang et al. [12] during the analysis of a closed-water multi-stage HDH desalination system, they observed that various levels of salinity and showed that salinity increases lead to a reduction in water productivity (~0.75% increase in salt content) and maximum efficiency of energy (at an average of 11.44% for 20% salinity). Chehayeb et al. [13] performed a thermodynamic analysis on a fixed-size two-stage HDH desalination system and concluded that using a multi-tray bubble column dehumidifier can produce better results than a conventional dehumidifier. Gang Wu et al. [14] conducted a theoretical and experimental study of a novel direct sun-focused heating desalination system that uses a humidification and dehumidification process. As a solar concentrator, a specially built cylindrical Fresnel lens was employed in a three-stage HDH desalination system. The unit’s highest yield and GOR are 3.4 kg/h and 2.1, respectively.

The literature research demonstrates that in two-stage HDH desalination with a refrigeration system, very minimum effort is done. The combination of two-stage HDH desalination and cooling cycle results in two additional benefits: improved water yield and additional cooling gain. In this study, we introduced a unique hybrid desalination system design that can efficiently chill humid air while generating freshwater. The uniqueness of the system is using a combination of sea water and R134a refrigerant as a cooling medium in a two-stage hybrid desalination system. Another aspect of our system is that it harnesses the refrigerant heat from the condenser in the vapor compression refrigeration cycle to make cooling air acceptable within human comfort standards. The latest planned work focuses on the consolidated plant’s output standards under varying operating conditions. It is intended to conduct studies to optimize the parameters involved to obtain higher yields like an analysis of ambient temperature, relative humidity, hot water inlet temperature, and cooling temperature.

Methodology

Single-stage HDH desalination is modified with two-stage HDH desalination with VCRS. The process was modified by using normal water in the 1st stage dehumidifier for condensation of hot and humid air, using refrigerant heat to condensate the hot and humid air, and for space conditioning in the 2nd stage of the system. The heating and humidification of air are controlled by supplying hot water in the APH and humidifier. Using two-stage HDH desalination with VCRS results in combined desalination and cooling load. R134a is a working fluid in the VCRS. The proposed system performance such as distilled water, cooling load, EUF, GOR, and COP is analyzed for various ambient air temperatures, hot water temperature, evaporator temperature, and RH.

System Description

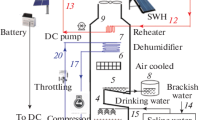

The present work consists of thermodynamic analysis of the two-stage HDH desalination system with VCR, which consists of two APH, two humidifiers, one normal water-cooled dehumidifier, and one VCR. The refrigerant used in the VCR is R134a. A blower is placed at the inlet of the plant which is used to force the ambient air through the 1st APH of the system, (1) then force air get heated by hot saline water which is circulating in the APH. Hot saline water in the APH is pumped through the hot water pump, which is heated by the solar water heater. High-temperature air obtained from 1st APH further leads to the 1st humidifier of the system where hot saline water, which is supplied through SWH, is sprinkled on the high-temperature ambient air (2) which is coming from the 1st APH for humidification of the air because high-temperature air has more water absorption capacity as compared to low-temperature air. After the heating and humidification, hot humid (3) air is directed to the normal water-cooled dehumidifier. The WBT of the humid air is high as compared to which is surrounded by the evaporator. Due to this, when humid air comes into contact with evaporative air, it condensates. The main purpose is to use the normal water dehumidifier to increase the energy utilization of the system (Fig. 67.1).

After the 1st stage HDH, the saturated air (4) leads to 2nd APH (5) and 2nd humidifier (6) similarly. And again, hot humid air (6) is directed to the refrigerant-cooled evaporator. The main purpose of using a refrigerant evaporator in the 2nd stage is to obtain more freshwater water and cooling load. When comparing single-stage HDH to two-stage HDH, the two-stage achieves a higher desalination yield and cooling load than the single stage. After the refrigerant evaporator, cooled air (7) is directed to the refrigerant condenser to utilize condenser refrigerant vapor heat for the reheating purpose of the cooled air because the air we obtained from the refrigerated evaporator is cooled and saturated, which is not favorable for human comfort, we need to decrease the relative humidity of the cooled and saturated air to make air comfortable. The use of refrigerant condenser heat to decrease the relative humidity of saturated air within 50% to 70% of RH is a more promising technique.

Figure 67.2 represents the detailed process of air (sensible heating, humidification, and dehumidification) that undergoes inside the system on a psychometric chart. The results show the benefits of air preheating for greater humidification. The 1st stage of heating, humidification, and dehumidification (1–4) and the 2nd stage of heating, humidification, and dehumidification (4–8) have been stated the affinity of the moisture condensed during the process. The chart shows that in the 1st stage and 2nd stage, approximately 35 g and 60 g of distilled water can be generated, respectively. The humidity ratio of the 2nd humidifier is greater than the 1st humidifier due to high moisture content and temperature as compared to an ambient condition, which results from a high cooling load in the 2nd stage as compared to the 1st stage.

The following section encapsulates the assumptions used in the thermodynamic evaluation of the proposed integrated system. System follows steady-state conditions. Isentropic efficiency (0.8) is used by the compressor. The evaporator’s outlet conditions are assumed to be saturated. The velocity of air flow throughout the system is assumed to be constant. The thermal effectiveness of APH is assumed as 75%, the thermal efficiency of the humidifier is assumed as 50%, and the contact factor of coil for a dehumidifier is assumed as 70%. The initial conditions for the system are assumed as 35 °C temperature of ambient air and 50% RH of air. Circulating normal used in the 1st dehumidifier is assumed to be 30 °C. The inlet hot water temperature supplied by the SWH in the humidifier is assumed to be 60 °C. Thermodynamic analysis is done on the 0.1 kg/s mass flow rate of the air in the integrated system and the 0 °C evaporative temperature in VCRS. And the makeup water used in the SHW is approximately 1% or 2% of the hot water supplied in the humidifier. To forecast the subsystem’s exit conditions, mass and energy balance equations are built under the aforementioned assumptions.

The temperature of the air exiting the APH is dictated by its effectiveness,

The humidifier efficiency,

Energy equation used for the humidifier is,

Mass balance equation of dehumidifier for determining distilled water,

Energy balance equation used for the dehumidifier is,

Cooling load of the integrated cycle calculated from,

Net power supplied in the integrated cycle,

The COP of the integrated cycle can be determined by,

EUF of an integrated cycle,

Results and Discussion

Results of this present work are analyzed, and a graph is plotted with the help of the energy equation solver. The desalination yield is determined by the ambient conditions, humidifier’s efficiency, quality, and hot water inlet temperature. The dehumidification mechanism is influenced by the cooling temperature. In the dehumidification process, the temperature of the evaporator and the temperature of the circulating water inlet have an impact on cooling output. The operating conditions are varied to optimize both the desalinated water yield and the cooling effect. Total desalination production is studied with different ambient temperatures with different RH in ambient (Fig. 67.3). Results depicted that improvement in desalination with an increase in ambient temperature and relative humidity because the high ambient temperature has a large moisture-absorbing capacity, due to which production of desalination is more effective in high temperature and high relative humidity.

Figure 67.4 depicts the improvement in GOR with increasing ambient temperature and RH, in which 0.1 kg/s air flow rate can be able to get 1.2 GOR, demonstrating that net power required for heating and humidification by the cycle is less when the temperature and RH of ambient air are high because less hot water is required for heating and humidification of air, resulting in less power consumption (Fig. 67.5). The graph depicts the trend of desalination yield and EUF as hot water temperature varies. It demonstrates that as the inlet hot water temperature rises, so does the desalination yield, because heating with humidification increases the water holding capacity of the air, resulting in more desalination. At the same time, EUF is also decreasing with increasing the hot water temperature. The reason for this scenario is that as the temperature of hot water rises, so does the power required to heat the water, because evaporators must deal with high heat loads, which leads to an increase in compressor work (Fig. 67.6). This graph depicts the variation in desalinated water and EUF as evaporative temperature changes. When the evaporative temperature is low, desalination production outnumbers power consumption, indicating that the system favors desalination. However, when the evaporative temperature rises, power consumption outnumbers desalination production.

Validation

See Table 67.1.

Conclusion

A thermodynamic study of a potential solar-powered two-stage desalination and cooling plant using the air humidification and dehumidification process was performed. The integration of two-stage desalination and cooling highlights that two-stage HDH desalination with VCR is more effective as compared to single-stage HDH desalination and cooling system. A high value of hot water temperature, humidifier efficiency, and dehumidifier effectiveness produces a good amount of desalination as well as cooling air. With a 0.1 kg/s air mass flow and 0.1 kg/s seawater flow rate and increase in ambient temperature from 35 °C to 40 °C, we were able to get 15.2 LPH to 17.24 LPH of freshwater and a 1.61 kW cooling load. The cycle’s maximum EUF and GOR are 0.59 and 1.2, respectively.

Abbreviations

- Hw:

-

Hot water

- T:

-

Temperature

- Mw:

-

Makeup water

- Q:

-

Heat duty

- A:

-

Wet air

- M:

-

Mass flow rate

- Da:

-

Dry air

- C:

-

Specific heat

- C:

-

Cooling capacity

- W:

-

Specific humidity

- H:

-

Enthalpy

- SWH:

-

Solar water heater

- HDH:

-

Humidification dehumidification

- ɛ:

-

Epsilon

- EUF:

-

Energy utilization factor

- η:

-

Efficiency

- COP:

-

Coefficient of performance

- VCR:

-

Vapor compression refrigeration

- I:

-

Inlet

- GOR:

-

Gained output ratio

- O:

-

Outlet

- APH:

-

Air preheater

- W:

-

Water

- RH:

-

Relative humidity

References

Energy, I. G. (2018). CO2 Status Report 2017. International Energy Agency. 2017c.

Chiranjeevi C, Srinivas T (2014) Combined two-stage desalination and cooling plant. Desalination 345:56–63

Chiranjeevi C, Srinivas T (2017) Augmented desalination with cooling integration. Int J Refrig 80:106–119

Gholizadeh T, Vajdi M, Rostamzadeh H (2020) Freshwater and cooling production via integration of an ethane ejector expander transcritical refrigeration cycle and a humidification-dehumidification unit. Desalination 477:114259

Anand B, Murugavelh S (2020) Performance analysis of a novel augmented desalination and cooling system using modified vapor compression refrigeration integrated with humidification-dehumidification desalination. J Clean Prod 255:120224

Lawal DU, Antar MA, Khalifa A, Zubair SM, Al-Sulaiman F (2020) Experımental investigation of heat pump driven humidification-dehumidification desalination system for water desalination and space conditioning. Desalination 475:114199

Hou S, Li H, Zhang H (2008) An open-air–vapor compression refrigeration system for air-conditioning and desalination on the ship. Desalination 222(1–3):646–655

Zhang Y, Zhu C, Zhang H, Zheng W, You S, Zhen Y (2018) Experimental study of a humidification-dehumidification desalination system with the heat pump unit. Desalination 442:108–117

Rajaseenivasan T, Shanmugam RK, Hareesh VM, Srithar K (2016) Combined probation of bubble column humidification dehumidification desalination system using solar collectors. Energy 116:459–469

El-Agouz SA (2010) A new process of desalination by air passing through seawater based on humidification–dehumidification process. Energy 35(12):5108–5114

Zhao, Y., Zheng, H., Liang, S., Zhang, N., & long Ma, X. (2019). Experimental research on four-stage cross flow humidification dehumidification (HDH) solar desalination system with direct contact dehumidifiers. Desalination, 467, 147–157.

Huang X, Wang H, Liu W, Ling X, Li Y, Wang Y, Li J (2020) Performance analysis of a multi-stage humidification–dehumidification desalination system with different salinity levels. Energy Convers Manage 215:112928

Chehayeb KM, Narayan GP, Zubair SM (2015) Thermodynamic balancing of a fixed-size two-stage humidification dehumidification desalination system. Desalination 369:125–139

Wu G, Zheng H, Ma X, Kutlu C, Su Y (2017) Experimental investigation of a multi-stage humidification-dehumidification desalination system heated directly by a cylindrical Fresnel lens solar concentrator. Energy Convers Manage 143:241–251

Acknowledgements

Acknowledge the project grant of the Science and Engineering Research Board (SERB) under Impacting Research Innovation and Technology (IMPRINT-2), PAC Water Resources & River System, New Delhi, India, (IMP/2019/000444).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kame, S., Srinivas, T. (2023). Performance Analysis of Two-stage Humidification and Dehumidification Desalination with VCR. In: Manik, G., Kalia, S., Verma, O.P., Sharma, T.K. (eds) Recent Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-2188-9_67

Download citation

DOI: https://doi.org/10.1007/978-981-19-2188-9_67

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-2187-2

Online ISBN: 978-981-19-2188-9

eBook Packages: EngineeringEngineering (R0)