Abstract

In recent years, the usefulness of infrared thermography (IRT) has been extended to multiple scenarios, due to several benefits: rapid inspection, multi-point detection, real-time monitoring, etc. However, the range of applicability can vary from the single building inspection to the analysis of municipalities. This chapter outlines the most common techniques based on qualitative and quantitative infrared thermography (IRT) for the diagnosis of elements at urban level, assessing different types of instrumentation (i.e., drones, vehicles, and portable cameras) for three representative investigated objects: building envelopes, PV panels, and urban heat island (UHI) effect.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Infrared thermography (IRT) allows to detect the infrared radiation (IR) emitted by a body and to convert it into the temperature of the body itself, providing its temperature pattern (thermal image).

This is a technique born for military purposes and spread to several fields of investigation: human and veterinary medicine, cultural heritage preservation, and botany to mechanical engineering. Its history has been recalled in [1], and it is strictly linked to the development and production sensors capable of offering a higher resolution with lower cost [2]. The different fields of IRT usefulness lead to a wide range of employment scenarios [3], which differ in: (i) the approaches (passive or active); (ii) the relative motion of camera and object (static or dynamic); (iii) the energy source; (iv) excitation form; (v) the way energy is transferred or generated (transmission, reflection or internal); and (vi) scanning way. The thermal resolution of an IR camera is influenced by a series of features and properties, which is summarized in Fig. 1.

Building and construction is probably among the fields that mostly benefited from the introduction, development, and employment of this non-destructive, non-invasive, and contactless technique. These characteristics add up to the real-time investigation, multi-point detection, and digital image collection [4]. The need for rapid inspection of wide areas has led the development of technologies and instrumentation that could facilitate this task over the years.

Indeed, the applicability of IRT ranges from the single building inspection to the analysis of sets of buildings or neighborhoods (Fig. 2), implementing different types of instrumentation (i.e., drones, vehicles, and portable cameras). This can involve the assessment of several targets: built quality of envelopes and preventive maintenance (i.e., detection of anomalies like heat losses, thermal bridges, and moisture); PV panels faults through corrective maintenance; and urban heat island (UHI) effect among others.

Within this context, the following sections pretend to overview the aspects mentioned above, highlighting the current state of IRT instrumentation and the most common investigated objects at urban level.

2 Instrumentation

Information provided by IRT become even more useful when they are coupled with those from other techniques: visual inspection, heat flow meter method, moisture measurement, and city geometry models among others. When techniques are fused and mixed, their strength points are enhanced by a multi-disciplinary approach, whose aim is to provide a depiction of the investigated object as much complete as possible, avoiding misinterpretations and errors. By way of example, some studies are reported below. Fox et al. [4] proposed a useful classification of the passive technique. Lucchi et al. [1] reviewed the employment of IRT in energy audits. Later, Kirimtat et al. [5] pointed out the main differences between passive and active approaches. Morrison et al. [6] analyzed the IRT at urban level to investigate the variability of surfaces temperature of several building and of vegetation and grass, coupling with modeling of urban geometries or materials properties. The work, besides focusing on the importance of camera sensors and their positioning, and of materials properties, aimed to highlight the importance of shadows in the temperature reading.

According to these works, the following methodologies (briefly described in the following) can be outlined: (i) aerial surveys; (ii) automated fly-past surveys; (iii) street pass-by surveys; (iv) walk-around surveys; (v) walk-through survey; (vi) repeat survey; and (vii) time-lapse survey. Such techniques differ in execution time, post-process time, cost, spatial resolution, need for specialized personnel, urban level at which they are employed, etc. (Fig. 3).

Aerial thermography (aIRT) is carried out when an airplane (or a helicopter as well) is equipped with an IR camera, and it flies over the area to be investigated. Normally, several flights are needed to have a proper depiction of the area. Given the survey typology, the portion investigated is the unique that faces the sky. Therefore, building roofs, PV panels, and vegetation foliage can be detected. From this kind of approach, even energy models of cities can be retrieved [7]. The flight altitude can be 350–450 m, and from that, distance images could not have the proper spatial resolution. It can somehow be included in this category also the investigations carried out from satellites that acquire with good quality information on the Earth surface, including thermal pattern. It is worth noting that, given the high distance between sensor and object, the spatial resolution is quite high in these cases (about 1 km2) [8], so data must be validated with point measurements. The complexity of this method is clearly shown in [9], where the principles of infrared machine vision are exposed, as well as the application of deep learning.

Automated fly-past employs the same principle, by using drones or small aircrafts, whose flight altitude is lower (50–100 m). Unmanned aerial systems (UAS) or vehicles (UAV) are employed very frequently in combination with thermographic inspection. An interesting review on their application has been recently proposed [10], where it emerged that the 29% of the considered publications (which account for a total of 92 on the topic) are referred to the building science. In fact, it has been also presented a decision tree for the UAS literature investigation, where importance is given to the drone flight path planning, that concerns not only the survey location but also the audit focus (windows, roof, landscape, etc.) and the flight path pattern (distance from surface, bearing angle, and altitude). The costs of such apparatuses are quite high, so some researchers are looking for less expensive solution. It is the case of [11], who self-assembled a low-cost drone with IR camera. Nevertheless, some encouraging results have been recently proposed, as widely illustrated in [12] where machine learning is employed. In that work, a review on thermal measurement technique is carried out, by grouping according to type (passive/active—qualitative/quantitative), method, application (overall building evaluation, insulation, thermal bridge or air leakage assessment, moisture detection) and quantification index (like the overall thermal transfer value—OTTV). Moreover, a data-driven framework has been used for estimating the energy loss by employing thermal images from UAS. Then, machine learning has been used to post-process data images and retrieve the U-value of different building elements (window, wall, and roof). In [13], unmanned aerial vehicles (UAVs) were implemented for quantitative analysis of the thermal properties of building envelopes (i.e., measurement of the thermal transmittance or U-value via IRT). Results have been compared with heat flow measurement (HFM) method, and a sensitivity analysis has also been conducted, showing the influence of the radiosity of the test object, the background reflection, and air temperature. The frontiers of drones in construction sector are multiple, ranging from the integration of the retrieved information with the building energy model (BEM) for the identification of the more suitable energy renovation strategies of maintenance interventions [14], to the calibration of outdoor microclimate simulation models [15], to the inspection of structures difficult to be accessed like decks [16, 17].

Of course, more common vehicles can be used as mobile support for an IR camera. That is how the street pass-by thermography origins. This is a useful way to rapidly investigate a multitude of building facades and structures, and to assess the thermal bridges or air leakages that might occur. The principle is similar to that of “Google Map” cars, where the thermal images of the surroundings are acquired. Although this kind of vehicle runs the street at low speed (to sketch details), this technique is still not enough precise to retrieve quantitative information. The object or wall emissivity should be properly set to have reliable quantitative results. In addition, the viewing angle plays a key role in the final image.

Another application of IRT is the man-based one, meaning that physically an operator, equipped with an IR camera, shoots the building or object of interest. Hence, the thermal images are acquired at pedestrian level but might also sketch relevant portion of buildings when perspective angles are employed. This approach is referred to as walk-around, since the object is observed from outside, by walking around it. Otherwise, when it is possible (or needed) to enter the building, the IR is called walk-through, meaning that the inspection is acquired from both side of the building. Regarding the walk-around thermography, it must be pointed out that on one hand it provides thermal information on façades human height, i.e., where they are not sketched by aerial or automated fly-past devices. Moreover, this method has lower costs, and it overcomes the inconvenience of a flight plan (needed for satellite, aerial, or airborne devices). On the other hand, some inconvenience arises, like the perspective of the thermal images. In this sense, a pixel-by-pixel rectification can be carried out [18]. This method can be also correlated to other techniques, like imaging from satellites, as also reported in [19]. The walk-through approach requires to access to the building and to possibly interfere with the normal activities inside it. To give an example, if a school façade is inspected by the indoor environment, thermal images of wall might include whiteboard, drawing, maps, and similar. Furthermore, this approach is quite time-consuming when several rooms or spaces must be analyzed. However, the information provided can be more accurate, since sky conditions and boundary conditions are more stable. In this case, the spatial resolution is high, given the fact that objects can be observed by a short distance.

Being the IRT a non-invasive and non-destructive technique, it can be employed as many times as needed, even on the same investigation object. This could be helpful, for instance, to monitor over the time the variations or modifications occurred to the object. Hence, there is the need to repeat survey, that is, to carry out an IR campaign on the same object from the same viewing angle at the same (o quite same) conditions at fixed time intervals (order of months or years). This helps to identify possible incoming damages before they become serious. Hence, IR is used for predictive maintenance to verify the health of the built environment [5], and of the technical plants that serve it, and for condition monitoring [20]. Repeated survey can also be useful to assess the quality and effectiveness of interventions once they are realized. For instance, IR repeat survey can be applied for assessing materials aging [21, 22], weathering [23, 24], faults [25, 26], detachment [27, 28], moisture [29, 30], degradation [31, 32], and so on.

The aforementioned methodologies referred to the analysis of thermal images that “freeze” the IR emission of the bodies into a thermal image. Despite this, there might be the need of assessing the dynamic behavior of materials. That is the birth of the time-lapse method that allows to see the transient phenomena over the decided time interval. Some works refer to time-lapse active thermography, but when buildings are concerned, the passive method is preferable. The time-lapse method consists in acquiring a series of thermal images at fixed acquisition rate, to visualize the changes in thermal pattern due to phenomena that change over time that might be incoming moisture, heat releases, etc. Some IR cameras have the possibility of recording videos; others involve the post-processing of a series of thermal images. The time-lapse survey allows to have both qualitative and quantitative information, according to the purpose and to the post-processing method. The time-lapse approach suffers for the variability of boundary conditions during the acquisition. The different approaches hereby mentioned differ for the cost (equipment plus survey), for the time taken by the survey, and also for the sizes of the investigated area, that often compensate with the spatial resolution. In Fig. 4, methods are qualitatively compared, while repeat survey and time-lapse are not reported since the concern the way methods can be applied.

Given the characteristics of the methods, several investigated objects can be distinguished at urban context (i.e., building façade, roof, pavement, photovoltaic installations, etc.). In Fig. 5, a summary of the methods is reported, for the analysis of the elements deepened in the following sections.

3 Investigated Object

3.1 Building Envelope

IRT has been widely employed to assess possible thermal anomalies and damages on the building envelope. Qualitative and quantitative analyses can be conducted to determine: (i) thermal characterization of building surfaces; (ii) thermal bridges; (iii) detachments; (iv) U-value measurements; (v) air leakages; (vi) moisture or rising damp; and (vii) cracks [1, 33,34,35,36,37].

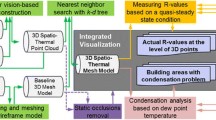

Initially, mainly ground-based IRT, such as walk-around and walk-through survey, was applied in a qualitative way for the thermal characterization of building surfaces concerning wall thicknesses, presence of different building components, surface properties (especially the thermal emissivity, also called ɛ-value), and energy problems related to layering technique [1]. This survey follows specific standard procedures, which requires the control of weather, boundary conditions, and environmental conditions [1]. Besides, thermal bridges, defined as additional heat losses in the building façade, might be due to structural elements (beams) or to geometry (like corners) and, in general, those points where a discontinuity causes an increase in heat flow. Therefore, they appear as hotter zone [38]. Detachments, instead, are those points where the plaster (or covering or coating) is separated from the wall. The air that is entrapped into the detachment causes an alteration on the heat flow, and it can be revealed by thermal inspection. The explanation of this phenomenon can be applied to moisture or rising damp: the water that goes from the ground to the wall appears as a colder region of the thermal image. The same applies to seepages, when drainpipes cause the water to flow along the wall or when there are voids, holes of discontinuity in the ceiling materials that allow water penetration. In a qualitative approach, even cracks and structural detachment can be revealed, especially to older buildings (like historical buildings) or churches or bridges. The quantitative approach, instead, entails the need to quantify the energy losses, by providing the capability of the investigated object of transferring heat [23, 39]. Different building elements can be assessed, from thermal bridges [37, 40] to entire façades [36, 41, 42]. Regarding the vertical opaque wall, different approaches are proposed in literature, depending on the need to access the building for the inspection. This applies both for the current wall and for the thermal bridges. In general, methods that do not require to access the building suffer for the variability of the boundary conditions (weather, sky radiation, humidity, direct solar radiation, wind speed, and direction), while those approached that are performed from indoor overcome these issues but require the permission of the occupants, and might require to move furniture or paintings and, in general, those objects and stuff that prevent a good image [36].

More recently, an IRT and automated fly-past in building inspections was performed for visualizing the thermal patterns within the envelope and the heat movements through and across different materials [10]. UAS and UAV, particularly, are low-cost and highly productive solutions for a large range of applications related to inspections and fault detection that requires non-destructive testing capabilities [4]. This approach reduces the manual workflow of processing and post-processing, also speeding the surveys on large buildings at reduced costs [10]. Besides, it imaging aids in client communications [43]. Also, physical risks, costs, limitations, and psychological impacts of human-UAV interactions have been deeply analyzed for identifying a road map to advance their knowledge [43]. The main sectors for their application are: (i) heat and water flow detection; (ii) thermal bridges; and (ii) U-value measurements. Heat flow detection refers to the identification of heat losses or/and water leakages on large building façades and roofs. Only few studies have been realized. To this purpose, Entrop et al. [44] developed a real-time approach that combines IRT with UAV for detecting remotely heat/water leakages in building structures to solve time and cost problems. Limitations of this approach are connected to the difficulties of sensing every portion of a large or complex building and saving and recording the IR images on 3D maps. Benefits are related to the accurately and rapidly examination of large areas reducing costs and safety risks. Besides, Benz et al. [45] introduced a general framework for the conventional qualitative assessments of thermal bridges and air leakages through a UAS-based assessment of IR thermograms. Otherwise, Bayomi et al. [14] identified a series of information on material deterioration and heat losses thanks to the thermal anomalies captured by a drone equipped with an IR camera. On the contrary, several studies estimated the U-value of the building envelope from UAV data. In general, the U-value is estimated using air temperature difference between outdoor and indoor conditions recorded simultaneously, respectively, with UAV and indoor-held IR camera. To this purpose, Sadhukhan et al. [12] and Bayomi et al. [14] installed thermocouples to verify the surface temperatures of the IR images, and internal and external sensors to measure air temperature. Besides, Benz et al. [45] mounted an external thermal sensor for each thermogram and matched this value with the temperature produced by the sensor spot to calibrate the U-value estimation. Several suggestions have been defined for improving the accuracy of the U-value measurements with IRT. First, the UAS flight should be planned in thermally steady phase of the façade and during precise measurement of the environmental conditions [45]. Better conditions are cloudy morning or evening hours, without precipitation and with stable temperatures [10]. A difference of 10 K between indoor and outdoor temperature is suggested [10]. Also, to reduce the error incorporated by the view angle, the orthogonal orientation of thermograms and the surface should be maintained [45]. Besides, the effects of solar irradiance must be avoided [12].

The challenges found for remotely piloted aircrafts in building inspection include [10]: (i) limitations in global positioning system (GPS) positioning and battery power, (ii) interferences with UAS and possible crashing, (iii) difficulties to reach building components for aIRT and UAS size and navigation; (iv) operation vibrations; and (v) risks in signal acquisition and interpretation. Like other applications, also in the energy audit, the accuracy of the drone flight depends on the accuracy of the GPS and inertial navigation system (INS). The root mean square error specifically is less with onboard GPS than with ground control points [10]. The technological advance in the automation sector is moving through the reduction of dimensions, weights, and costs of drones, also increasing stability, payload capabilities, automated obstacle avoidance, and connectivity assurance [10]. A benefit is related to the safety of workers that can operate remotely also under critical circumstances thank to the onsite presence of drones [46]. The application of automated fly-past passive thermal inspection in the energy audit sector needs further experimentation-based research and standardizations for fault detection [10, 47]. Standardized procedures or equations particularly should be interest optimal distances of flight paths, flight speed for clarity, geometry analysis, and automated post-processing [10].

3.2 PV Inspection

Temperature distribution is an empirical way for detecting defects on PV modules and roofs. It is expected that well-performing PV cells or modules have uniform temperature distribution during normal operating conditions [48]. Defective PV systems produce temperature differences (ΔT) or thermal anomalies. For this reason, passive IRT (automated fly-past surveys, walk-around surveys) and active IRT (time-lapse survey) are used in a qualitative way for quality control [48]. Defects detectable on PV systems concern optical degradation (e.g., delamination, discoloration of the encapsulate, micro-cracks, front cover breakage, soiling/dust accumulation), electrical mismatches and degradation (e.g., lifetime stress, hot spot browning, cell cracks/fracture, inactive or disconnected strings, completely or partially inactive modules, corrosion, junction boxes, ribbons or connections breakage, poor soldering, shunts and short-circuited cells, snail trails, solder bond failures, shading), and non-classified imperfections (defective/short-circuited bypass diode, open-circuited submodule, loss of adhesion, anthropogenic impacts) [26, 47, 49,50,51,52]. These problems cause a reduction in module efficiency and represent an electrical risk for the operators [52].

In general, IR images for PV inspections are captured in the mid-wave (about 3–5 µm) or long-wave (7–14 µm) that considered a trade-off between data availability, measuring conditions of IR sensors, and costs [53]. PV inspections can be performed with ground-based and remotely piloted aircrafts IRT approaches. In both cases, they are more efficient combining RGB and IRT cameras, allowing a simultaneous comparison of data to understand better the presence of shadow and specificities [47, 51].

Ground-based IRT uses handheld IR cameras on ground (called also walking method) or lifting platforms (called also crane/lift method) [54]. These methods are used for identifying and locating PV degradation and faults. In both cases, accurate PV inspections requires the selection of appropriate resolution and weight of the IR camera [54]. Camera resolution determines the monitoring distance and the accuracy of the surface temperature values [54]. Thus, high values should be chosen. Besides, low-weight cameras should be preferred as they influence the duration of the survey. The inclination of the camera lens influences the results of the survey. In both cases, the lens angle of the IR camera should be perpendicular to tilted module surface for acquiring adequate results. Walk-around surveys is high affected by the module inclination that should not less than 15° while crane/lift method that is less affected by module angles [54]. The first method is time-consuming and labor-intensive for the involvement of personnel walking the length of the array [48, 51]. The second one takes shorter times, but requires additionally footage to investigate some faults [54]. In both cases, the monitoring accuracy is prone to human error and competences [48].

The usage of remotely piloted aircrafts IRT in PV inspections grows considerably in the last decade to overcome the major drawbacks of the ground-based IRT, especially for utility-scale and large-scale PV power plants as well as for roof-mounted PV with limited access [47,48,49,50,51,52, 55]. They have multiple advantages, such as ability to reach difficult-access areas, large angles of vision, cost saving, increment of operator safety, reduction of data collection time, and operational risks [49]. Significantly reductions of inspection time (85%) have been found [48]. Otherwise, weaknesses refer to the lower image resolutions than ground-based IRT methods [51], sensitivity to environmental conditions [48], inaccuracy in hot-spots and micro-cracks detection and complexity and redundancy of IR image and data [48]. In this case, IRT measurements are performed outdoors, under steady-state illumination (i.e., clear-sky or maximum 2 non-cumulus cloud coverage) and maximum power-point conditions [26]. Mainly, UAS and drones are used for recognizing PV degradation and faults as well as problems caused by environmental events on PV roofs, such as windstorms, hailstorms, air turbulence, sunlight reflection, and lightning [51]. Similar to the ground-based IRT, the most important aspect for selecting the IR camera is resolution and weight, battery flight time, and lens type [51]. The resolution of the camera particularly determines the maximum flight height, strongly influencing the duration of the inspection [51]. This is a critical point for large-scale PV power plants, because normally the minimum irradiance conditions last around six hours per day [51]. In addition, stability of the system, flight duration, maximum payload, and compatibility between devices impacts on the quality and the cost of the inspection [51]. Various problems have been defined for remotely piloted aircrafts IRT on PV systems [26, 50, 53]: (i) other parts absorbed the incident radiation contributing to module heating (e.g., back sheet segment between the cells); (ii) high-temperature diffusion rate due to environmental conditions; (iii) absence of thermal stability for the changes in environmental conditions; and (iv) difficulties in detect defects that do not act as local heat sources. To overcome many of these problems, the ideal conditions need the presence of constant and perpendicular orientation of the UAV-mounted or drone-mounted IRT sensor to the PV modules and a flight altitude at least of five meters to prevent self-shading [51]. Also, the inspection should carry out on cloudless, bright, and dry days, with reduced wind speed (<4 m/s), a direction of the sun perpendicular to the PV modules, and an irradiance over 600 W/m2 on the plane of the inspected PV array [51]. Actually, there is a lack of interpreting the defects of different PV technologies and their impact on the output power generation, especially when PV systems operate under changing environmental conditions [48]. In parallel, image processing is an important role in an IRT of PV panels. An accurate interpretation of a 3-dimensional (3D) ortho-mosaic for each single rooftop requires high overlapping rates between the images, which must contain azimuth, and tilts of the PV panels [56]. This situation is hard to reach for an autopilot operated pre-flight route setting for a specific area. Normally, unnecessary noise is generated on the thermal values and the exterior orientation parameters, such as the measurement of distances, angles, and PV areas [56]. This causes serious data redundancy. Thus, the importance of the interpretation of the thermal images and the correlation between performance degradation, fault types, and thermal signatures of PV modules is largely introduced [47, 50, 51]. To overcome this problematic, Hwang et al. [56] developed a 3D video stream-based ortho-mosaic for widely scattered PV roofs. Despite this, the processing phase requires standard specifications to reduce computational complexities and assessment error in the identification of PV defects [48]. In addition, several studies displayed the potential of automated inspections for increasing the speed of the survey and generating a great number of images. The models developed for the automatic detection of PV module defects using deep learning techniques obtained an average accuracy of 99% [47, 52, 57,58,59].

3.3 Urban Heat Island (UHI)

UHI effect is defined as an increase of temperatures in urban areas in comparison with rural areas [60,61,62,63]. It is estimated that the ambient air temperature can grow between 3.6 and 5 °C in the canopy layer due to UHI effect [64]. Consequently, the energy consumption of cooling systems is greater in cities [61, 62, 64, 65], reaching values between 18 and 43% over the reference load [66]. This phenomenon often occurs in crowded cities and small cities (i.e., Rome [64]; Barcelona [67]; Beijing [66]; Tehran [63]), which are characterized by public spaces where the thermophysical properties of historical buildings amplify the UHI as well [64, 68].

In most cities, 50–60% of urban areas are comprised of roof and pavement [62], and some materials present a significant temperature sensitivity (i.e., asphalt concrete pavement) [62, 64]. According to Lassandro et al. [69], building façades should have an adaptive capacity at short-term and long-term, to ensure functionality under unpredictable conditions such as heat waves. Within this context, United States Environment Protection Agency (USEPA) suggested to use “cool pavement.” In contrast to the conventional material, cool pavement has a greater reflectance. Indeed, the pavement surface temperature can decrease 6 °C, if the increase of total reflectance/albedo is 0.1 [62]. This could help to reduce several significant parameters: citizens’ thermal stress [61, 70], primary energy demand [61,62,63], and surface temperature and heat release [71]. Consequently, an improvement of the urban microclimate and outdoor thermal comfort of the population could be achieved [15].

However, few studies evaluated the optical properties of reflective pavement coatings (i.e., spectral full scales, pigments of the sample), and green and cool materials for pavements or walls are still in development [62]. Li et al. [72] assessed the seasonal effects of albedo or solar reflectivity on the thermal behavior of pavements, using a portable solar reflectometer and dual pyranometer with automatic data collection system. The authors demonstrated that the measured albedo was high in the early morning and in the evening, while it was low and constant in the mid-day. In addition, peak solar radiation intensity was positively correlated with the cooling effect. Sham et al. [60] quantified the sensible heat release generated by building fabrics in hot and cold seasons. The CSTM technique was implemented to capture a sequence of thermal images of a larger sample of buildings simultaneously. The findings suggested that finish materials (i.e., ceramic, granite, or aluminum), building features (i.e., orientation), and seasonal change could affect the cooling pattern. By way of example, the sensible heat release change presented lower percentages (6.7–9.7%) for granite and aluminum walls, regardless the season. Furthermore, the ratio between sensible heat release and global solar radiation was slightly similar in hot and cold season. Salata et al. [64] analyzed three mitigation strategies of UHI on 27 buildings of Sapienza University (Rome) during a heat wave: (i) urban greening; (ii) cool pavement; and (iii) cool roofs. To quantify the impact of such strategies, numerical simulations were computed using ENVI-met Software. This made possible to obtain the Mediterranean Outdoor Comfort Index (MOCI) as well as the hourly values of the ambient air temperature and the mean radiant temperature. The researchers extrapolated that the optimum solution was the combination of all strategies, since the health risk could be decreased between 60 and 80%. Nevertheless, the solution did not have a high influence on pedestrians. Aguerre et al. [70] compared a sequence of thermograms with simulated thermal models of a real urban district using finite element method (FEM), to evaluate the spatial distribution of the radiation emitted by urban surfaces and the influence on the outdoor thermal comfort. The authors stated that changing the reflectance of southern façades could lead to temperature differences of up 10 °C. Xie et al. [62] applied infrared thermography to assess temperature distribution and thermal performance of reflective coating samples. The researchers concluded that solar reflectance can be increased by pavement coatings doped with chrome and nano-pigments. Furthermore, the most influential reflectance values ranged from 400 to 1100 nm. Carpio et al. [73] carried out a bibliometric analysis about UHI from 1990 to 2019. The findings showed that the topic presented an increasing trend in relation to laboratory experiments and new techniques to evaluate concrete elements with infrared-reflective pigments. In addition, the authors noted that building fabrics, urban planning, and climate zone could be causal factors of UHI. Hence, mitigation strategies cannot be generalized across the cities. It is required to adapt national building codes to local regulations. Fabbri et al. [15] considered that existing studies compared simulation results with punctual experimental measurements of ambient air temperature and mean radiant temperature. For this reason, the authors used infrared thermography to collect images of an urban area of Medicina (Italy) and subsequently, to calibrate holistic outdoor microclimate numerical models by ENVI-met Software. Overall, measured and simulated surface temperatures fitted well. The only limitation was given in areas with dense vegetation.

4 Conclusions

The International Energy Agency [IEA 2021] stated that cities are responsible for 75% of global energy use. For this reason, the diagnosis is essential at urban level (cities, neighborhood and single buildings). IRT is a non-invasive and accurate technique that provides real-time data in both qualitative and quantitative way. In fact, this chapter pointed out a wide range of instrumentation (i.e., drones, vehicles, and portable cameras), analyzing some key aspects: time of inspection, investigated area, cost and spatial resolution. It can be extrapolated that most of quantitative IRT applications are still ongoing. Some examples are exposed below. Data taken from neighborhoods and building with IR cameras installed on drones or vehicles cannot be directly integrated in building energy models (BEMs), and a calibration of model related to outdoor microclimate is required. Besides this, the incorporation a larger sensor network presents a high cost and post-processing time. Concerning PV panels, recent studies based on IRT and machine learning facilitated the tasks of preventive and corrective maintenance. Nevertheless, there is a gap for some research questions, such as correlation between defects and output power, additional noise in the measured parameters, technical problems of piloted aircrafts, etc. Regarding the UHI effect, IRT makes possible to identify and determine the most optimum mitigation strategy in cities, taking into account: building fabrics, urban planning, and climate zone. However, few studies were developed, and the analysis could be a challenging task in heavily vegetated areas.

References

Lucchi E (2017) Applications of the infrared thermography in the energy audit of buildings: a review. Renew Sustain Energ Rev 0–1. https://doi.org/10.1016/j.rser.2017.10.031

Rogalski A (2012) History of infrared detectors. Opto-Electron Rev 20:279–308. https://doi.org/10.2478/s11772-012-0037-7

Ibarra-Castanedo C, Tarpani JR, Maldague XPV (2013) Nondestructive testing with thermography. Eur J Phys 34. https://doi.org/10.1088/0143-0807/34/6/S91

Fox M, Coley D, Goodhew S, De Wilde P (2014) Thermography methodologies for detecting energy related building defects. Renew Sustain Energ Rev 40:296–310. https://doi.org/10.1016/j.rser.2014.07.188

Kirimtat A, Krejcar O (2018) A review of infrared thermography for the investigation of building envelopes: advances and prospects. Energ Build 176:390–406. https://doi.org/10.1016/j.enbuild.2018.07.052

Morrison W, Kotthaus S, Grimmond S (2021) Urban surface temperature observations from ground-based thermography: intra- and inter-facet variability. Urban Clim 35:100748. https://doi.org/10.1016/j.uclim.2020.100748

Bitelli G, Conte P, Csoknyai T, Franci F, Girelli VA, Mandanici E (2015) Aerial thermography for energetic modelling of cities. Rem Sens 7:2152–2170. https://doi.org/10.3390/rs70202152

Irani Rahaghi A, Lemmin U, Sage D, Barry DA (2019) Achieving high-resolution thermal imagery in low-contrast lake surface waters by aerial remote sensing and image registration. Rem Sens Environ 221:773–783. https://doi.org/10.1016/j.rse.2018.12.018

He Y, Deng B, Wang H, Cheng L, Zhou K, Cai S, Ciampa F (2021) Infrared machine vision and infrared thermography with deep learning: a review. Infrared Phys Technol 116:103754. https://doi.org/10.1016/j.infrared.2021.103754

Rakha T, Gorodetsky A (2018) Review of Unmanned Aerial System (UAS) applications in the built environment: towards automated building inspection procedures using drones. Autom Constr 93:252–264. https://doi.org/10.1016/j.autcon.2018.05.002

Kayan H, Eslampanah R, Yeganli F, Askar M (2018) Heat leakage detection and surveiallance using aerial thermography drone. In: 2018 26th IEEE signal processing and communications applications conference (SIU), pp. 1–4.https://doi.org/10.1109/SIU.2018.8404366

Sadhukhan D, Peri S, Sugunaraj N, Biswas A, Selvaraj DF, Koiner K, Rosener A, Dunlevy M, Goveas N, Flynn D, Ranganathan P (2020) Estimating surface temperature from thermal imagery of buildings for accurate thermal transmittance (U-value): a machine learning perspective. J Build Eng 32:101637. https://doi.org/10.1016/j.jobe.2020.101637

Patel D, Schmiedt JE, Röger M, Hoffschmidt B (2018) Approach for external measurements of the heat transfer coefficient (U-value) of building envelope components using UAV based infrared thermography. 1–8. http://www.qirt2018.de/portals/qirt18/doc/Fr.2.C.1.pdf

Bayomi N, Nagpal S, Rakha T, Fernandez JE (2021) Building envelope modeling calibration using aerial thermography. Energ Build 233:110648. https://doi.org/10.1016/j.enbuild.2020.110648

Fabbri K, Costanzo V (2020) Drone-assisted infrared thermography for calibration of outdoor microclimate simulation models. Sustain Cities Soc 52:101855. https://doi.org/10.1016/j.scs.2019.101855

Omar T, Nehdi ML (2017) Remote sensing of concrete bridge decks using unmanned aerial vehicle infrared thermography. Autom Constr 83:360–371. https://doi.org/10.1016/j.autcon.2017.06.024

Biscarini C, Catapano I, Cavalagli N, Ludeno G, Pepe FA, Ubertini F (2020) UAV photogrammetry, infrared thermography and GPR for enhancing structural and material degradation evaluation of the Roman masonry bridge of Ponte Lucano in Italy. NDT E Int 115:102287. https://doi.org/10.1016/j.ndteint.2020.102287

Acuña Paz y Miño J, Duport N, Beckers B (2021) Pixel-by-pixel rectification of urban perspective thermography. Rem Sens Environ 266:112689. https://doi.org/10.1016/j.rse.2021.112689

Hartz D, Prashad L, Hedquist BC, Golden J, Brazel AJ (2005) Linking satellite and hand-held infrared thermography to observed neighborhood climate conditions

Bagavathiappan S, Lahiri BB, Saravanan T, Philip J, Jayakumar T (2013) Infrared thermography for condition monitoring—a review. Infrared Phys Technol 60:35–55. https://doi.org/10.1016/j.infrared.2013.03.006

Kaplani E (2012) Detection of degradation effects in field-aged c-Si solar cells through IR thermography and digital image processing. Int J Photoenergy 2012. https://doi.org/10.1155/2012/396792

Nardi I, de Rubeis T, Perilli S (2016) Ageing effects on the thermal performance of two different well-insulated buildings. Energ Procedia. https://doi.org/10.1016/j.egypro.2016.11.133

Nardi I, De Rubeis T, Taddei M, Ambrosini D, Sfarra S (2017) The energy efficiency challenge for a historical building undergone to seismic and energy refurbishment. Energ Procedia 133:231–242. https://doi.org/10.1016/j.egypro.2017.09.357

Evangelisti L, Guattari C, Fontana L, De Lieto Vollaro R, Asdrubali F (2022) On the ageing and weathering effects in assembled modular facades: on-site experimental measurements in an Italian building of the 1960s. J Build Eng 45:103519. https://doi.org/10.1016/j.jobe.2021.103519

Schirripa Spagnolo G, Del Vecchio P, Makary G, Papalillo D, Martocchia A (2012) A review of IR thermography applied to PV systems. IEEE

Tsanakas JA, Ha L, Buerhop C (2016) Faults and infrared thermographic diagnosis in operating c-Si photovoltaic modules: a review of research and future challenges. Renew Sustain Energ Rev 62:695–709. https://doi.org/10.1016/j.rser.2016.04.079

De Freitas SS, De Freitas VP, Barreira E (2014) Detection of façade plaster detachments using infrared thermography—a nondestructive technique. Constr Build Mater 70:80–87. https://doi.org/10.1016/j.conbuildmat.2014.07.094

Lourenço T, Matias L, Faria P (2017) Anomalies detection in adhesive wall tiling systems by infrared thermography. Constr Build Mater 148:419–428. https://doi.org/10.1016/j.conbuildmat.2017.05.052

Edis E, Flores-Colen I, de Brito J (2015) Quasi-quantitative infrared thermographic detection of moisture variation in facades with adhered ceramic cladding using principal component analysis. Build Environ 94:97–108. https://doi.org/10.1016/j.buildenv.2015.07.027

Barbosa MTG, Rosse VJ, Laurindo NG (2021) Thermography evaluation strategy proposal due moisture damage on building facades. J Build Eng 43:102555. https://doi.org/10.1016/j.jobe.2021.102555

Kordatos EZ, Exarchos DA, Stavrakos C, Moropoulou A, Matikas TE (2013) Infrared thermographic inspection of murals and characterization of degradation in historic monuments. Constr Build Mater 48:1261–1265. https://doi.org/10.1016/j.conbuildmat.2012.06.062

Menezes A, Glória Gomes M, Flores-Colen I (2015) In-situ assessment of physical performance and degradation analysis of rendering walls. Constr Build Mater 75:283–292. https://doi.org/10.1016/j.conbuildmat.2014.11.039

Paoletti D, Ambrosini D, Sfarra S, Bisegna F (2013) Preventive thermographic diagnosis of historical buildings for consolidation. J Cult Herit 14:116–121. https://doi.org/10.1016/j.culher.2012.05.005

Lerma C, Mas A, Gil E, Vercher J, Peñalver MJ (2014) Pathology of building materials in historic buildings. Relationship between laboratory testing and infrared thermography. Mater Constr 64:1–11. https://doi.org/10.3989/mc.2013.06612

Di Maio R, Piegari E, Mancini C (2015) Quantitative analysis of pulse thermography data for degradation assessment of historical buildings. Eur Phys J Plus 130. https://doi.org/10.1140/epjp/i2015-15105-6

Tejedor B, Casals M, Gangolells M, Roca X (2017) Quantitative internal infrared thermography for determining in-situ thermal behaviour of façades. Energ Build 151:187–197. https://doi.org/10.1016/j.enbuild.2017.06.040

Tejedor B, Barreira E, Almeida RMSF, Casals M (2020) Thermographic 2D U-value map for quantifying thermal bridges in building façades. Energ Build 224:110176. https://doi.org/10.1016/j.enbuild.2020.110176

Mayer Z, Heuer J, Volk R, Schultmann F (2021) Aerial thermographic image-based assessment of thermal bridges using representative classifications and calculations

Nardi I, Lucchi E, de Rubeis T, Ambrosini D (2018) Quantification of heat energy losses through the building envelope: a state-of-the-art analysis with critical and comprehensive review on infrared thermography. Build Environ 146:190–205. https://doi.org/10.1016/j.buildenv.2018.09.050

Barreira E, Almeida RMSF, Ferreira JPB (2017) Assessing the humidification process of lightweight concrete specimens through infrared thermography. Energ Procedia 132:213–218. https://doi.org/10.1016/j.egypro.2017.09.757

Nardi I, Paoletti D, Ambrosini D, de Rubeis T, Sfarra S (2016) U-value assessment by infrared thermography: a comparison of different calculation methods in a Guarded Hot Box. Energ Build 122:211–221. https://doi.org/10.1016/j.enbuild.2016.04.017

Tejedor B, Casals M, Macarulla M, Giretti A (2019) U-value time series analyses: evaluating the feasibility of in-situ short-lasting IRT tests for heavy multi-leaf walls. Build Environ 159:106123. https://doi.org/10.1016/j.buildenv.2019.05.001

Jeelani I, Gheisari M (2009) Safety challenges of UAV integration in construction: conceptual analysis and future research roadmap. Coast Estuar Process 1–360. https://doi.org/10.1016/j.ssci.2021.105473

Entrop AG, Vasenev A (2017) Infrared drones in the construction industry: designing a protocol for building thermography procedures. Energ Procedia 132:63–68. https://doi.org/10.1016/j.egypro.2017.09.636

Benz A, Taraben J, Debus P, Habte B, Oppermann L, Hallermann N, Voelker C, Rodehorst V, Morgenthal G (2021) Framework for a UAS-based assessment of energy performance of buildings. Energ Build 250:111266. https://doi.org/10.1016/j.enbuild.2021.111266

Irizarry J, Gheisari M, Walker BN (2012) Usability assessment of drone technology as safety inspection tools. Electron J Inf Technol Constr 17:194–212

Stegner C, Dalsass M, Luchscheider P, Brabec CJ (2018) Monitoring and assessment of PV generation based on a combination of smart metering and thermographic measurement. Sol Energ 163:16–24. https://doi.org/10.1016/j.solener.2018.01.070

Rahaman SA, Urmee T, Parlevliet DA (2020) PV system defects identification using remotely piloted aircraft (RPA) based infrared (IR) imaging: a review. Sol Energ 206:579–595. https://doi.org/10.1016/j.solener.2020.06.014

García Márquez FP, Segovia Ramírez I (2019) Condition monitoring system for solar power plants with radiometric and thermographic sensors embedded in unmanned aerial vehicles. Meas J Int Meas Confed 139:152–162. https://doi.org/10.1016/j.measurement.2019.02.045

Waqar Akram M, Li G, Jin Y, Chen X, Zhu C, Zhao X, Aleem M, Ahmad A (2019) Improved outdoor thermography and processing of infrared images for defect detection in PV modules. Sol Energ 190:549–560. https://doi.org/10.1016/j.solener.2019.08.061

Kirsten Vidal de Oliveira A, Aghaei M, Rüther R (2020) Aerial infrared thermography for low-cost and fast fault detection in utility-scale PV power plants. Sol Energ 211:712–724. https://doi.org/10.1016/j.solener.2020.09.066

Manno D, Cipriani G, Ciulla G, Di Dio V, Guarino S, Lo Brano V (2021) Deep learning strategies for automatic fault diagnosis in photovoltaic systems by thermographic images. Energ Convers Manag 241:114315. https://doi.org/10.1016/j.enconman.2021.114315

Akram MW, Li G, Jin Y, Chen X, Zhu C, Ahmad A (2020) Automatic detection of photovoltaic module defects in infrared images with isolated and develop-model transfer deep learning. Sol Energ 198:175–186. https://doi.org/10.1016/j.solener.2020.01.055

Cubukcu M, Akanalci A (2020) Real-time inspection and determination methods of faults on photovoltaic power systems by thermal imaging in Turkey. Renew Energ 147:1231–1238. https://doi.org/10.1016/j.renene.2019.09.075

Du B, He Y, He Y, Zhang C (2020) Progress and trends in fault diagnosis for renewable and sustainable energy system based on infrared thermography: a review. Infrared Phys Technol 109:103383. https://doi.org/10.1016/j.infrared.2020.103383

Hwang YS, Schlüter S, Il Park S, Um JS (2021) Comparative evaluation of mapping accuracy between UAV video versus photo mosaic for the scattered urban photovoltaic panel. Rem Sens 13. https://doi.org/10.3390/rs13142745

Fernández A, Usamentiaga R, de Arquer P, Fernández MÁ, Fernández D, Carús JL, Fernández M (2020) Robust detection, classification and localization of defects in large photovoltaic plants based on unmanned aerial vehicles and infrared thermography. Appl Sci 10. https://doi.org/10.3390/app10175948

Henry C, Poudel S, Lee SW, Jeong H (2020) Automatic detection system of deteriorated PV modules using drone with thermal camera. Appl Sci 10:1–16. https://doi.org/10.3390/app10113802

Huerta Herraiz Á, Pliego Marugán A, García Márquez FP (2020) Photovoltaic plant condition monitoring using thermal images analysis by convolutional neural network-based structure. Renew Energ 153:334–348. https://doi.org/10.1016/j.renene.2020.01.148

Sham JFC, Memon SA, Tommy, Lo Y (2013) Application of continuous surface temperature monitoring technique for investigation of nocturnal sensible heat release characteristics by building fabrics in Hong Kong. Energ Build 58:1–10. https://doi.org/10.1016/j.enbuild.2012.11.025

Golasi I, Salata F, de Lieto Vollaro E, Coppi M, de Lieto Vollaro A (2016) Thermal perception in the mediterranean area: comparing the Mediterranean Outdoor Comfort Index (MOCI) to other outdoor thermal comfort indices. Energies 9:1–16. https://doi.org/10.3390/en9070550

Xie N, Li H, Abdelhady A, Harvey J (2019) Laboratorial investigation on optical and thermal properties of cool pavement nano-coatings for urban heat island mitigation. Build Environ 147:231–240. https://doi.org/10.1016/j.buildenv.2018.10.017

Sedaghat A, Sharif M (2022) Mitigation of the impacts of heat islands on energy consumption in buildings: a case study of the city of Tehran, Iran. Sustain Cities Soc 76:103435. https://doi.org/10.1016/j.scs.2021.103435

Salata F, Golasi I, Petitti D, de Lieto Vollaro E, Coppi M, de Lieto Vollaro A (2017) Relating microclimate, human thermal comfort and health during heat waves: an analysis of heat island mitigation strategies through a case study in an urban outdoor environment. Sustain Cities Soc 30:79–96. https://doi.org/10.1016/j.scs.2017.01.006

Pisello AL, Castaldo VL, Pignatta G, Cotana F, Santamouris M (2016) Experimental in-lab and in-field analysis of waterproof membranes for cool roof application and urban heat island mitigation. Energ Build 114:180–190. https://doi.org/10.1016/j.enbuild.2015.05.026

Cui Y, Yan D, Hong T, Ma J (2017) Temporal and spatial characteristics of the urban heat island in Beijing and the impact on building design and energy performance. Energy 130:286–297. https://doi.org/10.1016/j.energy.2017.04.053

Salvati A, Coch Roura H, Cecere C (2017) Assessing the urban heat island and its energy impact on residential buildings in mediterranean climate: Barcelona case study. Energ Build 146:38–54. https://doi.org/10.1016/j.enbuild.2017.04.025

Ambrosini D, Galli G, Mancini B, Nardi I, Sfarra S (2014) Evaluating mitigation effects of urban heat islands in a historical small center with the ENVI-Met® climate model. Sustain 6:7013–7029. https://doi.org/10.3390/su6107013

Lassandro P, Di Turi S (2019) Multi-criteria and multiscale assessment of building envelope response-ability to rising heat waves. Sustain Cities Soc 51:101755. https://doi.org/10.1016/j.scs.2019.101755

Aguerre JP, Nahon R, Garcia-Nevado E, La Borderie C, Fernández E, Beckers B (2019) A street in perspective: thermography simulated by the finite element method. Build Environ 148:225–239. https://doi.org/10.1016/j.buildenv.2018.11.007

Aboelata A (2021) Reducing outdoor air temperature, improving thermal comfort, and saving buildings’ cooling energy demand in arid cities—cool paving utilization. Sustain Cities Soc 68:102762. https://doi.org/10.1016/j.scs.2021.102762

Li H, Harvey J, Kendall A (2013) Field measurement of albedo for different land cover materials and effects on thermal performance. Build Environ 59:536–546. https://doi.org/10.1016/j.buildenv.2012.10.014

Carpio M, González Á, González M, Verichev K (2020) Influence of pavements on the urban heat island phenomenon: a scientific evolution analysis. Energ Build 226:110379. https://doi.org/10.1016/j.enbuild.2020.110379

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Tejedor, B., Lucchi, E., Nardi, I. (2022). Application of Qualitative and Quantitative Infrared Thermography at Urban Level: Potential and Limitations. In: Bienvenido-Huertas, D., Moyano-Campos, J. (eds) New Technologies in Building and Construction. Lecture Notes in Civil Engineering, vol 258. Springer, Singapore. https://doi.org/10.1007/978-981-19-1894-0_1

Download citation

DOI: https://doi.org/10.1007/978-981-19-1894-0_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1893-3

Online ISBN: 978-981-19-1894-0

eBook Packages: EngineeringEngineering (R0)