Abstract

Road construction and other infrastructure works have an ever-increasing demand for good quality construction materials. The availability of natural aggregates for such requirements are now becoming scarce due to the prevailing environmental constraints and the related need for socio-economic sustainability. As a result, recycling of used or waste materials has been gaining a dynamic momentum. One of such material is Reclaimed Asphalt Pavement (RAP) material obtained from the surface course of flexible (bituminous) pavements once the design life of pavement has exhausted. Though RAP material has got usage as partial replacement to the fresh bituminous mix, their performance as a fill material for the base layer of pavement is presented in this paper. To enhance the performance of RAP-filled base layers, it has been reinforced with different geosynthetic materials (geogrid, geocell) and their combination (geogrid plus geocell). For the need of clear distinction among the performance of different reinforcement cases, RAP-filled base layer was essentially prepared upon weak subgrade having low CBR value (black cotton soil). All studies were performed on laboratory-scale pavement model constructed inside an indigenously developed equipment named “Repeated Load Applicator for Pavement Performance”. The RAP-filled base layer when reinforced with geocell and geogrid in single combination was found to perform better than the geocell confinement followed by the geogrid reinforcement. The performance of different reinforcement cases in comparison to the unreinforced case were evaluated in terms of Traffic Benefit Ratio (TBR) and Rut Depth Reduction factors (RDRF).

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Geosynthetic reinforcement

- Reclaimed asphalt pavement (RAP) material

- Black cotton soil

- Traffic benefit ratio

- Rut depth reduction factor

1 Introduction

In a bid towards more sustainable construction practices, there has been a gradual shift towards the reuse and recycling of the used and waste materials like concrete wastes from demolished buildings and rehabilitation works, fly ash, and other slag materials from refineries, reclaimed asphalt pavement (RAP) material, etc. In this study, we have considered RAP as one of the probable alternatives for the base layer material which generally requires good granular material. RAP is basically bitumen coated aggregates which has been milled off (reclaimed) from the top surface course of bituminous roads once the pavement design life has exhausted. Thus, the recycled use of the reclaimed bituminous mix not only helps reduce the amount of discarded waste but also facilitates cost savings in terms of reduced requirements for fresh aggregate material. However, it has been observed that RAP material does not possess a good strength of its own to be directly used as a fill material for the base layer of pavements [1, 2]. In such case, RAP material when placed as base layer needs to be strengthened or stabilized using a suitable method. Many researchers in their studies have tried to chemically stabilize the RAP material and some had proposed to partially replace the RAP content with fresh aggregates [3,4,5,6,7,8]. The noted methods of chemical stabilization and partial replacement technique though helps in reducing the required quantity of fresh aggregates, they may not be considered to be highly sustainable as partial replacement still requires some amount of fresh aggregates and use of chemical stabilizers may not always be environment-friendly [9]. To overcome these shortcomings, one of the recent studies has suggested the mechanical stabilization of RAP-filled base layers using cellular geosynthetic material called geocells [10].

Many types of geosynthetic materials like geogrid, geocell, geotextiles, etc., are being used for different types of ground improvement works for several decades [11]. The punching failure of subgrade can be altered towards general failure with inclusion of reinforcement [11]. The lateral spread of the confined layers is reduced with the inclusion of geogrids and geocell due to the confinement and tensioned-membrane effects [12]. The lateral restraint provided by geosynthetics is mainly responsible for the enhanced pavement performance of the reinforced sections [11]. The reinforcing effect due to geocell or geogrid tends to minimize the deterioration of granular layer material and can be beneficially used for low-to-moderate traffic volume conditions [12]. The elastic modulus of the reinforced layers increases significantly [12]. The geosynthetic-reinforced pavements exhibits lower surface rutting [12] and higher TBR values in comparison to the unreinforced case [13,14,15,16]. Thus, the geosynthetic-reinforced sections exhibits higher design life and helps reduce the required pavement thickness [11, 17]. Some of the previous studies on geosynthetic-reinforced pavements indicating the geosynthetic type, location, and the respective performance criterion, captured by other researchers are summarized below in Table 1.

Geosynthetic-reinforced pavements have been generally designed while considering conventionally used fresh aggregates. Nowadays, RAP material is gaining popularity as probable alternative to the conventionally required fresh aggregates for various construction and rehabilitation works of roads. In this study, we have analyzed the performance of RAP-filled base layers with different geosynthetic materials like geogrid, geocell, and combination of geogrid plus geocell. The results and analysis of the experimental studies presented in this paper provides a comparative assessment for different cases of geosynthetic reinforcements provided into base layers composed of RAP material.

2 Material Properties

This study involves two layers (subgrade and base layer) composed of distinct materials, constituting as a pavement model. The details of the pavement material and the geosynthetic reinforcements used in this study are summarized below.

2.1 Subgrade Layer

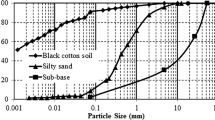

For subgrade layer, a highly expansive clayey soil called “black cotton soil” was used. The selection of this soil was based on the requirement of subgrade possessing low CBR value since the reinforcing effects are distinctly quantifiable in such cases [13, 21, 22]. The properties of the black cotton soil used in this study are given in Table 2. The grain size distribution of the black cotton soil and the RAP material (separated aggregates) used in base layer are shown in Table 3. The subgrade layer was compacted to 95% MDD (maximum dry density) at moisture content similar to its soaked CBR test condition. The thickness of the subgrade layer was kept as 500 mm (millimeter).

2.2 Base Layer

Base layer was prepared using RAP (Reclaimed Asphalt Pavement) material which was compacted up to 95% of its maximum dry density (MDD = 2.03) at its optimum moisture content (OMC) of 4.8%. The collected RAP material was subjected to bitumen extraction process for separation of aggregates and binder. The standard specification of ASTM-D 2172M-11 [29] was followed for this binder extraction process. The aggregates gradation checked for the RAP material considering these separated aggregates are presented in Table 3. The thickness of the RAP-filled base layer was kept as 225 mm.

2.3 Geosynthetic Reinforcement Material

Two types of geosynthetic material have been used in this study. One of the materials is Geogrid which is basically planar in structure and having square openings on it; the other type of geosynthetic material used is Geocell which mainly consists of a three-dimensional cellular structure which helps confine the filled materials. The properties of Geogrid and Geocell used in this study are presented in Tables 4 and 5, respectively.

3 Experimental Work

Laboratory-scale pavement models were constructed inside an indigenously developed equipment named “Repeated Load Applicator for Pavement Performance” which consists of a large size tank (circular in shape, diameter, and height of one meter each) with arrangements for application of repeated cyclic loads. All tests related to the performance evaluation of the unreinforced and reinforced cases were performed using this large size tank. The material for different layers of the pavement were filled into the tank and compacted to the desired density and thickness. The different layers were compacted with a uniform lift of 7.5 cm each, thus maintaining a uniform level of compaction throughout the depth. After completing the layered construction of the pavement model, a circular loading plate (diameter 150 mm) for repeated cyclic loading is then lowered onto the top surface. The repeated cyclic load was then applied in “haversine pattern” (shown in Fig. 1) as it closely simulates the actual field traffic loading conditions. The maximum load intensity was kept as 10 kN to generate a contact pressure of 0.56 MPa with each cycle of 1.3 s duration and the total number of cycles for each test was restricted to 18,000 due to the prevailing technical limitations. After completing the designated number of load cycles, the acquired data for peak surface deformations (surface settlements) corresponding to each load cycle was then processed to have a cumulative settlement of the loaded surface. The photographs depicting each step of the test program as discussed above are presented in Fig. 2.

Thus, we had different plots for the varied reinforced cases, which were then used for their comparative performance assessment. The four types of pavement models which have been considered in this study are mentioned below and they have also been shown schematically in Fig. 3a–d. The respective test data for the cyclic plate load tests performed for these reinforcement cases are shown graphically in Fig. 4.

-

(i)

Unreinforced case

-

(ii)

Reinforced with Geogrid (geogrid placed on top of subgrade)

-

(iii)

Reinforced with Geocell (geocell fixed on top of subgrade)

-

(iv)

Reinforced with Geogrid and Geocell (geogrid placed on subgrade, then geocell placed on geogrid)

4 Data Analysis

For each test performed on different reinforcement cases, we have test results in the form of cumulative surface settlement for the total number of loading cycles sustained by the test. These test results have further been used to calculate the two different performance parameters named TBR and RDRFs. The details for these two pavement performance parameters are discussed below.

4.1 Traffic Benefit Ratio (TBR)

It gives an indicative design life for the reinforced pavements in comparison to the unreinforced ones. The number of load cycles dissipated for the same value of surface settlement in the two comparative cases, gives the improvement in terms of a ratio called TBR. The mathematical equation used for the calculation of TBR is shown below in Eq. 1.

From Fig. 4, it can be observed that the unreinforced case is showing high surface settlement behavior, accordingly the reference value of surface settlement for the calculation of TBR has been selected as 30 mm. The calculation of TBR value for all the reinforced cases are summarized in Table 6.

4.2 Rut Depth Reduction Factor (RDRF)

It gives a comparative idea for the pavement performance in terms of improvement in rutting behavior for a given number of load cycles. Mathematically, it is opposite to TBR and its calculation is shown below in Eq. 2.

For the present study, 100 number of loading cycles have been considered as the reference criterion for computing the RDRF for different reinforcement cases. The calculation of RDRF is summarized below in Table 7. The graphical variation of the RDRF calculated up to 334 continuous cycles for each of the three reinforcement cases is shown in Fig. 5. The number of maximum cycles considered for calculation of RDRF is limited to 334, as it is the last possible loading cycle for the unreinforced case which acts as the reference for calculation of RDRF for the other reinforced cases.

5 Conclusions

This study is based on RAP-filled base layers on soft soil subgrades having low CBR. The test results for the laboratory scale pavement model studies were used to quantify the comparative improvement of the pavement performances for the case of reinforced sections in comparison to the unreinforced ones. The benefits of reinforcing the base layers were computed in terms of TBR and RDRF. The all three reinforcement cases namely (a) Geogrid on subgrade, (b) Geocell on subgrade, and (c) combination of Geocell and Geogrid; considered in this study were found to considerably enhance the pavement performance. The following conclusions can be drawn from this study:

-

The performance for the combined application of Geogrid and Geocell was found to be best among all three reinforcement cases, followed by the case of Geocell confinement and then the case of Geogrid reinforcement.

-

The RDRFs for all the three reinforcement cases were found to continuously increase with the number of loading cycles.

-

TBR values for the case of combined application of Geogrid and Geocell (TBR = 52), were found to be higher than the case of only Geocell (TBR = 31), followed by the case of only Geogrid (TBR = 9).

-

The RDRF for the three reinforcement cases: (a) Geogrid reinforced base layers, (b) Geocell-confined base layers, and (c) combination application of Geogrid and Geocell on base layers were found to be 30, 45, and 51%, respectively.

-

Geocell-confined base layer yields better performance than the Geogrid reinforced case. This can be related to the increased stiffness of the confined material under the action of lateral confinement and tension membrane effect offered by the geocell reinforcement.

-

The improved performance of the geosynthetic-reinforced pavements (measured in terms of TBR & RDRF) can either be used for the reduction of base layer thickness (for a particular design life) or the thickness of base layer can be kept unaltered thus providing an increased design life to the pavement.

This study is limited to large-scale laboratory studies under repeated loading on single source of RAP material. This study further requires field implementation of geocell/geogrid reinforced sections under actual traffic loading to study long-term performance behavior.

References

Kazmee H, Tutumluer E, Beshears S (2016) Using accelerated pavement testing to evaluate reclaimed asphalt pavement materials for pavement unbound granular layers. J Mater Civ Eng 29(2):1–13

Rana ASMA (2004) Evaluation of recycled material performance in highway applications and optimization of their use. Dissertation (PhD). Texas Tech University

Potturi AK (2006) Evaluation of resilient modulus of cement and cement fiber treated reclaimed asphalt pavement (RAP) aggregates using repeated load triaxial test. Thesis (MS). The University of Texas at Arlington

Deniz D, Tutumluer E, Popovics JS (2010) Evaluation of expensive characteristics of reclaimed asphalt pavement and virgin aggregate used as base materials. Transp Res Record: J Transp Res Board 2167:10–17

Puppala AJ, Hoyos LR, Potturi AK (2011) Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates. J Mater Civ Eng 23(7):990–998

Mohammadinia A et al (2014) Laboratory evaluation of the use of cement treated construction and demolition materials in pavement base and subbase applications. J Mater Civ Eng 28(7):899–1561

Avirneni D, Peddinti PRT, Saride S (2016) Durability and long term performance of geopolymer stabilized reclaimed asphalt pavement base courses. Constr Build Mater 121:198–209

Puppala AJ, Congress SSC, Bheemasetti TV et al (2018) Visualization of civil infrastructure emphasizing geomaterial characterization and performance. J Mater Civ Eng 30(10):04018236. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002434

Sambodh A (2017) Mechanical properties of soil-RAP-geopolymer for the stabilization of road base/subbase. Thesis (MS). University of Louisiana at Lafayette

George AM, Banerjee A, Puppala AJ, Saladhi M (2021) Performance evaluation of geocell-reinforced reclaimed asphalt pavement (RAP) bases in flexible pavements. Int J Pavement Eng 22(2):181–191. https://doi.org/10.1080/10298436.2019.1587437

Zornberg JG (2011) Advances in the use of geosynthetics in pavement design. In: Proceedings of the second national conference on geosynthetics, geosynthetics India ’11 Vol 1. India Institute of Technology Madras, Chennai, India, pp 3–21

Mamatha KH, Dinesh SV, Dattatreya JK (2017) Evaluation of flexural behaviour of geosynthetic-reinforced unbound granular material beams. Road Mater Pave Des. https://doi.org/10.1080/14680629.2017.1422790

Perkins SW (1999) Geosynthetic reinforcement of flexible pavements: laboratory based pavement test sections, final report: FHWA/MT-99–001/8138, State of Montana, Department of Transportation, Research, Development and Technology Transfer Program

Chen Q, Hanandeh S, Abu-Farsakh M, Mohammad L (2017) Performance evaluation of full-scale geosynthetic reinforced flexible pavement, Article in Geosynthetics International https://doi.org/10.1680/jgein.17.00031

Leng J, Gabr MA (2002) Characteristics of geogrid-reinforced aggregate under cyclic load. Transp Res Record 1786, Paper No. 02–4091

Qian Y, Han J, Pokharel SK, Parsons RL (2013) Performance of triangular aperture geogrid-reinforced base courses over weak subgrade under cyclic loading. Article J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000577

Sun X, Han J, Corey R (2010) Equivalent modulus of geogrid-stabilized granular base back-calculated using permanent deformation. J Geotech Geoenviron Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001761

Tanyu BF, Kim WH, Edil TB, Benson CH (2003) Comparison of laboratory resilient moduli with back-calculated elastic moduli from large-scale model Experiments and FWD tests on granular materials, Resilient Modulus Testing for Pavement Components. In Durham GN, Marr AW, De Groff WL (eds) ASTM, West Conshohocken PA, USA, STP, vol 1437, pp 191–2080

Bhosale SS, Kambale BR (2008) Laboratory study for evaluation of membrane effect of geotextile in unpaved road. In: The12th international conference of international association for computer methods and advances in geomechanics (IACMA), Goa

Murad Abu-Farsakh Y, Chen Q (2012) Evaluation of the base/subgrade soil under repeated loading: Phase I–In-Box and ALF cyclic plate load tests. Final Report. No. FHWA/LA.09/450, Louisiana transportation research center, Baton Rouge, LA

Kiptoo D, Aschrafi J, Kalumba D, Lehn J, Moormann C, Zannoni E (2017) Laboratory investigation of a geosynthetic reinforced pavement under static and dynamic loading. J Test Eval 45(1):76–84. https://doi.org/10.1520/JTE20160170

Jeremy Robinson W, Mahaffay BJ, Howard IL, Norwood GJ (2019) Cyclic plate testing of geosynthetic reinforced airfield pavements. https://doi.org/10.1680/jgrim.18.00106

IS 1498: Classification and identification of soils for general engineering purposes. Bureau of Indian Standards, New Delhi

IS 2720-3-1 (1980) Methods of test for soils, Part 3: determination of specific gravity, Section 1: fine grained soils. Bureau of Indian Standards, New Delhi

IS 2720-5 (1985) Methods of test for soils, Part 5: determination of liquid and plastic limit [CED 43: soil and foundation engineering]. Bureau of Indian Standards, New Delhi

IS 2720-8 (1983) Methods of test for soils, Part 8: determination of water content-dry density relation using heavy compaction. Bureau of Indian Standards, New Delhi

IS 2720-16 (1987) Methods of test for soils, Part 16: laboratory determination of CBR. Bureau of Indian Standards, New Delhi

IS 2720-2 (1973): Methods of test for soils, Part 2: determination of water content [CED 43: Soil and Foundation Engineering]

ASTM-D2172M-11 (2011) Standard test methods for quantitative extraction of bitumen from bituminous paving mixtures. ASTM international, West Conshohocken, PA, United States, pp 19428–2959

Acknowledgements

Authors are thankful to Director, CSIR—CRRI, New Delhi, for his kind permission to publish this paper. We thankfully acknowledge National Mission on Himalayan Studies, G.B. Pant National Institute of Himalayan Environment and Sustainable Development (GBPNHIESD) which gave us financial assistance for the project on “Sustainable Road pavements in high altitude regions using geosynthetics.”

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Bharath, G., Shaw, A.K., Prasad, P.S., Kamaraj, C. (2023). Laboratory Evaluation of a Geosynthetic-Reinforced Pavement over Poor Subgrade. In: Nandagiri, L., Narasimhan, M.C., Marathe, S. (eds) Recent Advances in Civil Engineering. CTCS 2021. Lecture Notes in Civil Engineering, vol 256. Springer, Singapore. https://doi.org/10.1007/978-981-19-1862-9_28

Download citation

DOI: https://doi.org/10.1007/978-981-19-1862-9_28

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1861-2

Online ISBN: 978-981-19-1862-9

eBook Packages: EngineeringEngineering (R0)