Abstract

We first give an introduction to the evolution of the fashion supply chain structure from linear to circular. Next, we review and discuss the important elements that should be considered and analyzed in sustainable operations in a fast-fashion era, namely, advanced technology, customer involvement, collaborative strategy, and government support. Finally, we draw our conclusion and propose future research directions.

Shuyun Ren’s research is partially supported by National Natural Science Foundation of China (Project account: 71801054).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Fast-Fashion Industry—From Linear to Circular

Fashion industry is an important sector that contributed $1.9 trillion in retail sales in 2019 (Intrado 2020). However, it is also perceived as the second dirtiest industry severely affecting our planet and generating a massive amount of air pollution, solid waste, and water pollution. It is reported that the fashion industry produces 10% of greenhouse gases emission globally (e.g., from generating electricity in the production process) and 20% of water pollution (e.g., from dying and bleaching the fabric) (Ro 2020). Besides, more than 90 million tonnes of textile and clothing waste are sent to the landfill annually and the amount is predicted to increase dramatically by 50% by 2030 (May 2020). Fast fashion has been blamed for its negative impact brought to the environment when compared with luxury fashion. It is due to the nature of fast fashion.

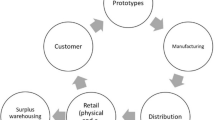

Fast fashion is characterized by having reduced lead time (such as using a quick response strategy to postpone the inventory ordering decision such that the fashion brands can observe the market trends to satisfy customer demand) and introducing the new fashionable items to the market quickly (Choi 2014a, b) at an affordable price. The life-cycle of the fast-fashion product is very short and the design of it changes frequently to capture the current fashion trend (Cachon and Swinney 2011). To produce the highly fashionable items, the fast-fashion supply chains have to consume a massive amount of non-renewable resources, water, and chemical to produce the trendy fashionable items to cope with customer’s needs on the trendy elements. However, making a piece of cotton shirt and a pair of jeans requires 700 and 2000 gallons of water, respectively (McFall-Johnsen 2019). Besides, customers are lured by the low retail price which results in impulse purchase, unnecessary consumption, and negatively affects our planet eventually. See Fig. 8.1 about a linear structure in a traditional fashion supply chain. On the other hand, to sell fashion products at an affordable price, fast-fashion brands have to control the production costs tightly. They prefer to use synthetic fabric (e.g., polyester, nylon, acrylic) to make clothing as these materials are cheaper and can be stretched easily; yet, they are non-biodegradable (Retviews 2019). Over the past decades, fast-fashion brands have implemented different sustainable practices to mitigate their waste and pollution problems, for instance, H&M uses environmentally friendly materials (e.g., organic cotton and lyocell) for making clothing and implements “fashion garment recycling programs” from end-customers, while Zara uses renewables sources of energy for production and adopts artificial intelligence to improve demand forecasting to reduce the chance of having overproduction.

Recently, a new sustainable business model has emerged in fast fashion by applying the concepts of circular economy (SAP 2019). A circular economy aims to reduce the use of scarce resources and waste generation. Choi et al. (2020a) define that a circular supply chain (CSC) is a supply chain system that targets to achieve environmental sustainability with a minimal level of waste and maximal use of “reuse, recycle, and remanufacturing”, and generates values in a “closed-loop” system. For example, Uniqlo has applied the concepts of “reuse and remanufacturing” by collecting the down jackets from end-customers, and then extracting the feathers and reusing them as materials for making the new down jackets for the new collection (see Fig. 8.2 for details). Nike gathers the plastic bottles from the ocean and recycles them as rubber for making shoes. As a remark, the terms “circular supply chain”, “sustainable operations”, and “closed-loop supply chain” are related to having sustainable practices. However, “circular supply chain” focuses more on “reuse”, “recycle”, and “remanufacturing” to result in zero solid waste ideally. See Fig. 8.3 about a circular structure in a fashion supply chain.

2 Circular Supply Chain Management

Developing a circular supply chain requires the application of advanced technology, customer involvement, collaborative strategy, and government support. We review the recent related literature and discuss the details as follows.

2.1 Advanced Technology

Advanced technology is important in the production, recycling processes, and inventory planning and forecasting in circular supply chain management. For example, Sandvik and Stubbs (2019) conducted interviews with stakeholders to understand the enablers and barriers of having “textile-to-textile” recycling systems in the apparel industry. They recommend applying technology to enhance sorting and recycling which could enhance the transparency and traceability in the supply chain management. Jia et al. (2020) conducted a literature review on the circular economy in the fashion industry. They proposed that future research can adopt multiple cases to reflect the circular economy situation, analyze the relationship between the social aspect and circular economy, conduct financial assessment when technology is used for facilitating circular economy, and adopt the network concepts to evaluate the ecological innovation outputs. Maranesi and De Giovanni (2020) conducted four case studies to illustrate how the circular economy concept is aligned with the corporate strategy and how to achieve industrial symbiosis and the corresponding performance. They found that the application of the circular economy concept in the company should be well supported by the shareholders and the top management. Besides, technologies and “eco-innovations” are the major components of circular supply chain management and the collaboration mechanism. Tedesco and Montacchini (2020) conducted company auditing on the environmental performance in small and medium enterprises (SMEs), and did experiments and prototyping to highlight the opportunities and difficulties of using textile waste as a building material for new product development. Besides, the authors also applied the life-cycle approach to evaluate the environmental performance by using recycled materials. To support sustainable operations, we can implement cleaner technology, 3D printing technology, and artificial intelligence to help.

-

Cleaner Technology. Producing fashion products is energy-intensive which significantly generates greenhouse gases and pollutes our environment. Fashion brands (e.g., Patagonia, H&M, and Nike) have started using renewable energy. For example, Nike adopts 100% renewable energy in its facilities in North America. The consideration of adopting cleaner technology to reduce carbon emissions has been examined in the literature for fashion supply chain management. In the analytical literature, Shen et al. (2017) conducted case studies to reveal the clean technologies adoption in Chinese textile suppliers and then develop an analytical model to derive the optimal decision in the clean technology selection. Chan et al. (2018) examined the effect of using a quick response strategy of the fashion industry when the supplier invests in clean technology while the retailer improves the inventory forecasting estimation by Bayesian theory. Besides, they proposed to use minimum ordering quantity (MOQ) and MOQ with buyback (MOQ-BB) to coordinate the supply chain. Shen et al. (2020) explored the spillover effect when clean technology is adopted in the fashion industry. They found that the spillover effect can enhance the greenness level of the product. Guo et al. (2020) considered the use of advantage technology to increase the greenness level of the product and study the effect of market competition. The above studies consider that the supplier is the one who should invest in clean technology.

-

3D Printing Technology. 3D printing, also called additive manufacturing, is perceived as a tool to drive sustainability. This technology builds an object layer by layer and it can reduce the amount of waste generated in the production process and the residual materials can be recycled for a new round of printing (Despeisse et al. 2017; Kerdlap et al. 2019). The 3D printing technology can use to support the circular supply chain. First, it does not require a mold prior to manufacturing the object in any shape when compared with transformative traditional manufacturing (Song and Zhang 2020; Sun et al. 2020). Second, it supports the mass customization project in which the object can be personalized according to the customer’s requirement and it results in “on-demand” manufacturing (Pasricha and Greeninger 2018). Therefore, with 3D printing, it is able to meet the unique needs of customers which can reduce the chance of having overproduction. For example, Adidas uses 3D printing technology to make a customized midsole of sports shoes. Existing literature on the 3D printing application investigates the management of the “spare parts” (Song and Zhang 2020), optimal pricings decisions (Sun et al. 2020), and the impact of competition intensity (Kleer and Piller 2019). However, the applications of 3D printing of the above studies do not specifically focus on the fashion supply chain.

-

Artificial Intelligence. In nowadays fashion industry, the applications of artificial intelligence (AI) play a crucial role in different management categories, from fashion demand forecasting to decision-making in supply chain management (Thomassey and Zeng 2018). AI-based forecasting methods and techniques are explored and applied more and more in both academic and industries due to the precise and effective performance in fashion demand forecasting (Lim and Zohren 2021). Loureiro et al. (2018) investigated the use of AI methods in fashion demand forecasting for new products and suggested that AI forecasting methods perform better than other traditional regression methods in the fashion retail market. Hofmann and Rutschmann (2018) examined the performance of big data analysis and AI techniques on fashion demand forecasting and revealed that big data analysis with AI technique can benefit fashion companies and supply chain management. With the use of information technology, fashion companies can gather information about customers’ preferences, and then they can improve their inventory policy for matching supply and demand. With this practice, the fashion companies are able to satisfy customers with a reduced chance of having unsold fashionable items and the wastage of scarce resources. In real-life situations, by exploring big data and AI techniques, H&M has eliminated stocking stores and replaced them with an assortment of products worldwide (Chaudhuri 2018). Zara uses artificial intelligence to improve the forecasting of the “best-selling” fashion items for inventory management (Heuritech 2020).

2.2 Customer Involvement

A circular supply chain cannot be successfully implemented without customer involvement. It is well agreed that the amount of solid waste going to the landfill can be reduced if the end-customers are willing to donate or “bring back” the unwanted fashionable items for recycling. Customer acceptance of using recycled materials for making new fashionable items is critical to the success of circular economy. Kim et al. (2021) found that the emotional value will positively affect the attitude of sustainable fashion products and the statistical results also support that a consumer with environmental awareness will have a higher tendency to purchase the sustainable fashion product. Pal et al. (2019) discussed the obstacles to forming a circular supply chain and the critical issues in future research directions. They highlight the effectiveness of the reverse supply chain, acceptance of the recycled products, technology support, and strategic alignment in the circular economy.

On the other hand, the clothing donation behavior has been widely examined using an empirical approach. For example, Ha-Brookshire and Hodges (2009) conducted interviews, questionnaires, and observations to study the clothing donation behavior of the consumers. They found that the major reason driving clothing donation is due to the closet cleaning. Bianchi and Birtwistle (2012) showed that the recycling behavior of the consumer will partially associate with clothing reselling to gain economic benefit. Bianchi and Birtwistle (2012) further found that consumer environmental awareness and consumer age will influence donation behavior. Joung (2014) suggests that fast-fashion consumers may simply discard the fashionable items because the perceived quality of the fast-fashion items is lower. Park et al. (2017) applied the behavioral reasoning theory and revealed that consumer environmental attitude will drive their intention to donate clothing to charity. Recently, empirical studies have considered the apparel resale attitude of consumers. Lai and Chang (2020) statistically showed that prosocial behavior is associated with apparel resale behavior, and both the environmental and prosocial behaviors are not related to apparel reuse intention.

However, there are very few analytical studies examining the customer involvement in clothing recycling. Choi et al. (2018) explored the used intimate apparel collection (UIAC) programs and studied the optimal level on the coupons value, collection investment, and the number of donors between charity collector and commercial collector. In the model, the authors considered that the donation rate of the end-customers is dependent on the coupon value. They also investigated how retail competition affects the levels of social, environmental, and economic sustainability in UIAC programs.

2.3 Collaborative Strategy

Being sustainable is the responsibility of every single firm, including suppliers, manufacturers, and retailers. Even though the fast-fashion products are sold at a lower retail price and hence the fast-fashion brands should have a lower sustainability commitment than the luxury brands (Chan et al. 2020b), they have also begun to collaborate with its supplier to implement various sustainable practices. It witnessed that business firms have collaborated with their supply chain members to achieve this goal. For example, H&M collaborates with recycling company I:CO which gets the donated clothing from H&M and performs sorting to determine whether to reuse, re-wear, or recycled. The most widely applied organizational theories to address the collaboration with suppliers for environmental sustainability are the stakeholder theory and resource-based theory. The majority of relevant literature uses “survey” and “case study” as the research methodologies. Readers can refer to Chen et al. (2017) for details. For example, Fischer and Pascucci (2017) conducted case studies in the fashion industry in The Netherlands. The authors define two ways for circular economy transition, namely status quo arrangement and product as service arrangement, and find that channel coordination, contracting, and financial performance are key elements for developing circular material flows. In other words, it is crucial to have a win–win situation when developing a circular economy. Fehrer and Wieland (2021) addressed the importance of social and ecological systems in the transformation process toward circular economy and emphasizes that the social, economic, and environmental goals should be balanced. They proposed a new circular business model and discussed future research directions. The concept of mutual benefit and the social, economic, and environmental performance in sustainable operations management has been considered in the analytical studies.

Regarding the analytical literature, a limited study specifically focuses on fashion supply chain management. For example, existing literature considers using the revenue-sharing contract as a kind of collaboration to improve the sustainability performance (Hsueh 2014; Govindan and Popiuc 2014; Zou et al. 2018; Li et al. 2019; Yu et al. 2020) or sharing of the used product collection responsibility (Wang et al. 2019). Regarding fashion supply chain management, Adhikari and Bisi (2020) considered a collaborative strategy in a sustainable fashion supply chain with a green cost-sharing contract. They studied how the fairness concern affects the greenness level and pricing decisions.

2.4 Government Policy and Support

Governments are also crucial in sustainable development and circular supply chain formation. Governments including Australia, China, and Singapore, have already imposed regulations and have issued carbon-related tax policies (e.g., carbon tax, cap-and-trade) for environmental protection (Chow 2020). Apart from taxes, it is also reported that governments, including British and Australian governments, motivate the circular supply chain formation through recycling by offering financial subsidies (Ukft 2019). The carbon-related tax registration and financial subsidy will induce fashion companies to adopt a sustainable practice. Virta and Räisänen (2021) revealed three cases for sustainable production and consumption in the apparel industry according to the data collected from the Finnish news media. They predict that there will be a stronger need for the policy instruments to be sustainable, such as legislation, environmental tax, and eco-label.

Regarding the analytical studies, Choi (2013) investigated how the carbon tax affects the sourcing decision of the retailer. Shi et al. (2017) constructed an analytical model to explore the sustainability investment level and pricing decision in manufacturer Stackelberg, vertical Nash, and retailer Stackelberg models in a fashion supply chain with the consideration of carbon tax. Shen and Li (2019) derived the optimal pricing and product greenness level in the presence of retail competition and carbon tax. Choi and Luo (2019) examined how the quality of the market data affects the fashion supply chain profitability and social welfare when the carbon tax is imposed by the government. Shen et al. (2020) found that a higher carbon tax price will motivate the manufacturer to adopt the clean technology in the monopoly situation and the optimal product greenness level will increase in the carbon tax if and only if the market share of the retailer is sufficiently large. Chan et al. (2020a) analytically examined the effect of carbon taxes and consumer returns on the optimal inventory policy of the retailer when she is risk-neutral and risk-averse, respectively. Apart from the taxation, the government can also provide financial subsidies to motivate sustainable operations in the fashion industry. However, the related literature in this area is minimal. In the literature, Wang et al. (2014) addressed the government subsidy for remanufacturing activities. They found that the extreme value of subsidy will intensify the competition between the remanufacturer, while a moderate value of subsidy will result in cooperation between the supply chain partners in a fashion supply chain.

3 Conclusion Remarks and Future Research Directions

In this chapter, we first give an introduction to the evolution of the fashion supply chain structure from linear to circular. Next, we review and discuss the important elements that should be considered and analyzed in sustainable operations in a fast-fashion era, namely, advanced technology, customer involvement, collaborative strategy, and government support. Overall, the success of the circular economy formation involves support from the stakeholders, including top management, fashion brand, supplier, government, and even customers. After reviewing the literature, we have realized the following research directions:

-

Nowadays, customers are not only concerned about the greenness level of the fashion product but also the sustainable actions of the fashion brands and their suppliers. Having transparent supply chains is essential in future circular supply chain management. To support this functionality, blockchain is one of the possible technologies. Wang et al. (2020) illustrate how blockchain technology can support circular supply chain management in the fast-fashion industry. Blockchain adoption is still in the infant stage and it requires our effort to evaluate the impact and risk of using blockchain technology for circular supply chain management in terms of environmental, social, and economic performance. Dutta et al. (2020) and Choi et al. (2020b) provide good references in this area.

-

Adopting cleaner technology is a commonly seen approach to enhance sustainability, and the majority of literature considers that the supplier is the one who invests in this technology. In the future, it is also interesting to investigate the situation in which the manufacturer also has the capability to invest in clean technology (such as the study by Guo et al. 2020), or both the supplier and manufacturer co-invest in the technology.

-

Studies on the fashion circular supply chain management related to the real-world practice are still underexplored. It is suggested to conduct interviews, case studies, and observations to strengthen our knowledge of the supply chain context. The findings will become fundamental for building different supply chain structures in the circular economy for analytical modeling studies. Therefore, a multi-methodology approach is highly recommended to analyze the value and impact of the real-world situation. For example, we can consider that the supplier (e.g., Nike) rather than the remanufacturer collected the used apparel from the end-customers directly for remanufacturing. In addition, it is interesting to examine the possible form of sustainability collaboration between the supplier and retailer in real-world practice and then analyze the pareto/win–win mechanism for such kind of collaboration.

-

3D printing technology can facilitate the “on-demand” production nature which can significantly reduce the amount of unsold fashionable items going to landfills. To our best knowledge, there is a research gap on the 3D printing technology adoption for sustainability operations in the fashion industry which deserves our further investigation. For example, in the competitive market, how does the 3D printing technology affect the pricing and quality decisions? Are the environment, social and economic performance always better off when 3D printing is used for making customized products? If the lead-time is also considered, how does it affect our operational decisions as well?

-

From the literature, it is observed that the majority of literature studies on sustainable fashion supply chain management consider the carbon tax, and limited studies focus on the cap-and-trade policy and financial subsidy. In the future, it is worth our effort to examine the different sustainable operations in the fashion industry with the consideration of cap-and-trade government policy and financial subsidy. Dong et al. (2016) provide a good reference in this area. Besides, it is also interesting to compare and analyze whether a taxation scheme is better than a financial subsidy to motivate the fashion firms to be sustainable and whether it is also good for the society.

-

As we all know, it is often a challenging task to combine inventory management and demand forecasting to perform the quick response strategy in the fashion supply chain management. Different from general products, fashion products have a short life-cycle with a large number of varieties, and the market demand is changeable which makes it difficult to predict accurately. Consumer changes the position from the end of the entire process to the front in the big data era (Guo et al. 2020). It is difficult for the traditional forecasting methods that are based on historical sales data and expert experience to handle the complicated influencing factors and the rapid changes in demand. How to grasp the changes in fashion trends and market demand in real time in the big data environment and respond quickly is an urgent problem in the nowadays fast-fashion industry.

References

Adhikari A, Bisi A (2020) Collaboration, bargaining, and fairness concern for a green apparel supply chain: An emerging economy perspective. Transp Res Part E: Logistics Transp Rev 135:101863

Beltagui A, Kunz N, Gold S (2020) The role of 3D printing and open design on adoption of socially sustainable supply chain innovation. Int J Prod Econ 221:107462

Bianchi C, Birtwistle G (2010) Sell, give away, or donate: an exploratory study of fashion clothing disposal behaviour in two countries. Int Rev Retail, Distrib Consum Res 20(3):353–368

Bianchi C, Birtwistle G (2012) Consumer clothing disposal behaviour: a comparative study. Int J Consum Stud 36(3):335–341

Cachon GP, Swinney R (2011) The value of fast fashion: quick response, enhanced design, and strategic consumer behavior. Manage Sci 57(4):778–795

Chan HL, Choi TM, Cai YJ, Shen B (2020a) Environmental taxes in newsvendor supply chains: A mean-downside-risk analysis. IEEE Trans Syst Man Cybern Syst 50(12):4856–4869

Chan HL, Wei X, Guo S, Leung WH (2020b) Corporate social responsibility (CSR) in fashion supply chains: A multi-methodological study. Transportation Research Part E: logistics and transportation review, 142, 102063

Chan HL, Shen B, Cai Y (2018) Quick response strategy with cleaner technology in a supply chain: coordination and win-win situation analysis. Int J Prod Res 56(10):3397–3408

Chaudhuri S (2018) H&M pivots to big data to spot next big fast-fashion trends. Available at: www.wsj.com/articles/h-m-pivots-to-big-data-to-spot-next-big-fast-fashion-trends-1525694400. Accessed 21 July 2018

Chen L, Zhao X, Tang O, Price L, Zhang S, Zhu W (2017) Supply chain collaboration for sustainability: a literature review and future research agenda. Int J Prod Econ 194:73–87

Choi TM (2013) Carbon footprint tax on fashion supply chain systems. Int J Adv Manuf Technol 68(1–4):835–847

Choi TM (2014a) Optimal apparel supplier selection with forecast updates under carbon emission taxation scheme. Comput Oper Res 40(11):2646–2655

Choi TM (ed) (2014b) Fast fashion systems: theories and applications, vol 4. CRC Press

Choi TM, Luo S (2019) Data quality challenges for sustainable fashion supply chain operations in emerging markets: roles of blockchain, government sponsors and environment taxes. Transp Res Part E: Logistics Transp Rev 131:139–152

Choi TM, Chow PS, Lee CH, Shen B (2018) Used intimate apparel collection programs: a game-theoretic analytical study. Transp Res Part E: Logistics Transp Rev 109:44–62

Choi TM, Taleizadeh AA, Yue X (2020a) Game theory applications in production research in the sharing and circular economy era. Int J Prod Res 58(1):118–127

Choi TM, Feng L, Li R (2020b) Information disclosure structure in supply chains with rental service platforms in the blockchain technology era. Int J Prod Econ 221:107473

Chow C (2020) Carbon tax: a shared global responsibility for carbon emissions. Retrieved from https://earth.org/carbon-tax-a-shared-global-responsibility-for-carbon-emissions/#:~:text=A%20national%20carbon%20tax%20is,%2C%20Japan%2C%20Ukraine%20and%20Argentina

Despeisse M, Baumers M, Brown P, Charnley F, Ford SJ, Garmulewicz A, Rowley J (2017) Unlocking value for a circular economy through 3D printing: a research agenda. Technol Forecast Soc Chang 115:75–84

Dong C, Shen B, Chow PS, Yang L, Ng CT (2016) Sustainability investment under cap-and-trade regulation. Ann Oper Res 240(2):509–531

Dutta P, Choi TM, Somani S, Butala R (2020) Blockchain technology in supply chain operations: applications, challenges and research opportunities. Transp Res Part E: Logistics Transp Rev 142:102067

Fehrer JA, Wieland H (2021) A systemic logic for circular business models. J Bus Res 125:609–620

Fischer A, Pascucci S (2017) Institutional incentives in circular economy transition: the case of material use in the Dutch textile industry. J Clean Prod 155:17–32

Govindan K, Popiuc MN (2014) Reverse supply chain coordination by revenue sharing contract: a case for the personal computers industry. Eur J Oper Res 233(2):326–336

Guo S, Choi TM, Shen B (2020) Green product development under competition: a study of the fashion apparel industry. Eur J Oper Res 280(2):523–538

Ha-Brookshire JE, Hodges NN (2009) Socially responsible consumer behavior? Exploring used clothing donation behavior. Cloth Text Res J 27(3):179–196

Heuritech (2020) How can zara maintain its leadership in fast fashion thanks to artificial intelligence? Retrieved from https://www.heuritech.com/blog/company-analysis/zara-leadership-artificial-intelligence/

Hofmann E, Rutschmann E (2018) Big data analytics and demand forecasting in supply chains: a conceptual analysis. Int J Logistics Manage 29(2):739–766

Hsueh CF (2014) Improving corporate social responsibility in a supply chain through a new revenue sharing contract. Int J Prod Econ 151:214–222

Intrado (2020) Global fast fashion market report (2020 to 2030)—COVID-19 growth and change. Retrieved from https://www.globenewswire.com/news-release/2020/06/09/2045523/0/en/Global-Fast-Fashion-Market-Report-2020-to-2030-COVID-19-Growth-and-Change.html#:~:text=The%20global%20fast%20fashion%20market%20is%20expected%20to%20decline%20from,CAGR)%20of%20%2D12.32%25

Jia F, Yin S, Chen L, Chen X (2020) The circular economy in the textile and apparel industry: a systematic literature review. J Clean Prod 259:120728

Joung HM (2014) Fast-fashion consumers’ post-purchase behaviours. Int J Retail Distrib Manage 42(8):688–697

Kerdlap P, Low JSC, Ramakrishna S (2019) Zero waste manufacturing: a framework and review of technology, research, and implementation barriers for enabling a circular economy transition in Singapore. Resour Conserv Recycling 151:104438

Kim I, Jung HJ, Lee Y (2021) Consumers’ value and risk perceptions of circular fashion: comparison between secondhand, upcycled, and recycled clothing. Sustainability 13(3):1208

Kleer R, Piller FT (2019) Local manufacturing and structural shifts in competition: market dynamics of additive manufacturing. Int J Prod Econ 216:23–34

Lai CC, Chang CE (2020) Clothing disposal behavior of Taiwanese consumers with respect to environmental protection and sustainability. Sustainability 12(22):9445

Li T, Zhang R, Zhao S, Liu B (2019) Low carbon strategy analysis under revenue-sharing and cost-sharing contracts. J Clean Prod 212:1462–1477

Lim B, Zohren S (2021) Time-series forecasting with deep learning: a survey. Phil Trans R Soc A 379(2194):20200209

Loureiro AL, Miguéis VL, da Silva LF (2018) Exploring the use of deep neural networks for sales forecasting in fashion retail. Decis Support Syst 114:81–93

Maranesi C, De Giovanni P (2020) Modern circular economy: corporate strategy, supply chain, and industrial symbiosis. Sustainability 12(22):9383

May N (2020) This exercise is greenwashing at its absolute worst: the truth about fashion’s recycling bins. Evening Standard. Retrieved from https://www.standard.co.uk/insider/fashion/fashion-recycling-bins-primark-fast-fashion-sustainability-a4512311.html

McFall-Johnsen M (2019) The fashion industry emits more carbon than international flights and maritime shipping combined. Here are the biggest ways it impacts the planet. Insider. Retrieved from https://www.businessinsider.com/fast-fashion-environmental-impact-pollution-emissions-waste-water-2019-10

Pal R, Shen B, Sandberg E (2019) Circular fashion supply chain management: exploring impediments and prescribing future research agenda. J Fashion Market Manage Int J 23(3):298–307

Park M, Cho H, Johnson KK, Yurchisin J (2017) Use of behavioral reasoning theory to examine the role of social responsibility in attitudes toward apparel donation. Int J Consum Stud 41(3):333–339

Pasricha A, Greeninger R (2018) Exploration of 3D printing to create zero-waste sustainable fashion notions and jewelry. Fashion Textiles 5(1):1–18

Reviews (2019) Polyester fiber—the impact of fashion brands on ocean pollution. Retrieved from https://retviews.com/blog/industry/polyester-fiber/

Ro C (2020) Can fashion ever be sustainable? Retrieved from https://www.bbc.com/future/article/20200310-sustainable-fashion-how-to-buy-clothes-good-for-the-climate

Sandvik IM, Stubbs W (2019) Circular fashion supply chain through textile-to-textile recycling. J Fashion Market Manage Int J 23(3):366–381

SAP (2019) Can “Fast Fashion” be sustainable? Forbes. Retrieved from https://www.forbes.com/sites/sap/2019/11/21/can-fast-fashion-be-sustainable/?sh=69f3c3b32c9c

Shen B, Li Q (2019) Green technology adoption in textile supply chains with environmental taxes: production, pricing, and competition. IFAC-PapersOnLine 52(13):379–384

Shen B, Ding X, Chen L, Chan HL (2017) Low carbon supply chain with energy consumption constraints: case studies from China’s textile industry and simple analytical model. Supply Chain Manage Int J 22(3):258–269

Shen B, Zhu C, Li Q, Wang X (2020) Green technology adoption in textiles and apparel supply chains with environmental taxes. Int J Prod Res. https://doi.org/10.1080/00207543.2020.1758354

Shi X, Qian Y, Dong C (2017) Economic and environmental performance of fashion supply chain: the joint effect of power structure and sustainable investment. Sustainability 9(6):961

Song JS, Zhang Y (2020) Stock or print? Impact of 3-D printing on spare parts logistics. Manage Sci 66(9):3860–3878

Sun L, Hua G, Cheng TCE, Wang Y (2020) How to price 3D-printed products? Pricing strategy for 3D printing platforms. Int J Prod Econ 226:107600

Tedesco S, Montacchini E (2020) From textile waste to resource: a methodological approach of research and experimentation. Sustainability 12(24):10667

Thomassey S, Zeng X (2018) Introduction: artificial intelligence for fashion industry in the big data era. In: Artificial intelligence for fashion industry in the big data era. Springer, Singapore, pp 1–6

Ukft (2019) Fund opens to boost textile recycling. Retrieved from https://www.ukft.org/fund-opens-reduce-textile-waste/#:~:text=17%2F06%2F2019&text=The%20UK%20Government%20has%20launched,textile%20and%20plastic%20packaging%20waste

Virta L, Räisänen R (2021) Three futures scenarios of policy instruments for sustainable textile production and consumption as portrayed in the Finnish news media. Sustainability 13(2):594

Wang K, Zhao Y, Cheng Y, Choi TM (2014) Cooperation or competition? Channel choice for a remanufacturing fashion supply chain with government subsidy. Sustainability 6(10):7292–7310

Wang W, Yang S, Xu L, Yang X (2019) Carrot/stick mechanisms for collection responsibility sharing in multi-tier closed-loop supply chain management. Transp Res Part E: Logistics Transp Rev 125:366–387

Wang B, Luo W, Zhang A, Tian Z, Li Z (2020) Blockchain-enabled circular supply chain management: a system architecture for fast fashion. Comput Indus 123:103324

Yu B, Wang J, Lu X, Yang H (2020) Collaboration in a low-carbon supply chain with reference emission and cost learning effects: cost sharing versus revenue sharing strategies. J Clean Prod 250:119460

Zou H, Qin J, Yang P, Dai B (2018) A coordinated revenue-sharing model for a sustainable closed-loop supply chain. Sustainability 10(9):3198

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Chan, HL., Ren, S., Liu, N. (2022). Overview and Research Agenda for Sustainable Operations Management in Fast-Fashion Era. In: Chan, HL., Ren, S., Liu, N. (eds) Operations Management in the Era of Fast Fashion . Springer Series in Fashion Business. Springer, Singapore. https://doi.org/10.1007/978-981-19-1177-4_8

Download citation

DOI: https://doi.org/10.1007/978-981-19-1177-4_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1176-7

Online ISBN: 978-981-19-1177-4

eBook Packages: Business and ManagementBusiness and Management (R0)