Abstract

The transportation sector is dominated by compression ignition (CI) engines. Their high power output, portability, efficiency, and overall prevalence in vehicles have resulted in their status as the largest petroleum consumer in any field. The present research aims to reduce petroleum reliance by using biodiesel as an alternative fuel to diesel in the CI engine. As a renewable, eco-friendly alternative to fossil fuels, biodiesel requires thorough investigation under operational conditions. The studies on the mixture of diesel and single biodiesel have been carried out for most available plant and animal sources. With the combination of two different biodiesel blends with diesel, very little work has been done, and much potential has been left in this region. This investigation involves examining a 50:50 mixture of biodiesels extracted from non-edible Pongamia pinnata and Neem plant seed oil to blend with diesel. An acid catalyst chemically treats both non-edible oils before transesterification and reduces their free fatty acid (FFA) content. The results show that blends B10 to B30 have better or adjacent values with conventional diesel in fuel consumption and thermal efficiency. With all biodiesel blends, CO and HC emissions were reported to be reduced than that of diesel. As biodiesel is constituted of more oxygen molecules it enables better combustion of fuel in the combustion chamber. The emission of NOX is slightly higher in biodiesel blends when compared with diesel. In conclusion, dual biodiesel blends up to 30%, could be used as substitute to diesel in a conventional CI engine without significantly altering the engine and compromising on the engine's performance and emissions.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

As a species, humanity has adapted remarkably well to the whims of the environment. We have been fortunate enough to inherit a world containing a ready source of fuel in the form of fossilized organic matter [1]. This buried treasure has enabled humankind to survive harsh environments and drastic climate changes. It has helped us prosper on the tide of cheap energy powering our lives [2]. Consumption of fossil fuels and their derived products is ruinous to the environment, economy, and therefore, every living being’s health [3].

The supply chain dynamics of crude oil hold many countries hostage to the petroleum market’s whims [4]. For example, at the time of this writing, we face a pandemic that prevents the free movement of products due to restrictions to slow the spread of infection in communities. The covid-19 pandemic currently affecting most of the world has revealed the fragile supply chains that most countries are dependent on [5]. Plant-based biodiesel is a better option among all available alternative fuels since it is renewable, biodegradable, environmentally friendly, and domestically available [6]. Hence, biodiesel is an excellent candidate for the same. Locally produced biodiesel can provide a fillip to agriculture, employment, and the local economy [7].

1.1 Non-edible Plant Seed Oil

Non-edible oils are considered second-generation feedstocks for the production of biodiesel [8]. An investigation regarding single biodiesel with diesel has been carried out and reported their potential to be alternative diesel fuel. Some of the non-edible seed oil sources explored by researchers are Karanja [9], Neem [10], Jatropha [11], Bilva, Cottonseed [12], Moha, Saemuruba [12]. There is minimal literature about mixing two biodiesels with diesel as a fuel blend in the CI engine. Inadequate investigations on dual biodiesel as an alternate fuel to diesel are worth reconnoitering.

The FFA content in non-edible seed oil is higher than in edible seed oil due to triglyceride molecules presence in a large percentage. Triglycerides are chemically treated to separate fatty acid esters (biodiesel) and glycerin using a two-phase catalytic reaction. The fatty acid compositions of biodiesel derived from these feedstocks presage desirable variations in their physicochemical properties. The percentage of FFA affects the fuel properties, considerably influencing engine performance and emission characteristics [10]. NOx and CO2 in biodiesel emissions appear in higher percentages than in diesel, but the more toxic HC, CO, and smoke were lower [13]. The utilization of biodiesel in an engine is reported to reduce engine wear by 30% because of their additional lubricity [14]. Based on the literature survey, the CI engine performance with biodiesel is on the negative side compared with diesel when used in the existing engine [8].

In the present investigation, the domestically available Pongamia pinnata (Karanja) and Neem seed oil extracts respective methyl esters. The physicochemical properties of vegetable oil-derived biodiesels are examined, and their suitability as fuels in a diesel engine is determined. The standard test procedures are followed for testing biodiesel and validated based on the values of the ASTM D6751 standard for biodiesel [15]. The results indicated that the mixture of two biodiesel exhibited favorable improvement in their properties like calorific value and density regarding single biodiesel [16]. Fuel blends B00, B10, B20, B30, B40, and B100, are prepared for experimentation, and their composition is as listed in Table 1. Engine performance is gauged based on the amount of fuel consumed by the engine at different loading conditions while maintaining a constant speed. Furthermore, the engine performance is justified by heat generation after air-fuel combustion. Engine exhaust analyzer is used to detect emissions like NOx, CO and HC in the exhaust gas.

2 Experimental Setup and Procedure

The production procedure of biodiesel and the properties of biodiesel blends produced are estimated to check their feasibility as fuel in an engine according to ASTM Standard testing method are discussed in this section. And the experimental setup of the CI engine test rig used for the present investigation.

2.1 Production of Biodiesel and Properties of Biodiesel

Oil extracted from the Pongamia pinnata and Neem seeds is dense as it has an FFA content of more than 4%. A two-step catalytic reaction can reduce the density of crude seed oil [17]. The first step is to treat the crude seed oil with methanol and an acid catalyst. This pretreatment of seed oil with an acid catalyst is called esterification. Step two involves chemical modification of pretreated oil by transesterification to produce fatty acid methyl esters (FAME) or biodiesel. The FAME extracted from Pongamia Pinnata seed oil is called Pongamia methyl esters or Pongamia biodiesel. Furthermore, the esters extracted from Neem seed oil are called Neem methyl esters or Neem biodiesel.

After the transesterification process, FAME derived from plant seed oil has a much lower viscosity, making it capable of replacing petroleum [18]. The triglyceride present in oil reacts with alcohols like methanol to produce FAME, called transesterification. A base catalyst like sodium hydroxide is used to speed up the reaction to form fatty esters and glycerin [19]. Figure 1 represents a triglyceride composed of three long-chain fatty acids with a glycerin base. The number of these FFA determines the characteristics of the produced biodiesel.

The estimated properties of biodiesels and diesel with the help of the test methods approved by ASTM standards are listed in Table 2. The blends are prepared with different compositions of Neem biodiesel and Pongamia pinnata biodiesel with diesel. The properties of dual biodiesel blends like the flashpoint and calorific value are improved, as shown in Table 2.

2.2 Engine Specification

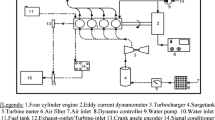

It consists of a single-cylinder CI engine, cooled using water, and computerized to capture data. An eddy current dynamometer is employed to vary the torque and achieve different loading conditions.

The test rig used for this experiment is represented in Fig. 2, and its specification is listed in Table 3. The engine was kept in running condition for around 20 min before taking the readings with every fuel blend. The exhaust gas analyzer indicates the different engine exhaust emissions.

3 Results and Discussion

3.1 Engine Performance Analysis

The analysis of the subject engine’s performance is characterized based on a speed of 1500 rpm is maintained at different load conditions. A variety of fuel blends are used to collect data relating to performance and efficiency. Fuel consumption and thermal efficiency of prepared blends were compared with diesel as a benchmark. There were three iterations of this experiment for all fuel modes to ensure accuracy, and the error bars are included while plotting the results.

Brake-Specific Fuel Consumption (BSFC). Figure 3 demonstrates the impact on BSFC for the six fuel modes at all load conditions. The BSFC is higher at a lower engine load due to high engine speed and lower in-cylinder temperatures [20]. The higher in-cylinder temperature results in increased atomization of fuel and a better air-fuel mixture, thereby decreasing BSFC.

From Fig. 3, the BSFC decreases with an increase in engine loading and tends to stabilize for all fuel modes at maximum load. The BSFC of the CI engine for fuel blend B00 (100% diesel) was observed to be 0.39 kg/kW-hr at full load condition. The BSFC with dual biodiesel blends B10 and B20 was 0.37 kg/kW-hr and 0.36 kg/kW-hr, lower than diesel. The higher cetane number and fire point of dual biodiesel blends reduce the physical ignition delay during the combustion phase [21]. The BSFC with blend B30 was observed to be 0.40 kg/kW-hr, marginally higher than diesel. This might be due to the lower calorific value of the B30 blend when compared with diesel [22]. The lower energy content of the esters in biodiesel increases the BSFC of the engine.

Further, with the increase of biodiesel percentage in the fuel blends, the BSFC increases. BSFC for blends B40 and B100 was 0.45 kg/kW-hr and 0.58 kg/kW-hr, higher than diesel due to the ester’s lower energy content. The dual biodiesel blend can be used in CI engine for up to 30% of diesel without any engine modifications.

Brake Thermal Efficiency (BTE). The impact of brake power on the BTE of an engine under all load conditions is represented Fig. 4. BTE is lower at lower loads due to higher engine speed and BSFC [23]. BTE is higher at higher loads because of the increased temperature inside the combustion chamber.

The BTE was 23.02% with blend B00 or diesel at full load condition. The BTE of blends B10 and B20 is 23.21% and 23.17%, marginally higher than diesel due to oxygenated biodiesel in the fuel blend. When blended with diesel, the oxygenated biodiesel enhances the fuel’s complete combustion ability and increases the BTE with a drop in BSFC. The BTE of blend B30 was 22.56%, slightly lower than diesel. The BTE of blends B40 and B100 was 21.63% and 20.07%, respectively. The diesel dilution in the higher biodiesel blends results in lower energy release due to the burning of low energy biodiesel esters. Lowering the energy released after combustion will lower the in-cylinder temperature and peak pressure, causing reduced BTE [24].

3.2 Engine Emissions

The significant components of emissions from diesel engines such as NOx, CO, and unburnt HC that have exited out of the combustion chamber are graphically represented for different fuel modes at various load conditions.

NOx Emission. The influence of brake power on the emissions of oxides of nitrogen with dual biodiesel blends is represented in Fig. 5. The graph demonstrates the presence of NOx in the engine exhaust at different loads. The NOx emission increases with increasing load for each dual biodiesel blend [20]. It is clear from the graph that the dual biodiesel blends tend to emit higher levels of NOx. Higher exhaust gas temperature and oxygen in fuel with dwelling time at higher load conditions contribute to higher NOx emissions in the blends.

CO Emission. The effect of brake power deviation on carbon monoxide emission at all load condition is shown in Fig. 6. CO content present in engine exhaust increases with an increase in load conditions. An increase in engine load leads to a corresponding rise in combustion temperature and increases CO emissions. A paucity of oxygen and lowered cooling time leads to partial combustion and generates CO.

HC Emission. The variant brake power effect on unburnt hydrocarbon emission is as shown in Fig. 7. HC emission is directly proportional to load, brake power, and indirectly proportional to temperature and oxygen availability [16]. Longer ignition delays mean that fuel combustion time is lowered, and HC emissions display an uptick. At part-load condition, HC emissions are 55 ppm for B00 or diesel, 45 ppm for B10, 40 ppm for B20, 38 ppm for B30, 35 ppm for B40, and 37 ppm for B100. HC emission in comparison to diesel is dropped in 18.18% with B10, 27.27% with B20, 30.9% with B30, 36.36% with B40, 32.7% with B100. When compared with biodiesel blends, a diesel fuel exhibits a longer ignition delay.

4 Conclusions

Dual biodiesel blends of Pongamia pinnata, Neem and regular diesel are used as fuel in a single-cylinder diesel engine. The results obtained are subject to analysis for their performance and emission characteristics.

-

No modifications to the diesel engine were necessary to accommodate the utilization of a dual biodiesel blend.

-

Properties of Pongamia pinnata and Neem biodiesel after chemically modified with transesterification are in the range of ASTM standards and can be used as an alternative to replacing fossil fuel.

-

From the experimental analysis, dual biodiesel blends B10, B20, and B30 have BSFC and BTE values strikingly close to those of the diesel.

-

The dual biodiesel blends have lesser CO and HC emissions than that diesel at all load conditions.

-

The emission of NOx from dual biodiesel blends was higher than that of diesel.

From this investigation, it could be summarized that biodiesel derived from Pongamia pinnata and Neem oil blended with diesel has the potential to be fuel in a conventional diesel engine. Dual biodiesel can be used as a substitute to diesel in the ratio of up to thirty by volume, which is B30 could be used without significant compromise to the engine performance and emissions. It also provides the opportunity to combine the biodiesels and not limit ourselves to one feedstock of biodiesel.

References

Shafiee S, Topal E (2009) When will fossil fuel reserves be diminished- Energy Policy 37:181–189

Asif M, Muneer T (2007) Energy supply, its demand and security issues for developed and emerging economies. Renew Sustain Energy Rev 11:1388–1413

Perera F (2017) Pollution from fossil-fuel combustion is the leading environmental threat to global pediatric health and equity: solutions exist. Int J Environ Res Public Health 15:16

Olson C, Lenzmann F (2016) The social and economic consequences of the fossil fuel supply chain. MRS Energy Sustain 3:E6

Kumar A, Luthra S, Mangla SK, Kazançoğlu Y (2020) COVID-19 impact on sustainable production and operations management. Sustain Oper Comput 1:1–7

Jeswani HK, Chilvers A, Azapagic A (2020) Environmental sustainability of biofuels: a review: environmental sustainability of biofuels. Proc R Soc A Math Phys Eng Sci 476

Biofuels S (2010) Sustainable production of. Renew Energy 35:1027–1032

Tasneem HRA, Ravikumar KP, Ramakrishna HV (2022) Performance and wear debris characterisitcs of karanja biodiesel and biolubricant as a substitute in a compression ignition engine. Fuel 319:123870. https://doi.org/10.1016/j.fuel.2022.123870

Prasada R, Suresh KV (2014) Pongamia Pinnata (karanja) biodiesel as an alternative fuel for diesel engine: a review. Adv Eng Appl Sci 4:52–61

Ali MH, Mashud M, Rubel MR, Ahmad RH (2013) Biodiesel from neem oil as an alternative fuel for diesel engine. Procedia Eng 56:625–630

Kawade GH, Satpute ST (2013) Jatropa biodiesel blending with diesel fuel suitable for diesel engine. In: 2013 international conference on energy efficient technologies for sustainability, ICEETS 2013:508–511. https://doi.org/10.1109/ICEETS.2013.6533437

Bobade SN, Khyade VB (2012) Detail study on the properties of Pongamia Pinnata (Karanja) for the production of biofuel. Res J Chem Sci 2. www.isca.in

Monyem A, Van Gerpen JH (2001) The effect of biodiesel oxidation on engine performance and emissions. Biomass Bioenergy 20:317–325

Agarwal AK, Bijwe J, Das LM (2003) Effect of biodiesel utilization of wear of vital parts in compression ignition engine. J Eng Gas Turbines Power 125:604–611

Knothe G, Jürgen K, Gerpen JV (2010) The biodiesel handbook (2nd ed). Urbana, Illinois: AOCS Press. https://doi.org/10.1201/b17510-1

Srithar K, Arun Balasubramanian K, Pavendan V, Ashok Kumar B (2017) Experimental investigations on mixing of two biodiesels blended with diesel as alternative fuel for diesel engines. J King Saud Univ Eng Sci 29:50–56

Hassani M, Amini G, Najafpour GD, Rabiee M (2013) A two-step catalytic production of biodiesel from waste cooking oil. Int J Eng 26:563–569

Ramírez-Verduzco LF, Rodríguez-Rodríguez JE, del Jaramillo-Jacob AR (2012) Predicting cetane number, kinematic viscosity, density and higher heating value of biodiesel from its fatty acid methyl ester composition. Fuel 91:102–111

Efavi JK et al (2018) The effect of NaOH catalyst concentration and extraction time on the yield and properties of Citrullus vulgaris seed oil as a potential biodiesel feed stock. S Afr J Chem Eng 25:98–102

Sivakumar M, Shanmugasundaram N, Rameshkumar R, Syed Thasthagir M (2017) Effects of pongamia methyl esters and its blends on a diesel engine performance, combustion, and emission characteristics. Environ Prog Sustain Energy 36:269–276

Lahane DSV, Subramanian K (2012) Analysis of physical and chemical ignition delay of a diesel engine for biodiesel-diesel blend (B20) using combustion characteristics

Adaileh WM, Alqdah KS (2012) Performance of diesel engine fuelled by a biodiesel extracted from a waste cocking oil. Energy Procedia 18:1317–1334

Dhanamurugan A, Subramanian R (2013) Performance of single cylinder diesel engine with bael seed biodiesel. J Sci Ind Res 72

Amriya Tasneem HR, Ravikumar KP, Ramakrishna HV, Kuldeep B (2021) Ceramic materials for thermal barrier coatings in compression ignition engine for its performance evaluation with biodiesel. Mater Today Proc 46:7745–7751. https://doi.org/10.1016/j.matpr.2021.02.274

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Amriya Tasneem, H.R., Ravikumar, K.P., Ramakrishna, H.V. (2023). Effects of Mixing Two Non-edible Biodiesels on Performance and Emission of CI Engine. In: Singari, R.M., Jain, P.K., Kumar, H. (eds) Advances in Manufacturing Technology and Management. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-9523-0_7

Download citation

DOI: https://doi.org/10.1007/978-981-16-9523-0_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-9522-3

Online ISBN: 978-981-16-9523-0

eBook Packages: EngineeringEngineering (R0)