Abstract

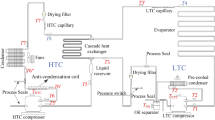

New vaccines have been developed in response to the current COVID-19 pandemic, and some of these require ultra-low temperature refrigeration (at −80 °C). After their appearance, the number of ultra-low temperature freezers of different capacities has been increased worldwide. Sustainable transition is ongoing in many refrigeration and heat pump applications following what is established in national and international regulations. However, many have not controlled ultra-low temperature refrigeration because of the challenges associated with these systems’ operation. The energy performance is low for this range of temperatures because of the distance between the heat sink and source temperatures. Moreover, a limited number of refrigerants are available because of restrictions in their normal boiling point and other challenges related to the lubricating oil. This chapter presents the main characteristics of several technologies (vapor compression cycle with element variations, sublimation, or absorption cycle) that can be applied for this range of temperatures, focusing on the constructing elements, advantages, and drawbacks. Then, recently developed configurations that can appear in commercial systems in the coming years are explored. These configurations are based on vapor compression cascade cycles, including an intermediate heat exchanger, ejector, and three-stage. It is seen that despite the increase in complexity and investment of the advanced configurations, the decrease in coefficient of performance is still notable, causing an increase in the operating cost. Apart from the additional elements or stages, working fluids used in these configurations are critical parameters for increasing the resulting energy performance and cooling capacity, ending with more sustainable ultra-low temperature freezers.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Srikhirin P, Aphornratana S, Chungpaibulpatana S (2000) A review of absorption refrigeration technologies. Renew Sustain Energy Rev 5(4):343–372. https://doi.org/10.1016/S1364-0321(01)00003-X

Mota-Babiloni A et al (2020) Ultralow-temperature refrigeration systems: configurations and refrigerants to reduce the environmental impact. Int J Refrig 111:147–158. https://doi.org/10.1016/j.ijrefrig.2019.11.016

Mumanachit P, Reindl DT, Nellis GF (2012) Comparative analysis of low temperature industrial refrigeration systems. Int J Refrig 35(4):1208–1221. https://doi.org/10.1016/j.ijrefrig.2012.02.009

Di Nicola G, Giuliani G, Polonara F, Stryjek R (2005) Blends of carbon dioxide and HFCs as working fluids for the low-temperature circuit in cascade refrigerating systems. Int J Refrig 28(2):130–140. https://doi.org/10.1016/j.ijrefrig.2004.06.014

Lee TS, Liu CH, Chen TW (2006) Thermodynamic analysis of optimal condensing temperature of cascade-condenser in CO2/NH3 cascade refrigeration systems. Int J Refrig 29(7):1100–1108. https://doi.org/10.1016/j.ijrefrig.2006.03.003

Alberto Dopazo J, Fernández-Seara J, Sieres J, Uhía FJ (2009) Theoretical analysis of a CO2-NH3 cascade refrigeration system for cooling applications at low temperatures. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2008.07.006

Sun Z, Wang Q, Dai B, Wang M, Xie Z (2019) Options of low global warming potential refrigerant group for a three-stage cascade refrigeration system. Int J Refrig 100:471–483. https://doi.org/10.1016/j.ijrefrig.2018.12.019

Adebayo V, Abid M, Adedeji M, Dagbasi M, Bamisile O (2021) Comparative thermodynamic performance analysis of a cascade refrigeration system with new refrigerants paired with CO2. Appl Therm Eng 184:116286. https://doi.org/10.1016/j.applthermaleng.2020.116286

Bhattacharyya S, Garai A, Sarkar J (2009) Thermodynamic analysis and optimization of a novel N2O-CO2 cascade system for refrigeration and heating. Int J Refrig 32(5):1077–1084. https://doi.org/10.1016/j.ijrefrig.2008.09.008

Liu XF, Liu JH, Zhao HL, Zhang QY, Ma JL (2012) Experimental study on a −60 °C cascade refrigerator with dual running mode. J Zhejiang Univ Sci A 13(5):375–381. https://doi.org/10.1631/jzus.A1100107

Dubey AM, Kumar S, Das Agrawal G (2014) Thermodynamic analysis of a transcritical CO2/propylene (R744-R1270) cascade system for cooling and heating applications. Energy Convers Manag 86:774–783. https://doi.org/10.1016/j.enconman.2014.05.105

Aghazadeh Dokandari D, Setayesh Hagh A, Mahmoudi SMS (2014) Thermodynamic investigation and optimization of novel ejector-expansion CO2/NH3 cascade refrigeration cycles (novel CO2/NH3 cycle). Int J Refrig 46:26–36. https://doi.org/10.1016/j.ijrefrig.2014.07.012

Li Y, Yu J, Qin H, Sheng Z, Wang Q (2018) An experimental investigation on a modified cascade refrigeration system with an ejector. Int J Refrig 96:63–69. https://doi.org/10.1016/j.ijrefrig.2018.09.015

Johnson N, Baltrusaitis J, Luyben WL (2017) Design and control of a cryogenic multi-stage compression refrigeration process. Chem Eng Res Des 121:360–367. https://doi.org/10.1016/j.cherd.2017.03.018

Acknowledgements

The authors acknowledge the funding provided by the program “Proyectos de I+D+I 2020” of the Spanish Ministry of Science and Innovation (PID2020-117865RB-I00). Adrián Mota-Babiloni acknowledges the postdoctoral contract “Juan de la Cierva-Incorporación 2019” of the Spanish State Research Agency (IJC2019-038997-I). Carla Espinós-Estévez acknowledges the “la Caixa” Foundation (ID 100010434) fellowship under the code LCF/BQ/DR19/11740012.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Udroiu, C.M., Mota-Babiloni, A., Espinós-Estévez, C., Navarro-Esbrí, J. (2022). Energy-Efficient Technologies for Ultra-Low Temperature Refrigeration. In: Howlett, R.J., Jain, L.C., Littlewood, J.R., Balas, M.M. (eds) Smart and Sustainable Technology for Resilient Cities and Communities. Advances in Sustainability Science and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-16-9101-0_22

Download citation

DOI: https://doi.org/10.1007/978-981-16-9101-0_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-9100-3

Online ISBN: 978-981-16-9101-0

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)