Abstract

Demand for fishery products is on the rise as it is regarded as health food due to their easily digestible protein with all the essential amino acids, essential fatty acids, vitamins and minerals in good proportion. However, they are also highly perishable due to their intrinsic properties apart from other external factors which affect their quality. Suitable processing and storage will enhance the eating quality of fish for an extended period. Processing methods adopted to preserve the quality of fishery products have to be appropriately supplemented with the selection of better packaging materials. Conventional packaging materials used for food packaging offer limited advantages. Apart from this, the petroleum-based packaging materials pose environmental problems if not properly managed. As a result, the demand for biodegradable packaging materials is increasing worldwide. Biomaterials from the aquatic origin are gaining increased attention in developing biodegradable packaging materials, especially with certain functionality. This chapter gives a brief note on the functional packaging materials like oxygen scavenging film, fish freshness indicating film, thermochromatic indicating film, antimicrobial film, antioxidant film, pathogen indicating film, off-odour scalping, flavour emitting films, etc.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Functional packaging film

- O2-scavenging film

- Antimicrobial film

- Freshness indicating film

- Thermochromatic film

7.1 Introduction

The demand for very good quality fresh and minimally processed products is on the rise. Consumers do not want processing techniques adopted by the industry to affect both the nutritional and characteristic quality of the product. This has led to the development of minimal processing or novel food processing technologies which minimize the changes after processing and storage. Apart from processing, widespread awareness and advancements in hygienic handling, packaging and preservation have improved the quality of food products. The aim of consumer is to get best quality product for the price paid and at the same time food manufacturers strive to supply quality products with sustainable quality for an affordable price. Of the variety of options available for food, fish and fishery products have special importance. Historically, fish has long been an important part of human diets, and increasingly a major source of economic value. Globally, fish accounted 6.7% of all protein consumed by humans, as well as offering a rich source of omega-3 fatty acids, particularly EPA and DHA, vitamins, calcium, zinc and iron. There is a great demand for fish and shellfishes in international market due to its proven health benefits. Fish business not only provides foreign exchange it also helps in ensuring nutritious food, employment to millions of people, many of whom are below the poverty line. As per FAO (2018), the world fish production in 2016 has reached 171 million tonnes and 88% of this was used for direct human consumption. Of the total fish produced, aquaculture represented 47%. Global sale value of fisheries in 2016 was estimated at US$ 362 billion of which US$ 232 billion was the contribution from aquaculture production. The value of global fish exports in 2017 was US$ 152 billion, up from $8 billion in 1976 and 54% of this was originating from developing countries, indicating the contribution of seafood export to the building of nations. Nearly 57 million people are engaged in the primary fish production sector, a third of them in aquaculture. Of all the global merchandise trade, fishery products accounted for one per cent in terms of value, representing more than 9% of total agricultural exports. Export of fishery product is one of the major foreign exchange earners in developing countries which accounted to over US$ 80 billion in 2017, providing higher net trade revenues than meat, tobacco, rice and sugar combined. The per capita consumption during 2016 reached 20.3 kg and is expected to increase further. On an average, fish provides nearly 6.7% of all protein consumed by human beings. These indicate there is an ever-increasing demand for fish across the countries, which should be met by increasing the production.

Due to ever-increasing demand for fish, global requirement is increasing steadily. From the available data, it is observed that both fish production as well as fish consumption increased from 1975. Till 1990s, capture fisheries was the major contributor and later, the importance of aquaculture increased resulting in sizeable contribution to total production. As the years pass, the fish consumption level is also increasing. Per capita consumption was 9 kg in 1961 which increased to 17.2 kg in 2008 and further increased to 20.5 kg/year in 2018 (FAO 2020). Considering a stable consumption at 2008 level, the fish requirement estimated as nearly 140 and 152 million tonnes by 2025 and 2050, respectively. However, as the consumption is not stable and it is increasing steadily, the additional demand considering the rate of increase in consumption between 1975 and 2008 will be 164 and 232 million tonnes by 2025 and 2050, respectively. Meeting this huge demand is a herculin task, which creates huge pressure on both capture production as well as on aquaculture. As it is very important to increase the production of fish to meet the global demand, it is also equally important for its proper utilization without wasting by adopting responsible handling, advanced processing and packaging to reduce the post-harvest loss. It is estimated that, nearly 18–20% of global fish production is wasted as post-harvest loss resulting in huge loss of valuable nutrient-rich food commodity. This also affects the economy of the country negatively. For instance, in India alone, very huge economic loss is estimated annually, which is very huge loss to the economy as well as loss of nutritive food commodity. Proper handling of food including fish from its primary production centres and processing them into suitable forms, packaging and storage at desirable temperature will help in reducing the post-harvest losses. Proper handling for fishery products includes segregation of catch based on species and size. Evisceration of large size fishes and icing of fishes with appropriate fish to ice ratio is the first step immediately after catching fish for maintaining better quality. Avoiding more than 3 layers of stacking of fish and ice to avoid damage to fishes in the bottom layer is another good handling practice on board the fishing vessel. Upon arrival at landing centres, care should be taken to unload as early as possible. They should be placed on the raised platform/surface/floor which can be easily cleaned and chlorinated after the auction is over. Processing factories should receive only good quality fish which have maintained the minimum temperature of <4 °C. Once it is processed in suitable form viz., chilling, refrigerated, freezing, curing and drying, thermal processing, smoking, freeze-drying or developing value-added products, they have to be properly packed and stored at the proper temperature. Packaging material should be chosen wisely so that it will complement to the processed food product to extend the eating quality maintaining all the desirable quality.

Food packaging in simple words is wrapping or covering or placing in sealable materials to give protection from its external environment to preserve the quality for an extended duration or till it is utilized by consumers. Although all the activities including processing with advanced techniques are practised with utmost care and if the packaging techniques and packaging materials are not selected suitably it may not protect the food as it is expected. Hence, it assumes great importance to offer the required characteristics to the food till the end of shelf life. Proper packaging not only protects the food from chemical changes during storage, microbial contamination arising from its external environment but also prevents physical damage from the wear and tear during handling, transportation and storage. If the products are not packed properly, the packaging process can become a source of contamination. The main purpose of packaging is to provide protection from biological hazards (pathogens and spoilage organisms), pests, physical damage (shock or vibrations), should act as barrier to external gases, moisture and light, and should provide protection during storage, handing and distribution and transportation. Packaging also provides information about the product contained with ingredients, nutritional information, allergens if any, manufacturer details and also manufactured date. The concept of packaging is also fast changing as the modern packaging is also intended to provide security against tampering, counterfeit by providing authentic seals and helps in tracking and tracing the product.

Traditionally, food packaging is aimed for protection, communication, convenience and containment (Paine 1991; Robertson 2006). Packaging material intended to be used for food package should be able to withstand the internal pressure as in the case of vacuum packaging and modified atmosphere packaging, should be able to withstand the processing conditions like high temperature and pressure as in the case of thermal processing, should be able to withstand storage conditions like normal room temperature, chilled or refrigerated temperature, frozen temperature or elevated temperature as desired to maintain its quality and shelf life, should withstand process conditions and machinability. External factors which are considered for protecting food include but not limited to conditions like heat, light, presence or absence of moisture, pressure, gases, microbial contamination, etc. Convenience and time-saving attributes and different attractive shape and size of package to contain the products are other advantages offered by the packaging materials (Yam et al. 2005; Marsh and Bugusu 2007). The inertness of the packaging material was the key safety objective for traditional packaging materials.

7.2 Overview of Food Packaging Industry

Packaging industry is growing rapidly due to its ever-increasing importance. Globally packaging industry accounts to 700 billion US$ excluding turn-out for machineries. The United States of America is the major market for packaging materials accounting nearly 24% of the global market. European Union is the second largest market and Germany, France, Italy and UK dominate packaging industry in Europe. Among the different packaging materials, paper and board lead the sector with 36% of the world market followed by petroleum-based packaging materials. World food packaging market size is to the tune of over 300 billion US$ in 2019 and is expected to increase to more than 460 billion US$ by 2027 (https://www.fortunebusinessinsights.com/industry-reports/food-packaging-market-101941). Glass, metal, paper & paperboard, wood and plastic packaging materials are widely used for a variety of food sectors like fruits and vegetables, meat, poultry and seafood, dairy products, bakery and confectionery, sauces, dressings, condiments, etc. Changing lifestyle, convenience, increasing purchase power, increased percentage of working women and crave for spending more valuable time with the family are the factors influencing the growth of packaged food and beverages apart from extended and stable shelf-life with improved safety and quality. Rising consumer awareness and demand for processed food is another factor influencing the growth. Multinational giants taking rapid strides in the food and beverages industry is another important factor influencing the growth of food packaging industry. As a result, the per capita consumption of packaging food is worth US$ 400, 260, 90, 46 and 9 for the USA, Europe, Latin America, Asia and India, respectively. Being one of the fastest-growing industries, it is expected that the food packaging industry will grow to new heights.

7.3 Selection of Packaging Material

Appropriate packaging material should be chosen based on the composition of the food. The use of proper packaging will ensure the safety and durability of the product during its entire shelf life. Important aspects to be considered while selecting packaging materials are its moisture content, sensitiveness to oxygen, acidic or alkaline, alcohol content and fat content. A container that is appropriate for one type of food may not be suitable for another. It is very important to choose the proper packaging for the food intended to pack. The packaging materials/packages used in fish industry are both modern as well as traditional types, ranging from bamboo baskets, jute bags, leaf mats to corrugated fibre-board boxes, duplex board cartons, metal containers of aluminium and tinplate, plastic films and their laminates, thermoformed trays, polypropylene/high-density polythene crates, expanded polystyrene insulated boxes, glass bottles, etc. Each packaging material has its own merits and demerits. Paper & paperboards are very common packaging materials used for wide applications. These are made using pulp extracted from wood and other non-wood sources like straw, bamboos, etc. As wood pulp is very easily accessible, and commonly available its use is on the rise. Due to its natural and low price, it is one of the preferred packaging materials. They are suitable for small-scale, large-scale, retail and bulk packaging. All kinds of foods can be packed using paper and paperboard after slight modifications. They can be used as bags, pouches, wrapping, boxes, cartons, tetra packs, folding cartons, etc. The presence of cellulose fibres provides them good rigidity and high shock resistance. They are also light in weight, cheap and are widely available. However, they need to be laminated for packing foods with moisture content. They also need external protection during transportation to protect from damage. Apart from this, they have to be stored in proper facility to prevent damage by rodents and insects. Another important aspect to be considered is the selection of safe wood for the manufacturing of paper and paperboard which comes in contact with food directly. It is common practice to use chemical preservatives to protect wood. Care should be taken to select the preservative free wood. Due to its sustainability nature, the paperboard will be the most prevalent and attractive packaging material in the food industry in future due to increased investments leading to innovations in packaging design and digital printing.

Glass is commonly used as packaging material for a variety of foods due to its inertness. Glass containers are manufactured by heating the mixtures like silica (sand), calcium carbonate in the presence of sodium carbonate (melting agent) and alumina (hardner) at very high temperatures to melt the mixture, cast them into the mould to get suitable shape and size and finally cooling them (Keleş 1998; Marsh and Bugusu 2007). Surface coating and oiling is done during the production process to prevent the abrasion of the glass surface (Aday 2014). Normally soda-lime glass is used in the packaging industry for producing transparent, transluscent or coloured glasses. Also, to mask the colour emerging from minute quantity of impurities like iron and sulphur compounds especially during the manufacturing of colourless glass, nickel and cobalt are added (Keleş 1998). Glass is one of the highly preferred materials for food packaging due to its inertness, durable, transparent, touch as it withstands high temperature and pressure, impermeable to gas, odour, liquids and water vapour (MEB 2011). It has a very smooth and shiny surface, it will neither corrode nor degrade or erode over time. However, they are not devoid of drawbacks. Major drawback is its heaviness and very fragile leading to break. It requires extra care while transporting and distribution and hence are more costly than petroleum-based packaging materials. Being transparent, it allows light to pass through the glass resulting in light-induced oxidation and discolouration.

Metal is another important material for packaging applications. Unlike glass, metals have free and mobile electrons that absorb light energy. That is why they cannot be transparent and translucent as in the case of glass. There is a long history of packing food products in metal containers. Mainly tin plate or aluminium or stainless steel coated with the food-grade lacquer material is commonly used. Among these, tin-plate containers were very commonly used for many food applications. Tin plate was used to make containers for food over 120 years. Tin-plate containers are very attractive and have an appealing golden colour. Tin can is made up of 98% steel and 2% tin coated on both the sides of container differentially. The surface coming in contact with the food material is coated thicker layer of tin. Normally low carbon steel is used in the manufacturing of this type of can. They are light in weight, rigid, strong, corrosion-resistant and easy to handle. They are comparatively easy to fabricate and offer more shelf life to food products compared to other metal containers. The major drawback of this container is its limitation for packing acidic products. In the earlier days, 3-piece cans were used soldering with a lead:tin ratio of 98:2 percentage. Some lead from this solder may migrate to food depending on the type of product packed and on the amount of solder exposed. Apart from this, lead contamination may also originate as impurity from the tin coating. Due to its proven ill effects, regulatory agencies have stipulated a maximum level of 2 ppm for lead in canned food products. Apart from this, tin may also permeate into the food and higher levels of tin will implicate in the gastro-intestinal disturbance. A level of up to 250 ppm is generally permitted by regulatory authorities in canned foods. Invention of 2-piece, solder-free cans reduced the problem of lead in canned foods. Canned shrimp products from India were very well appreciated from many importing countries and this industry was flourishing until 1980s. Later on the canned seafood industry collapsed as it could not compete with the neighbouring countries in terms of its pricing. As India does not have tin resources, it has to import tin-plate for manufacturing cans and hence it became costlier. This has resulted in search for other alternative metal cans. Aluminium is one such metal used as an alternative to tin-plate cans. In India and also in many parts of the world, aluminium is very abundantly available and is light in weight. It is recognized as generally regarded as safe (GRAS) material by the US FDA. The use of 100% aluminium for manufacturing cans or containers results in weak material. To overcome this, small amount of magnesium, manganese, iron, zinc, copper and silicon is added while manufacturing. Aluminium-based containers can be used as cans for meat and fishes, beverages and as bottle tops or closures. Aluminium is easy to fabricate and one cannot make out the corrosion due to its colourless character. Metallic taste is not imparted when aluminium containers are used as compared to tin cans. Requirement of very high energy for the production, tendency to bleach with some pigmented foods and impossibility of soldering are the drawbacks of this container. Apart from this, aluminium is implicated in Alzheimer’s disease up on chronic exposure from water and food. World Health Organization (WHO) has stipulated the limit of 1 mg kg−1 body weight per day. Tin-free steel is another metal container used for a wide range of food products like fruits, vegetables, meat and seafood. TFS cans are made by electrolytic coating of a thin layer of chromium and chromium oxide on the steel base material. The presence of chromium helps in preventing rust formation and corrosion. It can withstand very high internal pressure and is suitable for attractive printing. The major problem with this container is it cannot be recycled or reused and is not suitable for soldering or welding.

Petroleum-based plastic packaging material is another widespread material used for many applications including food packing. Plastic is the material that is obtained when the bonds between carbon and hydrogen, oxygen, nitrogen and other organic or inorganic elements are broken from their simple structured molecule, known as ‘monomer’ and formed into the long and chained structure, known as ‘polymers’ (Durusoy and Karababa 2011; MEB 2011). With the help of polymer science and engineering, many variety of plastics with varying characteristics can be manufactured so that almost all the food products with varying processing, storage and transportation conditions can be packed with plastic materials. Their lightweight, transparent/translucent with low or high gas and moisture barrier properties, requiring less storage space and easy to use, seal, open and dispose makes one of the most preferred packaging materials for food products (Kızılırmak 1997). They can be made either as thin films or as rigid containers depending on the requirements. Different packaging materials with their code and applications are given in Table 7.1. Codes from 1 to 7 are given for easy identification during its recycling. Different types of packaging material either single-layered or multi-layered packaging materials have to be selected appropriately depending on the category of food products which is given in Table 7.2. Among the different packaging materials, not all the materials are suitable for direct food contact application. The use of plastics and plastic-based materials are increasing across the food industry including fisheries.

During the manufacturing of plastic packaging materials, along with basic polymer materials, other non-polymeric compounds are added either inherent or deliberately to achieve desired properties. These are categorized into three different classes viz., polymerization residues (residual monomers, catalyst remnants, polymerization solvent, etc.); processing aids (plasticizers, stabilizers, antioxidants, slip agents, lubricants, antistatic agents, etc.) and end-use additives (antioxidants, brighteners, blowing agents, mould release agents, colourants, UV stabilizers, etc.). Among these, the polymerization residues compounds are unavoidable whereas processing aids and end-use additives are deliberately added to the polymer either during manufacture or subsequently to achieve the desired end properties of the finished plastic material. If we are not adding these additives, desirable properties of the plastic packaging materials will not be noticed in the end product. Polymers by their nature like very high molecular weight and low solubility in both aqueous and fatty systems may make them inert. The other additives, which are non-polymeric in nature, are lower molecular weight which may leach out from these plastic packaging materials and dissolve in the food system. These may pose threat to human health due to their risk factor and the awareness in this matter has led the national and international regulatory authorities in the formation of guidelines for the proper use of plastics for food packaging application. Such guidelines are necessary to restrict the indiscriminate use or abuse of plastics in food packaging. The residual monomer content and heavy metal content in different plastics specified by different countries and limits of heavy metals in colours used are presented in Tables 7.3 and 7.4 respectively. The other regulations on food packaging materials comprise of regulations for adjuvants (antioxidants, colourants, plasticizers, etc.) used in food packaging materials. Only permitted materials within their allowable limits can be used in the manufacturing of plastic packaging material.

Packaging protects, but it is also a potential source of risk. Plastics, paper, cardboard, and other packaging materials that come into contact with the food can react with it and affect its safety. The plastic packaging material may contain impurities such as leftover monomer residues, additives, stabilizers, odorous adjuvants, colorants and antioxidants. At different stages of converting, preparing and storing, chemical substances may migrate to the food. If the packaging is made from wrong materials which include printing substrates like, inks, varnishes and all the auxiliaries used in the printing process, it may pose a risk to the packed product, thus to human health. In paper, the group of potential contaminants include 1,2-benzisothiazoline-3-one (BIT); 2-(thiocyanomethylthio) benzothiazole (TCMTBT); 2,4,5,6-tetrachloro-isophthalonitrile (TPN); 2,4,6-trichlorophenol (TCP); pentachlorophenol (PCP); 4,4′-bis (dimethylamino)-benzophenone; 4,4′-bis (diethylamino)benzophenone; 4-(dimethylamino) benzophenone (DMAB) and bisphenol A (BPA), which in chlorinated form (BPAs) may be found in effluent from wastepaper processing plants. Sometimes even slimicides and fungicides used in both virgin and recycled paper may pose risk to consumers. Pentachlorophenol is used for wood conservation, therefore if the conserved wood or slimicides containing this substance are used in paper production there is a risk of contamination of packed food. Leaching of all these chemicals from packaging material into food affects the quality of food and increases the risk to consumer. Hence the materials coming in contact with food product need to comply with strict regulations in many countries. It is the manufacturer’s sole responsibility to deliver safe packaging materials which comply with all legal requirements. Due to this as well as due to the impact of these packaging materials on the environment and biota after disposal, there is an increased priority worldwide for the development of biodegradable packaging material which will not impact any health risk to consumers.

7.4 Biodegradable Packaging Materials

Biodegradable packaging materials are the materials derived from natural biological materials. This can be either plant- or animal-based packaging materials. The research interest on the development of biodegradable packaging material is on the rise constantly from 2000 onwards as indicated from the publications (Fig. 7.1). In 2000, the publications were only 1120 which have crossed 11,000 in 2020. The growing interest is basically due to its eco-friendly, sustainable nature and will not create any health or environmental related issues. These biodegradable packaging materials can be either protein-based or carbohydrate-based materials in addition to a plasticizer. They can be in the form of gels, film, bag and box. As the biodegradable packaging materials are made using eco-friendly materials, their recycle will be easier. They require less energy to produce and are non-toxic in nature. Their carbon emission will be very less. Long-term and increased dependence on the biodegradable packaging material may result in requirement of more plant- or animal-based matter for their production. If any additives or petroleum-based polymers are mixed in compounded packaging materials, they require special facility for composting. The physical barrier properties are very poor compared to petroleum-based materials and not all the biodegradable packaging materials are sealable. Bioactive ingredients derived from aquatic sources which can be used for biodegradable packaging material production are fish and shellfish proteins, protein from Surimi waste, blanched and cooked water protein extract from heat processing, protein extract from clam shuck water, chitosan extracted from shrimp, crab, lobster and squid pen, collagen and gelatin from fish scale and skin, squid and cephalopod skin and a variety of seaweeds. Although biodegradable packaging materials have various advantages, functionalizing these packaging materials will increase their applications and enhance the quality of food products.

7.5 Smart Functional Packaging Materials

Globalization and dynamism in the exchange of food products, along with reduced time for selection/cooking with fresh ingredients, and the growing interest in health safety and environment are the main challenges which trigger the development of new improved packaging concepts. Traditionally, the functions of the packages include protection, containment, communication with the user, ergonomics and marketing. However, in recent years additional functions are incorporated into the packaging materials to meet the growing global demand on the safety of food products. One of the main objectives of food law is the safety of the food products. Controlling the quality and assuring the safety of the product at all the stages of food supply is very much essential to enhance the market reach for a product. This can be achieved by using active and intelligent packaging technology, which is also known as smart packaging. Active packaging involves altering the surrounding environment of food suitably with favourable gases, antimicrobial and antioxidant agents, flavour bearing compounds, etc. whereas intelligent packaging monitors interaction between the food, the packaging, and the environment and provides information like the conditions of the package, freshness, leakage and presence of pathogen and informs to the manufacturer and consumer. Thus, the smart packaging provides a specific functionality beyond function physical barrier between the food product and the surrounding environment. Knowing information about the product quality, the packaging or the environment establishes a bond of responsibility throughout the food supply chain (storage, transport, distribution and sale). The global market for active and intelligent packaging will double between 2011 and 2021, growing at an annual rate of 8% until 2016, reaching US$ 17,230 million, and later at an annual rate of 7, 7%, reaching US$ 24,650 million in 2021. Among the smart packaging technologies, the development of intelligent packaging material which can detect the presence of pathogen assumes great importance as it can assure the safe and wholesome food to consumers without any microbial pathogen contamination. The technology of developing smart pathogen indicating film can be used in all the food products to monitor the quality and safety of food from the producers to the consumers. The technology provides an on-line quality control and safety for the consumers beyond the existing conventional technologies which are helpful for the authorities and food producers as well.

7.6 Active Packaging

Active packaging is an advanced concept that can be defined as ‘a type of packaging that changes the condition of the packaging and maintains these conditions throughout the storage period to extend shelf-life or to improve safety or sensory properties while maintaining the quality of packaged food’ (Vermeiren et al. 1999). Unlike other conventional packaging methods wherein packaging material or packaging system will not alter and remain passive in nature apart from their inertness. Any gases formed or introduced in the packaging atmosphere may escape or may enter from external atmosphere depending on the permeability of the packaging material resulting in alteration of the package atmosphere which affects the quality and shelf life of the product. In the case of active packaging, the packaging provides extra protection by interacting with the package atmosphere and modify the conditions of the package suitably to help the retention of the quality. This can be achieved either by removing undesirable constituents like oxygen, CO2, off-odour, ethylene or by releasing suitable constituents like nitrogen, carbon dioxide, antimicrobials, antioxidants, ethanol, pesticide, etc., depending on the food products. Major active packaging techniques are concerned with substances that absorb oxygen, ethylene, moisture, carbon dioxide, flavours/odours and those which release carbon dioxide, antimicrobial agents, antioxidants and flavours. The most important active packaging concepts for fishery products include O2 scavenging, CO2 emitters, moisture regulators, antimicrobial packaging concepts, antioxidant release and release or absorption of flavours and odours.

7.6.1 O2- Scavenger

Oxygen is a lifeline for all the animals when they are in living condition but becomes detrimental as soon as life is lost leading to spoilage and decay. Many food products including fish are highly sensitive to the presence of oxygen as it leads to the growth of aerobic microorganisms and oxidation which causes undesirable colour changes (e.g. discolouration of pigments such as myoglobin, carotenoids), off-odours and flavours (e.g. rancidity as a result of lipid oxidation) and leads to loss of nutrients (e.g. oxidation of vitamin E, β-carotene, ascorbic acid) which adversely affects the quality. Hence control of oxygen assumes its importance to control the spoilage and enhance the shelf life. This can be achieved by packing in high barrier films like EVOH, polyester-laminated with aluminium foil or laminated packaging materials. Further advanced packaging technologies like vacuum packaging and modified atmosphere packaging may be adopted. However, these techniques may not remove oxygen completely and there is no control on the permeation of oxygen through packaging materials. In such cases, the use of oxygen scavenger is highly suitable and very effective in reducing the oxygen level to very low level like less than 0.05% within short time. O2 scavengers were first commercialized in the late 1970s by Japan’s Mitsubishi Gas Chemical Company (Ageless®). O2 scavenging concepts are mainly based on iron powder oxidation, ascorbic acid oxidation, photosensitive dye oxidation, enzymatic oxidation (e.g. glucose oxidase and alcohol oxidase), unsaturated fatty acids (e.g. oleic or linolenic acid), rice extract or immobilized yeast on a solid substrate. These oxygen scavengers are useful in preventing discolouration of fresh and cured fish, rancidity problems, mould spoilage of intermediate and high moisture products or oxidative flavour changes. Apart from fish, they find its applications in most of the dried food items like grains, snacks, bakery items, fish and meat, dry fruits, ready meal, etc.

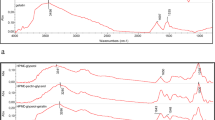

O2-scavenging film is developed either incorporating any oxygen scavenging systems mentioned above or by using the principle of photosensitive dye oxidation. This involves sealing of a small coil of an ethyl cellulose film containing a dissolved photosensitive dye and a singlet O2-acceptor in the headspace of a transparent package. Due to illumination of the film with the light of the appropriate wavelength, excited dye molecules sensitize O2− molecules, which have diffused into the polymer, to the singlet state. These singlet O2− molecules react with acceptor molecules and are consumed (Rooney 1985):

O2 acceptors can be tetraphenyl porphine (TPP), dimethyl anthracine (DMA), dioctyl thallate (DOT), etc. This can be used for both wet and dry fish products as it does not require any moisture for its activation. Most O2 scavengers in commercial use today are iron-based systems and only limited reports are available on film based O2 scavenger.

7.6.2 Antimicrobial Packaging

Antimicrobial packaging is the second commonly used active packaging system after oxygen scavenger. The concept of antimicrobial packaging was developed due to increased awareness on the antimicrobial agents used directly by the food manufacturer to retain the quality of food. As microbial spoilage is the major cause for food deterioration, various chemicals were used for treating food to reduce both food spoilage and pathogenic microorganisms. The classes of these antimicrobial agents include but not limited to alcohol (ethanol), ammonium compound (quaternary ammonium salts), antibiotics (natamycin), antimicrobial peptides (leucocin, sakacin, enterocin), antioxidant phenolic compounds (butylatedhydroxyanisole (BHA), butylatedhydroxytoluene (BHT), tertiary butylhydroquinone (TBHQ), grape seed extract, pomegranate peel and seed extract), bacteriocin (bavaricin, lacticin, nisin, pediocin), chelators (citric acid, EDTA, lactoferrin, polyphosphate), enzymes (chitinase, ethanol oxidase, glucose oxidase, glucosidase, lysozyme, lactoperoxidase, hydrolase), fatty acids (lauric acid, palmitoleic acid), fungicide (benomyl, imazalil, sulphur dioxide), metals (copper, silver), natural phenols (catechin, hydroquinones), organic acid (acetic acid, benzoic acid, citric acid, lactic acid, propionic acid, sorbic acid, tartaric acid), organic acid salt (potassium sorbate, sodium benzoate, acetic acid, propionic acid, benzoic acid, sorbic acid, calcium sorbate, benzoic anhydride, propionic acid, propyl paraben), paraben (ethyl, methyl and propyl paraben), plant based volatile compounds (allylisothiocyanate, cinnamaldehyde, eugenol, terpineol, thymol), polysaccharide (chitosan, carrageenan), etc. Recent advancements in the nanotechnology research have expanded the list of antimicrobial compounds with silver nanoparticle as one of the highly potential antimicrobial agents. The principle action of antimicrobial films is based on the release of antimicrobial entities into the food which extends the lag phase and reduces the growth phase of microorganisms in order to prolong shelf life and to maintain product quality and safety. To confer antimicrobial activity, antimicrobial agents may be coated, incorporated, immobilized or surface modified onto package materials. However, there is a growing concern both by consumers and by the regulatory agencies on the very high levels of these antimicrobial compounds in the food products if they are used directly to treat with these antimicrobial agents. The residual levels will be very high leading to increased concerns which can be overcome with the adoption of active antimicrobial packaging techniques. The antimicrobial compound embedded into the polymer acts by two different kinds of mechanisms. In the first method, the preservative is covalently immobilized into the polymer matrix and acts directly from the film when the food is brought in contact with the active material. Regarding the latter, the preservative is embedded into the matrix in the dry state. When the active material is brought in contact with a moist food or a liquid-like food, the preservative is released from the material and acts directly. In both cases the aim of the system is to extend the shelf life of the packaged foodstuff, inhibiting the microbial growth and preserving its properties. The classes of antimicrobials listed range from acid anhydride, alcohol, bacteriocins, chelators, enzymes, organic acids and polysaccharides. Several compounds tested for antimicrobial activity in food packaging including organic acids such as potassium sorbate, sorbic acid, propionate and benzoate or their respective acid anhydrides, bacteriocins, e.g. nisin and pediocin, enzymes such as lysozyme, metals, fungicides such as benomyl and imazalil, Ag- zeolite. Antimicrobial agents are selected based on their ability to withstand the processing or extrusion condition of the packaging material and its compatibility. Ethanol is another commonly used antimicrobial agent for surface immobilization with the polymer films. At a concentration of 60–70%, v/v, it exerts its effectiveness. Even at relatively low concentrations (4–12%), ethanol has proved effective in controlling growth of several moulds and bacteria (De Kruijf et al. 2002). Spraying ethanol onto fresh or dry fish prior to packaging can be adopted, but another option is to use sachets generating ethanol vapour. This contains food-grade ethanol embedded or absorbed or encapsulated in a carrier material. This is meant for either slow or rapid release depending on the requirement and is adjusted by varying permeability of the sachet material to water vapour. Its application mainly depends on the food products intended and the sensitivity of the food products to ethanol. Apart from these, various plant derivatives can be incorporated into the packaging system as antimicrobials.

7.6.3 Antioxidant Release

Antioxidants are another class of compounds used extensively in most of the oxygen-sensitive foods to improve the oxidation stability. Fish being highly rich in polyunsaturated fatty acid, are prone to oxidation. Common antioxidants used for direct food applications were BHA, BHT, etc. whose use is now not permitted in most of the food products due to its ill effects by accumulating in adipose tissue. Incorporation of natural plant extracts are also practised however it requires to use more quantity leading to influence the sensory properties. Direct incorporation of antioxidants into the packaging films and use as antioxidant is gaining more attention worldwide. However, the antioxidant compound should be able to withstand the extrusion conditions for its applications. Vitamins E and C are the common natural antioxidants, and their incorporation in polymer films to exert antioxidative effects is still at the experimental stage. Vitamin E is stable under processing conditions and has an excellent solubility in polyolefins. However, it is confirmed that, vitamin E is a less mobile antioxidant in low-density polyethylene (LDPE) than BHT, as vitamin E is a larger molecule (Wessling et al. 1998). Apart from these, natural antioxidants extracted from plant and animal substances and their use as antioxidant packaging are under experimental stages.

7.6.4 Release or Absorption of Flavours and Odours

Fish and shellfish have a typical fresh flavour, which is distinct from any food systems. Food packaging materials, particularly some plastics, may interact with these flavours, resulting in loss of flavour known as ‘flavour scalping’ which affects the quality of the product. Furthermore, flavours are usually lost or degraded during various stages of processing at different temperatures or after packaging. Therefore, there is a need to replace the lost flavour constituents when scalping or degradation occurs. Flavour incorporation in packaging material might be used to minimize flavour scalping. Consumers always like to smell good flavours when they first open a food package. The applications of suitable flavour enriched packaging materials have the potential to improve the organoleptic quality of the product by emitting desirable flavours into the food and to encapsulate pleasant aromas that are released upon opening. Flavour release may also provide a means to mask off odours coming from the fish or the packaging. It is of utmost importance that the aforementioned technology should not be misused to mask the development of microbial off-odours thereby concealing the marketing of products that are below standard or even dangerous for the consumer (Nielsen 1997).

Flavour scalping, i.e. sorption of food flavours by polymeric packaging materials, may result in loss of flavour. Generally, flavour scalping is detrimental to food quality, but it could be used in a positive way to selectively absorb unwanted odours or flavours. In contrast to flavour releasing systems, flavour absorbers scavenge undesirable flavours, aromas and odour present in the package headspace. The formation of off-flavour and off-odour in fish products are mainly from the oxidation of fat and oils, leading to the formation of peroxides and their decomposition products like aldehydes, breakdown of fish proteins into amines forming alkaline compounds. Flavour absorbing systems employ cellulose triacetate, acetylated paper, citric acid, ferrous salt/ascorbate and activated carbon/clays/zeolites to absorb off-odour and off-flavour. Removal of aldehydes from package headspaces can be achieved by means of the layer Bynel IXP101 which is a HDPE master batch. Amines can be removed by reacting with acidic compounds, e.g. citric acid incorporated in polymers.

7.6.5 Time-Temperature Indicators

Food and pharmaceutical products are highly sensitive to the temperature of storage. They need to be maintained at specified temperature throughout their shelf-life to ensure its quality and safety. Frozen food products have relatively very long shelf life ranging from 6 months to 2 years. They should be stored at −18 ± 2 °C from the point of production till they are consumed. However, cold chain is broken due to many reasons like improper cold chain facilities at all the stages of food distribution, frequent power failure and regular opening and closure of freezer door at retail outlets. Failure to maintain specified temperature will indirectly affect the quality and safety of the product. It is difficult to find out whether the frozen food product has thawed at some point and then refrozen. As there is no device/method to monitor such temperature abuses, consumers will end up buying inferior quality products. At the same the producers will get bad reputation due to breakdown of cold chain which is not in their hand to maintain. The principle behind this is that as the temperature increases, biochemical and microbial reactions take place at rapid rate leading to deterioration of food. TTIs are based on either chemical, electrochemical, enzymatic, microbial or mechanical reaction leading to visible response. TTIs find its applications not only in food products, but also in pharmaceutical products to ensure better quality product to consumers. Recent research on TTI indicates that the active compound, sensitive to temperature fluctuation can be incorporated into the polymer/biodegradable film that can change the colour as temperature is abused. Indicator dyes, plant and fruit extracts containing specific pigments responsible for giving colour change with the fluctuation in the temperature are used in this.

7.6.6 Freshness Indicators

Fish production as well as fish consumption is on the rise both in the domestic and international market. Understanding the ever-increasing demand for fish, retail marketing and online marketing is flourishing across India and the price of fish is also increasing. Due to recently reported adulteration menace, consumers are always at doubt while purchasing fish. Fish being highly perishable, undergoes spoilage leading to formation of various chemicals (oxidation products and amines) which may affect the health of the consumers. The fish quality is either ensured by sensory attributes or by analytical methods. However, the analytical methods are time consuming, costly and are not real-time in nature. This has resulted in relying on sensory quality assessment to judge the quality of fish being marketed. However, sensory quality analysis is qualitative and it can be biased and hence, quality control requires rapid methods for measuring fish freshness in real-time. An intelligent packaging technology will be beneficial for this purpose. This can be achieved by using freshness indicator or spoilage indicators. Commonly developed freshness indicators are based on the reaction between the volatile compounds or other constituents generated during the process of spoilage with the indicating material. Freshness indicators provide direct product quality information resulting from microbial growth or chemical changes within a food product. Microbiological quality may be determined through reactions between indicators included within the package and microbial growth metabolites (Smolander, 2003). Normally, the freshness indicators are incorporated into the packaging film, which reacts with volatile amines and other indicating agents produced during the storage of fish and other seafoods, and the freshness is indicated by a colour change.

7.7 Studies on Functional Packaging Materials

Smart packaging includes both active and intelligent packaging systems. Active packaging refers to alternation of package atmosphere/incorporation of suitable compounds to enhance the quality and shelf life, whereas intelligent system monitors the condition of packaged food to give information regarding the quality of food. Research on development of smart packaging devices for perishables including fish is very limited in India. Many researchers are carrying out work on various aspects of smart functional packaging materials. Chemical combinations for O2 scavenger, CO2 emitter is optimized using GRAS chemicals which can reduce the O2 level to 0.01% and increase the CO2 level to >80% within 24 h, respectively (Mohan 2008). Dual-action sachet, which combines the scavenging of O2 and emits CO2, is also developed and found to extend the shelf life of fatty fish up to 25 days (Mohan 2008). These developed active packaging systems follows first-order reaction and extends the shelf life of fishery products significantly (Mohan 2008). Studies indicated that O2 scavenger was very efficient in reducing oxygen concentration by 99.58% within 24 h inside the packages and found to extend the catfish steaks shelf-life up to 20 days, compared to 10 days in control air packs (Mohan et al. 2008). Studies on Seer fish indicated a shelf life extension of 20 days under O2 scavenger compared to only 12 days for air packs and inhibited the formation of biogenic amines, especially histamine by inhibiting bacterial enzyme activity (Mohan et al. 2009a). The use of O2 scavenger positively extended the shelf life by inhibited the formation of volatile bases, inhibiting the nucleotide degradation resulting in delayed formation of hypoxanthine, which is associated with the spoilage of fish (Mohan et al. 2009b). The use of O2 scavenger improved the shelf life of barracuda steaks by 20 days (Remya et al. 2018) and Indian oil sardine by 15 days (Mohan et al. 2019a, b) under chilled storage. A delay in the growth of microorganisms including specific spoilage flora like Pseudomonas spp. and H2S forming bacteria was observed in fishes packed with O2 absorber by extending the lag phase which is mainly due to the effect of altered atmosphere (Mohan et al. 2010a). A shelf life of 9–10 days was observed for long tail tuna (Thunnus tonggol) packed under O2 scavenger under chilled stored (Mohan et al. 2014).

Active antimicrobial packaging films prepared using chitosan incorporating ginger (Zingiber officinale) essential oil (GEO) was effective against foodborne pathogens (Remya et al. 2016). Keeping quality of steaks of barracuda (Sphyraena jello) fish improved significantly in the chitosan films with GEO (Remya et al. 2016). Antimicrobial packaging film incorporating silver nanoparticles synthesized using low and high molecular weight and other chemicals can be used effectively to control the growth of foodborne pathogens (Pankaj et al. 2017). Combination of O2 scavenger and antimicrobial film incorporating essential oil resulted in enhanced quality retention and reduced oxidation and extended the shelf life up to 30 days in chilled storage condition (Remya et al. 2017). Combination of curry leaf essential oil and O2 scavenger resulted in increased lag phase and reduced oxidation in Rachycentroncanadum and extended shelf life up to 30 days (Remya et al. 2014). Antimicrobial coating with chitosan resulted in reduced microbial growth, volatile formation, oxidation, drip loss and improved water holding capacity and improved the texture of Indian oil sardine (Mohan et al. 2012; Renuka et al. 2016). The formation of total volatile base nitrogen and trimethylamine nitrogen was less by 14.9–32.7 and 26.1–49% for different concentrations of chitosan-treated samples (Mohan et al. 2012). Biodegradable antioxidant packaging film developed using rosemary essential oil resulted in improved DPPH activity and total phenolic content (Mohan et al. 2018). Moisture absorbing system developed using aquatic weed, water hyacinth to absorb the drip formed during the storage of fish.

Similar to active packaging systems, ICAR-CIFT has also developed various intelligent packaging systems. A simple, easy to use and cheap (Only Rs 0.4 per pack equivalent to US$ 0.0055) freshness indicator is developed for indicating quality of fish and shellfishes. The effectiveness of freshness indicator is evaluated with fishes of freshwater, marine and brackish water origin and found effective, except for freshwater fishes. Studies on nanoparticle-based intelligent packaging system to develop temperature history sensor were developed in collaboration with University of Wisconsin-Madison, USA (Wang et al. 2017). Nanocomposite of chitosan and gold nanoparticles (AuNPs) was used to develop sensors that can indicate the frozen state and thermal history of foods and other temperature-sensitive products based on the visual colour change (Wang et al. 2017). A greener method used for the synthesis of Gold nanoparticle using chitosan to develop temperature history indicator to ensure the quality and safety of frozen stored perishable food and pharma products during shipment and transportation (Mohan et al. 2019a, b). Developed and characterized gold, silver and copper nanoparticles using different chemicals and biological sources of marine origin which finds application as biogenic amine and heavy metal detecting sensor. Developed paper-based colorimetric nano-biosensor strip for detection of foodborne pathogens including E. coli 0157:H7 and E. coli which reduced the detection time (Nadella et al. 2019). A detailed review on active and intelligent packaging systems is documented (Mohan et al. 2009a, b, 2010b, 2018; Biji et al. 2016).

Apart from this, the institute is also steer heading the research on developing biodegradable smart packaging materials with improved properties. Chitosan, collagen, chitosan-collagen-based films were developed for its application as wrap. PLA-based biodegradable packaging material with improved mechanical properties and heat sealability is developed. Seaweed based functional and edible films developed exhibited good sealing and antioxidant properties and can be used as novel packaging material in food industry as a sachet/pouch/bag for seasoning powder for instant noodles, instant coffee/tea, etc. Continued research and development is needed for enhancing the efficiency of smart packaging systems developed. Collaboration with other research institutes is the need of the hour to fine tune and upscale the developed smart packaging technologies, validate properties of smart packaging devices developed in field condition and commercialization.

7.8 Conclusion

Apart from proper handling, there is a need to adopt advanced packaging technologies, particularly cost-effective smart packaging to overcome this problem. Although advanced packaging technologies like vacuum and modified atmosphere packaging technologies are available, their adoption in middle- and low-income countries are very insignificant due to its high cost and its maintenance. Apart from reducing post-harvest losses, providing quality and safe fish products without the use of any chemical preservative is a challenge world is facing today. Advanced, low-cost packaging options to enhance the quality, shelf-life and safety are the need of the hour. Advancements in the biodegradable packaging material with functional attributes will continue to progress which brings new concepts and opportunities to enhance the quality and safety of perishable commodities. Adoption of these functional packaging materials will bring new avenues to entrepreneurs and industry persons to enhance their marketing capabilities as the consumers will get the trust on such products which use functional packaging materials to show that these products are better compared to conventional ones.

References

Aday MS (2014) Ambalaj Materyalleri. Turktarım, Gıda Tarım ve Hayvancılık Bakanlığı Dergisi (220):16–21

Biji KB, Ravishankar CN, Venkateswarlu R, Mohan CO, SrinivasaGopal TK (2016) Biogenic amines in seafood: a review. J Food Sci Technol 53(5):2210–2218

De Kruijf N, Van Beest M, Rijk R, Sipilainen-Malm T, Losada PP, De Meulenaer B (2002) Active and intelligent packaging: application and regulatory aspects. Food Addit Contam 19:144–162

Durusoy, Karababa AO (2011) Plastik Gıda Ambalajları ve Sağlık. TAF Prev Med Bull 10(1):87–96

FAO (2018) The State of World Fisheries and Aquaculture 2018 – Meeting the sustainable development goals. Rome. Licence: CC BY-NC-SA 3.0 IGO

FAO (2020) The State of World Fisheries and Aquaculture 2020. Sustainability in action, Rome. https://doi.org/10.4060/ca9229en

Keleş (1998) Gıda Ambalajlama İlkeleri. Ataturk Universitesi Ziraat Fakultesi Yayınları No: 189.2. Baskı, Ataturk Universitesi Ziraat Fakultesi Ofset Tesisi, Erzurum

Kishore P, Mohan CO, Sreelakshmi KR, Panda SK (2017) Antimicrobial activity of silver nanoparticles (AgNPs) against human significant pathogens. Fish Tech Rep 3(2):33–34

Kızılırmak O (1997) Gıda Sanayiinde Kullanılan Plastik Ambalajlar ve Migrasyon. TMMOB Gıda Muhendisliği Dergisi 4:19–21

https://www.fortunebusinessinsights.com/industry-reports/food-packaging-market-101941. Accessed 26 July 2021

Marsh K, Bugusu B (2007) Food packaging: roles, materials, and environmental issues. J Food Sci 72:39–55

MEB, Ministry of Eduction (2011) Cevre Sağlığı - Gıda Maddelerinde Kullanılan Ambalajlar. T.C. Milli Eğitim Bakanlığı, Ankara

Mohan CO (2008) Shelf-life extension of seer fish (Scomberomorus commerson) steaks using O2-scavenger and CO2 emitters in chilled condition. Mumbai, ICAR-CIFT, p 234

Mohan CO, Ravi Shankar CN, SrinivasaGopal TK (2008) Effect of O2 scavenger on the shelf life of catfish (Pangasius sutchi) steaks during chilled storage. J Sci Food Agric 88(3):442–448

Mohan CO, Ravishankar CN, SrinivasaGopal TK, Ashok Kumar K, Lalitha KV (2009a) Biogenic amines formation in Seer fish (Scomberomorus commerson) steaks packed with O2-scavenger during chilled storage. Food Res Int 42:411–416

Mohan CO, Ravishankar CN, SrinivasaGopal TK, Ashok Kumar K (2009b) Nucleotide breakdown products of seer fish (Scomberomorus commerson) steaks stored in O2 scavenger packs during chilled storage. Innov Food Sci Emerg Technol 10:272–278

Mohan CO, Ravishankar CN, SrinivasaGopal TK, Lalitha KV (2010a) Effect of reduced oxygen atmosphere and sodium acetate treatment on the microbial quality changes of Seer fish (Scomberomorus commerson) steaks stored in ice. Food Microbiol 27:526–534

Mohan CO, Ravishankar CN, SrinivasaGopal TK (2010b) Active packaging of fishery products- a review. Fish Technol 47(1):1–18

Mohan CO, Ravishankar CN, SrinivasaGopal TK, Lalitha KV (2012) Effect of chitosan edible coating on the quality of double filleted Indian oil sardine (Sardinella longiceps) during chilled storage. Food Hydrocoll 26(1):167–174

Mohan CO, Ravishankar CN, SrinivasaGopal TK (2014) Quality of longtail tuna (Thunnus tonggol) chunks packed under reduced oxygen atmosphere in chilled storage condition. In: International symposium “MECOS-2 marine ecosystems—challenges and opportunities”, The Marine Biological Association of India at Cochin during 2–5 Dec 2014

Mohan CO, Ashitha VA, Kishore P, Panda SK, Ravishankar CN (2018) Influence of mono- and multilayered packaging material on the quality of Seer fish (Scomberomorus commerson) during chilled storage. J Packag Technol Res 2(1):67–76

Mohan CO, Abin J, Kishore P, Panda SK, Ravishankar CN (2019a) Effect of vacuum and active packaging on the biochemical and microbial quality of Indian oil sardine (Sardinella longiceps) during iced storage. J Packag Technol Res:1–13

Mohan CO, Gunasekaran S, Ravishankar CN (2019b) Chitosan-capped gold nanoparticles for indicating temperature abuse in frozen stored products. npj Sci Food 3(2):1–6

Nadella RK, Mohan CO, Kishore P, Panda SK, Nilavan E, Prasad MM, Ravishankar CN (2019) Development of colorimetric nano-biosensor strip for detection of E. coli O157:H7 and E. coli. In: National conference Nano India 2019 organized by Mahatma Gandhi University, Kottayam, Kerala on April 26 & 27th, 2019

Nielsen T (1997) Active packaging-the literature review. SIK-rapport no 631, p 20

Paine FA (1991) The packaging users handbook. AVI, Van Nostrand Reinhold, New York

Remya S, Mohan CO, Bindu J, Sivaraman GK, Ravishankar CN (2014) A new generation active packaging system with antimicrobial film and O2 scavenger for fish preservation. In: The 10th Indian fisheries & aquaculture forum (10ifaf), NBFGR, NBFGB, Lucknow, 12–15 Nov 2014 organized by Asian Fisheries Society, Indian Branch (AFSIB), in collaboration with NBFGR, Lucknow

Remya S, Mohan CO, Bindu J, Sivaraman GK, Venkateshwarlu G, Ravishankar CN (2016) Effect of chitosan based active packaging film on the keeping quality of chilled stored barracuda fish. J Food Sci Technol 53(1):685–693

Remya S, Mohan CO, Venkateshwarlu G, Sivaraman GK, Ravishankar CN (2017) Combined effect of O2 scavenger and antimicrobial film on shelf life of fresh cobia (Rachycentron canadum) fish steaks stored at 2°C. Food Control 71:71–78

Remya S, Mohan CO, Ravishankar CN, Sivaraman GK, Jha AK, Venkateshwarlu G (2018) Effect of active packaging atmosphere on the shelf life of chilled stored steaks of barracuda Sphyraena jello. Indian J Fish 65(4):109–115

Renuka V, Mohan CO, Kirplani Y, Sivaraman GK, Ravishankar CN (2016) Effect of chitosan edible coating on the microbial quality of Ribbonfish, Lepturacanthus savala (Cuvier, 1929) steaks. Fish Technol 53(2):146–150

Robertson G (2006) Food packaging principles and practices. Taylor & Francis, Boca Raton, FL

Rooney ML (1985) Oxygen scavenging from air in package headspaces by singlet oxygen reactions in polymer media. J Food Sci 47(291–294):298

Vermeiren L, Devlieghere F, Van Beest M, de Kruijf N, Debevere J (1999) Developments in the active packaging of foods. Trends Food Sci Technol 10:77–86

Wang Y-C, Mohan CO, Jiehao G, Ravishankar CN, Gunasekaran S (2017) Chitosan and gold nanoparticles-based thermal history indicators and frozen indicators for perishable and temperature-sensitive products. Food Control 85:186–193

Wessling C, Nielsen T, Leufven A, Jagerstad M (1998) Mobility of tocopherol and BHT in LDPE in contact with fatty food simulants. Food Addit Contam 15:709–715

Yam KL, Takhistov PT, Miltz J (2005) Intelligent packaging: concepts and applications. J Food Sci 70:1–10

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Mohan, C.O., Remya, S., Sreelakshmi, K.R., Ravishankar, C.N. (2022). Functional Packaging Materials for Fishery Products Applications. In: Shukla, A.K. (eds) Food Packaging: The Smarter Way. Springer, Singapore. https://doi.org/10.1007/978-981-16-7196-8_7

Download citation

DOI: https://doi.org/10.1007/978-981-16-7196-8_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7195-1

Online ISBN: 978-981-16-7196-8

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)