Abstract

The study was planned to assess the workplace heat stress and its effect on worker’s health engaged in a glass manufacturing unit of UP, India with a total sample size of 120 workers selected purposively without replacement. Subjective symptoms of heat stress among 120 workers were assessed using a checklist whereas heat stress of the 30 blowers from the total and workplace heat stress were assessed through OSHA’S Heat hazard assessment method and heat stress monitor (QUESTempº 36), respectively. The findings revealed that almost all the workers were affected by the heat stress as they reported symptoms like rising in body temperature (96.66%), heavy sweating (94.16%), skin hot and dry red face (87.50%), weakness and fatigue (80.83%), headache (61.67%) and dehydration (57.50%). The workplace heat stress analysis showed that WBGT-IN (32.29 ± 1.42 °C) was above the TLV (29 °C) as recommended by ACGIH. The metabolic rate of workers lies in between (184.29–390 W). The finding of the research study suggests that the subjective symptoms of the heat stress reported by workers confirmed the fact that the workers were prone to heat illness as they are exposed to heat hazards conditions and working above the TLV of 29 °C.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Heat stress is one of the major burdens to human beings in the current scenario. People working in numerous industries are exposed to excessive heat burdens in addition to the environment due to which workers confront many health-related problems. Industries having an extremely hot environment are “iron, steel, glass, and ceramic units, rubber, foundries, coke ovens, mines, and construction industries” (Sabnavis et al. 2018). Heat stress can be at outdoor places or indoor workplaces. The sources of heat stress in indoor workplaces are “furnaces, ovens, smelters and boilers” (Chen et al. 2003) and workers working nearby these sources were at a higher risk to heat stress especially during summers (Xiang et al. 2014). A study on steel plants reports that in winters, the temperature near the furnaces has ranged from 35.5 to 46.5 °C when the outdoor temperature was only 14–18 °C (Chen et al. 2003).

The glass industry is also among one of the most vulnerable industries besides having an informal arrangement. A glass manufacturing unit uses 95% of the cullet (waste glass) and 5% of the batch (a mixture of sand, sodium and chemicals) as its basic raw material. A mixture of this material is fed to the furnace and the quantity of raw material is based on consignment. Coal is used for generating heat in the furnace. The mixture is melted to near about 1500 °C. This melting process amplified the heat levels and exposure of radiant heat to workers (Brahmapurkar et al. 2013). The working conditions inside glass manufacturing units are far beyond the normal range of heat and temperature. The glass industry workers are exposed to various occupational health hazards due to high temperature and heat conditions (NIOSH 1992). In an extremely hot environment, workers work under heat stress setting, resulting in deterioration of their efficiency and productivity at work (Pourmahabadian et al. 2008). It also impairs their health and sometimes even leads to life threatening conditions (Sabnavis et al. 2018). The symptoms of heat-related illness in the workplace are headache, nausea, vomiting to severe form of heatstroke, which if untreated can leads to death (Parameswarappa and Narayana 2014). Apart from the general hazards such as heat and noise exposure, respiratory and physical hazards, there are psychosocial and physical environment impacts of such manufacturing units on the workers (Wintour 2015). The dehydration induced as a result of heat stress leads to exceeding the human body capacity to cope, resulting in a decline of the mental functions and other performance-related issues in the glass industry workers (Gopinathan et al. 1988). Heat stress is among one such factor which has a very severe negative impact on worker's mental and psychological health along with the physical health hazards.

Also, the Glass manufacturing sector has witnessed tremendous changes in terms of growth and expansion (Wintour 2015). At present, the market size of the glass industry in India has been estimated at around Rs. 225 billion (Sabnavis et al. 2018). As per the CARE report, the industry earns a direct livelihood for approximately 30 lakh people and nearly 7 lakh people get indirect employment through glass manufacturing units.

Keeping in mind the severity of the heat stress conditions and engagement of workers in these informal sectors, it is important to assess the heat hazards among workers and suggest some preventive measures so that the negative impact on worker’s health can be minimized and wellbeing can be enhanced.

2 Material and Methods

Selection of respondents: The manufacturing of glassware or items includes four types of tasks that are performed stepwise at a time:

-

(1)

ball making (the molten glass was drawn from the furnace forming a ball-like structure with the help of blowing pipe),

-

(2)

ball blowing (the molten glass ball is then blown with mouth to cool the glass),

-

(3)

mold handling (the molten ball was again blown by the blowers accordingly based on the molds which were handled by mold handlers) and

-

(4)

Helping task (The final product was then taken to the inspection unit by the helpers).

For one consignment, these workers worked in a team of 8–10 members for four types of an assigned task continuously for half an hour provided with half an hour rest. When the first team rests another team takes their place and works for another half an hour. And at a time, there were 5–8 consignments running simultaneously. The workers work for 6 h. The manufacturing unit works for 24 h*7 in 4 shifts (Table 1) of 6 h. A total of 120 workers from the manufacturing unit performing the mentioned tasks were selected conveniently without replacement for assessing their heat stress. The 30 glass blowers were selected for the heat hazard assessment as these groups of people were more prone to heat stress.

3 Tools and Methods

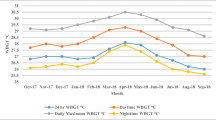

A 24-h analysis of the various heat stress parameters was done using a heat stress monitor QUESTemp° 36 in November 2018. As this manufacturing unit runs around the clock and the workers work in 4 shifts (Table 1).

Heat Stress Monitor was placed 9 feet from the furnace, 5 feet from the distributor and 3 feet from the bay. The readings were recorded at an interval of 10 min.

A checklist of the subjective symptoms was used to assess the heat stress of the workers. Heat hazard assessment of the glass blowers was done using the OSHA method.

Heat hazard assessment was done using the OSHA method and it helps in deciding whether the heat related hazard present in a workplace either indoor or outdoor. The steps for the assessment of heat are

Step 1: Determine the WBGT-In using the heat stress monitor.

Step 2: Determine the WBGT effective by adding a clothing adjustment factor (CAF). The CAF Table was given in Table 2

Step 3: Determine the metabolic work rate.

The ACGIH metabolic work rates define the effect of internal heat production to the core temperature of the body when exertion to the body increases impacts to the body core temperature from the heat produced internally as exertion increases. The work category can be selected from the given Table 3

Step 4: Determination of Threshold Limit Value (TLV) or Action Limit: The threshold limit was decided using Table 4.

4 Results

In this study, the mean age of the respondents was 32.125 ± 7.67 years and 60% of them belong to Other Backward Class, followed by Scheduled Caste (20.83%) and the rest 19.16% were unreserved. This study revealed that more than three-fourth of the respondents were literate (approximately 84%) and a maximum (33.3%) of them were high school passed in the glass manufacturing unit.

It was clearly evident from Table 5 that the dry bulb temperature was found to be the highest and common in shift 2 and shift 3, i.e. 34.69 ± 0.00 °C. The globe temperature was highest in shift 2 (52.50 ± 1.94 °C). The Wet Bulb Temperature was recorded highest in the first shift (25.62 ± 0.61 °C). The humidity recorded by the instrument in the manufacturing unit was found to be highest (11.15%) in shift4. And the determining factor of heat stress was Wet Bulb Globe Temperature Indoor (WBGT-In) and this was found to be 33.02 ± 0.92 °C in shift 1, 33.78 ± 1.08 °C in shift 2, 31.30 ± 0.83 °C in shift 3 and 31.88 ± 1.44 °C in shift 4 (Fig. 1).

The net value for the dry bulb temperature was 33.104 ± 2.34 °C, for globe bulb temperature was 49.42 ± 2.53 °C, for wet-bulb temperature was 24.95 ± 1.02 °C. The Net value for humidity was 10.38 ± 2.25% and the mean value of WBGT-In was found to be and 32.29 ± 1.42 °C. So, we can conclude that the workers were more exposed to radiant energy. As radiant energy and ambient temperature were high (30.38 °C), so the humidity of that area was very low (10.38%).

Table 6 represents the various parameters for assessing the heat hazard of the workers and it was found that the workers were exposed to excessive heat stress while working because the WBGT value exceeds the recommended threshold limit values (29 °C) (ACGIH 2004). The WBGT was 32.29 °C and the clothing adjustment factor was zero as workers were wearing a cotton shirt and pants. The average metabolic rate of the workers was found to be 264.29 W ranging from 184.29 to 390 W. It was very clear from Fig. 2 that all the workers were working under excessive heat exposure as from minimum to maximum range of metabolic rate comes above the action limit as well as TLV.

Exposure to heat in a workplace may cause many health problems starting from heavy sweating and skin rash to fatal heat stroke. Table 7 reflects the subjective symptoms of heat stress reported by the workers performing the various task in the manufacturing unit. It is inferred from Table 6 that the majority of the workers performing different tasks complained about the common symptoms. These symptoms were the rise in their body temperature (96.66%), heavy sweating (94.16%), skin hot and dry red face (87.50%) and weakness and fatigue (80.83%). Although other symptoms like headache (61.67%), dehydration (57.50%), painful muscle spasms (48.33%), blurred vision (42.50%), possible fainting (31.67%), nausea (27.50%), confused or erratic behavior (25.83%) and reduced movement (25%) were also reported by the workers. While very few workers reported brief fainting (16.67%), unconsciousness (8.33%), dizziness (5.83%) and cessation of sweating (3.33%).

The symptom of the cessation of sweating is the distinguishing feature of heat stroke along with unconsciousness and a rise in body temperature. So, it can be said that 3.33% were suffering from heat stroke and it was an alarming situation. The heat stroke was reported by workers performing ball making task and ball blowing task and this group of workers is more prone to such symptoms as they are the one who works in close contact with the furnace. Nausea is the characteristic feature of heat exhaustion along with heavy sweating, headache, dizziness. It can be concluded that 27.50% of the workers were suffering from heat exhaustion. Heavy sweating was the result of heat stress, heat exhaustion, heat cramps. Hence 96.66% were under heat stress conditions.

5 Discussion

The present study investigates the effect of heat stress on the workers of the glass manufacturing unit. The mean age and literacy level of the workers were found to coincide with building construction industry workers and were also found to be 32 years and 79% were literate (Tiwary et al. 2012). The majority of the construction laborers of Varanasi City were from the local community of SC and OBC (Raj and Singh 2018) which was also found similar to the study.

The heat-related symptoms reported in the study by the glass manufacturing workers also reported the alike symptoms of “heat exhaustion (28.1%), heat cramps (22.0%), heat hyperpyrexia (2.6%) which indicates the significant occurrence of heat stress among glass factory workers and burn was reported to be a direct effect of heat exposure among 27.7% of the workers of Central India” (Brahmapurkar et al. 2013). Fire-fighters also reported similar symptoms like heat exhaustion (18.3%), heat cramps (6.1%) and heat pyrexia (4.2%) (Patel et al. 2006).

A report on “vulnerability to heat stress: scenario in Western India” reported that workers in the iron industry (5.9%) and in the ceramic industry (20.3%) experienced heat cramps (Nag and Nag 2009).

The heat stress-related discomforts symptoms reported by ceramic and iron foundry workers were heavy sweating, elevated body temperature, sleeplessness, excessive thirst, muscular discomforts and fatigue (Majumder et al. 2016). They also reported that skin-related disorders like a red face, dry skin, bumps, itching were significantly higher among iron foundry workers, whereas sleeplessness, high blood pressure, heavy sweating, kidney stone, decreased urination, muscular discomforts and fatigue was significantly more among ceramic workers (Majumder et al. 2016).

The present study revealed that the WBGT-In also exceeds the Threshold limit value of 29 °C recommended by ACGIH. Similar findings were obtained which shows that WBGT was 40 °C against the ACGIH TLVs of 26.7 °C in front of an IS machine. The WBGT exceeds the TLV limits in all the areas of the manufacturing section WBGT in the glass manufacturing industry. They also suggested that the WBGT observation requires quick action to control heat stress-related problems in the manufacturing area of glass manufacturing units (Srivastava et al. 2000).

Another study also revealed similar findings in which high WBGT against TLV was found in raw material, furnace, the manufacturing and lehr section, whereas WBGT in sorting and packing section was within the permissible limit. They also concluded that the major contributing factor to the heat stress was radiant heat as the globe temperature was found to be higher than dry bulb temperature at raw material, furnace, manufacturing and lehr section (Brahmapurkar et al. 2012).

6 Limitation

The present study was limited to the manufacturing unit and was conducted in the winter season only due to procedural delay in obtaining informed consent from the higher authority of the industry.

7 Conclusion

The mean value of WBGT-In was found to be 32.29 + 1.42 °C shows that the workers were highly exposed to radiant energy as WBGT-In exceed TLV and also all the blowers were working above the TLV value of 29 °C. The symptoms of heat stress were reported by all the workers. As the study was conducted in the winter season, the further inference can be drawn that the heat stress during summers and in the rainy season has a greater impact on the workers’ health.

There is a limited research study on analyzing heat hazards by using OSHA’s heat hazard assessment method, therefore, this study also recommends that the worker’s exposure to heat stress in various heat stress conditions should also be assessed using this method.

References

ACGIH (2004) Threshold limit values for chemical substances and physical agents & biological indices. American Conference of Government Industrial Hygienists, Cincinnati

Brahmapurkar KP et al (2012) Heat stress and its effect in glass factory workers of Central India. Int J Eng Res Technol (IJERT) 1(8):13

Brahmapurkar KP et al (2013) Morbidities in the glass factory workers of Central India. IOSR J Dental Med Sci (IOSR-JDMS) 7(6):29–33. e-ISSN: 2279-0853, p-ISSN: 2279-0861

Chen ML, Chen CJ, Yeh WY, Huang JW, Mao IF (2003) Heat stress evaluation and worker fatigue in a steel plant. Am Indus Hygiene Assoc J (fairfax, Va) 64:352–359

Gopinathan PM, Pichan G, Sharma VM (1988) Role of dehydration in heat stress induced variations in mental performance. J Occupat Health Safety 43:15–17

Heat hazard assessment. https://www.osha.gov/dts/osta/otm/otm_iii/otm_iii_4.html. Accessed 12 Mar 19

Majumder J, Bagepally BS, Shah P, Kotadiya S, Yadav S, Naha N (2016) Comparison of workers’ perceptions toward work climate and health symptoms between ceramic and iron foundry workers. Indian J Occupat Environ 20:48–53

Nag, Nag (2009) Vulnerability to heat stress: scenario in Western India. National Institute of Occupational Health, 87 pp

NIOSH (National Institute for Occupational Safety and Health) (1992) Working in hot environments. Washington

Parameswarappa SB, Narayana J (2014) Assessment of heat strain among workers in steel industry a study. Int J Curr Microbiol App Sci 3(9):861–870

Patel HC, Rao NM, Saha A (2006) Heat exposure effects among firefighters. Indian J Occupat Environ 10(3):121–123

Pourmahabadian M, Adelkhah M, Azam K (2008) Heat exposure assessment in the working environment of a glass manufacturing unit. Iranian J Environ Health Sci Eng 5(2):141–147

Raj D, Singh BP (2018) Demographic and socio-economic profile of laborers in construction industry of Varanasi City (India). J Stat Appl Prob 7(1):151–159

CARE Ratings Ltd., Mumbai (2018) Glass industry. http://www.careratings.com/upload/NewsFiles/Studies/Glass%20Industry.pdf. June 05, 2018

Sabnavis M, Unwalla VM, Mishra M (2018) CARE rating: professional risk opinion. Industry Research. Glass Industry. Care Ratings Limited (Formerly Credit Analysis & Research Limited), Mumbai-400022, India. http://www.careratings.com/upload/NewsFiles/Studies/Glass%20Industry.pdf

Srivastava A, Kumar R, Joseph E, Kumar A (2000) Heat exposure study in the workplace in a glass manufacturing unit in India. Ann Occup Hyg 44(6):449–453

Tiwary G, Gangopadhyay PK, Biswas S, Nayak K, Chatterjee MK, Chakraborty D, Mukherjee S (2012) Socio-economic status of workers of building construction industry. Indian J Occupat Environ Med 16(2):66–71. https://doi.org/10.4103/0019-5278.107072

Wintour N (2015) The glass industry: recent trends and changes in working conditions and employment relations. Geneva, International Labour Office, 53 pp. ISBN: 9789221301172; 9789221301189

Xiang J, Bi P, Pisaniello D, Hansen A (2014) Health impacts of workplace heat exposure: an epidemiological review. Ind Health 52(2):91–101. https://doi.org/10.2486/indhealth.2012-014

Acknowledgements

The authors would like to acknowledge UGC for funding the above-mentioned work of the Ph.D. degree program through the NET-JRF fellowship and also Thanks to the glass manufacturing industry for granting permission to conduct the study considering the ethical concerns of the industry.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Tewari, S., Vinay, D. (2022). Workplace Heat Stress and Its Effect on Worker’s Health Employed in Glass Manufacturing Unit. In: Rana, N.K., Shah, A.A., Iqbal, R., Khanzode, V. (eds) Technology Enabled Ergonomic Design. HWWE 2020. Design Science and Innovation. Springer, Singapore. https://doi.org/10.1007/978-981-16-6982-8_44

Download citation

DOI: https://doi.org/10.1007/978-981-16-6982-8_44

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6981-1

Online ISBN: 978-981-16-6982-8

eBook Packages: EngineeringEngineering (R0)