Abstract

Gypseous soil is one of the problematic soils and greatly affects the stability of the engineering structures, especially in Iraq. The main geotechnical problem of this soil is the significant reduction of its bearing capacity upon loading and/or wetting processes due to the dissolution of gypseous cementing bonds. This study aims to improve the soil's bearing capacity by using geosynthetics material in single, double, and triple distribution patterns. The gypseous soil samples were brought from a site near Sawa Lake by coordinates (31°18′42.83″ N, 45°00′49.36″ E) in Al-Muthanna Governorate with gypsum content of 37.35% forms about 3.0 m high under the ground surface. The Soil-Model apparatus of dimensions (60 × 60 × 50) cm is used, while the proposed square footing dimensions are (10 × 10) cm. The main test program investigates the bearing capacity before and after the soil reinforcement with the geotextile layers. The results showed a considerable increase in bearing capacity and the increase of volume change when using the triple phase pattern with the allowable bearing capacity increase for reinforced gypseous soil, especially with the increasing reinforcement layers at the triple reinforcement pattern. The depth of the geotextile layer with the soil mass has a significant effect on the magnitude of the bearing capacity and decreases the settlement. The improvement proportion of soil bearing capacity using Geotextile Reinforcement at dry state is ranged 20–90% for relative densities 30 and 60% and different reinforcement patterns.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Collapsible soil is known as any unsaturated soil that passes into a radical changing of particles positions related to loss of volume upon wetting with or without extra load [1, 2]. Gypseous soils cover numerous districts in the world, particularly in parched and semi-arid locales, where the yearly amount of water is inadequate for filtering the gypsum from these soils [3]. Gypseous soil presents a wide collapse potential as a result of its metastable structure. It has weakly dry and damp content in its normal state due to the existence of cementation bonds and an open gypsum structure, especially at unsaturated states or in bone-dry or semi-arid districts. Additionally, change in volume, quick settlement, and a high lowering within the void proportion of a metastable soil structure can happen. Huge volume changes and sudden collapses occur when the soil is immersed in the water beneath steady vertical pressure. Soil distortion happens as a result of the disintegration of the cemented gypsum bonds causes an articulated increment within the compressibility of the soil [4]. The chemical composition of the gypseous soil is (CaSO4.2H2O). According to Barzanji [5], the soil is considered as slightly gypseous soil if the gypsum amount (3–10%) and highly gypseous soil if the gypsum amount is (25–50%). The collapse potential (CP) of gypseous soil can be estimated in the lab from single or double Oedometer tests where the soil considers as trouble or severe trouble when the collapse potential (CP) exceeds the value of 5% [4, 6, 7]. Geotextiles are considered to have the bearing capacity or have high tensile strength, while soils, in general, are considered low-stress materials and have high compressive strength. Therefore, geotextiles are the ideal material for improving and increasing the efficiency of the soil and thus increasing structural stability. To protect the soil from collapse [8, 9].

2 Material, Equipment, and Test Setup

Soil. The undisturbed soil sample is brought from a site near Sawa Lake, Al-Muthanna Governorate, from a depth of (3.0) m. This region is considered an arid area, and the soil can be defined as the medium to dense light brown silty SAND with white traces of gypsum particles. The soil classification is (SP-SM) according to the Unified Soil Classification System (USCS). The physical and chemical properties of the soil are shown in Table 1.

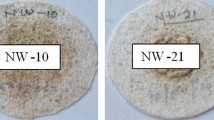

Geotextile Material. Geotextile soil fabrics or knitting warp is considered one of the successful practical solutions to some problems arising from the nature of the soil. Geotextile is used in road, and railway soil steady on waterways and beach corrosion control, asphalt pavement overlap crack relief, subsurface drainage systems, waterproofing membrane defend on, landfill, landscaping, etc. Its multiple-use functions include Separation, Filtration, Reinforcement and stabilization function, and drainage [8, 9]. The geotextile reinforcement used in this study is displayed in Fig. 1 and Table 2.

Soil-Model Apparatus. The Soil-Model Apparatus is made from rigid steel with inner dimensions of the model box are (60 × 60 × 50) cm length, width, and height, the plate thickness of 0.5 cm with square footing (10 × 10 × 1 cm) of rigid steel. The Soil-Model Apparatus consists of several mechanical and electronic parts: Steel load frame, Axial loading system, hydraulic jack, Load cell, a data logger (Adriano), dial gauges, computer software plate, as explained in Figs. 2 and 3.

Sample Preparation. The soil samples are prepared in a test box with a relative density of (30% and 60%). In order to achieve the required dry density, the box is distributed into layers with 50 mm height for every layer and an area of (60 × 60) cm till the full height of 50 cm is reached. The whole number of layers is 10 layers, and the weight of the sandy soil for every layer was (23.11 and 25.36) kg for relative densities 30 and 60%, respectively. Every layer is a store with a level plane and leveled from at that point utilizing the manual compactor instrument until the required density is gotten for all layers as appeared in Fig. 2.

Test Procedure. The compression (i.e., bearing capacity) test is showed by following method nonrepetitive static plate load technique according to the test process mentioned in ASTM D1194-94. The bearing capacity is measured for several layers of geotextile reinforcement with dry conditions of the gypseous soil model. In every case of test, the gypseous soil was put in layers with 5 cm depth. The raining technique measured the position of density. The gypseous soil was placed guardedly on two opposite sides to guarantee a matching density. After setting the final layer, leveled the surface carefully within the straight edge. At that point, the foundation was settled within the center of the test box in x and y trends in unpredictable loading, and after that, the two attractive holders utilizing dial gages within the edge of the box were associated. By the hydraulic jack starts applied the load constantly. The applied load was got from the load cell while the dial gauges determined the settlement. The application of load continuously until to reach the failure. The failure was exposed by the rise of settlement at a constant value of load amount. The diagram of the test setup is shown in Fig. 3.

3 Results and Discussion

To analyze and discuss the effect of using geotextile reinforcement in the gypseous soil under the footing, 20 model tests were carried out consisting of different patterns at the dry state of the soil. For the model tests, the soil bed was prepared with a dry unit weight of 12.84 and 14.1 kN/m3 identical to a relative density of 30 and 60%, respectively. The bearing capacity tests are divided into two main groups: untreated and treated soil tests. The treated and treated soil tests involve three different categories of soil sample conditions as follows: (10) model tests using a single geotextile layer, (6) model tests using double geotextile layers, and (4) model tests using triple geotextile layers.

Load-Settlement Results. These results display that the performance of load–settlement relations sound to be like the general shear failure relation and refer to the soil failure. The reinforcement geotextile layers were placed at a different depth such as (0.5 B, 1B, 1.5B, and 2B) when B represented the width of footing for all model tests. The results are shown in Figs. 4 and 5 with a relative density of 30 and 60%.

Ultimate Bearing Capacity of Dry Gypseous Soil at Relative Density (30%). Figures 6 explains the experimental work to determine the value of ultimate bearing capacity [untreated] at relative density (30%) by two tangent intersection methods under the square footing.

Ultimate Bearing Capacity of Dry Gypseous Soil at Relative Density (60%). Figures 7 explains the experimental results for determining the values of ultimate bearing capacity [untreated] at relative density (30%) by two Tangent Intersection Method under the square footing.

Comparison of Allowable Bearing Capacity and Relative Density 30 and 60% for Dry Gypseous Soil. Figure 8 explains the relation between allowable bearing capacity and relative density for dry gypseous soil using single-layer geotextile reinforcement. Figure 9 explains the relationship between allowable bearing capacity and relative density for dry gypseous soil when using double-layer geotextile reinforcement. Figure 10 explains the relation between allowable bearing capacity and relative density for dry gypseous soil using triple-layer geotextile reinforcement.

Tables 3 shows the results of experimental work and explains the improvement of using geotextile reinforcement on the bearing capacity of gypseous soil. The geotextile has proved it’s effective in improving the bearing capacity and lowering the settlement values, see Figs. 4 and 5. Figures 8, 9 and 10 show a comparison of allowable bearing capacity and relative density 30 and 60% for dry gypseous soil, the triple-layer phase pattern of geotextile reinforcement at depth (0.5B + 1B + 1.5B) gives a higher value of allowable bearing capacity equal to 155 kPa at RD (30) while equal to 245 kPa at RD (60).

4 Conclusions

The following points can be concluded from the results of this study:

-

The allowable bearing capacity of gypseous soil increase with the increase of relative density and reinforcement layers, where the allowable bearing capacity was 80 and 125 kPa at relative density 30 and 60%, respectively.

-

The reinforcement pattern, depth (i.e., position), and a number of the reinforcement geotextile layer have a large effect on the allowable bearing capacity of gypseous soil.

-

For a single geotextile layer model, the maximum value of allowable bearing capacity when the reinforcement is at depth (0.5B) with qall was 165 kPa at relative density 60%, while the minimum value of allowable bearing capacity when the reinforcement is at depth (1 B) with qall was 95 kPa at relative density 30%.

-

For the double geotextile layer model, the maximum value of allowable bearing capacity when the reinforcement is at depth (0.5 B + 1 B) with qall was 195 kPa at relative density 60%, while the minimum value of allowable bearing capacity when the reinforcement is at depth (1B + 2B) with qall was 115 kPa at relative density 30%.

-

For the triple geotextile layer model, the maximum value of allowable bearing capacity when the reinforcement is at depth (0.5 B + 1 B + 1.5 B) with qall was 245 kPa at relative density 60% while the minimum value of allowable bearing capacity when the reinforcement is at depth (1 B + 2 B) with qall was 150 kPa at relative density 30%.

References

Ahmad, F., Said, M. A., & Najah, L. (2012). Effect of leaching and gypsum content on properties of gypseous soil. International Journal of Scientific and Research Publications, 2(9), 1–5.

Al-Obaidi, Q. A., Ibrahim, S. F., & Schanz, T. (2013). Evaluation of collapse potential investigated from different collapsible soils. In Multiphysical testing of soils and shales (pp. 117–122) Berlin, Heidelberg: Springer.

Fattah, M. Y., Obead, I. H., & Omran, H. A. (2019). A study on leaching of collapsible gypseous soils. International Journal of Geotechnical Engineering, 1–11.

Al-Obaidi, Q. A., Karim, H. H., & Al-Shamoosi, A. A. (2020, February). Collapsibility of gypseous soil under suction control. In IOP Conference Series: Materials Science and Engineering (Vol. 737, No. 1, p. 012103). IOP Publishing.

Jha, A. K., & Sivapullaiah, P. V. (2017). Unpredictable behaviour of gypseous/gypsiferous soil: An overview. Indian Geotechnical Journal, 47(4), 503–520.

Al-Saoudi, N. K., Al-Khafaji, A. N., & Al-Mosawi, M. J. (2013). Challenging problems of gypseous soils in Iraq. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering (pp. 479–482).

Fattah, M. Y., Joni, H. H., & Al-Dulaimy, A. S. (2016). Compaction and collapse characteristics of dune sand stabilized with lime-silica fume mix. Earth Sciences Research Journal, 20(2), 1–8.

Koerner, R. M. (2005). Designing with geosynthetic. 5th edn. (P. 796) USA: Pearson Prentice Hall.

Tawfeeq, S. S. (2009). Performance of geosynthetics to improve gypseous soils. Thesis, Civil Engineering Department, University of Tikrit, Iraq.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Mohsen, M.K., Al-Obaidi, Q.A., Asker, A.O. (2022). Improving the Gypseous Soil Bearing Capacity Using Geotextile Reinforcement Under Dry Condition. In: Karkush, M.O., Choudhury, D. (eds) Geotechnical Engineering and Sustainable Construction. Springer, Singapore. https://doi.org/10.1007/978-981-16-6277-5_1

Download citation

DOI: https://doi.org/10.1007/978-981-16-6277-5_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6276-8

Online ISBN: 978-981-16-6277-5

eBook Packages: EngineeringEngineering (R0)