Abstract

This chapter deals with the safety, regulations and standards towards the implementation of neutron imaging activities in any neutron source. The basic requirements and implementation methodologies emphasize minimization of radiation doses to occupational workers and related limits set by regulatory bodies. General description on the radiation quantities, their units, operational limits following the principle of ALARA is provided. Since human safety is paramount, methodologies followed regarding radiation safety, electrical safety and materials safety are important and discussed including safety of systems. Since the portable neutron generators are available and various laboratories or institutions are using them for imaging purpose, precautions in handling them as radiation generating equipment are briefly discussed. Neutron metrology is a subject in itself, and it has huge implications towards realizing internationally adopted standards, using them for the betterment of the techniques and imparting socio-economic advantage of this technique. This chapter discusses the inception of neutron metrology, various established quantities related to neutron source and image characterization, their methodologies in different energy regimes as per internationally adopted schemes. Out of them, four standards typically dedicated towards image characterization in neutron imaging, namely effective collimation ratio, beam purity indicator, sensitivity indicator, beam alignment and divergence-related, are discussed in details for the sake of completeness. The personnel handling radioactive sources or responsible for smooth running of neutron imaging facilities are real asset to the respective organizations. They are the ones performing their job as per the guidelines laid down by the regulatory authority and minimizing radiation hazard to the occupational workers, researchers, etc. They need to be trained in utmost professional manner and the last part of the chapter deals on this with an emphasis on the Indian scenario.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

7.1 Basic Requirement and Implementation Methodology

Everybody is exposed to some kind of radiation either natural (terrestrial, cosmic, etc.) or man-made sources (accelerator, isotopic sources, nuclear reactors, etc.). The radiation exposure due to occupation needs to be controlled. The exposures to individuals need assessment, and guidelines must be set towards enabling safety practices. ICRP clearly mentions the development of special dosimetric quantities related to radiation exposures taking into account their variation of effectiveness as well as variation in the biological effectiveness from one organ/tissue to the other. IAEA, through international cooperation, has adopted safety standards for the protection of health and environment keeping in mind the necessities. The safety guides must be followed, in addition to those framed by national regulators, to ensure minimum radiation hazards as far as possible on human health. The 9-key point mentioned in the Occupational Radiation Protection Call-for-Action by IAEA in 2014, in collaboration with other international organizations, clearly states the avenues to focus towards ensuring best practices for workers and safe use of ionizing radiation. Any laboratory or Institute using radiation source must have a qualified expert such as health physicist or radiation safety officer who individually or in coordination with a safety committee designs the best practices for human safety with minimum risk towards achieving the desired goals. Three TDS principles in implementing minimization of radiation hazards are (a) minimize time (T) in radiation areas, (b) maximize distance (D) from the radiation source or area and (c) employ proper shielding (S) of the source.

Radiation Quantities and Units: A unit is necessary for the measurement of any physical quantity. Radiation units are frequently reviewed and updated from time to time by the international commission on radiation units and measurement (ICRU). ICRP Publication 74 provides an extensive and authoritative set of data linking the operational quantities defined by ICRU with the dosimetric and protection quantities defined by ICRP. Some of the important radiation protection quantities are discussed below in brief.

The quantities of interest are Activity, Air Kerma, Exposure, Absorbed dose, Equivalent Dose and Effective Dose.

Activity: It is defined as the number of disintegration per second from a radioactive material.

Unit of activity in SI is Becquerel (Bq), where 1 Bq = 1 disintegration per second. Its old unit was Curie (Ci), where 1 Ci = 3.7 × 1010 Bq = 37 GBq.

KERMA (K): The radiation field of indirectly ionizing radiations at any point in matter is given by the quantity KERMA (K), an acronym for “kinetic energy released per unit mass”. It is defined as the sum of the initial kinetic energies of all charged particles liberated by uncharged radiation in a material of mass 1 kg and its unit is J/Kg. Its unit in SI is named as Gray (Gy), where 1 Gy = 1 J/kg. When Reference material is air, the quantity is called as Air Kerma.

EXPOSURE(X): It is defined as the absolute value of the total charge of the ions of one sign produced in air when all the electrons liberated by photons per unit mass of air are completely stopped in air and is denoted as X and is defined by Eq. (7.1)

where dQ is the amount of charge developed in dm quantity of mass. It is expressed in SI unit as C/kg. The old unit was Roentgen (R) and expressed as 1 R = 2.58*10–4 C/kg (air) or 1 C/kg = 3876 R. The exposure rate (X/t) is defined as exposure produced per unit time.

Dose (D): The effect of radiation (either physical, chemical, biological or their combination) on a medium mainly depends on the energy absorbed by the medium. The amount of energy absorbed per unit mass of matter at the point of interest is called as absorbed dose or simply dose and is denoted in SI unit as 1 Gy = 1 J/kg. The old unit was rad, and it is related as 1 Gy = 100 rads.

Equivalent Dose (HT): Effects of radiation depend on the type of ionizing radiation and on the medium on which it is calculated. It is as per the energy loss per unit length of the medium. Hence, the biological damage caused by the same dose from different radiations may be different as the energy losses are different for different radiations. 1 Gy of alpha dose is found to be more effective than 1 Gy of gamma dose. Hence, in radiation protection, to account for this variation in the effectiveness of different types of radiations, a factor called radiation weighting factor (WR) is accounted for the absorbed dose due to each type of radiation towards the production of stochastic effects. The weighted absorbed dose in any tissue is called the equivalent dose HT and expressed as HT = ΣDR WR, where DR is the average dose over the tissue or organ due to radiation and the summation is accounted over all radiations (R). Since WR is a dimensionless quantity, the unit of equivalent dose is J/kg. In SI units, it is denoted as Sievert (Sv) and 1 Sv = 1 J/kg. Earlier its unit was “rem” and related to Sv as 1 Sv = 100 rem. Table 7.1 provides the values of WR for different types of radiation.

Effective Dose: The effective dose to the whole body is calculated by taking into account the doses received by individual organs or tissues considering their radio-sensitivity, seriousness of damage and curing susceptibility varies from one organ or tissue to the other. This is accounted by a weighting factor, called tissue weighting factor (WT), defined as per the extent of the stochastic effect in the organ/tissue. The effective dose (E) is defined as,

E = ΣWT · HT, where WT is the weighting factor for organ or tissue T and HT is the equivalent dose in organ or tissue T and the summation is accounted for all the tissues (T) affected. Organ/tissue-specific WT is provided in Table 7.2.

Ambient Dose Equivalent (H*(10)): This is defined as the dose equivalent at a point, lying at a depth 10 mm in the ICRU sphere, in a radiation field that would be produced by the field expanded and aligned in the direction of the measured point. The ICRU sphere, a phantom, is made up of 30 cm tissue-equivalent plastic (density ~ 1 g/cm3), made from oxygen, carbon, hydrogen and nitrogen with 76.2%, 11.1%, 10.2% and 2.6% mass composition, respectively. Ambient dose equivalent was conceptualized towards developing a unified metrology standard for all types of radiation, relatable and directly measurable through, in some cases using simplified phantom models of the human body, considering different radiation qualities towards ensuring adequate radiation protection. The reference depth of 10 mm was envisioned by ICRU as maximum dose equivalent happens in this depth for penetrating radiation [1].

Directional Dose Equivalent (H′(d, Ω)): This is defined as the ambient dose equivalent in a specified direction Ω.

Personal Dose Equivalent (Hp (d)): This is defined as the dose equivalent in a soft tissue, for both weakly and strongly penetrating radiation, at a depth “d” below a specified point on the body. As per the latest ICRU guidelines, d is taken as 0.07 mm for skin and 3 mm for eye. Hp(10) is the operational radiation quantity which is measurable and gives the estimate of effective dose having annual dose limits.

Operational Limits

The International Commission on Radiological Protection (ICRP) sets up guidelines on the safety standards in the use of ionizing radiations taking into account all the current scientific information available on radiation effects [2].

System of Dose Limitation: ICRP has recommended a system of dose limitation based on the following principles:

-

1.

Justification: No practice shall be adopted unless its introduction produces a positive net benefit.

-

2.

Optimization of protection: All exposure shall be kept As Low As Reasonable Achievable (ALARA), economic and social factors being taken into account.

-

3.

Application of dose limits: Dose to individuals shall not exceed recommended Limits.

Dose limits are designed to achieve the following:

-

1.

Prevent deterministic effects.

-

2.

Minimize the stochastic effects to levels which are acceptable.

-

3.

Ensure that practice involving radiation exposures is justified.

As per IAEA Basic Safety Standard (BSS), exposures can be categorized into two types, normal exposure arising out of certain medical or industrial practices having predictable magnitude and potential exposure arising out of unexpected circumstances such as accident and equipment malfunction. The former type can be controlled by using strict restrictions towards only the required dose delivery such as in medical imaging or radiotherapy. The later type can be controlled through design and implementation of proper shielding, administrative control and operating procedure. Radiation exposures can be divided into three categories: occupational, public and medical. Table 7.3 details the recommended dose limits as per ICRP.

7.2 Human Safety

Human safety is at the foremost important part, and all possible measures must be employed to ensure minimum radiation risk to the working personnel involved in any radiation facility. Radiation safety, electrical safety and other mechanisms such as interlock, administrative control and warning signs are the important mechanisms implemented to ensure human safety.

7.2.1 Radiation Safety

The biological effects of ionizing radiation [3] upon humans can be either deterministic or stochastic. When the radiation dose is above some threshold (>0.1 Gy), the effects shortly arising after exposure to the radiation dose is called deterministic. Acute radiation sickness (such as nausea, vomiting, tissue burns) and chronic radiation sickness (such as cataract, cancer and mutation) are two types of deterministic effects. In case when there is no dependence on threshold and severity but on the probability of occurrence, the effects are termed as stochastic. Somatic and genetic are two types of stochastic effects.

Radiation Shielding for Neutron Beamline

Neutrons interact with material through capture and scattering mechanism. The parameter defining the interaction probability with any material is called its cross-section. Since neutrons, irrespective of its energy, interact with the nucleus, they have the potential of changing the nuclear property of the materials upon interaction. Also, any neutron source will also have some gamma emission associated with it. Both neutrons and gamma possess radiation hazard for all personnel working with it or around the facility generating neutrons. This is why shielding of any neutron source is dealt with strictly as per the laid down procedures given in the guides and codes of regulatory authority. The emphasis is to design the experimental station involving neutron beam in such a manner and use suitable materials so that neutrons along with gamma (produced by neutron-induced interactions) should not exit the shielded enclosure. Also, care should be taken to provide shielding to the components used in the experimental station as to increase their operational life and minimizing activation due to prolonged exposure to neutrons. Neutrons interact with materials through elastic scattering, inelastic scattering, radiative capture and multiplication. So the choice of materials for shielding and their construction depends upon the neutron source spectrum.

Generally, low Z elements interact better with neutrons for elastic scattering due to their high cross-section. Materials such as hydrogenous compound or graphite, through multiple collisions reduce the energy of fast neutrons, and hence, their use is widespread for neutron shielding material in facilities generating fast neutrons. Since the mean free path of neutrons in graphite is approximately 6 times than hydrogen, hydrogenous materials are the best choice towards compact shielding design. Depending upon the neutron spectrum, the gamma produced upon their interaction with shielding materials needs to be taken into account even though their numbers are less. For example, thermal neutron capture in hydrogen and nitrogen gives 2.2 and 10.8 MeV gamma rays. Since the interaction cross-section of most materials with fast neutrons (~1 MeV or more) are couple of orders less than the thermal neutrons, they need to be slowed down through multiple collisions to the thermal neutron energy range before being absorbed. Moreover, fast neutrons interacting with carbon, nitrogen and oxygen through inelastic scattering produces 4.43, 5.15 and 6.12 MeV gamma lines respectively. To summarize, neutron shielding must have two parts: moderator and absorber.

To perform any shielding design, understanding of the depth of penetration of neutron of all the energies (either in binned or un-binned manner) present in the spectra is of prime importance. Neutron transport through materials can be described using the Boltzmann transport equation, and the methods to solve it are Monte Carlo method and deterministic method. In Monte Carlo method, the transport equation is not solved directly but history of every particle interaction is tracked through energy and change in direction till its existence in the material becomes insignificant. MCNP, GEANT4, FLUKA, PENELOPE are some commercially available Monte Carlo simulation packages. Deterministic methods are based on various approximations, and among them multi-group approximation is widely used [4]. Interested readers may delve deeper into specific books related to these subtopics.

In reactor-based imaging facilities, the experimental hutch shielding consists of layers of high-density borated polythene and lead in an interlocking manner. The boron part takes of the absorption of thermal neutrons producing 0.42 MeV gammas, and this can be shielded by suitable thickness of lead. These slabs are held in position using heavy metallic structures, preferably grouted to the floor. The portion of the shielding facing the beam port needs extra shielding as it faces directly the neutrons which are attenuated a little by the presence of components in its path used for experimentation such as sample, imaging unit and accessories. For example, in the neutron imaging beamline [5, 6] at Dhruva reactor, India, 400 mm thick borated polyethylene (BPE) blocks and 200 mm thick Pb has been used for the walls and 600 mm BPE in combination with 200 mm Pb has been used for the shielding hutch door facing the beam port. The total weight of Pb and BPE for the shielding motorized door is approximately 12 tonnes. This has been detailed in Chap. 6.

External shielding can also be provided by BPE and concrete slabs in an interlocking mechanism to avoid leakage of radiation by any means. This has been implemented in the TREAT (Transient REActor Test) radiography facility [7] used for imaging of irradiated fuels, which are highly radioactive and that is the reason for using concrete blocks. Figure 7.1 shows the picture of the TREAT neutron radiography facility having shielding walls made up of BPE and concrete. In case of neutron imaging in high radiation environment, the imaging system shielding also needs special attention and BPE in combination with Pb blocks is used for reducing the neutron and gamma background which creates hot spots in the image, thus reducing image quality [8]. Care should also be taken to remove the detector electronics heat through forced air or similar mechanism for reducing detector noise as well as maintaining its life. Figure 7.2 shows the new improved neutron imaging system designed for radiography stations at the Idaho National Laboratory where two-mirror mechanism, and enhanced shielding has resulted in lesser background and hence realization of better image quality. Implementation of vent and exhaust has resulted in lowering thermal effects in the camera system.

Neutron radiography facility at the TREAT [7].

Photographs of the improved imaging system realized at ANTERES where a shows the utilization of two mirrors to move the camera further away from the beam towards reducing background, incorporation of vents to reduce thermal effects in the camera, b robust shielding provided to the imaging system and, c incorporation of motorized mechanism towards online focusing remotely [8] (Open Access)

Safety Mechanisms Incorporated in Facilities Towards Implementing Best Practices

Interlock: Interlock is a means of Engineered Control and is implemented to control radiation by shutting off radiation or not allowing radiation-related risk in any event of emergency or malfunction of any related equipment to avoid accidental exposure to the personnel involved in the facility. In the case of a reactor neutron imaging beamline, various radiation area monitors (RAM) are placed, some of them are located inside the experimental hutch (EH), and some are outside. The RAM inside the EH is interlocked with the gate shutters and EH door to decide whether EH is safe for personnel entry as per the facility safety guidelines [9]. Neutron has the property of activating various materials used in the beamline. These activations will produce some background much higher than permissible, and interlocking with the EH door will prevent its opening and entry of personnel till the background radiation subsides to the permissible limit. For accelerator-based facilities, interlocks are provided to inhibit the production of radiation by various means such as stopping the ion beam reach the target, inadvertent entry door opening, vacuum system fault, cooling system fault, increase in the dose level more than the permissible value inside the accelerator hall on account of radiation source yield increase, fire alarm, smoke detection, etc. Options such as “Search and Secure” inside the experimental hutch or accelerator facility are a recommended practice before closing the entry/exit door and start of the radiation for experimental purpose. This procedure must be followed every time after opening the facility entry/exit door.

Administrative Control: Strict rules regarding restrictions and ensuring follow of safety practices in controlled areas are collectively called as administrative controls. Facility-specific protocols are designed towards allowing personnel access, working methodology, supervision and checking of written documents for all instances during the operation of the facility. Following safe work practices will avoid radiation risk and if in case of any untoward incidence, critical review of the laid down procedures will help in analysing the situation towards implementing further rules in avoiding such instances.

Warning Signs (Audio/Visual): Any facility dealing with radiation must have the warning symbols both in the form of picture or sign and also in written in languages familiar to all the personnel working in the facility. Signs such as “Radiation Area”, “High Voltage”, “Caution”, “Hot Surface”, “RF Source”, “Mind Your Steps” and “Heavy Shielding Door” are common. Visual display by illuminating signs can also be used. Audible warning system incorporating flashing light should be integrated into the facility operating system to warn all the persons present at the start as well as during the operation of the system. Radiation sources must be labelled properly mentioning the type of source, name, contact dose and the activity with date signed by the respective authority.

Radiation Area Monitors/Survey Instruments: Radiation area monitors are an integral part in any radiation facility in order to provide local radiation level towards ensuring safe practices to be followed. They are generally fixed at locations intended to be monitored for dose levels and can relay the signal to the observer location. Modern RAMs provide display and audible alarm with respect to the set threshold. They are available for different types of radiation environment and dose levels. They can be easily interlocked with the system and ensure no tolerance to radiation risk. Survey metres on the other hand are portable instruments used to evaluate radiation levels at intended locations such as isotope source assembly and activated materials after neutron irradiation. These types of instruments are based on ionization/proportional/Geiger–Muller/scintillation detectors and are mostly used for dose or activity measurements on X-ray or gamma ray. For neutron radiation measurement, the neutrons are either scattered elastically to generate protons which are then detected through scintillation mechanism or moderated (using polyethylene), absorbed in specific materials having high absorption cross-section (6Li, 10B, 157Gd) and finally detect the scintillations. Thermal neutron survey metres (e.g. Ludlum make) have 3He or BF3 detector housed in high-density poly-ethylene moderator. Since the availability of 3He has been scarce, various other methodologies have been adopted towards developing neutron radiation survey metres. Gas counter having mixture of methane and nitrogen embedded in bulk polythene are commercially available from Fuji Electric. These instruments can measure neutron dose in the range of 0.1 nSv to 100 mSv. They are to be periodically calibrated and maintained. Survey instruments providing the dose and spectrum of the radiation field are also available and are helpful in designing safety-related protocols.

Personnel Dosimetry: Radiation dosimeters are passive or active detectors intended to record total amount of external radiation received by an individual. These are mandatory in recording the dose received by an individual involved in a radiation generating facility in due course of time and ascertain the safe work practices in the facility as well as his /her lifetime dose. Various types of personal dosimeters are available such as thermoluminescent detectors (TLD), optically stimulated luminescent detectors (OSL), film badges, electronic personnel dosimeter (EPD) and pocket ion chamber (PIC). Dose reading recorded by TLD, OSL and film badges are processed after specific monitoring period such as quarterly or monthly. EPD- and EPC-type dosimeters are capable of providing real-time dose data.

Towards calibration of routine dosimetry systems for radiation processing ISO/ASTM 51261:2013 specifies the requirements for calibrating routine dosimetry systems for use in radiation processing, including establishing measurement traceability and estimating uncertainty in the measured dose using the calibrated dosimetry system.

7.2.2 Electrical Safety

All equipment using electricity for its operation has the potential to cause harm in terms of electrical shock, fire or arc flash, if proper care is not taken to resist it. The severity may depend upon various factors such as magnitude of current, time exposure and humidity conditions. Some important points regarding electrical safety are as follows:

-

Ensure proper safety ground to shunt away any dangerous currents arising out of malfunction or accident. All the wiring must be carried out with the highest professionalism, and there must not be any open.

-

Since accelerator facilities involve very high voltages and currents, requisite earthing and periodic maintenance of earth pits must be ensured.

-

All electrical points must be labelled with warning signs related to its nature.

-

In case of high voltage equipment, safety mechanisms must be in place to restrict personnel from accessing them when they are in ON condition. This is done by making enclosure with interlock. Care must be taken to ensure complete de-energizing them prior to their use after they have been put OFF.

-

Only qualified persons should handle the electrical equipment, in case they are of special requirements.

-

If imaging systems working on electrical power are sensitive to humidity conditions, necessary precautions must be taken into account to ensure their performance.

-

Laid down facility-specific procedures must be followed while putting ON / OFF the systems.

-

Short circuit, overloading, loose electrical connections, earth fault, etc. are major contributors towards the cause of electrical fire and must be avoided.

-

IEC standards such as 60059, 60060, 60073, 60204, 60231, 60243 and 60270 are to be applied wherever required.

7.2.3 Material Safety

Neutron facilities, small or big, have heavy shielding materials in and around them to minimize radiation risk. Local shielding inside a facility is done by stacking one above the other as well as sideways in order to provide adequate thickness of specified materials. Right from the design to the installation various protocols must be followed towards ensuring safety. These are

-

Design must incorporate the neutron source type, energy, yield and available area.

-

ISO 14152 must be adhered to while choosing materials for neutron and gamma shielding.

-

Shielding material must retain its physical characteristics in the facility environment and must have resistance to impact, wear, etc.

-

If possible, materials must be painted with permissible paints to minimize corrosion or oxidation if any.

-

Must be fire resistant and should not provide any thermal load to the facility

-

Load distribution must be ensured as per facility floor (or on which the shielding is laid) load characteristics

-

Interlocking of heavy materials ensuring their stability in case of any seismic activity

-

Materials should not be placed so as to obstruct movement of personnel. In case, if it is unavoidable, proper sign must be displayed at appropriate locations.

-

Overhead cranes if used for erection of the shielding must be operated by trained and qualified operator.

-

Since neutrons activate materials such as iron, stainless steel aluminium which is generally used in beamline hutch, activity measurements are a must ensuring safety of the working personnel.

-

Beam dump must ensure no radiation leak outside the hutch above the permissible radiation level. In case where the entry/exit door also serves the purpose of beam dump, being heavy, due considerations must be followed towards its smooth operation.

-

Toxic and corrosive materials must be avoided or kept as per the stipulated methodologies; otherwise, they can be a major concern for fire. As, for example, chromium, cobalt, iron, manganese, nickel and zinc react with acids. Similarly, aluminium and zirconium react with caustic alkalis. In such cases of fire, water must be avoided as there is a chance of severe steam explosion.

7.2.4 Radiation Hazard and Precautions Towards Handling DD/DT Neutron Generator (NG)

Radiation safety measures with proper shielding and standoff distance for remote operation are the principles to be followed to ensure best practices. Neutron and gamma shielding is generally taken care of by high-density concrete walls, whose thickness depends upon the neutron energy and yield. Additional arrangements of borated high-density polyethylene blocks may be used if required. In any case, radiation dose in the control room and accessible areas around the building or laboratory should not increase more than the permissible limit set by AERB. Typical thickness of shielding to reduce neutron flux and dose rate by a factor of ten is about 38cm of water or concrete. Failsafe safety mechanisms utilizing interlocks must be employed such that any breach to the radiation area should shut down the system without fail. As a matter of practice, health physicists are supposed to check radiation dose prior to entry to the NG area after shutting OFF the system and ensure follow of safety guidelines. Safety protocols followed for different types of DD/DT NG are summarized below.

-

(i)

In case of DD NG, there is no radioactivity issue as no radiation emanates from it when the generator power supply is OFF. But regulations laid by national authorities must be followed when storing or disposing off the deuterium target.

-

(ii)

In the case of DT NG, since tritium is radioactive, its handling needs special attention if it is an open type system or there is a mechanical breakage in the case of a sealed type system. The escape of tritium is very rare but cannot be ruled out. Hence, the following precautions must be followed.

-

(ii-a)

Open type systems:

-

The vacuum system of the accelerating column should be connected to a stack maintained at lower pressure.

-

The change of tritium target and suitable packing of the used target have to be strictly carried out in a glove box. The glove box needs to be connected to the target assembly during this process. The used and eroded targets should be disposed-off as per country laid regulations.

-

-

(ii-b)

Sealed systems:

In case of sealed systems, the barriers towards shielding are provided by the housing module and the target metal (generally zirconium, titanium, vanadium in hydride form) in which the tritium is adsorbed. In the case of mechanical breakage of the sealed system, the following protocols must be maintained.

-

do not panic.

-

ensure that the high voltages are put OFF.

-

carefully decouple the NG from the connected cables after proper check of the radiation level.

-

seal the housing NG assembly in a plastic bag and follow the safety regulations for either disposing it or repair by the manufacturer.

-

Since NGs can activate samples, they are to be handled with due safety regulations. Severity of activation depends upon various factors such as material, flux level and time of irradiation. Even the NG components (SS, Cu) exposed to the neutrons can get activated, and necessary checks are required before accessing them after irradiation/experimentations.

7.3 Neutron Metrology (NM)

Metrology is defined as the science of measures or measurements. According to Lord Kelvin, “To measure is to know” and as per D.L. Mendeleev, “Science begins when they start to measure”. In any sort of development, starting from basic needs of life to the far extragalactic objects in space, measurements and the methodologies to perform them in an un-ambiguous manner, needs careful procedures to be laid down with validity and scientifically proven knowledge. For performing any measurement, procedural reasons are carried out which is then standardized in a form acceptable to all concerned so that the fruits are shared with all with uniformity. This has manifold advantages such as removes language barriers, enhances knowledge base, development of confirmatory techniques towards increasing trade commerce and so on.

The Comite International des Poids et Mesures (CIPM) is the world’s highest authority in metrology. Bureau International des Poids et Mesures (BIPM) was set up by Metre Convention signed on 20 May 1875. CIPM is involved in all metrological-related work with all member state and discusses with BIPM under the delegated authority of CGPM.

BIPM has been tasked in establishing fundamental standards and scales, comparing national and international standards, ensuring coordination between different measurement techniques and coordinate measurements of the fundament of physical constants. The initial activities of BIPM were limited to measurement and metrological studies related to length and mass. Later on they were extended on standardizing electricity (1927), Photometry and Radiometry (1937), Ionizing radiation (1960), time scale (1988). Since 1965, an international journal, “Metrologia” under the guidance of CIPM, deals with publication related to development of standards, upgrading-related activates, decision and recommendation as per metre convention. In 1969, the consultative committee for standards of Ionizing radiation (CCEMRI) established four sections and Section III was for Neutron Measurements. CCEMRI was later and, in 1991, was renamed as consultative committee of ionizing radiation (CCRI). Neutron metrology (NM), though initially associated with nuclear industry recently added, accelerator-based neutron sources used for application in basic research, applied research and medical therapy. Its scope has broadened with more challenges. Accredited national laboratories from different countries work in unison with BIPM towards progress and implementation of developed standards in their respective nations. CIPM Mutual Recognition Arrangement (CIPM MRA) is a framework through which National Metrology Institutes demonstrate their measurement standards to match the international equivalence and the calibration and measurement certificates they issue.

International Commission on Radiation Units and measurements (ICRU) was conceived in 1925 in London with an objective towards proposing a unit of measurement of radiation as applied to medicine. ICRU report 85a (revised) defines fundamental quantities and units for ionizing radiation.

Regarding the development of internationally accepted recommendations, the objectives of ICRU are towards:

-

1.

Quantities and units of radiation and radioactivity.

-

2.

Procedure suitable for the measurement and application of these quantities in various fields and activities related to radiation.

-

3.

Assurance of uniformity in reporting ICRU works closely with other similar organizations such as US National Council of Radiation Protection (USNCRP), IAEA, WHO, UNSCEAR, ISO, BIPM and CIPM.

A network of Secondary Standard Dosimetry Laboratories (SSDL) has been set up by IAEA in collaboration with WHO in 1976 [10]. These SSDLs are designated by individual IAEA Member States. They provide linkage regarding national and international dosimetry and measurement standards having reference to BIPM. They were also made responsible towards the dissemination of S.I. quantities and units through the proper calibration of field instruments. The IAEA maintains the Dosimetry Laboratory in Seibersdorf, Austria, which is the central laboratory of the IAEA/WHO Network of Secondary Standards Dosimetry Laboratories. The quantities used for radiation dose measurements are established in Primary Standards Dosimetry Laboratories (PSDL).

Primary standards for neutron metrology at SSDL and as follows:

-

1.

Source emission rate (Mn bath)

-

2.

Thermal neutron fluence (Au foils)

-

3.

Fast neutron fluence (0.5–10 MeV): Neutron Telescope.

Secondary standard at SSDL should be established as per the guidelines set by PSDL. Radiation standards section of RSSD, BARC is recognized as the designated institute for ionizing radiation metrology in India. IAEA recognizes BARC as a secondary standard dosimetry laboratory. As and when required, BARC has developed primary, secondary and tertiary standards regarding neutron source yield and neutron fluence rate measurement.

ICRU report 66(2001) involves the determination of operational dose equivalent quantities for neutrons. ISO 8529 deals with reference neutron radiation fields and having energy range from 25 MeV to 20 MeV, used for calibration of neutron measuring devices and determining their response as a function of energy for radiation protection purposes. ISO 8529 is based on the technical report series 285 of IAEA (1998).

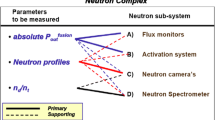

Components involving neutron imaging are neutron source, related collimation, shielding materials, detectors and finally analysis methods. The design of neutron imaging system or facility is primarily based on neutron spectrum as the shielding material including the detection, and imaging methodology will be different from fast, thermal, epithermal or cold neutron source. So, to start with one needs to have complete idea of neutron spectrum, and it needs measurement and quantification as per national and international standards. This importance can also be stressed as the health and safety of both instruments and personnel are linked to it. Depending on this, neutron fluence and dose rates can be ascertained using high purity metal foils, activating single or in groups and analysing the activation related γ-signature provides neutron fluence details. ASTM [11] E261-16 details standard practise for determining neutron fluence, fluence rate and spectra by Radioactivation technique, whereas ASTM E262-17, specifies the same for thermal neutrons. Various foils like indium, gold, dysprosium, cobalt are used depending upon the neutron fluence of 103 to 1020 neutron/cm2.

7.3.1 Basic Physical Quantities: Definitions and Methodologies

Fluence: This is the ratio of the particle (dN) incident or crossing an area da (in cm2) and the area da; Φ = dN/da (unit: cm−2).

Fluence Rate: This is defined as fluence per sec and has unit of cm−2 s−1. Fluence rate can also be differential in energy or solid angle or both.

The distribution of fluence with respect to energy is given by ΦE(E) = dΦ/dE, (cm−2/MeV).

Though the general term for number of neutrons crossing a particular area per unit time is flux, ICRU prefers the use of fluence or fluence rate.

Neutron Spectrum: This denotes the neutron energy histogram or in other terms the different energies of neutron present in the beam along with their effective relative weights, the total weight is 1. Since the absorption cross-section with hydrogenous materials is higher for cold neutrons than thermal neutrons, cold neutron sources using high flux reactor or spallation sources are the main workhorses for high resolution and high contrast imaging studies such as polarized or spin-echo neutron imaging.

Collimation Ratio: This parameter is also known as L/D, where L is the length of the divergent beam tube used to allow the neutrons out of the generating location to the imaging site and D is its input diameter. L/D decides the quality of the neutron radiograph as far as spatial resolution is concerned. The higher the L/D the better is the image quality but the drawback is that as L increases, the neutron fluence falls off by its square. The effective collimation ratio is provided by taking into account the scattering contribution arising out of the collimator wall [12]. ASTM standard E803-20 provides guidelines for measuring the effective collimation ratio of a neutron beam. One can correlate this parameter to the focal spot in case of an X-ray imaging system. Higher L/D can be achieved in nuclear reactor as well as spallation sources. Divergent collimator is easy to construct than the earlier concept of soller or multitube collimator though the later one provides better image sharpness.

Cadmium ratio: This parameter provides the approximate ratio between the thermal neutron component with respect to the epithermal part in the neutron beam, ignoring the fast neutron component as their numbers are much lower in comparison to the other two in a reactor neutron radiography facility. The cadmium ratio (Cd-ratio) is experimentally found out by making activation analysis on standard samples in bare and cadmium foil-covered conditions. The radiography exposure time decreases with the increase in the Cd-ratio but at the expense of reduced sharpness. The beamline parameters, excluding the detector and related parameters, responsible for determining the image quality are Cd-ratio, L/D and the associated gamma component.

Neutron Beam Purity: This is in general used in direct thermal neutron radiography practices for quantifying the thermal neutron purity in the beam. As an image quality indicator, the beam purity indicator determines the quality of image in terms of the neutron beam and imaging system employed. It is measured as per ASTM E2003-10 standard.

In order to standardize the thermal neutron fluence rate measurement, one needs a standard methodology for calibrating instruments in the first stage. Recommended radionuclide neutron sources as per ISO 8529:2001 are 252Cf (D2O moderated), 241Am-B and 241Am-Be. Out of these, the preferred one is 252Cf sources as its size is small, spectrum well-documented, very low γ-rays associated with it and can be prepared for any quantity. The main problem with 252Cf is that they have a relatively lesser half-life (2.65 years), and it needs frequent calibration/replacement. In such cases, Am-Be sources are helpful because their half-life is large (432 years). As these sources are relatively bigger in size, in comparison with 252Cf, effect of their size should be taken into account towards calculation. To produce thermal neutron from these isotopic sources (energy range from Kev to 10 MeV), they are placed in an aqueous solution of MnSO4 (~20 g/l) kept in a spherical vessel. The vessel diameter can be from 50 to 150 cm. Neutrons are thermalized in water (aqueous media), subsequently absorbed by inactive manganese and will become active. This induced activity is measured which in turn is correlated with the neutron source strength.

For carrying out fast neutron fluence rate measurement, the primary standard is neutron telescope (NT). NT or also known as proton recoil telescope (PRT) is based on elastic scattering of neutron in a thin (1–2 mm) hydrogenated target and detection of recoil protons by using CsI scintillator detector. Liquid scintillators (LS) are also used for neutron spectra measurements but they are bulky. LS have the property to distinguish between n and γ. Neutron and gamma generate different rise time pulses which are analysed by pulse shape discrimination (PSD) technique. Neutrons interact via (n,p) and γ through Compton scattering, and using time of flight method neutron energy is determined.

In case where the source emission or its anisotropy is not known or possess a different spectrum than those reported is ISO 8529:1 (2001), then the secondary standard should be established by means of transfer instrument which are moderated ambient dose equivalent metre (rem counter), Bf3-based counter encapsulated by borated HDPE moderator Bonner spheres having either 3He or 6LiI (Eu) scintillator. BARC in India, has a Mn bath setup (Vessel-Stainless steel tank of 1 m diameter) for thermal neutron fluence rate measurement. The NT setup at BARC has been established for 14 MeV neutrons. The secondary standard for neutron yield and fluence rate in BARC is the precision long counter and consists of BF3 counters place inside two consecutive cylinders separated by a neutron absorber. The primary standard or thermal neutron fluence rate measurement at BARC consists of six members of Am-Be neutron sources embedded in graphite pile. The thermal neutron flux in the central cavity has been standardized using gold and manganese foil activation method.

7.3.2 Neutron Fluence/Flux Measurement

The mechanism to determine neutron yield varies upon the energy of the neutron as their interaction cross-section with materials is energy-dependent. Here, by “materials” we mean on which the neutron interaction is carried out. Neutron activation analysis is the technique using which the neutron flux is estimated. The process is divided into two parts. First a foil having stable nuclei is irradiated with neutrons, having suitable neutron interaction cross-section at that energy or range and are made radioactive. In the next step, the signature gamma emissions correlated with the decay of the radioactive species are detected using a high resolution (in terms of energy) detector (say high purity germanium detector). From this data, one can infer with some simple calculations the thermal neutron flux at the measured location. From the flux, one can calculate the source yield incorporating the solid angle subtended by the foil with the source. The choice of irradiating foils is as per the energy or range of the incident neutrons. In general, though the neutron spectra are continuous upto 10 MeV, the beamlines, incorporated with Bismuth and Sapphire plugs get rid of gamma and fast neutrons, respectively, providing thermal neutrons for imaging applications such as radiography and tomography. In case of accelerator-based sources, the generated neutrons have varying energies depending upon the process employed.

-

(a)

Low Energy Neutrons: The underlying principle of (n, γ) reaction for this region is based on the assumption that the absorption cross-section follows a 1/v law, where v is the speed of neutron, upto an energy of 0.4 eV with resonance peaks superimposed on the 1/v curve for neutron energies above 0.4 eV (Hogdahl convention). In addition, it is also assumed that neutrons having energy below and above 0.4 eV will be completely stopped or transmitted by a 0.25 mm thick cadmium foil. The formula derived by Westcott, Walker and Alexander [13] is used for finding out the induced activity. In the case, where the epithermal neutron flux component is not proportional to 1/E, necessary changes in the formula have been proposed by Ryves [14].

The standard technique for measuring thermal neutron fluence rate of any thermal neutron facility is through foil activation. High purity gold, manganese and indium foils are mainly used for such purposes. The generalized equation governing correlation between the activity and the fluence rate is [15]

where

Ai is the count rate of ith detector in the counting setup, Ni is the number of the atoms, ε1 is the isotopic abundance, ε2 is the abundance of the radiation counted, ε3 is the efficiency, fs is the self-shielding factor for the foil, fd is the flux depression factor of the foil for that medium, σi (E) is the activation cross-section at the energy E, φ(E) is the neutron fluence rate of energy E, t is the irradiation time, T is the decay time.

Gold ( 197 Au) Foil Activation

The reaction is given in Eq. 7.2. The main reasons for choosing gold are as follows: (a) Gold being monoisotopic in nature, highly pure form can be obtained, (b) Its absorption cross-section is high ~98.6 ± 0.3 barns, (iii) activation time is rather small owing to its activated product half-life of 2.696 days and (iv) the deviation from 1/v below cadmium cut-off is small [16].

Pure gold foils of 99.95% or better purity, thickness ~0.025–0.1 mm and diameter ~4–8 mm are generally used for irradiation and activation purposes.

The β-decay half-life of 198Au is 2.6947(3) days with well-known 198Hg γ intensities and energies of 411.8 keV for the main transition, 675.9 and 1087.7 keV at lower intensities [17]. The cross-section is 98.8 barns for 25 MeV neutrons. The gamma lines are measured with a high purity germanium (HPGe) detector, and the analysis is carried out taking into account the integrated counts, decay characteristics, mass of the foil and volume of the foil irradiated. It is important to emphasize that the choice of the thickness of the foil depends upon the thermal neutron yield with an optimization that the activated gamma lines should be able to emit and reach the HPGe detector for counting.

The equation governing the yield is given by Eq. 7.3.

where λ is decay constant (s−1), L (cm) is distance between neutron source (target) and foil set, A (g) is atomic mass number of sample, Cp is the photopeak area (counts at 411.8, 675.9 and 1087.7 keV) for 197Au, Nais Avogadro number, m is atomic weight (g) of sample, ai is the isotopic abundance, ε is photopeak efficiency of HPGe, Py is gamma abundance, σ is reaction cross-section, t1, t2 and t3 are irradiation, cooling and counting time, respectively.

Using this Y and dividing by 4piL2, one can find out the flux at a distance L from the source. The measured value provides yield of neutrons below 0.4 eV. When activation is carried out in cadmium covering (~0.5 mm thick), it gives the measurement of all neutrons other than thermal. Difference of these two provides actual thermal neutron yield of the source being measured. In general, not one but multiple foils are irradiated to better the result [18,19,20].

Manganese (55Mn) Foil Activation

Mn used in either pure metal or alloy form (Mn-Ni) has 13.3 barns cross-section with thermal neutrons, and the reaction is 55Mn(n,γ)56Mn. The resultant nucleus has a half-life of 2.58 h. The reaction yields beta and gamma having energies of 2.85 MeV and 0.847 MeV, respectively, in coincidence. The absolute measurement can be carried out using 4π beta-gamma coincidence method.

New developments: A new technique for neutron flux estimation at highly collimated monochromatic cold neutron beam has been established using a boron-10 enriched B4C block and measuring the neutron-induced 478 keV gamma by a high-resolution HPGe detector [21]. The simplicity of this technique is that it does not involve neutron cross-sections, energy or branching ratio.

-

(b)

Fast Neutrons: On account of the relative smaller cross-sections and hence long free paths associated with fast neutrons, the materials are chosen for activation analysis are different from the ones used for thermal neutrons. Different foils are used depending upon the reaction threshold.

For DD neutrons, the flux determination is carried out by neutron activation analysis on indium foils (113In: 4.3% and 115In: 95.7%). The reaction channels for 115In are

and

Reaction (7.4) has high cross-section for fast neutrons and is used as the DD neutron flux estimation. As per ENDF database, the cross-section is 0.346 barns for 2.7 MeV neutrons and the DD neutron energy is 2.54 MeV. Various similar 115In foils can be placed with respect to the source position to estimate the neutron fluence rate profile.

39Al(n, p)27 Mg reaction having threshold of 3.25 MeV and cross-section 113 ± 1.5 mb has also been suggested [22]. In this radioactivation, photopeaks of 844 and 1014 keV are considered [23]. 63Cu(n, 2n)62Cu and 65Cu(n, 2n)64Cu reactions giving rise to 9.7 min and 12.8 h activity for 62Cu and 64Cu, respectively, are extensively used as 14 MeV neutron flux monitor [24]. The former has been extensively used for short irradiations, about half an hour and the later for longer irradiations. As an alternative 19F(n, 2n)18F reaction having threshold of 12 MeV has also been utilized for 14 MeV fluence measurements [25, 26]. Also, the 28Si(n, p)28Al reaction [27] has been shown to be useful for monitoring the emission of 14 MeV neutrons from d-t fusion plasmas.

7.3.3 Digital Image Archiving, Processing and Transfer Protocol

The ever-growing healthcare sector with a niche towards medical imaging and its widespread utilization from hospitals to tele-radiology prompted the developers to standardize the imaging modalities and bring it under an internationally adopted convention DICOM, an abbreviation of Digital Imaging and COmmunication in Medicine. Defined protocols towards the generation, archiving, processing and transfer of radiographic images in DICOM format [28] are practised by one and all in the healthcare sector. In the same line of work, all digital images generated through non-destructive techniques are taken care by the protocol named as DICONDE, an abbreviation for Digital Imaging and COmmunication in Non-Destructive Evaluation [29]. This was first introduced by ASTM in the year 2004 though it was established way back in 1993. Sharing NDE images from various techniques such as CR, DR, visual inspection, ultrasonic, eddy current, using a standard format, their study and examination by experts speeds up the whole evaluation process. These files contain metadata regarding the image in addition to the image. Metadata includes parameter such as process of examination involved/imaging modality, system used, study conditions (kV, mA, exposure, etc.), material description study performed by and many more including option towards report generation. The data is organized in a hierarchical way—study—series—instances. All the NDT technique, except neutron radiography and tomography, are widely used and hence had the support of the developers towards and DICONDE.

7.4 Internationally Adopted Standards for Neutron Imaging

Some of the important ASTM standards [30] related to neutron source and neutron imaging facilities are given in Table 7.3.

7.4.1 Effective Collimation Ratio Using No Umbra (NU) Device as per ASTM E803-20 (ISO 12721)

This standard [30] specifies the methodology to determine experimentally the L/D of the beam where L is the length of the neutron beam from its source to the imaging plane and D is the source inlet diameter. The basic approach is to find out the distance (say d) between the object having very high neutron absorption cross-section and the image plane which produces the sharpest image of the object. The condition is to use very thin wires having diameter much less than D. The NU device is made up of “U”-shaped aluminium plate having regularly cut grooves filled with very fine nylon and cadmium wires (Fig. 7.3). Imaging of the device is carried out by placing it 45° with respect to the beam plane. Measurements from the image are made for the width of the umbra, penumbra, and at minimum penumbral condition, the ratio between the diameter of the wire and the distance “d” is the measure of the L/D of the beam. ISO 12721 [31] specifies formulae for calculating the L/D for cases such as L/D < 100 and L/D > 200 in addition to find out the accuracies of the measurements.

Schematic view of a NU device showing the wire layout [12].

7.4.2 Beam Purity Indicator (BPI) as per ASTM E2003-20

BPI [30] provides quantitative information related to neutron beam and direct neutron radiographic examination carried out using film-based detectors. This is an image quality indicator and is fabricated using of boron nitride discs, lead discs and cadmium/gadolinium wires tightly fitted in holes in a highly crystalline linear polymer (as shown in Fig. 7.4). ASTM E2003-10 specifies the minimum purity conditions of the materials to be met for BPI measurements. Radiographic examinations are to be done as per the procedure mentioned in ASTM E545. Densitometric measurements on the image will provide quantitative data related to the materials used in the BPI. Since cadmium/gadolinium has appreciably high thermal neutron absorption cross-section, its image should be sharp. If that is not the case the effective collimation is not sufficient for performing this experiment. Since lead is almost transparent to thermal neutrons, image of lead with some contrast with the base material will certainly suggest the presence of gamma in the beam. If that is not the case then the gamma contribution is less and the design of the beam is said to be good. E2003-20 provides necessary formulas to determine mainly the thermal neutron content, gamma component along with the scattered neutron component towards characterizing the beam. Various parameters such as optical density of film, exposure, object to film distance must be as stipulated in the standard and multiple images are to be acquired along the film, at the centre and on the sides of the film.

Reproduced from [12] with permission from Rightslink CCC

Typical schematic of a BPI.

7.4.3 Sensitivity Indicator (SI) for Neutron Radiography as per ASTM E2023-19

The contrast that an image is able to reproduce of the internal features in a sample is of utmost importance as it provides quantifiable value regarding the quality of the whole imaging chain. The idea is to characterize the ability of the imaging chain towards reproducing minor transparency differences, as per the probe radiation, as features in the sample in terms of image. Sensitivity contrast in an image is defined by the minimum discernible variation detected. Same feature in a sample will provide different contrast for different materials and also with varying thickness. As an example, if an object has some features say holes with varying diameter, very small to large either through its depth or upto some length, the contrast for each feature will be different and can be deduced using simple mathematics and image data values. ASTM E2023-19 [30] standard is available regarding the performance of such an exercise in finding out the minimum detectable sensitivity the imaging chain can faithfully produce in terms of image. According to the standard, a test piece (shown in Fig. 7.5) made up of highly crystalline linear polymer, lead and aluminium having step wedges of different thickness with gaps and holes of known dimensions are imaged in a neutron radiography facility using direct technique. Lead is an optional and can be replaced by acrylic. Various parameters such as optical density of film, exposure, object to film distance must be as stipulated in the standard and multiple images are to be acquired along the film, at the centre and on the sides of the film.

Reproduced from [12] with permission from rightslink CCC

Typical schematics of a typical sensitivity indicator as per ASTM E2023-19.

7.4.4 Beam Divergence and Alignment Measurement of Radiography Beams as per ASTM E2861-16 (2000)

Divergent collimators serve as beam guides for neutron to travel from the source to the image plane in any neutron radiography facility. For medium to high flux sources such as a reactor and spallation, the L/D is large and the divergence is less. But in case of low flux sources such as thermal neutron assembly using DD/DT neutron generator and isotopic sources large L/D is not realizable as the thermal neutron fluence rate reduces drastically with increasing L or decreasing D. In such cases, imperfect beam alignment and divergence may introduce errors in the image analysis. In this direction, ASTM E2861-16 [30] has been developed towards determining beam centreline and its divergence. This was developed as an extension to ASTM E803 related to L/D evaluation. Since the divergence and alignment of the beam, which has circular cross-section at any point, are estimated from the image of the test piece, its shape is also circular. The test piece, as shown in Fig. 7.6, is a circular aluminium plate having very thin cadmium wires (<1 mm) in circular and radial fashion in machined grooves on one side of the plate. The radial ones forms an “X” aligned with the centre of the plate. The design is done to make the test piece symmetric for ease of the fabrication process as well as image calculation. Also it has 5 numbers of symmetrically placed cylindrical Al rods including one at the centre of the plate, with cadmium wire inserts at their centre, fixed perpendicular on the other side of the plate. The details regarding the preparation of the test piece are provided in Section 10 of the standard. The test piece must be placed centrally in the beam and perpendicular to the beam direction with the cylindrical Al rods facing the imaging device. The cadmium wires provide enough attenuation and provide good contrast. Measuring the Cd wire positions in the image with respect to the centre of the circular plate, imaging device misalignment with the beam can be estimated and corrected if required. The positional measurement of the radial cadmium wires at the intersection with the circularly symmetric ones will provide information regarding the divergence in the beam. Necessary formulas are provided in the document E2861-16 (2000).

Reproduced from [30] with permission from Rightslink CCC

Images of the two surfaces of the circular Al plate (left) with Al cylinder rods having Cd inserts and (right) symmetric arrangement of circular as well as radial cd wires in machined grooves on the other side of the plate.

7.5 Personnel Qualification

Neutron imaging can be carried out using neutrons from research reactors, isotopic sources and accelerator-based such as neutron generators and spallation sources. Neutron interacts with the elements via nuclear interaction mechanism. Being energetic and having high interaction cross-section with low Z materials, their use is guided by rules and regulations to avoid any untoward incidence causing risk to human life, environment and property. On an average, 60% of the human body is composed of water. Neutrons are highly attenuated by hydrogenous materials such as water and are more prone to deposit their energy in it. As the radiation weighting factor for neutron ranges 5–20 times in comparison to X-ray/gamma rays, the effect of neutrons on humans is much more severe. Experimental evidences [32] have suggested that neutrons affect human DNA sequence leading to cell death.

Here lies the requirement of qualified personnel in avoiding such hazards. Since neutron production is inherently associated with gamma ray production either inherent with source or neutron-induced interactions with surrounding materials, shielding of such sources is also important towards human safety. In case of using reactor beamline for neutron-related investigations, there are various safety mechanisms integrated such as inner gate, outer gate, beamline hutch entry/exit door, interlocked towards implementing the safety mechanism. Also in the case of accelerator-based neutron production facilities, safety mechanisms such as interlocks for beam, door, cooling, vacuum and emergency are strictly put in place and in failure of any of one of them the neutron production is halted. Qualified personnel is required to carry out such multiple checks ensuring the highest safety standards. But while handling isotopic sources (Am-Be, Pu-Be), extra care must be taken as they emit neutrons all the time, depending upon the source emission rate, and also isotropically. Though they are always encapsulated by neutron-absorbing materials such as Borax or borated polythene block, except while using care must be taken to ensure no radiation exposure to any personnel present nearby. Hence, knowledge of handling such sources is of utmost importance. Since neutron imaging is a non-destructive procedure, the personnel working in this domain including dosimetry is trained as per the guidelines of standards available for non-destructive testing (NDT).

Available standards for training, certification and working in the NDT domain are as follows.

ISO 9712:2012—Non-destructive testing, qualification and certification of NDT personnel.

ANSI/ASNT CP-189 1995—American national standard for qualification and certification of personnel.

EN 45013: (1989)—General criteria for certification bodies operating certification of personnel.

ISO/IEC 17024: 2012—conformity assessment—General requirement for bodies operating certification of persons.

Recommended practice M: SNT-TC-IA 1996—published by American Society for Non-destructive testing, USA.

IAEA TECHDOC 628 (1991): Training guidelines in NDT techniques, Published by the IAEA, Vienna, Austria.

ISO 9712:2012 has been prepared by technical committee ISO/TC 135, subcommittee SC7. This certification covers radiography testing including other NDT topics. Basics to in-depth knowledge along with practical hands or experience are provided by accredited bodies through professionals in this domain to entail the trainees to handle radioactive sources, radiation facilities and related instruments including their calibration perform management activities related to radiation protection and, database management. In addition, specific laboratories can provide in-depth knowledge of their work and make them competent. Upon successful completion of the training expertise of the candidate must be established to enable them handle and supervise radiation-related jobs.

All radiation facilities from university to private to government laboratories based on internationally approved guidelines make their own framework to choose/training/accredit personnel to perform radiation-related jobs as radiation safety officer (RSO)/ health physicist (HP)/radiography testing personnel (levels-1/2/3) [33].

According to the American Academy of Health Physics and Radiation Safety Operation Section of the Head Physics Society [34], first and foremost, the university management must establish RSO qualification, certification, licensing, previewing procedures along with sufficient resource and support to enable their sustainability as and when their programme demands.

For national laboratories, in accordance with the norms laid upon by IAEA and the national body responsible for such personnel are trained and provide authorization to render service. For private bodies in a country, the responsible body takes care of the training, certification and authorization of personnel in the respective domain.

Atomic Energy Regulatory Board (AERB), a Government of India body in the sole competent authority in India towards authorization of license, inspection and operation of equipment/facilities and personnel involving radioactive material. Certification of Radiography inspection personnel and site-in-charge is done by AERB through Radiological Physics and Advisory Division of Bhabha Atomic Research Centre (BARC), Mumbai, India. It may be noted that RT levels-1, 2, 3 certification is independent of AERB and does not cover licensing.

In India, IS 13805: 2004 specifies the general standard for qualification and certification of non-destructive testing personnel for various NDT methods such as acoustic emissions testing (AT), Eddy current testing (EDT), liquid penetrate testing, leak testing (LT), magnetic particle testing (MPT), neutron radiography testing (NRT), radiography testing (RT), infrared testing (IRI), ultrasonic testing (VT), vibration analysis testing and visual testing (VT).

In India, Radiography testing level-1 (RT-1) started way back before 1994. Some of the topics included in the training courses were general concepts of RT, equipment and radiation sources, photographic and non-photographic recording, radiography technique selection, standard and test methods, radiation safety including regulatory aspect, energy response plan and preparedness. On successful completion of RT-1 course, the candidate is allowed to work as a Certified Radiographer, subject to the approval of AERB.

Radiography testing level-2 (RT-2), training in being handled by Isotope and Radiation Application Division of BARC. BARC RT LEVEL-2 extensively covers Radiation safety as specified in AERB/RF/Training-Syllabi/2012 approved by AERB. Successful completion of this training course will qualify the candidate, subject to approval/authorization of AERB, as designated Radiological Safety Officer (RSO) and to procure radiation sources/equipment for radiography practise in the country. The guidelines are set by ISO 9712: 2012/BIS: IS-13805. Eligibility criteria for BARC-RT-LEVEL-2 training and related information is available in www.barc.gov.in/careers/information-brochure-rtl2.pdf all course structures are guided by Recommended Practice no: SNT-TC-IA which provides guidelines for employees to establish in-home certificate programme for the qualification and certification of NDT personnel.

In India, the training programme centres for RT (1, 2 and 3) are as follows [35].

RT 1 and 2: IXAR, industrial X-ray and allies’ radiographers PVT Ltd. (www.IXAR.in) Jogeshwari (w) Mumbai, Maharashtra, 400012.

RT 1 and 2: Quality NDT services, Pune, Maharashtra, 411026.

RT 1: IRC Engineering services, New Delhi, 110019 (www.ircengg.com).

RT 1 and 2: Indian society for Non-destructive Testing, Tiruchirappalli, chapter, Trichy-14 (www.isnttrichy.org).

RT 3: ISNT, Mumbai chapter, Andheri (E), Mumbai—400059.

The America society of non-destructive testing (ASNT) offers personnel training publication pertaining to radiography testing (RT). ASNT conducts NDT level-2 and Level-3, IRRSP (Industrial Radiography Radiation Safety personnel), ACCP (ASNT central certification programme) level-2 and level-3 training courses. Code of Ethics for NDT Personnel has been clearly mentioned in ISO 9712–2012 and equivalent standards mentioned in IAEA TECDOC 626 and IAEA TECDOC 628/Rev. 3 (2013) and are to be followed with integrity and professional competence as a rule [36].

References

https://inis.iaea.org/collection/NCLCollectionStore/_Public/36/097/36097704.pdf?r=1&r=1. Accessed date: 13/05/2021

ICRP (2007) The 2007 recommendations of the International Commission on Radiological Protection. ICRP Publication 103. Ann ICRP 37(2–4).

Choudhary S (2018) Deterministic and stochastic effects of radiation, cancer therapy. Oncol Int J Short Commun 12(2)

Radiation shielding of fusion systems (2010) Thesis by Andrew Davis. University of Birmingham Research Archive, Apr 2010

Shukla M et al (2016) Neutron imaging beamline for advanced imaging applications at Dhruva reactor, India. Non-destructive evaluation 2016, page 226–231

Shukla M, Roy T, Kashyap Y, Shukla S, Singh P, Ravi B, Patel T, Gadkari SC (2018) Development of neutron imaging beamline for NDT applications at Dhruva reactor, India. Nucl Instrum Methods Phys Res Sect A: Acceler Spectrometers Detect Associat Equipm 889:63–68

Jensen SR, Craft AE, Papaioannou GC, Empie WW, Ward BR, Batt LA (2019) Restart of the transient reactor test (TREAT) facility neutron radiography program. Nucl Technol 205(10):1325–1335. https://doi.org/10.1080/00295450.2019.1605780

Craft A, Schillinger B, Chuirazzi W, Papaioannou G, Smolinski A, Boutlon N (2020) First neutron computed tomography with digital neutron imaging systems in a high-radiation environment at the 250 kW neutron radiography reactor at Idaho National Laboratory. In: Materials research proceedings, vol 15, pp 42–47. https://doi.org/10.21741/9781644900574-7 (Open Access)

https://www.osha.gov/ionizing-radiation/control-prevention. Accessed date: 19/05/2021

https://www-pub.iaea.org/MTCD/publications/PDF/Newsletters/SSDL-NL-37.pdf. Accessed date:19/05/2021

www.astm.org. Accessed date: 19/05/2021

Morgan S, King J (2013) Beam characterization at the neutron radiography facility. In: Nuclear engineering and design, vol 265, pp 639–653

Westcott CH, Walker WH, Alexander TU (1958) Proceedings of 2nd conference on peaceful uses atomic energy, Geneva, vol 16, p 70

Ryves TB (1969) A new thermal neutron flux convention. Metrologia 5:119

Sathian V, Tripathi SM, Ghodke S, Singh Y, Shaiju L (2008) The performance evaluation studies of neutron detectors used in Indian nuclear reactors. BARC Report BARC/2008/I/010

Hargrove CK, Geiger KW (1964) A new thermal neutron flux density standard. Canad J Phys 42

Evaluated Nuclear Structure Data File (ENSDF) (2014) National nuclear Data Center. Brookhaven National Laboratory. www.nndc.bnl.gov/ensdf/

Shukla M, Roy T, Kashyap Y, Shukla S, Singh P, Ravi B, Patel T, Gadkari SC (2018) Development of neutron imaging beamline for NDT applications at Dhruva reactor, India. Nuclear Inst Methods Phys Res A 889:63–68

Craft AE, Hilton BA, Papaioannou GC (2016) Characterization of a neutron beam following reconfiguration of the neutron radiography reactor (NRAD) core and addition of new fuel elements. Nucl Eng Technol 48(1)

Becker H et al (2015) Neutron production and thermal moderation at the PSIUCN source. Nucl Instrum Methods Phys Res Sect A: Accel Spectrom Detect Assoc Equip 777:20–27. ISSN 0168-9002

Yue AT, Anderson ES, Dewey MS, Gilliam DM, Greene GL, Laptev AB, Nico JS, Snow WM (2018) Precision determination of absolute neutron flux. Metrologia 55(4)

Csikai J (1987) Handbook of fast neutron generators. CRC Press Inc., Boca Raton, vols I, II

Melent’ev VI, Ovechkin VV (1978) The 27Al(n, p)27Mg cross section for 14.9-MeV neutrons. Energy 44:183. https://doi.org/10.1007/BF01124710

Jarjis RA (1981) Some activation measurements with 3H(d, n)4He neutrons. Nucl Inst Methods 184(2–3):439–444

Shiokawa T, Yagi M, Kaji H, Sasaki T (1968) The 19F(n,2n)18F reactions as a 14 MeV neutron flux monitor. J Inorg Nucl Chem 30:1–4

Ikeda Y, Verzilov YM, Filatenkov (KRI) AA, Smith (ANL) DL, Maekawa F, Oychma Y (1995) Recent activities on (n, a) cross section measurements in the 14 MeV region at JAERI FNS, IAEA-RCM (Sendai, 1995), Attachment3

Sadler G, Jarvis ON, van Belle P, Pillon M (1990) Use of the 28Si(n, p)28Al reaction for the measurement of 14 MeV neutrons from fusion plasmas. Rev Sci Instrum 61:3175. https://doi.org/10.1063/1.1141678

ASTM E 2339: Standard practice for DICONDE (https://www.astm.org/Standards/E2339.htm)

Pang D, Berman BL, Chasovskikh S, Rodgers JE, Dritschilo A (1998) Investigation of neutron-induced damage in DNA by atomic force microscopy: experimental evidence of clustered DNA lesions. Radiat Res 150(6):612–618

RSO (2004) Training course on safety aspect in the research application of Ionizing radiation. In: Atomic energy (radiation protection) rules, by RPAD, BARC. https://www.aerb.gov.in/english/rso-training

www.aahp-abhp.org/sites/default/files/2018-06/SQP-001.pdf. Accessed on 24/05/2021

Sahoo S, Viswakarma RS, Palani Selvam T, Babu DAR (2014) Training and certification status of BARC-1 course. In: NDE 2014, Dec 4–6, Pune

Guidelines on training, examination and certification in digital industrial radiology testing (RT-D). IAEA training course series, No. 60. https://www-pub.iaea.org/MTCD/Publications/PDF/TCS-60_web.pdf

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Sarkar, P.S. (2022). Safety, Regulations, Metrology and Standards in Neutron Imaging. In: Aswal, D.K., Sarkar, P.S., Kashyap, Y.S. (eds) Neutron Imaging. Springer, Singapore. https://doi.org/10.1007/978-981-16-6273-7_7

Download citation

DOI: https://doi.org/10.1007/978-981-16-6273-7_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6272-0

Online ISBN: 978-981-16-6273-7

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)