Abstract

Stability of Earth and Rockfill Dams under steady-state seepage and rapid draw-down conditions largely depends upon the flownet generated in the core of dam. Direction of flow lines in flow direction or in reverse direction of flow in core may destabilize the factor of safety of dam. An analytical study has been undertaken to evaluate and compare the variation in the flownet under Steady-State Seepage and Rapid Draw-Down in the core of a dam on account of variation in the thickness of core. A 180 m high earth and rockfill dam section, founded on strong base, was used as a base section for analysis. The flow lines were obtained for Steady-State Seepage under full reservoir condition and Rapid Draw-Down (Hdd = H/2) using software (which employs FEM technique). It is observed that for thin and thick core, the direction of flow lines in core are always from upstream slope to downstream slope under Steady-State Seepage, while for all cases of Rapid Draw-Down for Hdd = H/2 condition, when the vertical core is very thin, bulk of the flow lines are towards downstream slope and some are towards upstream slope. As the thickness of core increases, more flow lines are observed towards upstream face including below draw-down level. Stability analysis shows that the factor of safety is constant for core thickness in the range of 1.0 V: 0.25 H to 1.0 V: 0.50 H for steady-state seepage and from 1.0 V: 0.25 H to 1.0 V: 0.75 H under rapid draw-down condition. However, after this range, there is a decrease in factor of safety. The rate of decrease in the factor of safety is also observed to be similar in both conditions.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Construction of earth and rockfill dams are most suitable when there is abundance of fine-grained and coarse-grained materials at site [1,2,3,4]. Core of earth and rockfill dam provides imperviousness and the shell provides the stability to the dam [11, 13,14,15]. If there is abundance of fine-grained materials and coarse-grained materials at site, there is a possibility to construct dam with various thicknesses of core depending upon the availability of construction materials. In steady-state and rapid-draw condition of dam, the stability of outer slopes depends upon various factors, i.e., the strength parameters of core and shell materials, imperviousness of core, and flow direction of flow lines in particular condition [5,6,7,8,9,10].

2 Objective

The objective of the study was to compare variation in the flownet under Steady-State Seepage and Rapid Draw-Down in the core of a dam on account of variation in the thickness of core and its effect on the stability of dam. FEM analysis (Rocscience [12]) was carried out for different thicknesses of core to see how the magnitude and direction of flowlines vary and its effect on stability.

3 Section of Dam and Parameters Used

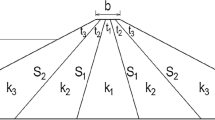

A dam section of height 180 m with flat base and founded on strong foundation was selected for the present study. A simplified dam section adopted is shown in Fig. 1. The parameters adopted in the present study are:

Shell materials:

c’ = 0 kN/m2, ϕ = 42° (for SSS and RDD).

Core material:

c’ = 0kN/m2, ϕ = 42° (for SSS and RDD).

Parametric studies on the following parameters were carried out for:

-

a.

Thickness of core: Starting from 25% of dam height to full base width

-

b.

FEM analysis for various thicknesses of core

-

c.

Levels of draw-down: H/2.

4 Analysis (Comparison of Flownets)

4.1 Variation of Flow Lines Under Steady-State Seepage

The flow lines of earth and rockfill dam were obtained by treating the shell material as highly pervious (without head loss) in comparison to core material. The flow lines were obtained by performing seepage analysis using software (which employs FEM techniques) for different thickness of core under steady-state seepage as shown in Fig. 2 under full reservoir condition. It is inferred from the figure that for all thicknesses of vertical core, the flowlines are directed towards downstream slope of core, and where these flow lines emerge from the core, the flow line is parallel to the outer slope of the core on the downstream side. For the thin core, flow lines are relatively horizontal, and the top line (phreatic line) meets the downstream slope near the top of the downstream face.

4.2 Variation of Flow Lines Under Rapid Draw-Down

The flow lines were obtained by performing seepage analysis using software (which employs FEM techniques) for different thickness of core under rapid-draw-down (Hdd = H/2) as shown in Fig. 3. It is observed from the figure that for all cases of rapid-draw-down, when the core is very thin, bulk of the flow lines are toward downstream slope and some are towards upstream slope. As the thickness of the core increases, more flowlines are towards upstream slope including draw-down level. When the vertical core is thick, flowlines in half the flow space are towards downstream face of core and the flowline in other half of space are toward upstream face.

5 Effect Flownet on Stability Analysis

5.1 Effect Flownet on Stability Analysis Under Steady-State Seepage

Stability analysis for downstream slope of dam was carried out for the core thickness of 25% of dam height to full width of dam using numerical modeling. The results from Fig. 4 shows that upto a slope of vertical core from 1 V: 0.125 H to 1 V: 0.50 H (100% thickness of core at bottom), there is no change in factor of safety because failure surface passes through the shell. Beyond U/s and D/s of core slope of 1 V: 0.50 H, the factor of safety begins to decrease as the failure surface passes through the core. The minimum factor of safety is obtained when the D/s slope of the core merges with the outer slope of the core. The factor of safety is close to tanф/tanβ (γb/γt) which is valid for flow parallel to outer slope in infinite slope.

5.2 Effect Flownet on Stability Analysis Under Rapid Draw-Down

Stability analysis for upstream slope of dam was carried out for the core thickness of 25% of dam height to full width of dam using numerical modeling. The results from Fig. 5 shows that upto a slope of vertical core from 1 V: 0.125 H to 1 V: 0.75 H (150% thickness of core at bottom), there is no change in factor of safety because failure surface passes through the shell. Beyond U/s and D/s of core slope of 1 V: 0.75 H, the factor of safety begins to decrease as the failure surface passes through the core. The minimum factor of safety is obtained when the U/s slope of the core merges with the outer slope of the core. The factor of safety is close to tanф/tanβ (γb/γt) which is valid for flow parallel to outer slope in infinite slope.

6 Discussions

It is observed for downstream slope of dam under steady-state seepage condition there is no change in factor of safety as long as the D/s and U/s slopes of vertical core is from 1 V: 0.125 H to 1 V: 0.50 H (100% thickness of core at bottom) because slip surface passes through the shell (highly pervious) and there is not any development of pore water pressure in shell material. Beyond U/s and D/s of core slope of 1 V: 0.50 H, the factor of safety decreases because the slip surface passes through the core and thus there is development of pore water pressure. As the thickness of core increases further, magnitude of flow lines increases towards downstream slope of dam and thus further decreases the factor of safety till the D/s and U/s slopes of vertical core merges with the outer slopes of dam. In a similar manner for upstream slope of dam under Rapid Draw-Down condition, as long as the core thickness is such that the vertical core of slope is steeper than 1 V: 0.75 H, there is no influence of core on stability of upstream slope of dam because the slip surface passes through the shell (highly pervious). Beyond this, the slip surface passes through the core because of that there is development of pore water pressure and thus factor of safety decreases. As the thickness of core increases further, magnitude of flow lines in reverse direction, i.e., towards upstream slope increases and factor of safety continue to decrease till upstream slope of core merges with the upstream slope of dam.

7 Conclusions

Factor of safety under steady-state seepage and rapid draw-down condition depends upon the magnitude and direction of flow lines. Also, after a critical thickness of core when slip circle passes through the core, the factor of safety decreases and continue to decrease till the U/s slope and D/s slope of core merges with the U/s slope and D/s slope of dam.

References

Datta, M.: Design of Beas dam embankment. Int. Water Power Dam Constr. J. Lond. 31 (6), 58–63 (1979)

Datta, M., Gulhati, S.K.: The influence of core thickness and inclination on stability of dams. In: Proceedings of the 9th Asian Regional Conference on Soil Mechanics and Foundation Engineering, Bankok, Thiland, vol. 1, pp. 227–234 (1991)

Datta, M., Kumar, M., Tankha, A.: The effect of core size and position on the slope stability of zoned embankment dams. Ground Eng. J. 27(9), 29–33 (1994)

Gulati, S.K., Datta, M.: Geotechnical Engineering. Tata McGraw- Hill, New Delhi (2005)

Khanna, R. et al.: End-of-construction stability of earth and rockfill dams having vertical core. In: Indian Geotechnical Conference, Kakinada, India (2014)

Khanna, R., et al.: Influence of thin core on stability of upstream slope of earth and rockfill dams. Electron. J. Geotech. Eng. Bundle U 2014, 6293–6305 (2014)

Khanna, R., et al.: Influence of thickness of vertical core on slope stability of earth and rockfill dams. J. Dams Reserv. 24(4), 152–167 (2015)

Khanna, R. et al.: Influence of core thickness on stability of upstream slope of earth and rockfill dams under rapid-draw-down. In: Indian Geotechnical Conference, Pune, India (2015)

Khanna, R. et al.: Influence of core thickness on stability of downstream slope of earth and rockfill dams under steady-state-seepage. In: 19th Southeast Asian Geotechnical Conference and 2nd AGSSEA Conference (19SEAGC & 2AGSSEA). Kuala Lumpur (2016).

Khanna, R. et al.: Influence of core thickness on stability of downstream slope of earth and rockfill dams under steady-state-seepage. Int. J. Geotech Eng. (2017)

Kutzner, C.: Earth and Rockfill Dams. Oxford and IBH Publishing, New Delhi (1997)

Rocscience.: SLIDE 5.0. Manual of SLIDE 5, 2D limit equilibrium slope stability analysis (2006)

Sherard, J.L., et al.: Earth and Rockfill Dams. Willy, New York (1963)

Singh, B., Varshney, S.R.: Engineering for Embankment Dams. Oxford and IBH Publishing Company, New Delhi. (1995).

Singh, B., Sharma, H.D.: Earth and Rockfill Dams. Sarita Parkashan, Meerut (2004)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Khanna, R., Chitra, R. (2022). Comparison of Flownets for Varying Thickness of Vertical Core Earth and Rockfill Dam Under Rapid Draw-Down and Steady-State Seepage and Its Effect on Stability Using Numerical Modeling. In: Satyanarayana Reddy, C.N.V., Krishna, A.M., Satyam, N. (eds) Dynamics of Soil and Modelling of Geotechnical Problems. Lecture Notes in Civil Engineering, vol 186. Springer, Singapore. https://doi.org/10.1007/978-981-16-5605-7_10

Download citation

DOI: https://doi.org/10.1007/978-981-16-5605-7_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-5604-0

Online ISBN: 978-981-16-5605-7

eBook Packages: EngineeringEngineering (R0)