Abstract

Three concrete mixes with different water-to-binder ratios and dosages of cement replacement materials (fly ash and slag powder) were exposed to alternate carbonation and freezing–thawing actions. The compressive strength, dynamic elastic modulus and mass of all specimens were measured and analyzed, also compared to the results obtained from the carbonation-only and freezing–thawing-only cases. Test data show that the relative compressive strength, the relative dynamic elastic modulus and the mass of concrete specimens exposed to carbonation-only cases increase with the carbonation time due to sufficient carbonation reaction, whereas they decrease with the corresponding testing time whenever they are exposed to freezing–thawing-only cases or alternate regimes. Additionally, under the same freezing–thawing numbers, the concrete specimens exposed to alternate regimes have slightly higher relative compressive strength, lower relative dynamic elastic modulus and larger mass loss than that exposed to freezing–thawing-only cases. Based on the obtained dynamic elastic modulus from the above different environmental cases, a damage mechanics fitting model of concrete considering alternate carbonation and freezing–thawing actions were established with high reliability.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Concrete

- Alternate carbonation and freezing–thawing actions

- Relative compressive strength

- Relative dynamic elastic modulus

- Mass

- Damage mechanics fitting model

1 Introduction

In concrete industry, more and more researchers realize that the deterioration of concrete cannot be really reflected just by simulating the single environmental factor in laboratory [1,2,3]. Therefore, some research efforts have begun investigating the concrete deterioration process considering the combined actions of various factors. Ramezanianpour et al. developed an environmental chamber to simulate tide cycles, and investigated the microscopic and mechanical properties of ordinary concrete exposed to CO2 gas, saline water, and the combination of CO2 gas and saline water by an accelerated test method [4]. David et al. proposed a numerical approach TransChlor to stimulate the realistic microclimatic conditions, and investigated the transportation phenomena of various substances in concrete [5, 6].

In cold regions, the reinforced concrete structures always subject to the coupling damage actions of freezing–thawing and CO2 gas in their surrounding environment. The material and structural integrity of concrete are seriously affected by the actions of freezing–thawing [7], and CO2 gas destroys the high pH environment of concrete pore solution which protects the steel bars of reinforced concrete from corrosion [8]. Therefore, the durability of concrete subjected to the combined actions of carbonation and freezing–thawing is important and needs to be studied.

Xiao et al. measured the mass loss rate and relative dynamic elastic modulus of concrete specimens subjected to alternate freezing–thawing and carbonation actions, showing that their combined actions accelerated the concrete damage [9]. Zhao et al. investigated the durability and pore structure of concrete exposed to freezing–thawing and carbonation in turn, showing that carbonation improved the freezing resistance of concrete in the early period, but the trend was reversed in the later period [10]. Jiang et al. investigated the frost and carbonation resistance of concrete with different water to cement ratios and fly ash contents under alternate freezing–thawing and carbonation actions, showing that the carbonation depth of concrete under the alternate actions didn’t follow a square root-of-time trend, also increased faster with alternate times [11].

From the above research efforts, it was found that the present experimental approaches on the alternate actions between freezing–thawing and carbonation were significant different, such as the sequences of test procedures, the duration time of each test, and the conditions of each test etc. Generally, the freezing–thawing test was always conducted at first in most previous research works, i.e. the concrete specimens had already been damaged before the carbonation test. This paper proposed an opposite experimental approach, i.e. the carbonation test was conducted at first, and then followed by the freezing–thawing test to simulate the coupling effect of carbonation and freezing–thawing. It is believed that the new sequence of testing procedure reflects the real environment concrete experiences, since the hydration procedure and calcium hydroxide content at the surface of concrete trigger carbonation before freezing–thawing happens [12]. Moreover, the damage mechanics fitting model of concrete exposed to alternate carbonation and freezing–thawing actions is attempted to propose based on the relationship developed from the test results of single environmental factors.

2 Materials and Experimental Methods

2.1 Materials

Commercially available ordinary Portland cement (PO 42.5R) is used as binder in concrete, which satisfies the Chinese standard GB 175–2007 specification. Fly ash (FA) conforms to the category of Class F Grade I in the Chinese standard GB/T 1596-2005 specification. Slag powder conforms to the category of S95 in the Chinese standard GB/T 18046-2008 specification. The fine aggregate is unwashed ordinary natural sand, and its fineness modulus is 2.6, equivalent to medium sand, and conforms to gradation zone 2 in the Chinese standard GB/T 14684-2011 specification. The coarse aggregate is unwashed crushed limestone, which nominal size is 5–25 mm and apparent density is 2.821 g/cm3, conforms to the requirements of coarse aggregate in the Chinese standard GB 14685-2011 specification. The chemical admixture is polycarboxylates high performance water reducing agent. The mixing water is ordinary tap water.

2.2 Mix Proportions

Three concrete mixes were used to investigate the effect of alternate carbonation and freezing–thawing actions on mechanical properties of concrete, their mix proportions were shown in Table 1.

2.3 Casting and Curing

Different size concrete specimens were casted in the moulds according to the above mix proportions. The cube specimens measuring 100 × 100 × 100 mm were used to determine the compressive strength, and the prism specimens measuring 100 × 100 × 400 mm were used to measure the mass and dynamic elastic modulus. These specimens were demolded after 24 h, and all of them were left to cure in standard curing chamber (20 ± 2 ℃ and more than 95% relative humidity) for 56 days to start the relevant tests.

2.4 Experimental Methods

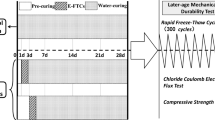

Based on the test procedures on carbonation-only and freezing–thawing-only cases in the Chinese standard GB/T 50082-2009 specification, the experimental approaches on alternate carbonation and freezing–thawing actions were as follows: the carbonation test was conducted first after the concrete specimens were dried in an oven at 60 ℃ for 48 h, and exposed to the environment of 20 ± 3% CO2 concentration, 20 ± 2 ℃ temperature and 70 ± 5% relative humidity for 7 days. Then, the specimens after carbonation test were immersed in water at 20 ± 2 ℃ for 4 days, then were left in the apparatus of freezing–thawing cycles, where the lowest freezing temperature was − 18 ± 2 ℃, and the highest thawing temperature was 5 ± 2 ℃. The time of every freezing–thawing cycle was about 3.5 h, and the corresponding cycle numbers were 50 (equivalent to 7 days). Then the compressive strength, mass and dynamic elastic modulus of concrete specimens were measured at each of the 6 times alternate.

3 Results and Discussions

3.1 Relative Compressive Strength of Concrete Exposed to Different Environmental Actions

Figure 1 showed that the relative compressive strength of concrete specimens exposed to carbonation-only cases increased with the carbonation time, largely due to carbonation leaded to the formation of important carbonation product (CaCO3) [4]. However, the relative compressive strength of concrete specimens exposed to freezing–thawing-only cases or alternate carbonation and freezing–thawing actions decreased with the corresponding testing time. Under the same number of freezing–thawing cycles, concrete specimens exposed to alternate regimes had slightly higher relative compressive strength than that exposed to freezing–thawing-only cases, especially at the early testing ages. This indicated that alternate actions did not degrade the concrete continuously like freezing–thawing-only cases, and 7 days’ carbonation would have a repairing effect on the strength loss of concrete after every 50 freezing–thawing cycles through carbonate deposition on its pores [13]. Therefore, carbonation improved the strength property of concrete [14, 15] degraded by freezing–thawing cycles. But it was worthy to note this effect reduced gradually with alternate repetitions, partially due to the narrowed pore structure in which carbonation filling exacerbates the freezing–thawing action.

3.2 Relative Dynamic Elastic Modulus of Concrete Exposed to Different Environmental Actions

Figure 2 showed that the relative dynamic elastic modulus of concrete specimens exposed to carbonation-only cases increased with the carbonation time due to sufficient carbonation reaction. However, the relative dynamic elastic modulus of concrete specimens exposed to freezing–thawing-only cases or alternate carbonation and freezing–thawing actions decreased with the corresponding testing time. Under the same number of freezing–thawing cycles, the relative dynamic elastic modulus of concrete specimens exposed to alternate regimes was lower than that exposed to freezing–thawing-only cases. With the extension of alternate repetitions, the relative dynamic elastic modulus decreased sharply, especially for C3 specimens. This could be due to concrete shrinkage occurred when CO2 gas penetrated into concrete and polymerized the silicate chains in C–S–H (which could decrease the volume, and consequently caused cracks) [16]. Building on the micro cracks caused by carbonation shrinkage, the freezing–thawing cycles contributed to their development, and yielded more microfractures [17]. Therefore, the alternate actions between carbonation and freezing–thawing cycles accelerated the frost damage of concrete, i.e. reduced the frost resistance of concrete.

3.3 Mass Change of Concrete Exposed to Different Environmental Actions

Figure 3 showed that the mass of concrete specimens exposed to carbonation-only cases increased slightly with the carbonation time. C2 specimens showed the largest mass increase, C3 specimens were the next, while C1 specimens were the least in mass increase. Some research results showed that the solid phase volume after carbonation increased 12–17% compared to its Ca(OH)2 volume, and led to a more compact concrete [18]. Moreover, the mass loss of concrete specimens exposed to freezing–thawing-only cases or alternate carbonation and freezing–thawing actions increased with the corresponding testing time. Under the same number of freezing–thawing cycles, the mass loss of concrete specimens exposed to alternate regimes was larger than that exposed to freezing–thawing-only cases. This indicated that the alternate actions between carbonation and freezing–thawing cycles accelerated the appearance damage of concrete.

4 Damage Mechanics Fitting Model of Concrete Exposed to Alternate Carbonation and Freezing–Thawing Actions

According to the concept of macroscopic phenomenological damage mechanics [19], the damage variable of concrete could be expressed as follows:

where D is the damage variable of concrete after certain deterioration actions; \(E_{d}^{i}\) is the dynamic elastic modulus of concrete after these deterioration actions; \(E_{d}^{0}\) is the dynamic elastic modulus of concrete before these deterioration actions.

4.1 Damage Mechanics Fitting Model of Concrete for Carbonation-Only Cases

The damage values of concrete exposed to carbonation-only cases were calculated via the above Eq. (1). Based on the damage data, a damage mechanics fitting model of concrete for carbonation-only cases was established as a logarithm expression, and actually it was a negative damage.

where D is the damage values of concrete after t days’ carbonation; t is the carbonation time; ac and bc are the fitting parameters, which could be determined via regression.

Table 2 showed that all of the R-square values of the fitting equations were 0.91 or more, which indicated an excellent correlation between carbonation time and concrete damage.

4.2 Damage Mechanics Fitting Model of Concrete for Freezing–Thawing-Only Cases

Similarly, the damage mechanics fitting model of concrete for freezing–thawing-only cases was established as a binomial expression.

where D is the damage values of concrete after N freezing–thawing-only cycles; N is the number of freezing–thawing-only cycles; af, bf and cf are the fitting parameters, which could be determined via regression respectively.

Table 3 showed that all of the R-square values of the fitting equations were 0.97 or more, which indicated an excellent correlation between the number of freezing–thawing-only cycles and concrete damage.

4.3 Damage Mechanics Fitting Model of Concrete Exposed to Alternate Carbonation and Freezing–Thawing Actions

Considering the relationship between the damage values of concrete exposed to alternate regimes and those exposed to carbonation-only and freezing–thawing-only cases, a multivariable linear function could be fitted through the obtained data.

where kc is the carbonation impact factor; kf is the freezing–thawing impact factor; k is the test constant; Dc, Df and Dc&f are defined as below, with i stands for the time of alternate repetition and 0 stands for the original strength. The fitted parameters were shown in Table 4.

Table 4 showed all of the R-square values of this damage mechanics fitting model were 0.98 or more, which indicated an excellent correlation among the carbonation time, the number of freezing–thawing cycles and concrete damage under alternate regimes. The completed damage mechanics fitting model of concrete exposed to alternate carbonation and freezing–thawing actions could be expressed as:

The significant test of the above equation was conducted via the F test statistics. Table 5 showed this damage mechanics fitting model of concrete was significant, i.e. the development of concrete damage under alternate carbonation and freezing–thawing cycles could be described via the data of concrete damage from the corresponding single environmental factors.

5 Conclusions

An experimental research on the influence of alternate carbonation and freezing–thawing actions on the mechanical properties and frost resistance of concrete was conducted. Through comparison with the experimental results obtained from carbonation-only and freezing–thawing-only cases, the following conclusions were reached:

-

(1)

The effect of carbonation on mechanical properties of concrete is complicated. Carbonation contributes to more compactness of concrete, whereas yields micro cracks at the surface of concrete due to carbonation shrinkage. This contributes strength increase at the early stage, but deteriorates quickly at later freezing–thawing cycles. Overall, the damage of concrete exposed to alternate carbonation and freezing–thawing actions is larger than that exposed to freezing–thawing-only cases.

-

(2)

The variation of relative dynamic elastic modulus and mass loss of concrete exposed to alternate carbonation and freezing–thawing actions is different with that of relative compressive strength. This indicates that these cracks or microfractures caused by carbonation are extremely small, which don’t yield adverse effect on the compressive strength of concrete at early stage, but increase the frost damage and appearance damage of concrete by the expansion of cracks from the surface to interior.

-

(3)

A damage mechanics fitting model of concrete exposed to alternate carbonation and freezing–thawing actions is expressed as a multivariable linear function, in which two independent variables (carbonation time and number of freezing–thawing) are taken into consideration.

References

Wu ZW (1991) Concrete durability syndrome and its prevention and treatment. Concrete:4–8

Sun W, Zhang YM, Yan HD (1999) Damage and its resistance of concrete with different strength grades under double damage factors. Cement Concr Compos 21:439–442

Sun W (2006) Durability and service life of structure concrete under load and environment coupling effects. J Southeast Univ (Nat Sci Edn) 36:7–14

Ramezanianpour AA, Ghahari SA, Esmaeili M (2014) Effect of combined carbonation and chloride ion ingress by an accelerated test method on microscopic and mechanical properties of concrete. Constr Build Mater 58:138–146

Conciatori D, Sadouki H, Brühwiler E (2008) Capillary suction and diffusion model for chloride ingress into concrete. Cem Concr Res:1401–1408

Conciatori D, Laferrière F, Brühwiler E (2010) Comprehensive modeling of chloride ion and water ingress into concrete considering thermal and carbonation state for real climate. Cem Concr Res:109–118

Qiao PZ, Chen FL (2013) Cohesive fracture and probabilistic damage analysis of freezing-thawing degradation of concrete. Constr Build Mater 47:879–887

Papadakis VG, Vayenas CG, Fardis MN (1991) Experimental investigation and mathematical modeling of the concrete carbonation problem. Chem Eng Sci 46:1333–1338

Xiao QH, Niu DT (2015) Damage model for concrete subjected to freeze-thaw cycles and carbonation. J Build Mater 18:763–766

Zhao GS, He Z, Yang HM (2013) Study of concrete durability under alternative effect of carbonization and freeze-thaw cycles. Eng J Wuhan Univ 46:604–609

Jiang LH, Na BB, Zhou XM, Wang T, Hu J, Xiong CS (2012) Tests for properties of concrete under alternate freeze-thaw and carbonation actions. Adv Sci Technol Water Resour 32:33–36

Glass GK, Page CL, Short NR (1991) Factors affecting the corrosion rate of steel in carbonated mortars. Corros Sci 32:1283–1294

Dias WPS (2000) Reduction of concrete sorptivity with age through carbonation. Cem Concr Res 30:1255–1261

Chang CF, Chen JW (2005) Strength and elastic modulus of carbonated concrete. ACI Mater J 102:315–321

Jerga J (2004) Physio-mechanical properties of carbonated concrete. Constr Build Mater J 18:645–652

Kropp TH, Hilsdorf HK (1989) The formation of silica gel during carbonation of cementitous systems containing slag cements. ACI J 114:1413–1428

Wang SR, Du X, Chen YL, Gao SS, Liang C, Ye PP (2015) Anti-frost property of concrete with different dosage of fly ash. J. Univ Shanghai Sci Technol 37:493–499

Fang J, Mei GX, Lu CR (1996) Influence of carbonation on properties of concrete. Water Resour Hydropower Eng:58–64

Li ZX (2002) Damage mechanics and its application. Science Press, Beijing

Acknowledgements

This research was funded by the Key Research Plan of Shandong Province, China (2019GSF109057).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ran, J., Feng, Q., Zhang, J., Wang, L., Cao, H. (2022). Mechanical Properties of Concrete Under the Alternate Carbonation and Freezing–Thawing Actions. In: Wang, W., Chen, Y., He, Z., Jiang, X. (eds) Green Connected Automated Transportation and Safety. Lecture Notes in Electrical Engineering, vol 775. Springer, Singapore. https://doi.org/10.1007/978-981-16-5429-9_8

Download citation

DOI: https://doi.org/10.1007/978-981-16-5429-9_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-5428-2

Online ISBN: 978-981-16-5429-9

eBook Packages: EngineeringEngineering (R0)