Abstract

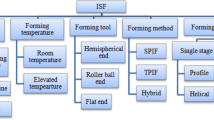

Incremental sheet metal forming (ISMF) is an innovative sheet metal forming in which not dedicated die is required. The paper is a review of the ISMF for its future research potential. The present study aimed to enlighten the innovative strategies used in the ISMF and highlighted the complexities that is still present in the ISMF. The key benefits of the ISMF are customer-orientated process, flexible manufacturing, and the part formation at low cost. With few advantages, the several difficulties are observed. The achievement of exact dimension i.e. geometrical accuracy, required surface finish, springback effect, forming of complex shape, prevention of thin sheet failure, optimized tool path, tool wear etc. are the major challenges in the ISMF. The causes for aforesaid difficulties are due to the variation in the process, undefined input variability, tool size, tool path, machines efficiency, etc. Wide recognition of this technique enumerates its prospects and the acceptability in industries. The current study enumerated the ISMF strategies and optimization technique has been reported by the researchers and directed to the area in which more concentrated study is required for the optimization of the ISMF.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kim YH, Park JJ (2002) Effect of process parameters on formability in incremental forming of sheet metal. J Mater Process Technol 130–131:42–46

Kim YH, Park JJ (2003) Fundamental studies on the incremental sheet metal forming technique. J Mater Process Technol 140:447–453

Shim MS, Park JJ (2001) The formability of aluminum sheet in incremental forming. J Mater Process Technol 113:654–658

Ambrogio G, Filice L, Fratini L, Micari F (2003) Some relevant correlations between process parameters and process performance in incremental forming of metal sheets. In: 6th international proceedings on ESAFORM. Salerno, Italy, pp 175–178

Jadhav S, Goebel R, Homberg W, Kleiner M (2003) Process optimization and control for incremental sheet metal forming. In: Proceedings of the international deep drawing research group (IRRDG). Bled, Slovenia, pp 165–171

Kopac J, Kampus Z (2005) Incremental sheet metal forming on CNC milling machine tool. J Mater Process Technol 162–163:622–628

Micari F, Ambrogiob G, Filice L (2007) Shape and dimensional accuracy in single point incremental forming: state of the art and future trends. J Mater Process Technol 191:390–395

Maidagan E, Zettler J, Bambach M, Rodríguez P, Hirt G (2007) A new incremental sheet forming process based on a flexible supporting die system. Eng Mater 344:607–614

Ambrogio G, Cozza V, Filice L, Micari F (2007) An analytical model for improving precision in single point incremental forming. J Mater Process Technol 191:92–95

Petek A, Jurisevic B, Kuzman K, Junkar M (2009) Comparison of alternative approaches of single point incremental forming processes. J Mater Process Technol 209:1810–1815

Franzen V, Kwiatkowski L, Martins PAF, Tekkay AE (2009) Single point incremental forming of PVC. J Mater Process Technol 209:462–469

Duflou JR, Callebaut B, Verbert J, Baerdemaeker DH (2007) Laser assisted incremental forming: formability and accuracy improvement. Ann CIRP Ann 5(1)

Duflou JR, Verberta J, Belkassem B, Gu J, Sol H, Henrard C, Habraken AM (2008) Process window enhancement for single point incremental forming through multi-step toolpaths. CIRP Ann Manuf Technol 57:253–256

Fan G, Gao L, Hussain G, Haoli J, Wu B (2008) Electric hot incremental forming: a novel technique. Int J Mach Tools Manuf:1688–1692

Hussain G, Gao L, Dar NU (2007) An experimental study on some formability evaluation methods in negative incremental forming. J Mater Process Technol 186:45–53

Wulfsberg JP, Terzi M (2007) Investigation of laser heating in microforming applying sapphire tools. Ann CIRP 56(1)

Malwad DS, Nandedkar VM (2014) Deformation mechanism analysis of single point incremental sheet metal forming. J Proc Mater Sci:505–1510

Reddy NV, Lingam R, Cao J (2015) Incremental metal forming processes in manufacturing. Springer-Verlag, Berlin Heidelberg

Pathak J (2015) A brief review of incremental sheet metal forming. Int J Latest Eng Manage Res:35–43

Soren S, Alexander P, Peter S, Sebastian M, Dieter W, Zdenek R (2019) Incremental sheet metal forming on the example of car exterior skin part. Proc Manuf 29:105–111

Dwivedy M, Kalluri V (2019) The effect of process parameters on forming forces in single point incremental forming. Proc Manuf 29:120–128

Scheffler S, Pierer A, Scholz P, Melzer S, Weise D, Rambousek Z (2019) Incremental sheet metal forming on the example of car exterior skin parts. Proc Manuf 29:105–111

Hartmann C, Volk W (2019) Knowledge-based incremental sheet metal free-forming using probabilistic density functions and voronoi partitioning. Proc Manuf 29:4–11

Dabwan A, Ragab AE, Saleh MA, Anwar S, Ghaleb AM, Rehman AU (2020) Study of the effect of process parameters on surface profile accuracy in single-point incremental sheet forming of AA1050-H14 Aluminum Alloy. Int J Adv Mater Sci Eng 14

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Toppo, B., Oraon, M., Roy, M.K. (2022). Incremental Sheet Metal Forming: The State of Art and Its Future Prospects. In: Agrawal, R., Jain, J.K., Yadav, V.S., Manupati, V.K., Varela, L. (eds) Recent Advances in Industrial Production. ICEM 2020. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-5281-3_27

Download citation

DOI: https://doi.org/10.1007/978-981-16-5281-3_27

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-5280-6

Online ISBN: 978-981-16-5281-3

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)