Abstract

We present a novel strategy to synthesize pure cubic garnet Li7La3Zr2O12 solid electrolyte at a relatively low temperature (700 °C) by two steps. During the process of obtaining Li7La3Zr2O12, the 8a oxygen vacancy in pyrochlore of La2Zr2O7 was used to occupy the “Li1” 8a site which the information of tetragonal phase Li7La3Zr2O12 requires lithium occupation. The lithium ion conductivity of the obtained cubic garnet Li7La3Zr2O12 as high as 1.7 × 10–4 S cm−1 at room temperature is consistent with the order of record conductivity in the literatures.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Solid-state electrolytes play an important role in power batteries that have large electrochemical windows, high energy densities and good electrochemical stabilities [1,2,3,4]. Among the oxide solid Li-ionic electrolytes, cubic garnets with nominal composition of Li7La3Zr2O12 (LLZO) have been extensively studied as one of the most promising candidate materials having high conductivities (∼10–3 S cm−1) at ambient temperature. The garnet-type LLZO was first reported by Murugan in 2007 [5]. It has two different crystal structures [6], one cubic termed as LLZOc, and the other tetragonal termed as LLZOt. It has been pointed out that LLZOc exhibits ionic conductivity two orders of magnitude higher than that of LLZOt. Furthermore, in the process of synthesizing LLZOc, there is always the existence of LLZOt, which limits its application in solid state lithium ion batteries [7]. Therefore, many efforts have been devoted to developing single-phase LLZOc.

Modified synthesis method and supervalent doping were considered as the main manners to stabilize the cubic crystal structure [8,9,10,11]. Hang et al. investigated the impact of temperatures on LLZOc synthesized with traditional solid state method, and found that the sintering temperature determines phase composition, and LLZOc was obtained when the temperature is above 1150 °C [12]. Subsequently, Rosenkiewitz et al. prepared LLZOc successfully by wet chemical techniques at 1000 °C [13]. Meanwhile, the supervalent doping was also effective in achieving the LLZOC. Thompson et al. showed the effect of substituting Ta5+ for Zr4+ on obtaining LLZOc, and demonstrated that 0.25 mol of Li vacancies per formula unit contributes to forming LLZOc [14]. Previous works have been mostly focused on modifying synthesis method and creating of Li vacancies by supervalent doping. However, these strategies take the way of changing tetragonal to cubic phase, instead of intrinsically avoiding the formation of tetragonal phase.

Herein, we report a novel strategy to directly obtain LLZOc by controlling the oxygen vacancy at 8a site in pyrochlore La2Zr2O7. As is well known, the 8a site in LLZO is an important Li vacancy resulting in the formation of LLZOc. If introduced a positive charge at the 8a position in LLZO, it can effectively prevent the Li ion occupying the 8a position and avoid from forming LLZOt. Using such strategy in this work, we obtained pure LLZOc successfully. Compared to traditional methods to synthesize LLZOc, our method features pure LLZOc obtaining by avoiding the generation of LLZOt and processing at a relatively low temperature. The LLZOc synthesized using our method demonstrates a decent lithium ionic conductivity of 3.7 × 10–4 S cm−1 for grain and 1.7 × 10–4 S cm−1 for overall.

2 Experimental Section

Chemicals: ZrOCl2·8H2O, La(NO3)3, LiNO3 and NH3·H2O were of analytical grade and purchased from Sigma-Aldrich, with 99.9% purity. Deionized water was used in all the experimental process.

Synthesis: Precursor A was prepared from ZrOCl2·8H2O and La(NO3)3, with molar ration of La3+:Zr4+ = 1:1. First, the two solution were mixed together and stirred for 10 min. Then, the mixture solution was added to dilute ammonia (ammonia: water = 1:2, volume ratio) with a titration rate of one drop per second. Under controlled pH = 10–11 with continuous stirring, a white complex precursor hydroxyl sol was formed, which could be represented as La(OH)3·Zr(OH)4·nH2O. It was then washed several times by centrifuge under a speed of 3000 r/min to remove Cl−. After being air-dried at 120 °C, the precursor A became dry powders. Precursor B was synthesized by hand-grinding 1 g of the single-source precursor A and 9 g of nitrate salt (6 g LiNO3 and 3 g La(NO3)3) with an agate mortar and pestle for a few minutes till fully mixed. The mixture was transferred into a covered nickel crucible and heated to a setting temperature for some time, then cooled to room temperature naturally. The hot ultrapure water was used to wash the product for separation and purification. After drying in an oven at 120 °C for some time, the target nano-powders, LLZOc, were obtained. The illustration of the process and formation mechanism of the LLZOc was shown in Fig. 1. In order to research their electrical performance, the LLZOc powders were pressed into pellets by universal testing machine under 200 MPa. The pellets were covered with LLZOc powders to compensate possible loss of lithium, and finally annealed at 1200 °C for 6 h in an alumina crucible.

Characterization: The crystal structure and phase purity of the samples were examined by means of X-ray Powder Diffraction using Bruker AXS D8-Focus with Ni filtered Cu Kα radiation (λ = 0.154056 nm). Raman spectra were obtained using Thermo Fisher Scientific Inc 5225 Verona Rd (USA) with a laser wavelength (780 nm) and the spectra were collected in an extended regime in the range of 100–600 cm−1. X-ray photoelectron spectroscopy (XPS) was carried out at bending magnet beamline 9.3.2 at the Advanced Light Source (ALS) in the Lawrence Berkeley National Laboratory (LBNL). XPS data of Li 1s, C 1s, O 1s, Zr 3d and La 4d were collected at 640 eV from the top surface of LLZO samples in ultrahigh vacuum with a sampling size of 1 mm in diameter. Binding energy correction of spectra was done by calibrating to the C 1s photoemission peak of adventitious hydrocarbons at 285 eV. The overview of the morphology and the grain size was checked by Field Emission Scanning Electron Microscope (FESEM; HITACHI SU8010). Electrical conductivity measurements were performed on the prepared circular pellets using Li-ion blocking Au-electrodes (Au pulp covering the pellets was cured at 550 °C for 30 min) over the room temperature using AC impedance spectroscopy (Soartron1287A/1260A, 10 mV; 0.1 Hz–1 MHz).

3 Result and Discussion

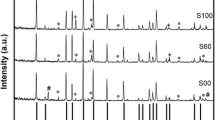

According to the strategy of obtaining LLZOc by use of oxygen vacancy, the pyrochlore La2Zr2O7 (LZOP) was an important intermediate product in this method. In order to characterize the process of phase transformation, XRD and micro-Raman spectroscopic were examined. Figure 2a shows the XRD patterns of the samples prepared at different temperature for 48 h. We found that the LZOP can be obtained at 600 °C which have two additional characteristic peaks (331) and (511) used to distinguish the defect fluorite from the pyrochlore [15]. When the calcination temperature is lower than 600 °C, only superlattice diffraction peaks of fluorite La2Zr2O7 (LZOF) were observed at 500 °C. While the temperature approaches to 700 °C, we found LZOP phase disappear, and a new phase of cubic garnet-type LLZO emerged.

3.1 Raman Spectroscopy

Raman spectroscopy is sensitive to metal–oxygen vibrational modes which can be used to distinguish the LZOF, LZOP and the phase purity of the LLZOc [16, 17]. To further confirm the phase structure, Raman was examined in Fig. 2b. It can be observed that there is only one peak Eg at 500 °C which could be described as defect fluorite (LZOF). From 500 to 600 °C, F2g and A1g were detected and Eg band became sharp. It indicated that the LZO was pure defect fluorite at 500 °C and pure pyrochlore at 600 °C. However, at 700 °C the wavenumbers 107 (T2g), 211 (T2g), 302 (T2g) and 401 (Eg/T2g) appeared, demonstrating the formation of pure cubic garnet structure with I43d space group. Raman spectroscopy results showed that the LZOF transformed to LZOP from 500 to 600 °C and to LLZOc from 600 to 700 °C, which is in good agreement with the XRD results.

3.2 XRD and FESEM Analysis

After sintering at 1200 °C for 6 h for the LLZOc pellet, XRD and FESEM analysis were performed to characterize the phase stability, and grain size distribution (Fig. 3). From Fig. 3a, it can be seen that the LLZOc remains cubic garnet structure. Figure 3b showed FESEM image of fracture surface of LLZOc pellet. In Fig. 3b, we observed the irregular block with the typical grain size distribution of 14–35 μm. At the same time, we recognize relatively low porosity, similar grain sizes were conducive to the conduction of Li ions [18]. The corresponding size distribution of LLZOc was shown in Fig. 3c. The average diameter of LLZOc grains were approximately 23 μm. Figure 3d showed a higher magnification micrograph of grains and grain boundary. The grain and grain boundary can be clearly distinguished which had a significance to analysis of response to electrical signal for the following AC impedance test [19].

XPS analysis was used to further understand the changes in the oxygen vacancies and binding energy of LZOP and LLZOc pellet surface. The spectra of O 1s, Zr 3d, La 4d and Li 1s are shown in Fig. 4. From Fig. 4a, it can be seen that the O 1s have two obvious satellite peaks at 529.1 eV and 53.4 eV of LZOP which corresponds to two oxygen sites at 48f and 8b, respectively [20]. The change in the O 1s XPS spectra from LZOP to LLZOc could be attributed to the structural transform from cubic pyrochlore to cubic garnet. While, it is noted that there is almost no change of Zr 3d and La 4d spectra in Fig. 4b, c. In general, the disorder of oxygen ions or oxygen vacancies will cause the La–O–La and Zr–O–Zr to change [20,21,22]. This can be explained by the ordered 8a oxygen vacancies of LZOP which are left in the LLZOc during the transition from LZOP to LLZOc, just like genetic inheritance. These genetic 8a oxygen vacancies are the key to prevent the formation of LLZOt and result in the LLZOc formation. Besides, we further observed weak peak at 52.6 eV of Li 1s for LZOP in Fig. 4d which demonstrated that a small amount of Li–O bond is present in the LZOP at 600 °C. After obtaining LLZOc at 700 °C, Li 1s peak exhibited a sharper peak and shifted to a higher binding energy from 52.6 to 55 eV. It could be a possible reason for forming strong Li–O bond and expansion of cell parameters after Li embedding into the space of LZOP. Therefore, it can be inferred from the XPS results that LLZOc inherited the 8a oxygen vacancies in LZOP, which can prevent the formation of tetragonal phase and directly obtain the cubic phase of LLZO.

3.3 The Formation Process from LZOF Transformed to LLZOc

According to XRD, Raman and XPS results, the schematic of the formation process from LZOF transformed to LLZOc can be illustrated in Fig. 5. For LLZOt, there are three different Li sites: “Li1” (8a) site occupied the center of tetrahedral, “Li2” (16f) site and “Li3” (32 g) site occupied the center of two different distorted octahedral [23]. In contrast, there are only two different Li sites in LLZOc: “Li1” (24d) site occupied the center of tetrahedral and “Li2” (96 h) site occupied the center of distorted octahedral [24]. Therefore, different Li site means different structure and phase of LLZO crystal. In this work, we use oxygen vacancy occupying 8a site to hinder the formation of LLZOt and contribute to obtain the LLZOc by use of pyrochlore La2Zr2O7 (LZOP).

As illustrated in Fig. 5, LLZOc was obtained as follows: (a) the defect fluorite La2Zr2O7 (LZOF) consists of 4 La occupied the 16d site, 4 Zr occupied the 16c site, 14 O occupied the 48f and 8b sites, and disordered oxygen vacancies; (b) after heating at 600 °C, the disordered oxygen vacancies located at 8a and the defect fluorite La2Zr2O7 (LZOF) transformed to LZOP; (c) when the temperature increases to 700 °C, the introduced Li occupied at 24d and 96 h, leading to and the formaiton of LLZOc. Therefore, we propose that oxygen vacancies are formed in LZOF first, then disordered and migrated to 8a position, giving rise to LZOP. At last, the Li embedded into the space outside the 8a position, enabling the formation of LLZOc. The process of forming LLZOc is shown in Fig. 5d–f.

3.4 AC Impedance Spectroscopy Analysis

The ionic conductivity of LLZOc at ambient temperature was determined by AC impedance spectroscopy of sintered pellet with attached symmetrical Au electrodes. A typical Nyquist plot of the LLZOc pellet measured at ambient temperature was displayed in Fig. 6a. The impedance data were fitted with an equivalent circuit shown in the inset of Fig. 6a. The grains resistance and grain boundary resistance are represented as Rg and Rgb in the equivalent circuit. Constant phase elements (CPE) were used to fit [25]. The formula σ = d/(A · R) was used to calculate the lithium ionic conductivity σ. Where d is the thickness of pellet, A is the area of Au electrodes and R is the value of fitted resistance by CPE [4]. The measurements showed an offset of the impedance response at high frequencies, a semicircle for intermediate frequencies, and a tail for low frequencies. We attribute these to grain resistance, grain boundary resistance, and double layer capacitance due to ion blocking by electrodes, respectively [26]. Arrhenius plot for frequency of the bulk ionic conductivity of LLZOc is shown in Fig. 6b. Notably, a high ionic conductivity of 3.7 × 10–4 S cm−1 for grain and 1.7 × 10–4 S cm−1 for overall, which is in good agreement with the literature [8, 10]. Compared with the modified synthesis method and supervalent doping method, the control of oxygen vacancy is a novel strategy to obtain pure LLZOc with high ionic conductivity.

4 Conclusion

In summary, we prepared pure LLZOc by utilize of oxygen vacancy of LZOP at 700 °C for the first time. In this process, we used oxygen vacancy occupied 8a site use of LZOP which formed LLZOt of L1 site, and then the introduced Li occupied 24d and 96 h site and formed LLZOc. Through this novel strategy, we can directly obtain pure phase LLZOc at lower temperature (700 °C), rather than the LLZOt by the traditional method. When the LLZOc was used as solid Li-ionic solid electrolytes, it exhibited a high conductivity of 1.7 × 10–4 S cm−1. In a word, this method provided a new idea for the synthesis of solid electrolyte materials with high ionic mobility.

References

Broek J, Af Yon S, Rupp J et al (2016) Interface‐engineered all‐solid‐state li‐ion batteries based on garnet‐type fast li+ conductors. Adv Energy Mater 6(19):1600736

Yu S, Schmidt RD, Garciamendez R et al (2016) Elastic Properties of the Solid Electrolyte Li7La3Zr2O12 (LLZO). Chem Mater 28(1):197–206

Zhang J, Zhao N, Zhang M et al (2016) Flexible and ion-conducting membrane electrolytes for solid-state lithium batteries: Dispersion of garnet nanoparticles in insulating polyethylene oxide[J]. Nano Energy 28(28):447–454

Zhang Q, Schmidt N, Lan J et al (2012) A facile method for the synthesis of the Li0.3La0.57TiO3 solid state electrolyte. Chem Commun 50(42):5593–5596

Murugan R, Thangadurai V, Weppner W et al (2007) Fast Lithium Ion Conduction in Garnet-Type Li7La3Zr2O12. Angew Chem 46(41):7778–7781

Liu C, Rui K, Shen C et al (2015) Reversible ion exchange and structural stability of garnet-type Nb-doped Li7La3Zr2O12 in water for applications in lithium batteries. J Power Sources 282:286–293

Han J, Zhu J, Li Y et al (2012) Experimental visualization of lithium conduction pathways in garnet-type Li7La3Zr2O12. Chem Commun 48(79):9840–9842

Thangadurai V, Narayanan S, Pinzaru D et al (2014) Garnet-type solid-state fast Li ion conductors for Li batteries: critical review. Chem Soc Rev 43(13):4714–4727

Quinzeni I, Capsoni D, Berbenni V et al (2017) Stability of low-temperature Li7La3Zr2O12 cubic phase: the role of temperature and atmosphere. Mater Chem Phys 55–64

Wagner R, Redhammer GJ, Rettenwander D et al (2016) Fast li-ion-conducting garnet-related Li7–3xFexLa3Zr2O12 with Uncommon I4̅3d Structure. Chem Mater 28(16):5943–5951

Mukhopadhyay S, Thompson T, Sakamoto J et al (2015) Structure and stoichiometry in supervalent doped Li7La3Zr2O. Chem Mater 27(10):3658–3665

Huang M, Liu T, Deng Y et al (2011) Effect of sintering temperature on structure and ionic conductivity of Li7−xLa3Zr2O12−0.5x (x = 0.5 ~ 0.7) ceramics. Solid State Ionics 204:41–45

Rosenkiewitz N, Schuhmacher JD, Bockmeyer M et al (2015) Nitrogen-free sol-gel synthesis of Al-substituted cubic garnet Li7La3Zr2O12 (LLZO). J Power Sources 278(278):104–108

Thompson T, Wolfenstine J, Allen JL et al (2014) Tetragonal vs. cubic phase stability in Al-free Ta doped Li7La3Zr2O12 (LLZO). J Mater Chem 2(33):13431–13436

Wang Y, Yang F, Xiao P et al (2014) Role and determining factor of substitutional defects on thermal conductivity: a study of La2(Zr1-xBx)2O7 (B = Hf, Ce, 0 ⩽ x ⩽ 0.5) pyrochlore solid solutions. Acta Materialia 68:106–115

Orera A, Larraz G, Rodriguezvelamazan JA et al (2016) Influence of Li+ and H+ distribution on the crystal structure of Li7-xHxLa3Zr2O12 (0 ≤ x ≤ 5) Garnets. Inorg Chem 55(3):1324–1332

Ou G, Liu W, Yao L et al (2014) High conductivity of La2Zr2O7 nanofibers by phase control. J Mater Chem 2(6):1855–1861

Ilina EA, Andreev OL, Antonov BD et al (2012) Morphology and transport properties of the solid electrolyte Li7La3Zr2O12 prepared by the solid-state and citrate-nitrate methods. J Power Sources 201:169–173

Huggins RA (2002) Simple method to determine electronic and ionic components of the conductivity in mixed conductors a review. Ionics 8(3):300–313

Pokhrel M, Wahid K, Mao Y et al (2016) Systematic Studies on RE2Hf2O7:5%Eu3+ (RE = Y, La, Pr, Gd, Er, and Lu) nanoparticles: effects of the A-Site RE3+ cation and calcination on structure and photoluminescence. J Phys Chem C 120(27):14828–14839

Cheng L, Crumlin EJ, Chen W et al (2014) The origin of high electrolyte-electrode interfacial resistances in lithium cells containing garnet type solid electrolytes. Phys Chem Chem Phys 16(34):18294–18300

Cheng L, Wu CH, Jarry A et al (2015) Interrelationships among Grain Size, Surface Composition, Air Stability, and Interfacial Resistance of Al-Substituted Li7La3Zr2O12 solid electrolytes. ACS Appl Mater Interfaces 7(32):17649–17655

Meier K, Laino T, Curioni A et al (2014) Solid-state electrolytes: revealing the mechanisms of li-ion conduction in tetragonal and cubic LLZO by first-principles calculations. J Phys Chem C 118(13):6668–6679

Yi E, Wang W, Kieffer J et al (2016) Flame made nanoparticles permit processing of dense, flexible, Li+ conducting ceramic electrolyte thin films of cubic-Li7La3Zr2O12 (c-LLZO). J Mater Chem 4(33):12947–12954

Rettenwander D, Welzl A, Pristat S et al (2016) A microcontact impedance study on NASICON-type Li1+xAlxTi2-x(PO4)3 (0 ≤ x ≤ 0.5) single crystals. J Mater Chem 4(4):1506–1513

Tenhaeff WE, Rangasamy E, Wang Y et al (2014) Resolving the grain boundary and lattice impedance of hot-pressed Li7La3Zr2O12 garnet electrolytes. ChemElectroChem 1(2):375–378

Acknowledgements

This work was financially supported in part by Department of Technology center of Dongfeng motor group Co. LTD (91224Y180014) and 928 project of Dongfeng motor group Co. LTD (912249282014).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Liu, M., Hu, Y., Shi, J., Cao, Y., Gong, Y. (2022). Synthesis of High Ion Conductivity Cubic Garnet Li7La3Zr2O12 Solid Electrolyte by Controlling the 8a Oxygen Vacancy. In: Proceedings of China SAE Congress 2020: Selected Papers. Lecture Notes in Electrical Engineering, vol 769. Springer, Singapore. https://doi.org/10.1007/978-981-16-2090-4_88

Download citation

DOI: https://doi.org/10.1007/978-981-16-2090-4_88

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-2089-8

Online ISBN: 978-981-16-2090-4

eBook Packages: EngineeringEngineering (R0)