Abstract

The crisis of conventional power generation is mostly praising wind power generation (WPG). In WPG, variable speed generators are giving more aids when compared with fixed speed generators. Doubly-fed induction generators (DFIG) are predominantly used in variable speed WPG. As speeds of wind are volatile, power to be generated with variable speeds is also volatile. But for grid-connected DFIG, it is needed to retain constant frequency with constant voltage, and this is feasible by coupling the rotor of DFIG with a back-to-back converter paired with DC capacitor. The operation of DFIG is to dispense maximum power at any wind velocities, and this is possible by operating DFIG with maximum power point (MPP) controller. Conventionally, sensors are used to achieve MPP, but its performance is modest with wild deviations of wind speeds. Hence, sensorless methods are mostly wished. In that, perturb and observation (P&O) is one of the finest methods, mostly adoptable in tracking MPP. The detriment of it is oscillating at final positions which motivates to add intelligent controllers like artificial neural networks (ANN). But training of the neural networks is very tedious and is determined by the trainer. Hence, heuristic controller is adopted to track the maximum powers. Ultimately, the results of all the controllers are competed with MATLAB/Simulink platform.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Wind power generation (WPG)

- Doubly-fed induction generator (DFIG)

- Maximum power point (MPP)

- Perturb and observe (P&O) method

- Artificial neural network (ANN)

- Neural network fitting tool (Nftool)

- Cuckoo search method

1 Introduction

Presently, the crisis of power generation is mostly compensated by renewable energy sources. In that, wind power generation (WPG) is taking the foremost role with numerous advantages like cost-effective, no economic damages, pollute free, etc. As the input to the wind turbine is never constant, its volatile behaviour offers more difficulties when the wind turbine is coupled to the grid. These difficulties of a grid-connected wind turbine can be condensed by providing additional operation and controlling methods. Nowadays, variable speed wind turbines (VSWTs) are mostly preferred in which a widespread of speeds are acceptable for power generation. In variable speed wind turbines, there are mainly two types of generators (i) Permanent magnet synchronous generator (ii) Doubly-fed induction generator. Permanent magnet synchronous generators do not require reactive power, but they are more weight and more cost. Hence, doubly-fed induction generators are mostly preferred for variable speed wind power generation. For a grid-connected doubly-fed induction generator (DFIG), the operation and controlling aspects are performed mainly from two aspects (i) Controlling of active and reactive powers that are fed to the grid from the generator (ii) Tracking of maximum power point at all wind speeds [1].

A DFIG is basically the stator that is directly connected to the grid, but the rotor of the DFIG is connected through a back-to-back converter with a DC coupling capacitor. Since the converters are added in the rotor circuit, the rating of the converters is reduced to 30% of the rated power output. Figure 1 gives DFIG block diagram.

As the wind velocities are variable, unpredictable capturing of maximum power at any wind velocities is desirable to improve the efficiency and performance of the wind power generation. This can be accomplished by adding an MPP tracking system. Sensorless methods are more advantageous because the cost decreases, and also, they are easily adaptable to the changes of wind speed. Perturb and observation is one of the best sensorless methods used for tracking the MPP. But size of the step may make the system to oscillate at final position. This can be overcome by moving to artificial intelligence methods like artificial neural networks (ANN).

Presently ANN’s are providing solutions to most of the non linear applications even with non linear characteristics also. But the tuning of ANN is reliant on trainer, and this stimulates to add an evolutionary algorithm for tracking MPP. Cuckoo search is one of the finest methods in utmost searching applications. This method is employed for tracking the MPP in this application.

The overview of this papers is as follows: Sect. 2 discusses modelling and scheming of DFIG, implementing of perturb and observe (P&O) MPP method, ANN method for tracking MPP, and cuckoo search method for tracking MPP, and Sect. 3 compares output results and conclusions with all the above methods.

2 Modelling and Scheming

2.1 Mathematical Modelling of DFIG

The stator of a DFIG is straightly associated to the grid, whereas the rotor is allied through AC-DC-AC converter [2]. The main purpose of DFIG is to align the rotor winding parameters with grid through slip rings along with back to back converters. For a DFIG, power is transmitted through the stator and also rotor. By using the current controlled converters, the rotor currents are governed to regulate active and reactive powers that are fed to grid. When the speed of the induction motors is above the rated speed due to the increased wind velocities, then the DFIG feeds power both from stator and rotor same as of a traditional generator. The key variance is that the magnetic field generated in the rotor is not fixed, and it changes with respect to the deviations of wind speeds. The magnetic field transitory to the windings of stator is not alone with rotor movement and also with revolving torque developed in the rotor windings due to AC currents fed. These rotor currents determine the speed of the stator rotating magnetic fluxes which also reflects on the AC potentials induced towards the stator windings. Main motive for employing a DFIG is mostly to get three-phase potentials with frequency persistent and made proportionate with the grid. To realize this, there must be persistent correction made in the frequencies of the feedback AC currents led into the rotor windings of the DFIG that responds towards the variations in the speeds of rotor that are caused by variations of the wind velocities. The basic block diagram of a DFIG is given in Fig. 1.

The control of DFIG is performed by adopting vector control, where the three-phase voltage, current flux parameters are converted to two-phase parameters. The two-phase parameters are assigned with stationary frame, one is d-axis, and the other is q-axis inherent. This makes DFIG to regulate as DC machine. The voltage equations of stator and rotor by means of d–q axis are given in Eqs. (1–4).

Similarly, the flux equations are given in Eqs. (5–8). Finally, the torque equation is given in Eq. (9).

In the DFIG, both the real and imaginary powers are regulated by controlling d–q axis current inherent of the rotor which indirectly regulates the stator currents and hence the power outputs.

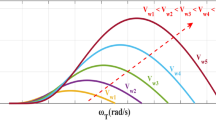

2.2 Fundamental of Tracking Maximum Power Point

By assimilating the proper duty cycle value of a Boost Converter based on dc capacitor voltage and current will tends to capture maximum powers with out using mechanical sensors. Hence, this is one of the approaches for employing MPPT without sensor. In addition to the back-to-back converter in the rotor circuit, boost converter is one more converter accommodated in the rotor circuit amid of capacitor and RSC as given in Fig. 2.

2.3 Boost Converter

Let \(V_{{\text{o}}}\) denote the output potential of a boost converter, and \(V_{{\text{s}}}\) denote the input potential as given in Fig. 2.

Both input and output potentials across a boost converter are represented by Eqs. (10–11). Equation (11) represents the impedance transfer function where \(R_{0} \;{\text{and}}\;R_{{\text{i}}}\) denote the output impedance and input impedance. Both input and output impedances are getting altered depending on peak power. If the input to the DFIG is altered as of wind speeds, this reflects on the potential across the DC capacitor. But a stable DC capacitor voltage is desired irrespective of alterations in wind speeds. RSC alone is unable to stabilize the DC capacitor potential, hence the added boost converter stabilized the DC capacitor potential, and hence, maximum powers are delivered to load. This can be attained by altering the duty cycle continuously.

2.4 Implementing Perturb and Observation (P&O) Method

As the rotor of the DFIG is coupled to the wind turbine, a volatile mechanical energy is continuously fed from the wind turbine to the rotor. Due to this mechanical energy input, a voltage Ej is injected into the rotor circuit [3, 4] which is the energy converted into electrical from the mechanical energy. This AC energy is altered to DC by RSC and is given to DC capacitor. As the voltage from the RSC is varying, the voltage fed to capacitor is also changing. The converter connected to the grid GSC controls this DC capacitor voltage as constant. This makes voltage and frequency supplied from the rotor towards the grid is maintained as constant [5]. To adopt the sensorless MPP, the output from the RSC is connected to the boost converter, and the DC voltage and DC current are used to measure the DC output power. The boost converter duty cycle is regulated by using perturb and observe method, in order to capture the extreme power at any wind velocity. The flow chart for implementing the P&O method is given in Fig. 3.

From flow chart, it can be observed that the duty ratio is changing with respect to the slope of the power that depends on the DC voltage of the boost converter. Finally, the duty cycle will settle where the MPP is reached. But the foremost problem in this method is if the change of duty cycle is more, it leads to oscillations at the final position at the same time, and if the change of duty cycle is less, it may take lot of time to reach the MPP. Hence, this disadvantage can be overcome by moving to intelligent method like artificial neural networks.

2.5 Implementing Artificial Neural Network for Tracking MPP

Fundamentally, neurons are divided in to several layers, the first layer is denoted as the input layer where the inputs are applied, the last layer is denoted as the output layer from the which the output is taken and in the middle of these two layers some additional layers are accomplished called as hidden layers, based on the Assignment want to be realized the hidden layers alters [6]. In a bidirectional network depending on feedback signal, the weights of the concerning links are trained or changed, and these signals move to and fro within the first and last layers. When the required target is accomplished, then the weights of all the layers are going to be invariant. The architecture of ANN is given in Fig. 4.

As ANN technique is used for the persistence of tracking MPP, the implementation of ANN is very comfortable with Nftool in MATLAB. Set of numeric inputs and outputs for the feed forward network must be defined first, inputs are given to input layer, and outputs are taken from the output layer. The layers amid of the input layer and output layer are termed as hidden layers. The hidden layers inputs are taken from outputs of the input layer as shown in Fig. 4 from the Architecture of ANN. There are numerous approaches available in this tool for training. Training of the ANN is done by using Levenberg–Marquardt proliferation algorithm (trainlm, this is one of the best methods that needs less time and stores more data. The error obtained is trained using root mean square (RMS), and the termination of the algorithm is depending on the increase in the error from validation samples (Fig. 5).

2.6 Tracking MPP by Applying Cuckoo Search Method

In recent times, meta-heuristic algorithms are used frequently in determining problems related to search optimization, and in that, cuckoo search algorithm is one of the most applicable methods for the present work. Cuckoos are fascinating and smart birds, their lovely and gorgeous sounds are very pleasing, and in addition to that, they have an emphatic approach in reproduction of their eggs. Searching a nest for reproduction of their eggs is the major task for cuckoo birds. Levy flight technique is used by cuckoo birds for searching of the best nest. To instigate the cuckoo search algorithm, flow chart is shown in Fig. 6. Equation (12) is used for accomplishment of the Levy flight.

2.6.1 Paces for Realizing the Cuckoo Search Algorithm

(i) Describing the primary values of samples \(\left( {I_{{{\text{dc}}}} , V_{{{\text{dc}}}} } \right)\) and fitness function \(\left( {W_{\max } } \right)\), (ii) Primarily produce samples of power, i.e. \(Pt\), duty ratio (\(Dt\)), and voltage (\(Vt\)), (iii) Levy flight is performed, and fresh samples are agreed and equated with the old samples as \(Pt + 1\). If \((Pt + 1\) > \(Pt)\), then old samples are demolished, and \(Pt + 1\) are the initial values for following search, and (iv) This penetrating method endures until the best sample is gained such that \(\Delta P, \Delta V\;{\text{and}}\;\Delta d\) are zeros.

3 Results and Conclusion

3.1 Results

The above have been performed on a DFIG with a nominal power = 1.5e6/0.9 Mw, nominal stator voltage = 575, grid voltage = 120 Kv, and length of transmission line is 30 km. Output results with P&O, ANN, and cuckoo search MPP methods are implemented on a DFIG model, and it is observed that adopting MPPT controller improves the power output with respect to the speed of the rotor. But the limitations of P&O method motivates to add NN controller that is offering much better outputs, and as the tuning of NN is tedious, it is recommendable to add a heuristic search method like cuckoo search by which the outputs are much enhanced. The output of the simulation results is given in Figs. (7, 8, 9, 10 and 11).

3.2 Conclusion

From the table in Fig. 12, it can observed that cuckoo search is the ideal for tracking the maximum powers. The addition of NN improves MPP when compared to P&O MPP control technique. But the drawback of ANN motivates towards the evolutionary algorithm like cuckoo search method for tracking MPP. This shows that the performance of the system is enhanced by adopting evolutionary controllers in place of conventional control that not only increases the performance of the system but also overcomes the uncertainties of the conventional methods.

References

B.H. Chowdhury, S. Chellapilla, Double fed induction generator control for variable speed wind power generation. Electric Power Syst. Res. 76, 786–800 (2006)

A.A. Tanvir, et al., Real-time Control of active and reactive power for (DFIG) based wind energy conversion system. Energies 10389–10408 (2015)

D.-C. Phan, S. Yamamoto, Maximum energy output of a DFIG wind turbine using improved MPPT curve method. Energies 205(8), 11718–11736. ISSN 1996-1073

A.A. Elbaset, et al., MPPT with P&O method for a solar panel using Buck and Boost converters and limits of P&O method. J. Eng. Sci. 43(3), 344–362

M.J. Khan, L. Mathew, Conventional MPPT Controllers that are Incorporated in the Wind Energy Systems and then Real-Time Simulation is Performed with OPAL-RT Simulator

S.A. Barbale, et al., Design and analysis of a small-scale wind energy conversion system. Νeural network based control of DFIG in wind power generation. Int. J. Adv. Res. Technol. 1(22) (2012). ISSN 2278-7763

J. Ahmed, Z. Salam, A maximum power point tracking (MPPT) for PV system using Cuckoo search with partial shading capability. Appl. Energy 119, 118–130 (2013)

M.J. Khan, L. Mathew, Comparative study of maximum power point tracking techniques for hybrid renewable energy system. Int. J. Electron. 106(8), 1216–1228 (2019)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Vasavi Uma Maheswari, M., Ramana Rao, P.V., Jayaram Kumar, S.V. (2021). Tracking Maximum Power Point of a Grid-Connected DFIG Wind Turbine Systems Using AI and Evolutionary Controllers. In: Mohapatro, S., Kimball, J. (eds) Proceedings of Symposium on Power Electronic and Renewable Energy Systems Control. Lecture Notes in Electrical Engineering, vol 616. Springer, Singapore. https://doi.org/10.1007/978-981-16-1978-6_23

Download citation

DOI: https://doi.org/10.1007/978-981-16-1978-6_23

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1977-9

Online ISBN: 978-981-16-1978-6

eBook Packages: EnergyEnergy (R0)