Abstract

Stone columns increase the bearing capacity and reduce the compressibility of soft clayey soil. However, the use of stone columns is limited because of subsequent settlement upon loading. The settlement is due to the bulging of the stone columns. Hence the major application includes strengthening of embankment foundation, oil tank foundation, etc., where a large settlement is permitted. In case the bulging of a stone column is restricted, its use may include building a foundation also. In the present study, a soil-cement bed is placed over the stone columns to reduce the bulging effect of the stone columns. Numerical analysis based on Plaxis-2D is conducted to observe the behavior of soil-cement bed and stone columns. The analysis is conducted on both Ordinary Stone Columns (OSCs) and stone columns underlying Soil-Cement Bed (SCB). From the result of this study, it is observed that the use of soil-cement bed reduces the bulging effect and increases the load-carrying capacity more than two times. The degree of improvement depends on the thickness of the SCB. As such an optimum thickness is obtained by trial and error. The settlement at the maximum bearing capacity is also found to be a bare minimum. The group effect of the stone columns is also studied. The bulging of the stone columns in a group is not similar to that in a standalone condition. It suggests that the existing theory on the determination of bearing capacity of composite soil must be modified for a group. A limited number of small-scale laboratory studies was also conducted to verify the analytical results.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The most familiar characteristic of the soft soil is that it undergoes an excessive settlement on the application of surcharge load. This is due to its low shear strength and high compressibility, which increases the importance of soil improvement techniques for the construction of soft soil. Amongst the various well-established soil improvement methods, the use of stone columns is proved to be a good alternative to a pile foundation as it is cost-effective, and environmentally friendly [1]. In the case of soft soil, Golakiya et al. [2] also preferred the use of stone columns to the use of pile due to the prohibitive costs for its large length and negative drag force. Moreover, this method shows excellent performance in the improvement of load-carrying capacity, minimization of the foundation settlement, and, accelerating the consolidation settlements by shortening the drainage pathway [2]. Bergado et al. [3] carried out a full-scale load test and reported qu of soft soil was increased by three to four times with the installation of stone columns [3]. Rao and Reddy [4] reported that the end bearing does not have any effect on qu for column length greater than ten times of column diameter [4]. Several researchers tried to obtain the load-carrying capacity (qu) of stone columns through numerical and analytical methods using different concepts. For example, some used unit cell concept [5,6,7,8,9], that is, a single column surrounded by six stone columns; some [10,11,12,13,14] used the behaviour of homogeneous soil with improved soil properties; some [15,16,17] usduced numerical model; some [18, 19] used 3-D finite element technique, etc.

It is now well understood that the stone column or granular pile achieves its bearing capacity from the shear strength of the surrounding soft soil. Upon loading, the stone column bulges and pushes the soft soil which in turn tries to resist by imparting radial stress based on its shear strength. For very soft clay (cu < 12.5 kPa) the radial stress is very low and thus columns bulge or expand excessively, which is the main reason behind the failure of the stone columns [20]. Again, due to bulging, there is a settlement of the ground surface resulting in the limitation of its application. The expected settlement will be around 40–50% of the total settlement of untreated ground as per the Greenwood chart [21]. Thus, the construction of residential buildings over stone columns may become unsafe. Researchers have tried to reduce the bulging effect in order to reduce the settlement. Notable works include geosynthetic encasement [22,23,24,25,26,27,28], placement of sand bed reinforced with geogrid [29], jacketing the stone columns with tubular wire mesh [30], etc. All the techniques have their inherent merits and demerits.

The present study shows the application of a compacted soil-cement bed (SCB) over the stone column to reduce the bulging effect of the stone columns. Numerical analysis based on Plaxis-2D was conducted on both ordinary stone column (OSC)s and stone columns underlying SCB. It is observed that the use of SCB reduces the bulging effect and increases the load-carrying capacity of stone columns by more than two times. The degree of improvement depends on the thickness of the soil-cement bed and an optimum value is obtained. A limited number of small-scale laboratory tests were also conducted to validate the analytical results.

2 Numerical Modelling

Numerical modeling for this study was performed by using Plaxis2D software. Many researchers obtained satisfactory results using this software. For example, Marto et al. [31] conducted the analytical study using the software Plaxis 2D for the prediction of bearing capacity of geogrid reinforced stone columns [31]: Phutthananon et al. [32] developed a numerical model on the behavior of conventional deep cement mixing and T-shaped column constructed in an embankment [32], etc. In the present study, a group of three stone columns of diameter 20 cm under a circular footing was taken and an axisymmetrical analysis was carried out. Figure 1 shows a sectional elevation. The Mohr-Coulomb failure criterion was considered to govern the stage of failure of the clay, soil-cement bed, and stone column materials. All the material properties that were applied to the numerical models are listed in Table 1. The values of Poisson’s ratio (ν) for both the column materials and clay were taken from the data available in the literature [33]. The other parameters were obtained from the experiments conducted in the laboratory as mentioned in the subsequent paragraphs.

In this finite element model, fifteen nodded triangular elements were considered. All the analyses were carried out with the application of loading in increments. Figure 1 presents the boundary conditions considered which are vertical roller for lateral boundaries and fixed for a bottom boundary. The other dimensions are: tank size 1 m × 1 m × 1 m; stone column diameter, d = 50 mm, and length, l = 40 cm. The depth (t) of the SCB was considered to be variable like, t = 0.5D, 0.75D and 1D (where D = diameter of footing). After the application of load, the settlement of stone columns was recorded and plotted against the bearing pressure as shown in Fig. 2. One additional analysis on ordinary soft clay was also performed for a comparison purpose. It is observed that for the ordinary soil, the bearing pressure increases with the settlement. For a single stone column without any soil-cement bed, the bearing pressure increases with settlement and the increase is nearly two times the value for normal soil. With the introduction of the soil-cement bed, the bearing pressure increases many fold. However, a sudden failure is observed when the settlement is more than 10 mm. That means, up to 10 mm settlement, the application of stone columns underlying SCBis completely safe. From the graph, the qu of the soft soil was noticed as 7.7 and 32 kPa corresponding to the settlement of 10 and 50 mm respectively. With the use of single stone columns, the qu of soft soils can be increased by 148 and 72% corresponding to the settlement of 10 and 50 mm respectively. The qu of soft soil can be improved by 1900 and 470% with the utilisation of stone columns underlying soil-cement bed corresponding to the settlement of 10 and 50 mm respectively. For the group stone columns, the load-carrying capacity of the soft soil is increased by 523 and 249% with the use of group stone columns corresponding to the settlement of 10 and 50 mm respectively. For the group stone columns underlying SCB, the bearing pressure was increased by 2536 and 572% corresponding to the above-mentioned settlements as shown in Fig. 3. It is also observed from Figs. 2 and 3 that with an increase in t from 0.5D to 1D, the bearing pressure also increases, however, after t = 0.75D, the increment in qu was marginal. So, the optimum thickness was considered as 0.75D. The improvement in bearing capacity can also be defined by using a term Improvement Factor (I.F.) which is stated as the ratio of bearing pressure acting on the reinforced clay bed to that of the unreinforced soft soil bed at the same value of footing settlement (s/D %). Figure 4 shows I.F. versus non-dimensional settlement (s/D in %) graph for all the combinations of reinforcements which shows a distinct improvement in qu for both single and group stone columns with the placement of SCB. The I.F. versus s/D (in %) graph of clay bed reinforced with only SCB (without stone column) is also shown in the figure for comparision purpose. The maximum increment was noticed corresponding to the settlement of 2–3% of the diameter of footing. At this point, the values of improvement factors are 2.75, 7, 24.5, 25, 45 for clay bed with the single stone column, group stone column, only SCB, single stone column underlying SCB, and group stone column underlying SCB respectively. Therefore, it can be concluded that the maximum IF is obtained with the placement of SCB over the stone columns at a settlement of 2–3% of the diameter of footing. The deformed mesh of the single and group stone columns without SCB obtained from the analysis are shown in Figs. 5a and b whereas Fig. 5c and d show the deformed mesh of single and group stone columns underlying SCB respectively. The deformations due to loading are also clearly observed from these figures. That means maximum improvement can be achieved by combining the group of stone columns with SCB.

3 Experimental Investigation

3.1 Material Used

To compare the numerical results obtained from PLAXIS-2D, three experiments (one with clay bed alone, one with a group of OSC without SCB, one with a group of stone columns underlying SCB) were conducted in the laboratory. Each experiment was conducted in a steel tank of size 1 m × 1 m × 1 m. The dimensions of a stone column were diameter d = 50 mm and length, l = 400 mm and thickness of SCB, t = 0.75D = 15 cm (optimum value).

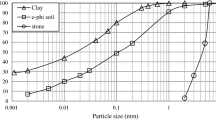

For constructing the clay bed, the tank was wrapped with a polythene sheet to minimize side friction. Clay was collected from a nearby paddy field, pulverized, thoroughly mixed with water, put in the tank in layers and uniformly compacted. The compacting effort was achieved after a number of trials so that the density of clay would be 15 kN/m3. In all the tests the water content was kept constant as 33% corresponding to the undrained cohesion of 10 kPa. For the tests on clay bed and OSC, the thickness of the clay bed was 90 cm, and for the test on stone columns underlying SCB, the thickness of the clay bed was 75 cm. The geotechnical properties of clay are presented in Table 2.

After constructing the clay bed, three boreholes were dug using an auger of 50 mm diameter up to the required depth for the construction of stone columns. Then the boreholes were cleaned with repeated insertion of the auger. Before filling the holes with stones, the diameter and length of the hole were checked with an open-ended steel pipe having inner and outer diameters of 48.5 and 50 mm, respectively.

The holes were filled by the stones of size 2–6 mm with uniform compaction in each layer. For compacting the stones in each layer, one tamping rod of 10 mm diameter was used. The number of blows was adjusted after a number of trials to achieve a density of 17 kN/m3. It is very difficult to maintain a uniform relative density of stones placed in the stone column. A number of trials were made with a different number of blows for each of five layers and a plot was made between a number of blows and the relative density of the stone. The number of blows corresponding to 70% relative density was adopted for the present experiments.

The spacing between the columns was kept as 2.5 times the diameter of the stone column.

The soil-cement stabilized bed was placed over the columns in one of the tests. The SCB was prepared by thoroughly mixing locally available c−ϕ soil, reddish in colour, with ordinary Portland cement, and water in a proportion of 1part of cement with 6 parts of soil. All the materials were mixed and placed over the columns by compacting the mixture uniformly in three layers. Each layer was compacted by using a square hammer with uniform compaction energy to achieve a density of 15.2 kN/m3.

The shear strength parameters of the three materials were obtained at the compacted density in the laboratory and are shown in Table 1. The parameters c and ϕ were obtained by direct shear test; Poisson’s ratio was obtained from unconfined compressive strength (UCS) test and Young’s modulus was obtained from Four-point bending test.

3.2 Loading Arrangement

One steel plate of 20 cm diameter and 10 mm thickness was used as a footing for all the tests. The diameter of the loading plate was chosen so that all three columns would be covered by the plate. Figure 6 shows the arrangement of stone columns used in the experimental setup. After placing the footing at its specific position, that is, centre of the bed, a uniformly distributed load was applied on it through the hydraulic jack of 10 t capacity. The experimental setup is shown in Fig. 7.

The applied loads were measured using a load cell, which was connected to a loading frame as shown in Fig. 7. To estimate the settlement that occurred due to the applied load, two LVDTs of capacity 50 and 25 mm were located at diametrically opposite ends of the footing. The LVDTs and load cell were connected to a data acquisition system to store the data in a computer. Two dial gauges were also fixed on the opposite diagonal for validation of the data obtained from LVDTs.

3.3 Test Procedure

The procedure of load test involves the application of uniformly distributed load on footing and measurement of settlements of the plate. In all the tests, the load was applied in equal increments and was maintained until the settlement became <0.02 mm/h [34]. The loading was continued till 50 mm settlement or failure whichever occurred earlier.

4 Comparison of Numerical Results with Experimental Results

The results of the finite-element analysis are compared with the results obtained from the experimental model test results. The results were compared in terms of bearing pressure versus settlement response as shown in Fig. 8 for unreinforced clay bed, clay bed reinforced with group OSC, and clay bed reinforced with group columns underlying SCB. The figure presents a very good match between the numerically obtained results and experimentally obtained responses which reflects the accuracy of the FEM results.

5 Conclusions

The study reported herein presents the response of a soil-cement bed on the improvement in the bearing capacity of a single and a group of floating stone columns in the soft clayey ground. The following concluding remarks are obtained from the present study:

-

1.

With the use of single stone columns, the bearing capacity of soft soils can be raised by 148 and 72% corresponding to the settlement of 10 and 50 mm respectively.

-

2.

The bearing capacity of soft soil can be increased by 1900 and 470% with the construction of single stone columns underlying SCB corresponding to the settlement of 10 and 50 mm, respectively.

-

3.

By using the group of three stone columns, the bearing capacity of soft soil can be increased by 523 and 249% with the use of group stone columns corresponding to the settlement of 10 and 50 mm, respectively.

-

4.

The bearing capacity of soft soil can be increased by 2536 and 572% corresponding to the settlement of 10 and 50 mm respectively with the use of group stone columns underlying SCB.

-

5.

Based on the maximum improvement percentage of bearing capacity, the optimum thickness of SCB was obtained as 0.75 times of footing diameter.

Thus from this study, it is clear that the bearing capacity of soft soil can be increased manifold with the installation of stone columns underlying a soil-cement bed. The technique also reduces the bulging of stone columns and thereby minimizes settlement of footing.

References

Shien, N.K.: Numerical study of floating stone column. A Thesis Submitted for the Degree of Doctor of Philosophy Department of Civil And Environmental Engineering, National University of Singapore (2013)

Golakiya, H.D., Lad, M.D.: Ground improvement by using stone columns. Int. J. Emerg. Technol. Innov. Res. 2(11), 133–144. ISSN: 2349-5162, www.jetir.org

Bergado, D.T., Rantucci, G., Widodo, S.: Full scale load tests on granular piles and sand drains in the soft Bangkok clay. In: Proceedings International Conference on In Situ Soil and Rock Reinforcement, Paris, p.p 111–118 (1984)

Rao, S.N., Reddy, K.M.: Load transfer in stone column in soft marine clay. In: Proceedings, Indian Geotechnical Conference, Madras, India, pp. 403–406 (1996)

Priebe, H.J.: Evaluation of the settlement reduction of a foundation improved by vibro–replacement. Bautechnik 5, 160–162 (1976)

Aboshi, H., Ichimoto, E., Enoki, M., Harada, K.: The composer: a method to improve characteristics of soft clays by inclusion of large diameter sand columns. In: Proceedings of International Conference on Soil Reinforcement: Reinforced Earth and Other Techniques, pp. 211–216. Champssur-Marne, Paris (1979)

Balaam, N., Booker, J.: Effect of stone column yield on settlement of rigid foundations in stabilized clay. Int. J. Numer. Anal. Methods Geomech. 9(4), 331–351 (1985). https://doi.org/10.1002/nag.1610090404

Van Impe, W.F., Madhav, M.R.: Analysis and settlement of dilating stone column reinforced soil. Österreichische Ingenieur und Architekten-Zeitschrift 137(3),114–121 (1992)

Ambily, A.P., Gandhi, S.R.: Behavior of stone columns based on experimental and FEM analysis. J. Geotech. Geoenviron. Eng. 133(4), 405–415 (2007)

Schweiger, H.F., Pande, G.N.: Numerical analysis of stone column supported foundations. Comput. Geotech. 2(6), 347–372 (1986)

Lee, J.S., Pande, G.N.: Analysis of stone-column reinforced foundations. Int. J. Numer. Anal. Meth. Geomech. 22(12), 1001–1020 (1998)

Wang, W.G., Leung, C.F., Ichikawa, Y.: A simplified homogenization method for composite soils. J. Comput. Geotech. 29, 477–500 (2002)

Jellali, B., Bouassida, M., Buhan, P.D.: Stability analysis of an embankment resting upon a column-reinforced soil. Int. J. Numer. Anal. Meth. Geomech. 35, 1243–1256 (2011). https://doi.org/10.1002/nag.954

Abdelkrim, M., Buhan, P.D.: An eleastoplastic homogenization procedure for predicting the settlement of a foundation on a soil reinforced by columns. Eur. J. Mech. A/Solids 26, 736–757 (2007)

Das, M., & Dey, A. K. Determination of bearing capacity of stone column with application of neuro-fuzzy system. KSCE Journal of Civil Engineering, 22(5), 1677–1683 (2018)

Das, M., Dey, A.K.: Prediction of bearing capacity of stone columns placedin soft clay using ANN model. Geotech. Geol. Eng (2018). https://doi.org/10.1007/s10706-017-0436-0

Das, M., Dey, A.K.: Prediction of bearing capacity of stone columns placed in soft clay using SVR model. Arab. J. Sci. Eng. 1–11 (2018)

El Kamash, W., Han, J.: Displacements of column-supported embankments over soft clay after widening considering soil consolidation and column layout: numerical analysis. Soils Found. 54(6), 1054–1069 (2014)

Killeen, M.M., McCabe, B.A.: Settlement performance of pad footings on soft clay supported by stone columns: a numerical study. Soils Found. 54(4), 760–776 (2014)

Ranjan, G., Rao, A.S.R.: Basic and applied soil mechanics. New Age International, Daryaganj, New Delhi, India (2007)

Bowles, J.E.: Foundation Analysis and Design, 4th edn., McGraw-Hill, Singapore

Van Impe, W.F.: Soil improvement techniques and their evolution. Balkema, Rotterdam (1989)

Murugesan, S., Rajagopal, K.: Geosynthetic encased stone columns: numerical evaluation. J Geotext. Geomembr. 24(6), 349–358 (2006)

Lo, S.R., Zhang, R., Mak, J.: Geosynthetic-encased stone column in soft clay: a numerical study. Geotext. Geomembr. 28, 292e302 (2010)

Dash, S.K., Bora, M.C.: Improved performance of soft clay foundations using stone columns and geocell-sand mattress. Geotext. Geomembr. 41, 26–35 (2013)

Castro, J.: Groups of encased stone columns: influence of column length and Arrangement. Geotext. Geomembr. 45, 68–80 (2017). http://dx.doi.org/10.1016/j.geotexmem.2016.12.001

Cengiz, C., Güler, E.: Seismic behavior of geosynthetic encased columns and ordinary stone columns. Geotext. Geomembr. 46, 40–51 (2018)

Chen, J.F., Wang, X.T., Xue, J.F., Zeng, Y., Feng, S.Z.: Uniaxial compression behavior of geotextile encased stone columns. Geotext. Geomembr. 46, 277–283 (2018)

Deb, K., Samadhiya, N.K., Namdeo, J.B.: Laboratory model studies on unreinforced and geogrid-reinforced sand bed over stone column-improved soft clay. Geotext. Geomembr. 29(2), 190–196 (2011)

Black, J.A., Sivakumar, V., Madhav, M.R., Hamill, G.A.: Reinforced stone columns in weak deposits: laboratory model study. J. Geotech. Geoenviron. Eng. 133(9), 1154–1161 (2007). https://doi.org/10.1061/(ASCE)1090-0241(2007)133:9(1154)

Marto, A., Moradi, R., Helmi, F., Latifi, N., Oghabi, M.: Performance analysis of reinforced stone columns using finite element method. Electron. J. Geotech. Eng. 18, 315–323 (2013)

Phutthananon, C., Jongpradist, P., Jongpradist, P., Dias, D., Baroth, J.: Parametric analysis and optimization of T-shaped and conventional deep cement mixing column-supported embankments. Comput. Geotech. 122, (2020)

Bowles, J.E.: Foundation analysis and design, 5th edn. McGraw-Hill, New York (1997)

IS (Indian Standard): Method of load test on soils. New Delhi, India, IS: 1888-1982 (1983)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Das, M., Dey, A.K. (2022). Improvement of Bearing Capacity of Stone Columns: An Analytical Study. In: Satyanarayana Reddy, C.N.V., Saride, S., Krishna, A.M. (eds) Ground Improvement and Reinforced Soil Structures. Lecture Notes in Civil Engineering, vol 152. Springer, Singapore. https://doi.org/10.1007/978-981-16-1831-4_27

Download citation

DOI: https://doi.org/10.1007/978-981-16-1831-4_27

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1830-7

Online ISBN: 978-981-16-1831-4

eBook Packages: EngineeringEngineering (R0)