Abstract

Decentralization of the main grid into microgrid levels largely depends upon the energy storage penetration level. The limits of the energy storage duration have been pushed with the increase in the penetration of renewables, from intermittent to hours based upon the application requirement. Energy storage technologies are majorly categorized into mechanical, chemical, thermal, electromagnetic and its combination depending upon the application requirement. Energy storage helps in decoupling the energy production and demand, thereby reducing the effort of constant monitoring of the load demand. Storage offers economic benefits of reduction in generation station energy to meet the average demand rather than the peak demands. This also helps in the appropriate sizing of the transmission lines and balance of plant for the average power demands. The storage technologies are compiled and evaluated based upon project/market requirement parameters such as energy/power density, specific energy/power, efficiency, cycle life, capital energy/power costs, technical maturity and its environmental impact, keeping in view their capacity and its microgrid application. Although every storage technology has its own advantages and disadvantages, with focus on the incremental development of existing technology, certain storage technology has the potential to meet the requirement with increased reliability and longevity of the decentralized system.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The modern energy economy has undergone rapid growth change, focusing majorly on the renewable generation technologies due to dwindling fossil fuel resources, and their depletion projections [1]. Figure 1 shows an estimate increase of 32% growth worldwide by 2040 [2, 3]. Asia, North America and Europe has the highest share whereas Asia, Africa and Latin America has shown 1.9%, 2.7% and 1.5% respectively increase per year (2015–2040) [4].

Total energy consumption of world in Mtoe (2000–2040) [3]

The overall consumption of the electricity worldwide has gain momentum as shown in Fig. 2, where Asia and Africa have the highest YoY % increase of 3.4 and 4.5% respectively [2,3,4].

The global challenge is well-known, i.e. transforming power and transportation systems through the integration of reliable energy storage systems which can provide a solution to complete the energy transition towards renewables.

Energy storage (which is not only batteries) systems represent a set of technologies and methods that are used to store various forms of energy. Energy storage can be used to manage power supply, to create a resilient energy system and to bring cost savings to both prosumers and utilities.

Energy storage will play a major role in the future for residential, commercial and industrial sectors, and will lead to a transformation of both the power and the transportation sectors. Depending on the sector and the needs, energy storage applications will be a significant part of the future energy system. The goal for a 100% renewable energy system could be achieved in the future, thanks to state-of-the-art batteries and development in the other forms of storage systems.

2 Energy Storage Technologies Overview

There are different forms of energy storage depending on two scales, power and time. Certain energy storage technologies are used to store power for different periods of time based upon the application requirement. In this context, understanding which energy storage technology is appropriate in each case is crucial.

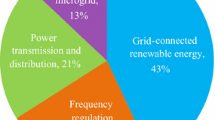

As shown in Fig. 3, it is broadly classified into four categories; namely mechanical, electromagnetic, chemical and thermal storage. Out of this, currently pumped hydroelectric (of mechanical storage system) is dominant in terms of deployed forms of energy storage (nearly 99%) [5, 6].

Pictorial view of the energy storage systems and generation [3]

Storage system has no immediate environmental or air quality impacts, helps in demand charge reduction, allows participation in demand response programs and in maximizing time-of-use rates. In remote areas, storage systems plays a vital role of resilience power supply as emergency backup. With the aforesaid commercial advantages, it also helps in the optimal sizing of the transmission lines and equipment followed by the mitigation of problems associated with the intermittency of the renewable energy generation.

In 2017, pumped storage accounts for 96.28% (153 GW) out of the Global utility scale energy storage capacity (by technology), followed by electro-mechanical (1.3 GW), electro-chemical (2.3 GW) and Thermal (2.3 GW) [3]. More than 75% of stationary grid-connected storage capacity was operating in only 10 countries as of 2017 [5].

Technologies such as flywheels and superconductors are having high parasitic losses, are useful for very short duration applications in power quality and regulation. Technologies with lower parasitic losses drop (e.g., pumped hydro), become more relevant for longer term energy management. In the next subsection, positive and negative aspects of each class of technology are represented and concluded in identifying key issues and likely future trends in the energy storage landscape. Figure 4 represents the share of renewables and its trend (region-wise) over the period from 1997 to 2017. The drive for the renewables (due to paradigm shift in the application requirements) has pushed the limitation of the storage duration from seconds to months.

Distribution trend of renewables (region-wise) and its overall share [4]

The energy storage system scales are categorized based upon their power rating as well as their application (storage duration) based upon the categories mainly power quality and regulation, bridging power and energy management as shown in Tables 1 and 2. The energy storage technologies are classified based upon the application requirement with storage duration.

2.1 Mechanical Energy Storage

Mechanical energy storage has the highest share across all the energy storage technologies. It is comprised of systems such as, pumped hydro storage (PHS), flywheels (FES) and compressed air energy storage (CAES). These systems are widely used and are advantageous on large scale in various commercial, industrial, and residential uses (Table 3).

Mechanical energy storage systems have a huge potential to grow, pertaining to its various beneficial factors such as, technical maturity, regulation of power and frequency, relatively lower environmental impact, high energy/power densities and long duration [8,9,10]. However, lack of site availability, high capital costs, safety issues and disapproval of governments in initiating capital inducement projects, along with the development of recent modern technologies can hinder the mechanical energy storage market [11, 12].

2.2 Chemical Energy Storage

This type of energy storage has the highest diversity of research and energy storage products which are commercialized presently. This includes traditional batteries, molten salt/liquid metal batteries, metal air batteries, fuel cells and flow batteries.

-

(1)

Traditional batteries

Tables 4 and 5 shows comparison between most known and generally used forms of chemical storage in traditional batteries category, namely Zinc Silver oxide (Zn–Ag), Alkaline Zinc Manganese Dioxide (Zn–Mn), lead Acid (Pb–Acid), Lithium-ion (Li–Ion), Nickel Metal Hydride (Ni–MH), Nickel Cadmium (Ni–Cd), Nickel–Iron (Ni–Fe) and Nickel Zinc (Ni–Zn) [13].

Batteries can help when the demand of energy is higher than the available energy at specific times and places. Batteries can help to compensate for different limitations of the power system [13,14,15].

-

(2)

Molten Salt, Liquid metal and Metal Air batteries Traditional batteries

Molten salt (Sodium Sulphur-NaS and Sodium Nickel Chloride-NaNiCl) and liquid metal are the typical class of high temperature chemical batteries (as in Table 6) which uses molten salts and liquid metals which acts as electrolyte as well as the electrodes [13, 16].

Metal air batteries (Zinc Air and Iron Air) are the cross-over of fuel cells and traditional chemical batteries, having one anode electrode and other as oxygen electrode (catalyzes the production of hydroxyl ions).

Although the typical nature of chemistries of electrolytes, electrodes and its stability, non-distributed charge–discharge patterns due to dynamic load variations, and sensitivity to change in environmental conditions, still traditional batteries are the mostly used storage devices till date in portable applications mostly due to high energy/power densities [17,18,19].

-

(3)

Fuel Cells

Fuel cells (FC) are generally energy generation devices rather energy storage devices, which takes hydrogen and oxygen as input and produces electricity and water as output. The fuel is oxidized at anode and reduced at the cathode [20, 21]. The hydrogen fuel can also be derived from the natural gas, methanol, ethanol, hydrocarbon gas and ammonia with the help of reformers.

Table 7 shows the comparson between four main types of fuel cell system namely, Proton Exchange Membrane (PEMFC), Solid Oxide (SOFC), Direct methanol (DMFC) and Molten Carbonate (MCFC).

Fuel cells technologies is cleaner, quieter and higher efficiency as compared to other technologies. They do have higher specific power/energy and energy densities. However, water and thermal management [22] along with the setup of Hydrogen ecosystem are the critical areas of concern along with its high capital intensive and lifespan, which restricts its economical viable uses to aerospace and large scale grid backup generation application [23,24,25].

-

(4)

Flow batteries

Flow batteries are very much similar in operation to fuel cell systems. To generate electricity, the electrolytes containing dissolved active material flow through the fuel cell. This are classified into 2 types, namely Redox flow batteries and halide/metal batteries as compared in Table 8 [13].

Redox flow batteries usually have 2 tanks storing electrolytes (known as catholyte and anolyte), series/parallel connected bipolar cell stacks and pumping system. Metal/Halide batteries are those which utilizes deposition of metals as a means of storing energy [13, 26, 27].

Flow batteries are having good depth of discharge, simplicity in operation and uses non-toxic materials in their operation but due to lack of cost competitive ness, loses its race with other chemical storage technologies.

Metal/halide batteries has high efficiency and utilises inexpensive materials, resulting in potential of becoming cost competitive due to abundance availability of the electrolyte materials [27, 28].

2.3 Electromagnetic Storage

Electromagnetic storage generally covers storage in inductors (magnetic field) and capacitors (electric field) [29, 30]. With advancement in the technologies, this has been extended to super conductors and supercapacitors (Electrochemical double-layer capacitors) [31] for large scale applications as compared in Table 9.

Super conductors have long cycle life, high efficiency, fast response with very high discharge rates, because of which is used mostly in power quality and stability applications [29, 32]. The major hurdle faced by such technology is the high costs (to maintain the stringent operation parameters) and the mismatch between power capacity and its energy performance.

Supercapacitor usually have low capacitance resulting in making it not suitable for high power applications, however combining them other storage systems such as battery systems will help in increasing life span of battery system by absorbing the surges and spikes during the transient operations and also fast delivery of the stored energy during requirement of the load [30, 31, 33].

2.4 Thermal Energy Storage

Thermal storage systems (TES) are used in mainly thermal power plants (industry scale) [34, 35]. Since mechanical, chemical and electromagnetic storage technologies are focusing on electricity storage, however the thermal storage needs to be coupled to heat engines or some thermoelectric generators for electricity generation (useable form).

Thermal storage is further categorized into three types namely, sensible heat, latent heat and reaction heat whose comparson is given in Table 10. This system contains three main components: the containment system, the thermal material and heat exchanger.

Thermal storage has wide range of applications in existing power plants and potential for the solar power plants, where the heat loss can be utilized to increase the overall system efficiencies (also with the use of phase change material, PCM for storing solar heat [36, 37]). Research is underway for the underground thermal storage technology, which can take advantage of the planet’s inner heat.

3 Conclusion

The energy storage technologies are vast and out of which twenty-seven types of storage technologies are considered. The technologies are compared based on parameters such as technical maturity, specific energy/power, energy/power density, efficiency, cycle life, energy/power cost, environmental impact and its applications.

Ni–MH, Ni–Cd, ZnAg, ZnMn and Pb-Acid from chemical energy storage systems and PHS spearheaded the technology maturity stage, however recycling and disposal of the batteries are still critical to the environment. Due to low loss storage and high share among energy storage systems (nearly 99%), PHS is mostly used for the energy management applications.

FES (followed by SMES) and flow batteries has the lowest and lowest impact respectively on the environment among other storage technologies. Superconducting at room temperature condition would be a game changer for energy storage Flow batteries has the potential for cost competitive when compared with CAES along with the improvements in power/energy capacities,

Fuel cells (SOFC followed by MCFC), FES, Metal Air (Zn–Air followed by Fe–Air), Super capacitors, SMES, SMES, leads in the specific energy (Wh/kg), specific power (W/kg), energy density (kW/m3), power density (W/m3), efficiency (%), cycle life (cycles) parameters respectively.

Fuel Cells (SOFC followed by MCFC) is far more than PHS, CAES and flow batteries in terms of energy performances, which means huge reduction of land requirement/usage, whereas Metal Air (Zn–Air followed by Fe-Air) shows higher power performances among others. This helps in putting fuel cell systems for large scale applications in future.

Li-ion has significant potential in the small scale applications such as electric vehicle applications due to its high energy/power densities as against molten salt, NaS, NaNiCl, NiCd, NiZn and NiMH which are having shorter life cycles and requires complex thermal management.

Energy cost (USD/kWh) and power cost (USD/kW) is highest for SMES (followed by Supercapacitors) and Zn–Ag (followed by DMFC) respectively, which makes its commercialization restraint. CAES has the lowest energy cost, with high power/energy capacities making it a good contender for utility scale energy storage applications.

Thermal energy storage systems are the major focus areas for the already installed generation systems as well for the renewables energy systems (mainly PV solar) for efficiency improvements. Hence, these systems are going to be integrated part of other storage systems. Furthermore, with respect to grid power quality management and regulation, FES, supercapacitors and SMES systems are the three main storage systems.

Other storage systems which are yet to be explored are biomass energy storage [38], gravity-based storage [39], mechanical spring systems-based storage [40], rail energy storage (RES) [41], phase change material (PCM) storing solar heat energy [36, 37].

The advancements in the energy storage systems from small scale to large scale, with duration from seconds to months are largely driven by the application requirements as well as the policies, standards and regulations adapted by the countries to reduce the impact of fossil fuel consumption on the environment with rapid modernization of the industry and transportation sector.

For the development of the energy storage technologies, continual effort needs to be in place for the improvement of the existing technologies as well as disruption of new technologies. But due to decreased energy cost of the competitors and lower investment in the new technology, the consumer patterns are unchanged which focuses on lower cost and increased performance of technology.

4 Assumption

Discharge rate assumed is 1C-rate. Data has been collected from multiple online databases available online. Specific power and energy are calculated based upon the dry mass of the systems. In case of energy generation systems such as fuel cell, 24 h time duration is considered for evaluation. Specific system dimensions for concerned systems are considered based upon the online available brochure/technical datasheet for the volume-based densities computation. Maximum efficiency has been considered in case of non-availability of information. Cost comparisons are made based on the recent trends in the current market scenario assuming exchange rates are in the acceptable variable range.

References

Shafiee S, Topal E (2009) When will fossil fuel reserves be diminished. Energy Policy 37:181–189

https://yearbook.enerdata.net/total-energy/world-consumption-statistics.html

https://www.enerdata.net/publications/world-energy-statistics-supply-and-demand.html

https://eneroutlook.enerdata.net/forecast-renewables-in-electricity-generation-share.html

Key World Energy Statistics (2013) International Energy Agency (IEA). Paris, France

Renewables (2013) Global status report; Renewable energy policy network for the 21st century. Paris, France

Swain P, Kashyap K (2019) Energy storage technologies: A qualitative analysis. Int Conf Energ Storage. New Delhi, India

Bueno C, Carta JA (2006) Wind powered pumped hydro storage systems, a means of increasing the penetration of renewable energy in the canary islands. Renew Sustain Energy Rev 10:312–340

Deane JP, Gallacho BPO, McKeogh EJ (2010) Techno-economic review of existing and new pumped hydro energy storage plant. Renew Sustain Energy Rev 14:1293–1302

Droste-Franke B (2012) Assessing environmental impacts of storage technologies and competing options for balancing demand and supply in 2050. In: Proceedings of the international renewable energy storage conference (IRES). Berlin, Germany, 12 Nov 2012

Yang C-J, Jackson RB (2011) Opportunities and barriers to pumped-hydro energy storage in the United States. Renew Sustain Energy Rev 15:839–844

Steffen B (2012) Prospects for pumped-hydro storage in Germany. Energy Policy 45:420–429

Buchmann I, Battery University. Available online: https://batteryuniversity.com/

Tarascon J-M, Armand M (2001) Issues and challenges facing rechargeable lithium batteries. Nature 414:359–367

Linden D, Reddy TB (2002) Handbook of batteries. McGraw-Hill, New York, NY, USA

Dueber R (2008) Strategic overview of silver-zinc rechargeable batteries. Battery Power Prod Technol 12:1–2

Olivetti E, Gregory J, Kirchain R (2011) Life cycle impacts of alkaline batteries with a focus on end-of-life. Massachusetts Institute of Technology, Cambridge, MA, USA

Huang Y-J, Lin Y-L, Li W-S (2012) Manganese dioxide with high specific surface area for alkaline battery. Chem Res Chin Univ 28:874–877

Ghaemi M, Amrollahi R, Ataherian F, Kassaee MZ (2003) New advances on bipolar rechargeable alkaline manganese dioxide–zinc batteries. J Power Sources 117:233–241

Swain P, Jena D (2015) Modeling, simulation and optimal control of non-linear PEM fuel cell with disturbance input. In: 2015 international conference on innovations in information, embedded and communication systems (ICIIECS). Coimbatore, pp 1–7

Swain P, Jena D (2015) PID control design for the pressure regulation of PEM fuel cell. In: 2015 international conference on recent developments in control, automation and power engineering (RDCAPE), Noida, pp 286–291

Cheng X, Shi Z, Glass N, Zhang L, Zhang J, Song D, Liu Z-S, Wang H, Shen J (2007) A review of PEM hydrogen fuel cell contamination: impacts, mechanisms, and mitigation. J Power Sources 165:739–756

Ren X, Zelenay P, Thomas S, Davey J, Gottesfeld S (2000) Recent advances in direct methanol fuel cells at los Alamos national laboratory. J Power Sources 86:111–116

Cassir M, Ringuede A, Lair V (2013) Molten carbonates from fuel cells to new energy devices. In: Molten salt chemistry. Elsevier, Burlington, MA, USA

Zhao Y, Xia C, Jia L, Wang Z, Li H, Yu J, Li Y (2013) Recent progress on solid oxide fuel cell: lowering temperature and utilizing non-hydrogen fuels. Int J Hydrog Energy 38:16498–16517

Blanc C, Rufer A (2010) Understanding the vanadium redox flow batteries. In: Paths to sustainable energy. InTech, Glasgow, UK

Skyllas-Kazacos M, Menictas C (2013) Redox flow batteries for medium- to large-scale energy storage. In: Electricity transmission, distribution and storage systems. Woodhead Publishing Limited, Cambridge, MA, USA

Parasuramana A, Lima TM, Menictasc C, Skyllas-Kazacos M (2013) Review of material research and development for vanadium redox flow battery applications. Electrochim Acta 101:27–40

Superconductivity: present and future applications. Available online: https://www.ccas-web.org/pdf/ccas_brochure_web.pdf. Accessed on 25 Dec 2014

Buckles W, Hassenzahl WV (2000) Superconducting magnetic energy storage. Power Eng Rev, 16–20 May 2000

Sharma P, Bhatti TS (2010) A review on electrochemical double-layer capacitors. Energy Convers Manag 51:2901–2912

Ali MH, Wu B, Dougal RA (2010) An overview of SMES applications in power and energy systems. IEEE Trans Sustain Energy 1:38–47

Dai T, Tang Y, Shi J, Jiao F, Wang L (2010) Design of a 10 MJ HTS superconducting magnetic energy storage magnet. IEEE Trans Appl Supercond 20:1356–1359

Thermal Energy Storage (2013) Technology brief. International Renewable Energy Agency (IRENA). Abu Dhabi, UAE

Muthukumar P (2011) Thermal energy storage: methods and materials. Indian Institute of Technology Guwahati, Sevilla, Spain

Sharma A, Tyagi VV, Chen CR, Buddhi D (2009) Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev 13:318–345

Farid MM, Khudhair AM, Razack SAK, Al-Hallaj S (2004) A review on phase change energy storage: materials and applications. Energy Convers Manag 45:1597–1615

https://techxplore.com/news/2018-11-brick-solution-topple-energy-storage.html

Rossi F, Castellani B, Nicolini A (2015) Benefits and challenges of mechanical spring systems for energy storage applications. Energy Proc 82:805–810. ISSN 1876-6102

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Swain, P., Shyamaprasad, A. (2022). Energy Storage Technologies: Past, Present and Future. In: Pillai, R.K., Dixit, A., Dhapre, S. (eds) ISUW 2019. Lecture Notes in Electrical Engineering, vol 764. Springer, Singapore. https://doi.org/10.1007/978-981-16-1299-2_18

Download citation

DOI: https://doi.org/10.1007/978-981-16-1299-2_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1298-5

Online ISBN: 978-981-16-1299-2

eBook Packages: EnergyEnergy (R0)