Abstract

Integration of renewable in hydro–thermal scheduling considering economic and environmental factors forms a multi-objective nonlinear optimization problem involving many equality and inequality constraints. Main objective of this problem is to minimize emission as well as generation cost on short-term basis maintaining all system constraints. In this research, a framework for hydro–thermal–wind generation scheduling (HTWGS) has been proposed using a modified particle swarm optimization (MPSO) algorithm. Results showed that this algorithm provides better result while various complex constraints were considered in the HTWGS problem.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In recent times, global warming has become a matter of great concern due to increase in power demand involving more pollution. To address this problem, an optimum operation of a thermal-renewable energy mixture is a promising option.

Inclusion of solar and wind energy into the energy sector has been proved as more cost-effective, necessitating its enclosure in the scheduling progression.

Genetic algorithm (GA) gives satisfactory results in various areas such as optimal solution of scheduling problem [1,2,3], hydro generator governor tuning [4], and economic dispatch [5]. However, in the literature, different classes of empirical algorithms such as genetic algorithm (GA) approach based on differential evolution (DV) [6, 7], particle swarm optimization (PSO) [8], modified dynamic neighborhood learning-based particle swarm optimization (PSO) [9], simulated annealing (SA) [10], evolutionary programming (EP) [11], modified differential evaluation (MDE) [12], and some other population-based optimization techniques have proved their effectiveness particularly in solving short-term hydro–thermal scheduling (STHTS) problems. Recently, random optimization methodologies and many other empirical algorithms based on natural phenomenon like adaptive chaotic artificial bee colony (ACABC) algorithm, artificial immune system (AIS) have given better result in solving STHTS problem. Recently, many other empirical algorithms inspired by natural phenomenon and random optimization methodology [13, 14] have been applied successfully in ST-HTWS problems.

Derived from the relationship among uncertainty budget of renewable energy, number of intermittent power supplies and upper bound of constraints-violating probability of spinning reserve capacity, the uncertain-budget decision is guided, and the blindness of decision can be reduced. The computational steps of MPSO, the contradiction between optimization depth and velocity generally existed in swarm intelligence evolutionary algorithms. The proposed technique in the test systems and its simulation results are discussed and summarized in the conclusions in this paper.

2 Mathematical Formulation of Generation Scheduling

This article demonstrates the scheduling formulation of a hydro–thermal–wind generation scheduling problem considering various economics and environmental factors. Due to its impulsive nature, renewable resources make the generation scheduling problem more challenging.

2.1 Formulation of Multi-objective Function

Cost involved in a hydro system is independent of its output, and hence, in the proposed HTWS scheduling, overall generation cost involves coal cost involved in thermal plant along with miscellaneous cost involved in solar and wind power.

The optimization involved in this problem is minimization of the generation cost of thermal, wind, and solar power plants along with maintaining minimum emission by considering different constraints involved in the proposed scheduling.

To achieve this, a nonlinear multi-objective function can be mathematically formulated as follows:

The hydro units power output is expressed as a function of reservoir volume and head given by

Thus, the multi-objective function (1) can be modified as

Fuel cost of the thermal power plant can be expressed mathematically as a quadratic function of the real power output including valve point effects [2]. This can be mathematically formulated as follows:

Emission from thermal power plant depends on its output by the penalty factor hi. Overall emission of pollutant ET can be expressed mathematically as

Wind velocity is the deterministic factor for wind power generation. Total operating cost for a wind extraction unit consists of three components: (a) direct cost, (b) underestimation cost, and (c) overestimation cost [46]. The concerned cost function can be formulated mathematically as

2.2 Constraints

Constraints related to the proposed HTWS problem mainly are generator capacity (operating limits), storage volume of the reservoir, discharge limit, power balance, and water balance constraints.

Dynamic water balance equation of the reservoir can be written as

Initial and final reservoir storage volume is expressed as

Thermal power unit generation limit is given as

Hydro power unit generation limit is given as

Wind power unit generation limit is given as

Reservoir storage volume limit is given below

Reservoir storage discharge limit is given below

Power system power balance constraint is given as

3 Modified Particle Swarm Optimization (MPSO) Algorithm

Conventional PSO maintains a random search considering random values in velocity equation for each particle. In such a case, calculation of velocity for each particle assigns different random values.

Whereas in modified particle swarm optimization (MPSO) algorithm, a unique random value is fixed to enhance individual searching (pbest) for the population in one iteration. Similarly, each particle is assigned with different random values during global search (gbest) of velocity equation. MPSO shows improved result for individual searching, thereby providing more optimal solutions.

According to MPSO, velocity update equation can be written as

The computational steps of the MPSO methods are as follows:

Step 1: The algorithm starts with initialization of the particles. The initial velocity is generated for all the particles.

Step 2: Compute penalty factor for all thermal power plants.

Step 3: Calculate the hydro power plant’s output, and apply the respective power inequality constraints.

Step 4: Compute the fuel cost and emission of thermal power plants.

Step 5: Compute the wind power generation cost.

Step 6: Calculate the fitness of the particles, considering all costs and equality constraints. Set the present value of each particle as its best position, pbest.

Step 7: Check for the lowest value of particle best position. Set the value as gbest.

Step 8: Calculate the updated velocity of each individual by Eq. (17)

Step 9: Update each individual position.

Step 10: Calculate the new fitness value for each particle. Replace the old pbest value with new one, if the present value shows improvement over the previous value.

Step 11: Replace the gbest with the lowest value from the new pbest, if the present value shows improvement over the previous value.

Step 12: Repeat step 8–11 until the equality constraints fall within a specified tolerance limits or maximum number of iterations reached.

Particle giving latest gbest value provides optimum schedule of generation.

4 Simulation and Test Results

In the present study, objective function is treated along with the penalty factor. In this analysis, maximum penalty factor approach is used as it offers an acceptable solution for the problem of emission and fuel cost.

Main problem involved in applying any heuristic algorithm is the parameter setting. Range selection for such parameters is considered by considering the concerned values in the literature, and then, a fine-tuning is carried out by a trial-and-error method.

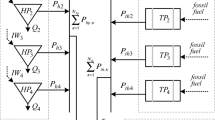

Proposed test system for the present research involves four hydro plants, three thermal plants, and two wind plants. The schematic diagram is shown in Fig. 1.

The hourly water discharge from hydro plant is shown in Fig. 2. Hourly water discharge and reservoir storage volume are tabulated in Table 1. The storage volume limitation was addressed by adjusting the water discharge from each reservoir.

Optimal demand allocation for hydro–thermal–wind system and corresponding economic and emission values from the simulation are tabulated in the following tables. Optimal hydro–thermal–wind generation scheduling for the test system is depicted in Table 2. This analysis considers various economic and emission factors obtained from MPSO method.

The simulations were carried out in MATLAB 2019a platform for 50 iterations, and results were analyzed based on the best, average, and worst case with standard deviation. It is imperative to note that MPSO provides competent and effective solution from quality and consistency point of view.

Optimal load allocation among thermal, wind, and hydro system on daily basis is shown in Fig. 3. The comparison regarding total fuel cost is shown in Table 3. It is evident that MPSO provides a better the optimal generation schedule is shown in Fig. 4.

5 Conclusion

Present study investigates the effectiveness of certain empirical algorithm belonging to different empirical groups for a solution of optimal generation of an HTWGS system considering various environmental and economic factors. Modified particle swarm optimization (MPSO) method is proposed in this purpose. In the present analysis, maximum penalty factor approach was used as it converts the multi-objective economic and emission function into a single objective one. Simulations also verified that MPSO demonstrated a better performance than the other selected algorithm in terms of solution quality as well as consistency. The proposed method is very effective as it takes less time due to less computational steps involved in the analysis. Besides, the method is easy to implement which makes the algorithm suitable for addressing large-scale hydro–thermal–wind optimal scheduling problem.

Abbreviations

- i, j, k:

-

Index of thermal, hydro, wind power unit, respectively

- CT, FT, WT:

-

Total cost, fuel cost, and wind cost, respectively

- Nt, Nh, Nw:

-

Total number of thermal, hydro, wind units, respectively

- τ, T:

-

Time sub-interval and scheduling period, respectively

- Up:

-

Index of upstream reservoir

- Qhj,τ, Ihj,τ:

-

Discharge and inflow rate of jth hydro unit τ, respectively

- Pti,τ, Phj,τ, Pwk,τ:

-

Thermal, hydro and wind of ith, jth and kth at τ, respectively

- \(V_{hj,\tau } ,S_{hj,\tau }\) :

-

Reservoir volume and spillage of jth hydro unit τ, respectively

- \(P_{d,\tau } ,P_{L,\tau }\) :

-

Total demand and transmission loss at τ

- OECwk,τ, UECwk,τ:

-

Over and under estimation cost of kth wind at τ, respectively

- \(\alpha_{i} ,\beta_{i} ,\gamma_{i} ,\delta_{i} ,\varepsilon_{i}\) :

-

Emission coefficient of ith thermal unit

- \(a_{i} ,b_{i} ,c_{i} ,d_{i}\) :

-

Fuel cost coefficient of ith thermal unit

- ei, hi:

-

Coefficient of the valve point effect of ith thermal unit

- \(C_{{\left( {1 - 6} \right)j}}\) :

-

Hydro power output coefficient of jth hydro unit

- \(P_{ti}^{{\min} } ,P_{ti}^{{\max} }\) :

-

Minimum and maximum power limit of ith thermal unit

- \(P_{hj}^{{\min} } ,P_{hj}^{{\max} }\) :

-

Minimum and maximum power limit of jth hydro unit

- \(Q_{hj}^{{\min} } ,Q_{hj}^{{\max} }\) :

-

Minimum and maximum discharge limit of jth hydro reservoir

- \(V_{hj}^{{\min} } ,V_{hj}^{{\max} }\) :

-

Minimum and maximum volume limit of jth hydro reservoir

- \(V_{hj}^{{\min} } ,V_{hj}^{{\max} }\) :

-

Minimum and maximum volume limit of jth hydro reservoir

- \(V_{hj}^{\text{begin}} ,V_{hj}^{\text{end}}\) :

-

Initial and final storage volume of jth hydro reservoir.

References

Gil, E., Bustos, J., Rudnick, H.: Short-term hydro thermal generation scheduling model using a genetic algorithm. IEEE Trans. Power Syst. 18(4), 1256–1264 (2003)

Kumar, S., Naresh, R.: Efficient real coded genetic algorithm to solve the non-convex hydrothermal scheduling problem. Int. J. Electr. Power Energy Syst. 29(10), 738–747 (2007)

Lansberry, J.E., Wozniak, L.: Adaptive hydro generator governor tuning with a genetic algorithm. IEEE Trans. Energy Convers. 9(1), 179–185 (1994)

Baskar, S., Subbaraj, P., Rao, M.V.C.: Hybrid real coded genetic algorithm solution to economic dispatch problem. Int. J. Comput. Electr. Eng. 29(3), 407–419 (2003)

He, D., Wang, F., Mao, Z.: A hybrid genetic algorithm approach based on differential evolution for economic dispatch with valve-point effect. Int. J. Electr. Power Energy Syst. 30(1), 31–38 (2008)

Zoumas, C.E., Bakirtzis, A.G., Theocharis, J.B., Petridis, V.: A genetic algorithm solution approach to the hydrothermal coordination problem. IEEE Trans. Power Syst. 19(3), 1356–1364 (2004)

Zhang, J., Wang, J., Yue, C.: Small population-based particle swarm optimization for short-term hydrothermal scheduling. IEEE Trans. Power Syst. 27(1), 142–152 (2012)

Rasoulzadeh-akhijahani, A., Mohammadi-ivatloo, B.: Short-term hydrothermal generation scheduling by a modified dynamic neighbourhood learning based particle swarm optimization. Int. J. Electr. Power Energy Syst. 67(2), 350–367 (2015)

Wong, K.P., Wong, Y.W.: Short-term hydro thermal scheduling part. I Simulated annealing approach. IEE Proc. Gener. Transmiss. Distrib. 141(5), 497–501 (1994)

Hota, P.K., Chakrabarti, R., Chattopadhyay, P.K.: Short term hydrothermal scheduling through evolutionary programming technique. Electr. Power Syst. Res. 52(2), 189–196 (1999)

Lakshminarasimman, L., Subramanian, S.: Short-term scheduling of hydrothermal power system with cascaded reservoirs by using modified differential evolution. IEE Proc. Gener. Transmis. Distrib. 153(6), 693–700 (2006)

Basu, M.: Artificial immune system for fixed head hydrothermal power system. Energy 36(1), 606–612 (2011)

Cotia, B.P., Borges, C.L.T., Diniz, A.L.: Optimization of wind power generation to minimize operation costs in the daily scheduling of hydrothermal systems. Int. J. Electric. Power Energy Syst. 113, 539–548 (2019)

Basu, M.: ‘Optimal generation scheduling of fixed head hydrothermal system with demand-side management considering uncertainty and outage of renewable energy sources. In: IET Generation, Transmission & Distribution (2020)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Choudhary, S.K., Pain, S. (2021). Modified Particle Swarm Optimization (MPSO)-Based Short-Term Hydro–Thermal–Wind Generation Scheduling Considering Uncertainty of Wind Energy. In: Muthukumar, P., Sarkar, D.K., De, D., De, C.K. (eds) Innovations in Sustainable Energy and Technology. Advances in Sustainability Science and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-16-1119-3_18

Download citation

DOI: https://doi.org/10.1007/978-981-16-1119-3_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1118-6

Online ISBN: 978-981-16-1119-3

eBook Packages: EngineeringEngineering (R0)