Abstract

In the past decades, herbal plants had been used widely by indigenous or even urban people for disease treatment or taken orally as appetizers, including Colubrina asiatica (C. asiatica) or known as Peria Pantai. Previous studies reported that this plant contains a high amount of active compounds that are responsible for foaming ability and various bioactivities. However, these active compounds are sensitive towards many factors; temperature, pH, light, and others in the production line. Thus, this study was conducted to optimize the extraction conditions using microwave-assisted extraction (MAE) using Response Surface Methodology (RSM) and the Box-Behnken Design method was selected. The parameters used in RSM were irradiation time (3, 5, and 7 min), solvent to solid ratio (10, 20, and 30 mL/g), and power (300, 400, and 500 W). The optimal extraction for the extract was 6.06 min irradiation time, solvent to solid ratio 28.31 mL/g, and 445 W of microwave power provide 42.63 w/w %. The actual yield value from the experimental procedure was 43.1 ± 0.05 w/w %. The total saponin content of the extract was determined using Folin-Ciocaltaeu’s colorimetric method with a reading of 15.36 ± 0.001 mg ESE/mg.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Colubrina asiatica

- Foaming agent

- Microwave-assisted extraction

- Solvent extraction

- Ultrasonic-assisted extraction

1 Introduction

Nowadays, the majority of the world’s population uses various cleansing agents in their daily lives to maintain proper hygiene and avoid germs or bacterial infections that can cause undesired diseases, especially the millions of people in the vast rural areas of developing countries. In the formulation of either cosmetic or pharmaceutical products, a surfactant is often present, which is usually used as detergent and emulsifier. The major concern is that most of the ingredients that comprise these cleansing agents are chemical-based, including synthetic surfactant that is harmful to human health. Examples of those chemical-based ingredients are sodium lauryl sulphate (SLS) and ammonium laurel sulphate (ALS). Chemical-based foaming agents that are extensively applied worldwide in food, cosmetics, and pharmaceutical preparations can be harmful to human health and the environment. It may also lead to skin reactions such as inflammation and can cause irritant contact dermatitis [10]. Generally, the inclusion of a natural foaming agent as a substitute for the chemical-based foaming agent will result in a significant improvement to its consumer-friendly and environmentally friendly qualities. In addition, the presence of a natural foaming agent would lead to an increase in ecosystem conservation effort and a decrease in chemical pollution. Thus, the next logical approach is to replace chemical-based ingredients with natural ones.

Aside from the effectiveness of cleansing agents towards dirt and stains, the antimicrobial activity of the cleansing agent needs to be considered as well in order to maintain its hygiene. Some medicinal plants, such as C. asiatica, can act as antimicrobial agents [13]. C. asiatica was chosen in this study because it believes to contain high saponin content that will possess foaming properties. Chen et al. [3] reported that crude saponin content in the seed of C. oleifera was 8.34% and its total saponin content in the crude saponin extract was 39.5% (w/w). Besides that, the potential of C. asiatica as a natural foaming agent has yet to be widely explored. Therefore, this research could present a new approach in the selection of a natural foaming agent and cleansing agent production studies in the sense that it will produce a product with good and safer properties for human consumption. Also, some natural foaming agents that have been studied previously have less stability of foam and possess weak foam properties. According to Somdee et al. [20], C. asiatica has exceptional advantages in phytomedicine because of the diversity in biological activities, including antimicrobial, anti-inflammatory, and antioxidant effects.

Microwave-assisted extraction (MAE) is a green extraction technique with shorter irradiation time, less solvent used, and lower CO2 emission compared to other conventional extraction methods [19]. Ahmad et al. [1] reported the used of MAE for encapsulation of anthocyanin-rich product are environmentally friendly, low-cost, low energy and require short processing period. Other researcher also reported higher yield of saponin extract from Safed musli using MAE when compared to other extraction technique such as maceration, soxhlet and sonication [4]. Therefore, this study aims to optimize the extraction of C. asiatica by using MAE with three main parameters, which were time, microwave power, and solvent to solid ratio, to give the best yield of saponin.

2 Methodology

2.1 Preparation of Colubrina asiatica Leaves Samples

Colubrina asiatica (C. asiatica) leaves were carefully washed with tap water to remove undesired substances or particles. After that, the samples were dried for a day using an oven (Memmert, Germany). The leaves of C. asiatica were left in the oven at 52 °C for 2 days to make sure that they were completely dry. The dried samples were ground using a commercial electric blender (Waring® Products Division, U.S.A.). Then, the sample powder was sieved to obtain particles of small size. For further experimental work, the dried sample was placed in a sealed transparent container and stored in a −30 °C freezer to maintain the optimum condition and freshness of the sample.

2.2 Extraction of Colubrina asiatica Leaves Using Microwave-Assisted Extraction

A method from Kerem et al. [7] was modified and used for the extraction of C. asiatica using MAE, in which 95% methanol was used as a solvent instead of water. Extraction solvents have a significant effect on the yield of bioactive compounds, and methanol has been found to be superior to other solvents for the extraction of saponins. The C. asiatica leaves powder was weighed according to the solvent to solid ratio at a fixed volume of solvent; 40 mL. For the ratio of solvent to solid 10:1, 4 g of leaves powder were used. The mixture was poured into a 100 mL round bottom flask and was placed inside a microwave. The mixture was irradiated in a closed system microwave extractor using two levels of heating: 1 min of preheating to set temperature and irradiation time based on the experimental design. The extraction procedure was performed via MAE using MAS-II Plus Microwave Synthesis/Extraction Reaction Workstation (SINEO Microwave Chemistry Technology Co. Ltd., China). The temperature was set at 60 °C, and the solvent volume was 40 mL. The mixture was filtered using a vacuum pump (model: DOA-P504-BN) with Whatman qualitative filter paper No 1 and then the solvent was evaporated completely using a rotary evaporator (IKA RN10 Digital, Germany). The extracts were stored in a 4 °C refrigerator for further analysis. The experimental processes were performed in triplicate and the average values were calculated.

2.3 Optimization of Colubrina asiatica Extract by Using Microwave-Assisted Extraction

Table 1 shows the independent parameters of Box-Behnken Design (BBD) that include irradiation time (A), solvent to solid ratio (B), and power (C). The range of the parameters was set according to the preliminary results obtained prior to the optimization process. BBD was chosen because it has been frequently applied in analytical method optimizations due to its advantages, which include the reduction of the number of experiments. This advantage resulted in lower reagent consumption and significantly less laboratory work considering its ability to develop mathematical models to evaluate the significance of the relation between the factors [5]. A total of 17 runs were generated using BBD in the Design of Expert version 6 software, as shown in Table 2.

The design included 1 block, 5 center points to assess pure error and the parameters values were fitted according to Eq. 1 as a polynomial equation:

where; Y represents the total oil yield in MAE while αij values represent constant regression coefficients, A: Irradiation time, B: Solvent to Solid Ratio and C: Power

2.4 The Yield of Colubrina asiatica Leaves Extract

After all extractions completed, the extract was filtered to remove undesired particles, and the extracts were evaporated by using a rotary evaporator to separate the solvent and the crude extract. All the extract was stored in the refrigerator under 4 °C until further analysis. The weight of extracts was recorded. Then the percentage of yield was calculated according to the equation shown in Eq. 2.

2.5 Determination of Saponin

The saponin content was measured according to the method described by Vuong et al. [21] and Pham et al. [16]. Briefly, 0.25 ml of the extract was sequentially mixed with 0.25 ml of 8% (w/v) vanillin solution and 2.5 ml of 72% (v/v) H2SO4, which then was incubated in a water bath (Ratek, Ratek Instruments Pty., Ltd., Victoria, Australia) at 60 °C for 15 min. The solution was then cooled in an ice water bath to room temperature (RT). The absorbance was measured at 560 nm using a UV–VIS spectrophotometer (Cary 50 Bio, Varian Australia Pty., Victoria, Australia). Aescin was used as the standard, and different concentrations of aescin from 100 to 1000 µg/mL were prepared to generate the standard curve. The content of saponin was expressed as mg aescin equivalents per gram of dried sample (mg ESE/g). The total saponin content concentration was calculated by using leaves powder dry weight and extract volume following the Eq. 3.

3 Results and Discussion

3.1 Effect of Irradiation Time on Total Yield of Colubrina asiatica

Figure 1 shows the experimental result for the effect of irradiation time on the extract yield (w/w) %. Based on Fig. 1, the results show that the highest extract yield was obtained at time 5 min with 41.27 (w/w) % followed by irradiation time of 7 min, 20 min, 10 min and 3 min with oil yield of 33.10 (w/w)%, 31.49 (w/w)%, 24.95 (w/w)% and 24.40 (w/w)% respectively. The result shows that the extract yield increased from 3 min to 5 min but decreased for the extraction time of 7 min onwards. The highest extract yield percentage at 5 min was significant (P < 0.05) compared to other irradiation times. Extract yield percentage from irradiation time of 10 and 20 min did not show a significant difference with statistical analysis (P > 0.05) of extract yield compared to 3, 5 and 7 min.

These results show that if the ground leaf was exposed to irradiation time for a longer time, it could not yield the highest amount of extract. This result is supported by previous research by Ren et al. [17], who discovered that the highest yield of steroid saponins from Dioscorea zingiberensis by using microwave-assisted extraction was at 5 min. Koyu et al. [8] reported a significant decrease in anthocyanin content from Morus nigra fruits when the extraction was done at 15 min. In contrast, it was at the highest yield when extracted for 10 min.

It shows that longer irradiation time does not yield more targeted bioactive compounds, but it might reduce targeted bioactive metabolites content because of the simultaneous extraction of other compounds. This is because the irradiation time is affected by the dielectric properties of the solvent. Extreme heat up may occur on extensive exposure to microwave heating for solvents like water, ethanol and methanol [11]. Minimum time extraction was desirable to minimize the usage of power. Thus, for this study, the temperature range for optimization was set up from 3 to 7 min only because 10 and 20 min did not show significant extract yield extracted (P > 0.05).

3.2 Effect of Solvent to Solid Ratio on Total Yield of C. asiatica

Figure 2 shows the experimental result for the effect of solvent to solid ratio on the extract yield (w/w) % of C. asiatica. It shows that the highest extract yield was obtained at solvent to solid ratio of 30 mL/g, followed by 40 mL/g, 20 mL/g and 10 mL/g with extract yield of 41.51 (w/w) %, 39.42 (w/w) %, 36.70 (w/w) % and 27.72 (w/w) % respectively. The extract yield increased with the increasing of ratio, however, became depleted at 40 mL/g. Extract yield extracted for the solvent to solid ratio of 10–30 mL/g was significant (P < 0.05) to each other. It showed that there was no significant difference (P > 0.05) in the extract yield was observed between 30 and 40 mL/g.

Based on Fig. 2, it can be deduced that higher solvent to solid ratio did not guarantee more extract yield. This shows that MAE does not require a high quantity of solvent to obtain an optimum yield of extract from C. asiatica leaf. Yuan et al. [22] reported a similar pattern of result on the extraction of Vaccaria segetalis with different solvent to solid ratio from 10 to 50 mL/g where the extract yield was increased from 10 to 30 mL/g but started to decrease after 40 mL/g.

A higher ratio of solvent volume to solid is commonly desirable for effective extraction process in conventional extraction methods. This is in line with results proposed by Hu et al. [6] which stated higher ratio of solvent volume provide greater contact area for higher yield of total saponins. However, homogeneous and effective heating was ensured by using the optimum solvent to solid ratio. This shows that MAE process required adequate amount of solvent because higher ratio may yield lower recoveries, which may be due to insufficient stirring to distribute the sample thoroughly through the solvent in the MAE [11]. Based on these results, 40 mL/g was excluded in the range of the parameters for optimization due to its effect on the reduction of extract yield.

3.3 Effect of Power on Total Yield of Colubrina asiatica

Figure 3 shows the experimental result for the effect of power on the extract yield (w/w)%. It shows that the extract yield of C. asiatica was highest at the power of 500 W. The highest yield was 42.54%, followed by 38.16%, 30.97% and 29.96% at the power of 500 W, 400 W, 300 W and 600 W respectively. The result shows no significant difference (P > 0.05) between extract yield at 300 W and 600 W. The extract yield was increased with power from 300 W to 500 W, however, decreased at 600 W. This phenomenon shows low extract yield at both lowest power and highest power used, 300 W and 600 W respectively.

According to Benmoussa et al. [2], the extraction of cumin essential oil resulted in the low oil yield at lowest and highest power used. The same pattern was observed in this study where the extract yield was increased with the increased of power; however, decreased after a certain power level. Research from Olalere et al. [14] on microwave extraction of piperine-oleoresin from black pepper (Piper nigrum) also showed the same pattern of extract yield. The extract yield of Piper nigrum was low at the power of 300 W, increasing at 400 W but decreasing at 450 W. Similar finding was reported by Ren et al. [18] on the extraction of Sargassum thunbergii polysaccharides using power ranging from 200 to 1000 W showed that extract yield was increasing from 200 to 600 W. After 600 W, the extract yield was slightly decreased due to polysaccharides degradation under excessive power exposure. Based on these results, 600 W was not included in the optimization experiment because the results showed degradation of extract yield at 600 W.

3.4 Optimization of Microwave Assisted Extraction Method of Colubrina asiatica

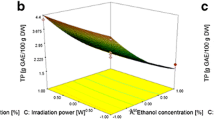

Various parameters of extraction in this method are conducted and optimized. The optimum condition from selected ranges was obtained to produce the highest yield of extract for further analyses. An empirical quadratic polynomial model corresponding to the BBD was fitted to correlate the relationship between three independent variables (irradiation time, solvent to solid ratio and power) and the response (yield) in order to predict the optimum conditions of extract yield. Figure 4 shows the graph of actual versus predicted values of the response. The determination coefficient (R2) of the quadratic regression model was 0.9379. High values of R2 showed that most variation of extract yield could be explained and predicted by the obtained model. Hence, the model can be used to explain the response. The interaction term that gave the largest effect to the yield was AC. The relationship between the response (yield) and independent variables (irradiation time, solvent to solid ratio and power) was given in Table 3.

The regression coefficients of the quadratic model equation were used to describe the extract yield from C. asiatica leaf. Table 3 summarized the actual parameters of the extract yield. Its shows that the extract yield was positively affected by the irradiation time, solvent to solid ratio and power. Based on the P-value, irradiation time was the most significant parameter followed by solvent to solid ratio and power. This result indicates that the extract yield increases as the factors increase. The quadratic term of irradiation time was negatively affected the extract yield and significant (P < 0.05). The interaction between time and power has significantly (P < 0.05) shown a positive effect on the response, together with the interaction between ratio and power. The most significant interaction was observed between irradiation time and power, followed by the interaction between the solvent to solid ratio and power.

The model was verified based on the results obtained from response surface analysis; the optimal extraction for the extract was 6.06 min irradiation time, solvent to solid ratio 28.31 mL/g, and 445 W of microwave power. Based on the optimal conditions, the predicted yield value was 42.63 w/w %. The actual yield value from the experimental procedure was 43.1 ± 0.05 w/w % at 6 min irradiation time, solvent to solid ratio of 28 mL/g, and 445 W microwave power. The optimal conditions are reasonable and adequate as the percentage error was 0.47%.

Table 4 shows the percentage of yield and total saponins content (TSC) of C. asiatica leaves extract produced from the optimal condition. The result indicates that methanol is a good solvent for the extraction of saponin. Low alcohols such as methanol and ethanol have usually been used as effective solvents for the extraction of saponins from plant materials [9]. According to Pham et al. [15], Catharanthus roseus leaf MAE extraction by using methanol as solvent gave a higher amount of TSC compared to extraction using hexane and ethyl acetate as solvent. This result is because saponin is polar compounds. Thus, the usage of methanol, which has a higher polarity, is useful to increase the polarity of the solvent and extract a higher yield of the saponin compound [15]. In addition, another supported study by Ngo et al. [12] reported that absolute methanol as solvent had the highest yield of saponin TSC (15.6%) from the root of Salacia chinensis followed by absolute ethanol, 50% methanol and 50% acetone (14.3%, 12.3%, and 12.2%, respectively).

4 Conclusion

In conclusion, the extraction of C. asiatica using microwave-assisted extraction (MAE) showed that the highest extraction yield obtained at 6 min irradiation time, solvent to solid ratio of 28 mL/g and 445 W microwave power with 43.1 ± 0.05 w/w % extract yield. The experimental data of MAE were analyzed using Box-Behnken Design from response surface methodology (RSM) to study the factor that affects the extract yield. The results show that irradiation time and solvent to solid ratio have a significant effect (P < 0.05) on extract yield. The experiment was considered satisfactory as the R2 was 0.9379, which has a good correlation between experimental data and calculated data.

References

Ahmad F, Mohd Jusoh YM, Abang Zaidel DN, Zakaria ZY, Muhamad II (2020) Optimization of microwave-assisted encapsulation of Black Mulberry (Morus nigra) extract. Chem Eng Trans 78:145–150. https://doi.org/10.3303/CET2078025

Benmoussa H, Elfalleh W, He S, Romdhane M, Benhamou A, Chawech R (2018) Microwave hydrodiffusion and gravity for rapid extraction of essential oil from Tunisian cumin (Cuminum cyminum L.) seeds: optimization by response surface methodology. Ind Crops Prod 124:633–642. https://doi.org/10.1016/j.indcrop.2018.08.036

Chen YF, Yang CH, Chang MS, Ciou YP, Huang YC (2010) Foam properties and detergent abilities of the saponins from Camellia oleifera. Int J Mol Sci 11(11):4417–4425. https://doi.org/10.3390/ijms11114417

Deore SL, Baviskar BA, Rangari AS (2015) Rapid and high yield extraction method for saponins from Safed musli. Pharmacogn J 7(4):210–214. https://doi.org/10.5530/pj.2015.4.1

Ferreira SLC, Bruns RE, Ferreira HS, Matos GD, David JM, Brandão GC, dos Santos WNL (2007) Box-Behnken design: an alternative for the optimization of analytical methods. Anal Chim Acta 597:179–186. https://doi.org/10.1016/j.aca.2007.07.011

Hu T, Guo YY, Zhou QF, Zhong XK, Zhu L, Piao JH, Jiang JG (2012) Optimization of ultrasonic-assisted extraction of total saponins from Eclipta prostrasta L. using response surface methodology. J Food Sci 77(9):975–982. https://doi.org/10.1111/j.1750-3841.2012.02869.x

Kerem Z, German-Shashoua H, Yarden O (2005) Microwave-assisted extraction of bioactive saponins from chickpea (Cicer arietinum L). J Sci Food Agric 85(3):406–412. https://doi.org/10.1002/jsfa.1989

Koyu H, Kazan A, Demir S, Haznedaroglu MZ, Yesil-Celiktas O (2018) Optimization of microwave assisted extraction of Morus nigra L. fruits maximizing tyrosinase inhibitory activity with isolation of bioactive constituents. Food Chem 248:183–191. https://doi.org/10.1016/j.foodchem.2017.12.049

Le AV, Parks SE, Nguyen MH, Roach PD (2018) Effect of solvents and extraction methods on recovery of bioactive compounds from defatted Gac (Momordica cochinchinensis Spreng.) seeds. Separations 5(39):1–13. https://doi.org/10.3390/separations5030039

Lemery E, Briançon S, Chevalier Y, Bordes C, Oddos T, Gohier A, Bolzinge MA (2015) Skin toxicity of surfactants: structure/toxicity relationships. Colloids Surf A: Physicochem Eng Asp 469:166–179. https://doi.org/10.1016/j.colsurfa.2015.01.019

Mandal V, Mohan Y, Hemalatha S (2007) Microwave assisted extraction—an innovative and promising extraction tool for medicinal PHCOG REV.: review article extraction tool or medicinal plant research. Pharmacogn Rev 1(1):7–18

Ngo TV, Scarlett CJ, Bowyer MC, Ngo PD, Vuong QV (2017) Impact of different extraction solvents on bioactive compounds and antioxidant capacity from the root of Salacia chinensis L. J Food Qual 2017:1–8. https://doi.org/10.1155/2017/9305047

Nivas D, Dethe UL, Gaikwad DK (2015) In vitro antioxidant activities and antimicrobial efficacy of Asian snakewood; Colubrina asiatica (L.) Brong. Res J Med Plant 9(7):307–320. https://doi.org/10.3923/rjmp.2015.307.320

Olalere O, Nour A, Alara O, Akbari S, Yunus R (2018) Evaluation of optimization parameters in microwave reflux extraction of piperine-oleoresin from black pepper (Piper nigrum). Beni-Suef Univ J Basic Appl Sci 7. https://doi.org/10.1016/j.bjbas.2018.07.006

Pham HNT, Vuong QV, Bowyer MC, Scarlett CJ (2018) Ultrasound-assisted extraction of Catharanthus roseus (L.) G. Don (Patricia White cultivar) stem for maximizing saponin yield and antioxidant capacity. J Food Process Preserv 42(5):1–12. https://doi.org/10.1111/jfpp.13597

Pham HNT, Nguyen VT, Vuong QV, Bowyer MC, Scarlett CJ (2015) Effect of extraction solvents and drying methods on the physicochemical and antioxidant properties of Helicteres hirsuta Lour. Leaves. Technologies 3(4):285–301. https://doi.org/10.3390/technologies3040285

Ren Y, Chen Y, Hu B, Wu H, Lai F, Li X (2015) Microwave-assisted extraction and a new determination method for total steroid saponins from Dioscorea zingiberensis C.H. Wright. Steroids 104:145–152. https://doi.org/10.1016/j.steroids.2015.09.008

Ren B, Chen C, Li C, Fu X, You L, Liu RH (2017) Optimization of microwave-assisted extraction of Sargassum thunbergii polysaccharides and its antioxidant and hypoglycemic activities. Carbohydr Polym 173:192–201. https://doi.org/10.1016/j.carbpol.2017.05.094

Samad NA, Abang Zaidel DN, Salleh E, Mohd Yusof AH, Dailin DJ, Abang Zaidel DN (2019) Optimization of Plectranthus amboinicus (Lour.) Spreng extraction process using microwave-assisted technique. Chem Eng Trans 72:397–402. https://doi.org/10.3303/CET1972067

Somdee T, Mahaweerawat U, Phadungkit M, Yangyuen S (2016) Antioxidant compounds and activities in selected fresh and blanched vegetables from northeastern Thailand. Chiang Mai J Sci 43(4):834–844

Vuong QV, Hirun S, Roach PD, Bowyer MC, Phillips PA, Scarlett CJ (2013) Effect of extraction conditions on total phenolic compounds and antioxidant activities of Carica papaya leaf aqueous extracts. J Herb Med 3:104–111. https://doi.org/10.1016/j.hermed.2013.04.004

Yuan XH, Fu LN, Gu CB, Zhang YD, Fu YJ (2014) Microwave-assisted extraction and antioxidant activity of vaccarin from the seeds of Vaccaria segetalis. Sep Purif Technol 133:91–98. https://doi.org/10.1016/j.seppur.2014.06.002

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zabidi, N.N.M., Salleh, E., Pa’e, N., Jusoh, Y.M.M., Zahan, K.A. (2021). Effect of Irradiation Time, Solvent to Solid Ratio and Power on Microwave-Assisted Extraction of Colubrina asiatica. In: Zaini, M.A.A., Jusoh, M., Othman, N. (eds) Proceedings of the 3rd International Conference on Separation Technology. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0742-4_22

Download citation

DOI: https://doi.org/10.1007/978-981-16-0742-4_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0741-7

Online ISBN: 978-981-16-0742-4

eBook Packages: EngineeringEngineering (R0)