Abstract

This study focused on the preparation of green and environmentally friendly cassava starch film. Firstly, apple pomace polyphenols extracted from apple pomace under optimized conditions were used as solvent. By adding modified micro-nanocellulose (M-MCC) and modified nano-cellulose (M-NCC) respectively, composite cassava starch was prepared by casting method, and compared with pure cassava starch edible film. The edible film was characterized by a thermogravimetric analyzer, and its antioxidant properties, surface hydrophobicity and water vapor transmission rate were tested. The results show that the starch edible film containing apple pomace polyphenols has higher thermal stability. Compared with pure starch edible film, after adding M-NCC and M-MCC, on one hand, the water vapor transmission rate of apple pomace polyphenol starch edible film is reduced, on the other hand, the hydrophobicity of apple pomace polyphenol starch edible film has been improved. In addition, the scavenging rate of DPPH free radicals is increased, indicating antioxidant performance has increased. It was proved that the modified starch film has great potential in fresh food packaging.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

With the improvement of modern economy level and the development of green lifestyle, the fresh food packaging have attracted considerable attention in many industries. The fresh food packaging has been developed towards the trend of good freshness, intelligence, convenience and personalization. However, when considering the functionalization of fresh food packaging, it is important to solve the environmental pollution problem of waste. At present, the relatively mature fresh food packaging in the market is cheap and easy to process fresh-keeping film. According to different substrates, it can be divided into polyethylene (PE) film, polypropylene (PP) film, polyvinyl chloride (PVC) film and polyvinylidene chloride (PVDC) film, fresh-keeping film can reduce the respiration of fresh food and slow the water loss of fresh food. In addition to the direct use of plastic wrap, the more demanding fresh food will also be pasted on the plastic film with adjustable silicone film or special technology to make it have certain micropores [1]. Because the plastic wrap is based on petroleum, not only is it not environmentally friendly, but now the requirements for freshness of fresh food are becoming higher and higher. We are constantly developing other degradable biological substrates for fresh food packaging.

Apple pomace is a by-product of apple juice processing and one of the world’s major wastes. Most of them are discarded and only a small part is used as fertilizer. Therefore, people have spent a lot of energy to develop and use this agricultural pomace. For example, it can be used as food ingredients and additives after processing. It is worth noting that apple polyphenols extracted from apples are natural antioxidants and are reported to have a variety of physiological functions [2,3,4].

In this paper, using the extracted apple pomace polyphenols as solvent, then adding modified micro-nano-cellulose and modified nano-cellulose. We are expected to prepare cassava starch composite food packaging film with good mechanical properties, hydrophobicity and antioxidant properties [5, 6].

2 Materials and Methods

2.1 Materials

Red Fuji Apple (purchased from Guangzhou Tianpingjia Fruit Wholesale Market); Modified micro-nano cellulose (self-made, preparation of cellulose powder and high concentration H3PO4 solution by mechanical stirring and high speed freezing centrifugation); Modified nano cellulose (self-made, the cellulose powder was reacted with 65% concentrated sulfuric acid and then freeze-centrifuged dialysis until a constant neutral PH was obtained); Tapioca starch, amylose, amylopectin (Hongfeng Starch Co., Ltd. Guangxi, China); Glycerin, Anhydrous ethanol, Anhydrous calcium chloride (Zhiyuan Chemical Reagent Co., Ltd. Tianjin, China); DPPH free radical (96%) (Macleans Biochemical Technology Co., Ltd. Shanghai, China).

Constant temperature oil bath (DF-101S, China); L&W thickness measuring instrument (251, 0.1-2000 μm, Sweden). Ultrasonic cleaner (KH3200E, China); Constant temperature blast drying oven (101-0 type, China); Thermogravimetric analyzer (TA Q500, USA).

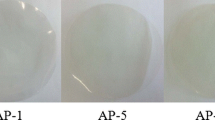

2.2 Preparation of Compound Edible Film

First of all, apple pomace polyphenols were prepared from apple under optimized experimental conditions. Then, the preparation process of each film was shown in Fig. 1. Firstly, dissolve the starch granules in distilled water and apple pomace polyphenol solution to prepare 4.5% (w/w) starch solution. Secondly, the starch solution dissolved in distilled water was marked as S1, and the starch solution dissolved in apple pomace polyphenol extraction solution was marked as S2, S3 and S4. Thirdly, put each starch solution in a constant temperature oil bath, magnetic stirring at 85 °C for 30 min to paste. Finally, add 30% (w/w) plasticizer glycerin after gelatinization, in which 1.5% (w/w) M-NCC and 0.5% (w/w) M-MCC were added to S3 and S4 solutions, respectively. It should be noted that M-NCC and M-MCC were dissolved in advance with a small amount of absolute ethanol. For comparison, no other additives were added except for adding glycerin to S1 and S2.

After stirring each suspension for 20 min, a film-forming solution could be obtained. After that, each film-forming solution was placed in an ultrasonic cleaner at 60 °C for 10 min to remove air bubbles in the solution. After ultrasound, the solution was poured into a petri dish and dried at 40 °C for about 12 h to form a thin film. The films formed by S1, S2, S3 and S4 were marked as C film, P film, PN film and PM film.

2.3 Characterization

2.3.1 Optimization of Response Surface for Extraction of Polyphenols from Apple Pomace

Design and optimize the experiment with the help of the Box-Behnken pattern in the response surface design experiment. Two significant factors, ethanol concentration as A and material to liquid ratio as B, were selected to analyze the response value of polyphenol concentration when the extraction time was 14 min and the extraction temperature was 55 °C (Table 1).

2.3.2 Thermal Stability of Each Compound Edible Film

Using a thermogravimetric analyzer (TAQ500, USA) to measure the thermal stability of each sample, shred the membrane, and then weigh about 10 g of sample into the crucible of the instrument. Set the heating range of the instrument: from room temperature to 600 °C, during the heating process, control the rate at 10 °C/min. Nitrogen is used as the protective gas in the whole process, which is controlled in 20 ml/min.

2.3.3 Antioxidant Properties of Each Composite Edible Film

According to the method of Kim et al. [7, 8], the film was cut into slices of 3 cm × 3 cm, and then soaked in a glass bottle containing 30 mL of deionized water. After immersing for two days, take 3 mL of film extract and mix with 1 mL of 1 × 10−4 mol/L DPPH ethanol solution, and after standing for 30 min in a dark environment, the absorbance of the solution at 517 nm is measured with an ultraviolet spectrophotometer. The scavenging rate of DPPH free radicals is calculated by the following formula:

A2—it is the absorbance value measured by using absolute ethanol instead of DPPH free radical solution.

A1—the absorbance value of the sample.

A0—substitute distilled water for the measured absorbance value of the sample.

2.3.4 Water Vapor Transmission Rate of Each Compound Edible Film

The water vapor transmission rate of the film is improved by referring to GB/T1037-1988 and literature [9]. Cut the membrane to 3 cm × 3 cm, and dry it to constant weight in the blast drying oven. Then seal it with a sealing grease in a weighing bottle containing 3 g of fully ground and dried anhydrous CaCl2. At this time, the weight of the bottle is weighed and recorded as m0. After that, the weighing bottle sealed with each film is placed in a desiccator, where a beaker containing distilled water is placed in the desiccator, after being placed in this environment for 48 h, the weight of the bottle is weighed as m1 and the water vapor transmission rate (WVP) calculation formula is as follows:

Among them: m1—weigh the bottle after 48 h, g;

m0—the initial weight of the weighing bottle, g;

s—the area of the weighing bottle mouth, g;

d—heaven number, d.

2.3.5 Hydrophobic Property of Each Compound Edible Film

The hydrophobic property was determined using the contact angle meter (OCA40 Micro, Paraphysics, German). The films were cut into 2 cm × 2 cm squares then the contact angle for a drop of distilled water on the surface was measured at 20 ± 1 °C and 50 ± 2% RH. The contact angle was monitored at 0.1 and 2 s, and the average of at least three measurements was calculated.

3 Results and Discussion

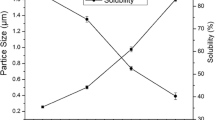

3.1 Results of Interaction Between Ethanol Concentration (A) and Material to Liquid Ratio (B)

It can be seen from Fig. 2 that the center of the contour map is oval, and it can be concluded that the interaction of ethanol concentration and material to liquid ratio has a significant effect on the extraction concentration of polyphenols from apple pomace.

As can be seen from Fig. 2a, when the extraction time is 14 min and the extraction temperature is 55 °C. When the material to liquid ratio is constant, the extraction concentration of polyphenol from apple pomace increases with the increase of ethanol concentration. This is because anhydrous ethanol as an organic solvent can break the binding bond of polyphenols in apples to proteins or polysaccharides through hydrogen or hydrophobic bonds, thus polyphenols are released. When the concentration of ethanol was constant, the extraction concentration of polyphenols from apple pomace increased at first and then decreased with the increase of material to liquid ratio. When the two factors interact with each other, the maximum extraction concentration of polyphenols from apple pomace is about 14.3500 g/mL in the range of 70.1–73.3% ethanol concentration and 21.9–23.5 mg/mL ratio of material to liquid.

3.2 Thermal Stability of Each Compound Edible Film

As shown in Fig. 3, the observation of thermogravimetric curves shows that the thermal decomposition process of the four kinds of films can be divided into three stages. There is a similar thermal decomposition process: the first stage is the evaporation process of water vapor and solvent in the film, the temperature section and mass loss of the first pyrolysis process of each film are: pure starch edible film: 68.8–148.8 °C, mass loss 7.21%. Apple pomace polyphenol starch edible film: 77.5–138.1 °C, mass loss 4.57%. Apple pomace polyphenol/M-NCC starch edible film: 88.2–145.6 °C, mass loss 5.35%. Apple pomace polyphenol film/M-MCC starch edible film: 105.9–147.1 °C, mass loss 4.11%. Comprehensive analysis and comparison shows that the edible film of pure starch begins to decompose earlier, and mass loss is greater at this stage, because the edible film of pure cassava starch contains more water vapor. Because of the addition of M-NCC and M-MCC, the film surface of apple pomace polyphenol film/M-NCC starch edible film and apple pomace polyphenol/M-MCC starch edible film have a certain water vapor resistance, so in this stage more is the evaporation of the solvent in the film. The results show that apple polyphenols have good thermal stability, and a small part of them decompose in the range of 200–400 °C [10].

The temperature and mass loss during the second thermal decomposition process are as follows: (i) pure starch film: 145.6–272.8 °C, mass loss 19.24%, mainly due to the thermal decomposition of the plasticizer glycerin. (ii) Apple pomace polyphenol starch film: 138.1–271.0 °C, mass loss 22.38%, mainly due to thermal decomposition of plasticizer glycerin and a small amount of apple pomace polyphenols. (iii) Apple pomace polyphenol/M-NCC starch edible film: 145.6–272.4 °C, mass loss 19.03%, mainly due to the thermal decomposition of the plasticizer glycerin, a small amount of apple pomace polyphenols and some M-NCC. (iv) Apple pomace polyphenol film/M-MCC starch edible film: 147.1–273.7 °C, mass loss 15.71%, mainly due to the loss of plasticizer glycerin, a small amount of apple pomace polyphenols and some M-MCC.

The third thermal decomposition process of the four membranes is mainly the decomposition of the unsaturated molecular chain structure of starch, the thermal decomposition temperature range is around 272–351 °C, the quality losses are: 62.64, 56.67, 60.64 and 62.8%. It can be seen from the analysis of results that with the addition of M-NCC and M-MCC, the thermal stability of the film will decrease to a certain extent. Comprehensive analysis of the thermal decomposition process of the four membranes shows that the addition of apple pomace polyphenols improves the thermal stability of the membrane and reduces the quality loss. This is similar to previous research results [11].

3.3 Antioxidant Performance of Various Composite Edible Films

DPPH (1,1-diphenyl-2-picrylhydrazyl) is a stable dark purple prismatic active free radical. After dissolving in ethanol, it appears purple, with a maximum absorption peak at 517 nm. Antioxidant substances can reduce DPPH free radicals to diphenylpicryl hydrazine to make the color lighter. The degree of lightening of DPPH free radical solution is mainly determined by the hydrogen supply capacity of antioxidants. Therefore, the scavenging rate of DPPH free radicals by antioxidants can be calculated by measuring the change in absorbance value at 517 nm [12].

Figure 4 shows the effects of pure starch edible film, apple pomace polyphenol starch edible film, apple pomace polyphenol/M-NCC starch edible film and apple pomace polyphenol/M-MCC starch edible film on DPPH free radicals clearance rate. It can be seen from Fig. 3 that the pure starch edible film has a particularly low scavenging rate of DPPH free radicals. Compared with pure starch edible film, P film, PN film and PM film containing apple polyphenols have much higher scavenging rate of DPPH free radicals. Their scavenging rates increased by 164.7, 163.3 and 134.7. This is because the main components of apple polyphenols are substances such as flavanols and chlorogenic acid with a polyhydroxyl substituted benzene ring structure. The delocalization of electrons on the benzene ring makes the phenolic hydroxyl groups easy to ionize, the delocalization of the electrons on the benzene ring makes the phenolic hydroxyl groups easy to ionize, so that these substances become good hydrogen donors [13, 14]. Then reduce more DPPH free radicals to diphenylpicryl hydrazine, thereby making the color lighter and improving the scavenging rate of DPPH free radicals. Compared with the P film containing only apple polyphenols, the PN film with M-NCC and the PM film have similar scavenging rates to DPPH free radicals, while the PM film has a lower rate of scavenging DPPH free radicals, this may be due to the fact that M-MCC has less active hydroxyl groups. This may be that a small part of the aggregation of M-MCC hinders the electron delocalization of the benzene ring structure of polyphenols and reduces the ability of hydrogen supply.

3.4 Water Vapor Transmission Performance of Various Compound Edible Films

The picture shows the water vapor transmission rate of the prepared pure starch edible film, apple pomace polyphenol starch edible film, apple pomace polyphenol/M-NCC starch edible film and apple pomace polyphenol/M-MCC starch edible film. There are three main steps for water vapor to pass through the film:

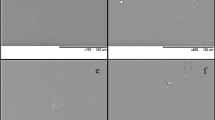

(i) Water vapor molecules adsorb to the surface of the film. (ii) Water vapor molecules penetrate the inside of the film under the pressure difference between the two sides of the film. (iii) Evaporate on the other side of the film. Therefore, the water vapor transmission rate of the film is mainly affected by the hydrophilicity of the film itself and the size of the water vapor barrier inside the film [15]. Figure 5 shows that the water vapor transmission rate of pure starch edible film is relatively large. This is because the starch film itself is very hydrophilic. Moreover, the addition of plasticizer glycerin improves the flexibility of the starch molecular chain, making water vapor permeable. Compared with pure starch edible film, the water vapor transmission rate of starch film added with apple pomace polyphenols increased by 9.59%, this is because in addition to the hydroxyl groups of the starch itself, the polyphenols of apple pomace also contain phenolic hydroxyl groups, so they are more hydrophilic and have higher water vapor permeability. The observation of apple pomace polyphenol/M-NCC starch edible film and apple pomace polyphenol/M-MCC starch edible film showed that their water vapor permeability was much lower than that of pure starch edible film and apple pomace polyphenol starch edible film. When stearic acid modified NCC and MCC are added to the two kinds of thin films, on the one hand, because the surface of the composite film has certain hydrophobicity, water vapor molecules are not easily adsorbed to the film surface, on the other hand, because M-MCC and M-NCC are uniformly distributed in the film, the path of water vapor penetration becomes longer, so it is difficult to pass through the film.

3.5 Surface Hydrophilic of Films

The surface hydrophilicity of films was evaluated by means of the contact angle machine, and the contact angle of different kind of films is shown as Table 2. The C film had the contact angle at 44.5° that was not high. It is known that starch molecules contain a large amount of hydroxyl groups, have greater polarity and hydrophilicity, and contain 13–20% of water [16]. These waters and the hydroxyl groups in the starch formed stronger and more hydrogen bonds, causing the poor hydrophobic property. Compare to C film, P film had a lower contact angle, that was because there were more hydroxyl groups in polyphenol caused by the polyphenols in AP [17]. So, when the stearic acid modified MCC or NCC added, the improvement of contact angle wasn’t high. But the addition of fillers did improve the contact angle of P film, which increased by 32.66%, 33.94%, respectively. Considering these two fillers enhancing effect, after esterified modification of MCC and NCC, introducing the non-polar carbon chain and forming the hydrophobic ester group, which lead to the improvement in hydrophobic properties of P film. Modification of MCC and NCC, introducing the non-polar carbon chain and forming the hydrophobic ester group, which lead to the improvement in hydrophobic properties of P film.

4 Conclusion

The properties of these three kinds of films were characterized and compared with those of pure starch edible films.

The results of thermogravimetric analysis showed that the mass loss of starch edible film containing apple pomace polyphenols decreased, while the thermal stability of apple pomace polyphenol starch edible film decreased slightly with the addition of M-NCC and M-MCC.

In addition, the results of antioxidant experiment showed that the DPPH radical scavenging rate of starch edible film containing apple pomace polyphenols was higher than that of pure starch edible film, indicating that the antioxidant activity was enhanced. With the addition of M-NCC and M-MCC, the scavenging rate of DPPH radical was also increased.

And then, the results of water vapor transmittance showed that the starch edible film containing apple pomace polyphenols had more water vapor transmittance, which increased by 9.59%. After the addition of M-NCC and M-MCC, the water vapor permeability decreased by 35.48 and 39.37%.

Finally, compared with the pure starch edible film, the starch edible film containing apple pomace polyphenols has lower hydrophobicity. However, the hydrophobicity of the film was enhanced with the addition of M-NCC and M-MCC.

References

Luo HY, Chen HJ, Mu HL et al (2015) Research progress of fresh food packaging materials. Chin. J. Food 15(10):1–0

Sun J, Chu YF, Wu X et al (2002) Antioxidant and antiproliferative activities of common fruits. J. Agricult. Food Chem. 50(25):7449–7454

Boyer J, Liu RH (2004) Apple phytochemicals and their health benefits. Nutrit J 3(1):5

Boyer J, Liu RH (2003) Antioxidants of apples. New York Fruit Q 11(4):11–15

Miao C, Hamad WY (2013) Cellulose reinforced polymer composites and nanocomposites: a critical review. Cellulose 20(5):2221–2262

Gaikwad KK, Lee JY, Lee YS (2016) Development of polyvinyl alcohol and apple pomace bio-composite film with antioxidant properties for active food packaging application. J Food Sci Technol 53(3):1608–1619

Sun WZ, Yang K, Lin LZ et al (2017) Research of high acid apple polyphenols and study on antioxidation and antihemolysis activity. J South China Univ Technol (Nat Sci Ed) 45(03):146–152

Kim KW, Thomas R (2007) Antioxidative activity of chitosans with varying molecular weights. Food Chem 101(1):308–313

Tian CM (2007) Study on the properties of cassava starch/chitosan edible composite film and its application in fresh-cut jackfruit. South China Tropical Agricultural University (2007)

Liang D, Yang X, Guo YR (2018) Effects of different concentrations of apple polyphenols on the physicochemical properties of chitosan composite membrane solution. Chin Agric Sci 51(14):2799–2813

Godbillot L, Dole P, Joly C et al (2006) Analysis of water binding in starch plasticized films. Food Chem 96(3):380–386

Jin Y, Sun AD (2006) Study on the scavenging activity of apple polyphenols on DPPH free radicals. Brewed China 5:48–51

Jin Y, Sun AD, Hu XD et al (2007) Study on ultrasonic extraction and antioxidation of apple polyphenols. J Beijing For Univ 5:137141

Sekhon-Loodu S, Warnakulasuriya SN, Rupasinghe HP et al (2013) Antioxidant ability of fractionated apple peel phenolics to inhibit fish oil oxidation. Food Chem 140(1–2):189–196

Xu Y. Preparation and study of Nano-Cellulose whisker / chitosan degradable Packaging Composite Film [D]. Zhejiang University of Technology, 2011.

Godbillot L, Dole P, Joly C, B. Roge, and M. Mathlouthi, Food. Chem., 96, 380 (2006).

Chen Q, Shi Y, Chen G et al (2019) Int J Biol Macromol

Acknowledgments

This study is funded by the National Natural Science Foundation of China (61973127). This is also supported by Guangdong Science and Technology Program Project (2017B090901064) and Guangdong Chaozhou Science and Technology Plan Project (020ZX14).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Wang, W. et al. (2021). Preparation and Characterizations of Apple Pomace Polyphenols Modified Cellulose/Starch Edible Packaging Films. In: Zhao, P., Ye, Z., Xu, M., Yang, L., Zhang, L., Zhu, R. (eds) Advances in Graphic Communication, Printing and Packaging Technology and Materials. Lecture Notes in Electrical Engineering, vol 754. Springer, Singapore. https://doi.org/10.1007/978-981-16-0503-1_97

Download citation

DOI: https://doi.org/10.1007/978-981-16-0503-1_97

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0502-4

Online ISBN: 978-981-16-0503-1

eBook Packages: EngineeringEngineering (R0)