Abstract

The present research aims to estimate the thermal performances of an evacuated tube solar dryer (ETSD) and analysis of thin-layer drying kinetics of garlic clove. The experiment of the drying was conducted at individual air velocities, viz. 1, 2, and 3 m/s to evaluate the moisture ratio during the drying progression. The solar intensity and collector outlet temperature were increased up to 2 PM and found to be 964 W/m2 and 85.5 ℃, respectively, and thereafter both are decreased. The maximum drying chamber temperature was noted 76.5 ℃ for drying of the garlic clove. Five thin-layer drying kinetic models were selected and fitted with experimental values of moisture ratio for the identification of the best appropriate drying model. Among the different mathematical models, Weibull model was identified to be best-fitting curve capable for described the drying kinetics at 2 m/s as well as 3 m/s air velocity with highest coefficient of determination (R2) values, least chi-square (χ2) and root mean square error (RMSE) values. However, Modified Page model was showed the best-fitted model at 1 m/s air velocity to describe the drying behavior of garlic clove.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Renewable energy sources have the potential to provide solutions to the possible energy requirement being faced by developing countries. Solar energy could play a very vital role in the drying of food products and helping to decrease the postharvest losses and thereby increases the availability of food products [1]. The potential application of solar radiation energy in food processing is mostly emphasized on drying operation. Drying is a method of removing moisture content of food materials by virtue of heat as well as mass transfer occurred simultaneously during the process. Garlic clove is highly perishable which can be spoilage due to the presence of a high amount of moisture content [2]. To overcome the spoilage, the garlic clove is dried and its moisture content is reduced up to the desired level for safe storage. Therefore, the reduction of moisture content for safe storage is performed by drying applications. Mainly direct and indirect solar dryers are used to drying of the food materials. Solar energy is absorbed either by flat plate collector (FPC) or evacuated tube collector (ETC) and the energy transfer to the drying chamber for drying of food materials. ETC is higher thermal efficiency in comparison with the normal FPC for drying of food materials [3]. Indirect solar dryer mainly comprises solar collectors, blower assembly and drying chamber, etc.

The drying kinetic behavior of the food materials is a complex heat and mass transport phenomenon that involves the representation of the prediction of the drying process behavior and to the optimization of the drying process parameters [4]. Shringi et al. [5] investigated the thermal profile performance of developed solar dryer and found that the temperature 342 K was achieved at drying chamber, and the efficiency of energy varied from 43.06 to 83.73%. Moreover, it has been found that the Midilli model was finest fitted to experimental values of moisture ratio. The outlet temperature of the solar collector was varying from 47.4 to 91 ℃ in ETC-based solar drying system, and the efficiency of the dryer was estimated from 26.68 to 54.72% [6]. Page’s model was showed the best-fitted model to describing the drying behavior of mango slice dried at ETC-based solar dryer [7].

Thin-layer drying kinetic models were applied to predict the moisture ratio (MR) and drying time for the simplification of drying curves. Limited research in drying characteristics of garlic was reported based on ETSD. The purposes of the research were to investigate thermal performance of ETSD and to study the drying kinetics of garlic cloves to identify the best-fitted model of the thin-layer drying process.

2 Materials and Methods

2.1 Sample Collection

Garlic cloves were procured from the local market Narela, Delhi, India, and separated the cloves from the whole garlic. The cloves were soaked for 5 h in mild hot water to remove the peel for the further drying process. The initial moisture content was determined and found to be 69%, and almost equal size of garlic cloves are selected for the further drying process.

2.2 Drying Equipment and Experiments

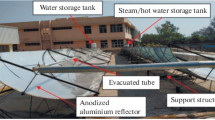

The solar dryer based on ETC was considered to evaluate the performance and study the drying kinetics of garlic clove. The experimental setup of ETC-based solar dryer is as shown in Fig. 1. The dryer consists of a series of 15 evacuated tubes mounted on a common manifold, and centrifugal blower of 0.2 hp is attached for airflow through manifold and drying chamber with the dimension of (0.78 × 0.70 × 1.36) m3.

The experiment was conducted to evaluate the thermal profile of the ETSD during clear sunny days in the month of July, 2019, at NIFTEM, Kundli, India, situated at 28.8676°N, 77.1180°E. The solar dryer was placed in southwest facing at a tilt angle of 45o. The different parameter of thermal profile, viz. solar radiation intensity, drying chamber inlet and outlet temperature, ambient temperature and relative humidity was noted at one-hour interval during 9 AM to 5 PM. The drying experiment was performed at different air flow velocities, viz., 1, 2, and 3 m/s measured by digital Anemometer (±0.17), to evaluate the changes of moisture ratio throughout the drying process. The moisture ratio data was fitted at different thin layers model equations to identify the best-fitted model of the drying curve.

2.3 Drying Kinetics

The drying behavior of garlic clove was expressed in terms moisture ratio which is determined based on the initial and final moisture contents and also the equilibrium moisture content (EMC).

The moisture ratio (MR) is expressed as by this equation given below [8].

where \(M_{t}\) is the MC at time t, Mi and Me are the initial and EMC, respectively.

2.4 Mathematical Modeling of Thin Layer Drying

The moisture ratio of the garlic cloves was estimated experimentally and fitted with different models to identify the best fitted suitable model of drying kinetics of garlic clove in different drying techniques. The following models are considered and were applied to moisture ratio to describe the drying curves and to estimate the different coefficients of the thin-layer model by fitting the data obtained from drying experiments as shown in Table 1.

A non-linear regression modeling was carried out using ‘Origin 18’ (version 2018) to estimate the drying rate constant (k) and various coefficients of the above semi-empirical and empirical models. The identification of best model was done based on the higher value coefficient of determination (R2), the lowest value of chi-square (χ2), and RMSE values for identifying the best the drying curve of food materials. These parameters can be calculated by Eqs. 2, 3 and 4 [9]

where MRexp, i is the experimental MR of the ith data, MRpre,i is the predicted MR of the ith data, N and n are the number of experimentation and drying constant, respectively.

3 Results and Discussion

3.1 Thermal Performance of ETSD

The performance of the solar drying system based on ETC was investigated and represented graphically as shown in Fig. 2. The thermal attributes, viz. solar radiation intensity, collector outlet temperature, relative humidity, drying chamber temperature and atmospheric temperature were noted on an hourly basis throughout the experiment. The solar intensity varied from 606 to 964 W/m2 throughout the days. The solar intensity and collector outlet temperature were increased up to 2 PM and found to be 964 W/m2 and 85.5 ℃, respectively, and thereafter, both decreased with the drying time.

Similarly, the ambient temperature and relative humidity are varied slightly and recorded 30.5–42.5 ℃ and 42–54%, respectively, during the experimentation. The results of the experiment revealed that the temperature of the collector outlet was raised with the increase of solar radiation intensity. A similar variation of thermal parameters was found by Wang W and Umayal Sundari AR. [7, 10].

3.2 Drying Kinetics of Garlic Clove

The moisture ratio of the garlic cloves was determined at different air flow velocities in an ETSD, and the variations are shown in Fig. 3. The concluding moisture ratio was found 0.195, 0.0483, and 0.101 at 1, 2 and 3 m/s, respectively, at the same drying period. It was noted that the optimum diminishing moisture ratio was observed at 2 m/s fluid velocity in comparison with the other air velocities. The results showed that the maximum moisture was removed at 2 m/s fluid velocity followed by 3 m/s and 1 m/s velocity of air during the drying process. A similar trend was reported that the moisture ratio declines consistently with drying time [5].

3.3 Mathematic Modeling

The moisture ratio of garlic clove dried at different airflow velocities was described with five various thin-layer drying kinetics models to identify their suitability to describe the drying behavior. The coefficient of determination (R2) and findings of statistical analyses like chi-square (\(\chi^{2}\)), RMSE, and different model coefficient values are obtained from nonlinear regression modelling analysis are given in Table 2. The best-fitted model to describe the drying kinetics of garlic was identified in accordance with the highest value of R2 = 0.99891 and the lower value obtained of \(\chi^{2}\) = 0.000258 and RSME = 0.00093. From the analysis results, it was noted that the Weibull model gave the highest value of R2 at 2 m/s velocity of air, whereas the \(\chi^{2}\) and RSME values were found lowest during the analysis.

Thus, Weibull model is represented as the best-fitted model for drying kinetic of garlic clove drying at ETSD. Similarly, Modified Page model and Weibull model were identified as the best-fitted models to describe the drying kinetics of garlic clove at 1 and 3 m/s air velocity, respectively. The best-selected-fitted models at different air velocity by plotting the data of the experimental values of moisture ratio with that of the predicted values are displayed in Fig. 4a–c. The experimental values of MR were found to be best aligned to the predicted values with R2= 0.99891 at 2 m/s and R2= 0.99846 at 3 m/s described by Weibull model. The experimental values of moisture ratio at 1 m/s are very closed to the predicted value represented by the best suitable Modified Page model with R2= 0.99862.

4 Conclusion

The thermal performance of an ETSD and drying kinetics of the garlic cloves are investigated. The maximum temperature achieved at the solar collector outlet was found to be 85.5 ℃ at 2 PM; afterward it reduced with the drying time. The moisture ratio curve was less diminishing at airflow velocity of 2 m/s followed by 3 and 1 m/s. The Modified Page model was found to be the best-fitted model of air velocity at 1 m/s. The Weibull model showed the best fit through higher coefficient of determination R2 at 0.998 with low \(\chi^{2}\) and RSME value both at 2 m/s as well as 3 m/s air velocity during the drying process of garlic clove.

References

Chauhan YB, Rathod PP (2018) A Comprehensive Review on Solar Dryer. Int J Ambient Energy 41(3):1–28

Singh A (2014) Effect of Drying Characteristics of Garlic-A Review. J. Food Process. Technol. 05(04):1–6

Chopra K et al (2018) Global advancement on experimental and thermal analysis of evacuated tube collector with and without heat pipe systems and possible applications. Appl Energy 228(June):351–389

Velić D et al (2004) Influence of airflow velocity on kinetics of convection apple drying. J Food Eng 64(1):97–102

Shringi V et al (2014) Experimental investigation of drying of garlic clove in solar dryer using phase change material as energy storage. J Therm Anal Calorim 118(1):29–41

Venkatesan N, Arjunan TV (2014) An experimental investigation and performance analysis of a solar drying of bitter gourd using an evacuated-tube air collector. Int J ChemTech Res 6(14):5510–5518

Wang W et al (2018) Thermal performance of indirect forced convection solar dryer and kinetics analysis of mango. Appl Therm Eng 134:310–321

Mehta P et al (2018) Design and performance analysis of a mixed mode tent-type solar dryer for fish-drying in coastal areas. Sol Energy 170(May):671–681

Chayjan RA et al (2013) Modeling moisture diffusivity, activation energy and specific energy consumption of squash seeds in a semi fluidized and fluidized bed drying. J Food Sci Technol 50(4):667–677

Umayal Sundari AR et al (2013) Performance evaluation of a forced convection solar drier with evacuated tube collector for drying amla. Int. J. Eng. Technol. 5(3):2853–2858

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Malakar, S., Arora, V.K. (2021). Mathematical Modeling of Drying Kinetics of Garlic Clove in Forced Convection Evacuated Tube Solar Dryer. In: Sikarwar, B.S., Sundén, B., Wang, Q. (eds) Advances in Fluid and Thermal Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0159-0_72

Download citation

DOI: https://doi.org/10.1007/978-981-16-0159-0_72

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0158-3

Online ISBN: 978-981-16-0159-0

eBook Packages: EngineeringEngineering (R0)