Abstract

Despite of the fact that Earth’s atmosphere has abundant freshwater inform of moisture, water scarcity is one of the crucial problems especially in humid, hot, and drought prone regions. The conventional systems which extracts atmospheric water are very bulky, incompatible with the existing system, energy intensive, impractical, low water yield and expensive. These adverse effects hinder their deployment for large scale applications. In this manuscript, a water harvesting device is deigned and fabricated for extracting water from moist air. The device uses vertical copper pipes entrenched in horizontal Al fins as the condensing surfaces. All the components of the device functions on solar powered energy. The proposed device is environment friendly, compact, lightweight, low manufacturing, and maintenance cost. The device generate water with turbidity of 40 PPM. Results shows that condensation rates strongly depend on the relative humidity, saturation temperature of the moist air, and degree of subcooling. In this device, the cost of water is estimated as Rs. 10 per liter. This device is efficient for providing drinkable water in hot and humid, water scare regions globally.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Water cries is particularly severe challenge in hot, humid, arid, and drought prone region of the world. However, enormous amount of freshwater is present in atmospheric air in form of moisture. Harvesting water from atmospheric air is an innovative technology which have strong potential to combat the problem of potable water cries by producing liquid water from atmospheric air. In literature, three variation of this technology is reported for instance; generating drinkable water by cooling the atmospheric air onto/underneath a cold solid or mesh like surfaces below than the dew point temperature, concentrating water vapor by using liquid or solid desiccants, or by inducing and controlling convection in tower like structure [1, 2]. Out of these variations, the desiccant and condensation on solid and mesh like surfaces methodologies are predominantly implemented for extracting atmospheric water [3]. However, the common problem typically associated with the desiccant methods is, this system includes corrosion and the carryover of desiccant solution into the air stream [4]. Therefore, the condensation technique is more practically viable as it has ability to exploit huge amount of water from atmospheric air, it is safe for human consumption and environment as it does not produce any hypersaline waste discharge.

Various authors [5,6,7,8,9,10,11,12] have developed technologies for generating water from moist air. Ming et al. [5] designed and developed a freshwater harvesting system from moist air using solar chimney power plant. They implemented 1-D compressible fluid transfer model and estimated condensation level and rates, efficiency, and output power of the system. Eslami et al. [6] reported a holistic thermodynamic analysis of condensed water from moist air using Peltier modules. Jradi et al. [7] combined a moist air dehumidification system with solar distiller system and enhanced the distillate output to 10 l/day of fresh water from moist atmospheric air. Bamisaye and Oke [8] developed an empirical relation for estimating the water produced from moist air in an conventional room air conditional systems specially for Nigeria regions. Suryaningsih and Nurhilal [9] developed an atmospheric water generator using thermo-electric cooler and performed a CFD analysis for the same to optimize the design process. Also, several devices for generating water from moist air are commercially available [10,11,12]. However, these systems are very bulky, incompatible with the existing system, energy intensive, impractical, low water yield, and expensive. These adverse effects limit their implementation for large scale industrial and domestic applications.

In this background, the device for harvesting water from atmospheric air is designed and fabricated to investigate its performance parameters for enhancing its efficacy. The proposed device presents a modified alternative to the state-of-the-art available technologies. The study incorporated an experimental procedure for evaluating the effect of various parameters on the condensation rate. The effect of relative humidity, degree of subcooling, and saturation temperature are addressed. The device comprises of Cu pipes embedded in Al fins as the condensing unit and solar powered fan module for moist air intake. The device generates pure water with turbidity of 40 PPM which after mineralization and UV filtration is fit for human consumption. The proposed device has wide application in providing potable water in hot and humid regions worldwide. The results of study are useful for engineers and designers while optimizing the performance parameters of the atmospheric water harvesting devices.

2 Experimental Study

In this experimental study, moist air is condensed on extended surface (Al fins) which are attached with the series of array of Cu tubes. Cu and Al has higher thermal conductivity as compared to other metallic surfaces. However, Cu is expensive and more corrosive in nature than Al. Therefore, in this work, the condensing surfaces were selected as the Cu tubes entrenched in the Al fins, where fins house the major portion for the condensation process and significantly helps in optimizing the cost of condenser unit. Such condenser designs are also widely used in conventional household air-conditioning unit. Hence, the study is also helpful for optimizing the performance parameters of the room air conditioners.

Atmospheric moist air is a combination of dry air and water vapor. The quantity of water vapor present in moist air depends on the environmental temperature and pressure. The water vapor can be either in saturated or unsaturated state in the moist air. This state defines the difference between moist air temperature and dew point temperature. Moist air is a binary fluid whose thermophysical properties are strong function of temperature and pressure; the properties are estimated as [13].

In this expression, \(\bar{M}_{m}\) is the molecular weight of moist air, P0 is the total pressure of moist air (P0 = 1 atm) for moist air at atmospheric condition and the density (ρm) and specific heat of moist air (Cpm) are determined as;

Here, T is the moist air temperature, RH is the relative humidity, Ma is the mass of air (28.963 kg/Kmol), Mv is the mass of water vapor (18.02 kg/Kmol), Psat is the pressure corresponding to saturation temperature, Cpm, Cpa, and Cpv is the specific heat capacity of moist air, dry air, and water vapor in J/kg K.

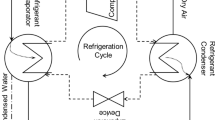

The experimental setup used in this study is as shown in Fig. 1a, b. Figure 1a shows the schematic diagram, and Fig. 1b shows the photograph of the device for atmospheric water harvesting. It consists of a condenser unit and solar fan module mounted inside a rectangular duct of cross-sectional area A = 420 mm × 390 mm and solar powered customized water-cooling unit. The condenser unit incorporates vertical copper pipes entrenched into number of horizontal thin aluminum fins in order to ensure maximum area for condensation. The solar powered fan is used for moist air intake inside the condensing chamber. The fan was operated at required speed to ensure optimal mass flow rate of the moist air onto the condenser unit. In order to measure the CFM at required speed (QN), initially, the maximum velocity (Vmax) was measured using digital hot wire anemometer, Kusum Meco (KM-734). The velocity was measured perpendicular to the direction of motion of moist air at 20 different location across the height of the duct of cross section area (A). In addition, the revolutions per minute (RPM) of the fan at maximum speed (Nmax) and required speed (Nreq) was measured via a digital tachometer in non-contact mode (ESCORP). The required speed of the fan is set such that the viscous dissipation of moist air flow is negligible. The flow rate of moist air at the required speed is evaluated as;

In this device, the solar energy is converted to electrical energy using custom built-in inverter unit and used for powering water-cooling unit. This unit flows cold water into copper pipes of the condenser unit at constant temperature. As soon as the temperature of the condenser unit reaches a temperature below than the dew point temperature of ambient moist air, the water vapor present in the moist air condenses on the copper pipes and aluminum fins of the condenser unit. The condensed water gradually grows by direct condensation and coalesce mechanism and subsequently fall-off from horizontal aluminum strips and slide-off from the vertically oriented copper pipes. The condensed water is further collected into the collection tank and used for analyses.

Experiments were carried out in month of July and August at controlled moist air temperature and relative humidity during daytime. The moist air condensation experiment was repeated 5 times for ensuring the repeatability of the results. Throughout the experiment, humidity and temperature of moist air at inlet and outlet of condenser unit and temperature of the condenser unit were measured at various locations. The real-time data acquisition of the temperature was carried out using T-type thermocouples attached with National Instruments LabVIEW controlled NI-9211(National Instruments) temperature card, and humidity was measured via hygrometer, Kusum Meco (KM-918). The uncertainty in the temperature and humidity of moist air were measured as 1.5% and 2.3%, respectively. The amount of condensate collected was measured in calibrated collection tank and TDS meter, Wellon (TDS-3) was used for measuring the turbidity of the condensed water to quantitatively and qualitatively analyzes the condensed water and ensure its consumption for human use.

3 Results and Discussion

The results of the experimental study carried out for the atmospheric water harvesting device is detailed in this section. Moist air condensation experiment was carried out for various values of moist air temperature, relative humidity, and degree of subcooling. The temperature and humidity were directly measured from the environment at inlet and outlet locations. Various set of degree of subcooling was achieved by suppling cold water at desired temperature using constant temperature water cooling unit. In this study, all the experiments were conducted for total duration of 3 h. The values of parameter under study was recorded using respective sensors, further the acquired data was averaged to obtain the final value of the parameters. The efficiency of the device was estimated by analyzing the mass of condensate collected from experimental studies.

Figures 2 and 3 show the condensation rate as a function of relative humidity, degree of subcooling and moist air temperature. Results shows that as the relative humidity, moist air temperature, and degree of subcooling increase, the condensation rate linearly increases for the proposed device. Hence, the device is efficient for curing water scarcity especially in hot and humid regions with humidity and temperature ranging from 50–90% and 20–50 ℃, respectively.

In addition, the quality of condensed water was also examined to investigate that the water is fit for consumption or not. According to WHO, the permissible limit of TDS in India is <500 PPM [14]. In the present work, the turbidity of the condensed water was measured using sensor as 40 PPM. Apparently, the water collected from the proposed water harvesting device is fit for human consumption.

The cost of a liter of water produced by the proposed water harvesting device was estimated for operating conditions inlet moist air temperature = 40 ℃, degree of subcooling (ΔT) = 10 ℃, relative humidity = 80%. In this device, solar energy was converted to electrical energy and was supplied to fan module and water-cooling unit. This cooling unit cools the water at desired temperature and flows the water at constant temperature using preinstalled pump. The power requirement of water-cooling unit, PWC (kW) is estimated as;

where \(\dot{m}\)(= 0.0105 kg/s) is the mass flow rate of water-cooling unit and Cpw is the specific heat of water. Further, the power requirement of fan modules Pfan (kW) was estimated as;

where dp is the total pressure increased in the fan (N/m2) and QN is the volumetric flow rate of moist air through fan (m3/s). Finally, the total energy requirement of the water harvesting device Ptotal (kW) is;

Further, total energy requirements of the device are Etotal (kWh)

where t (hours) is the total time for which the condensation experiment was performed. It is well acquainted that the cost of solar energy in India is \(\bar{C}\) = Rs. 3.5 per kWh. So, the cost of producing 1 L of water C (Rs.) from the proposed device is estimated as,

Here, mcond (liters) is the amount of condensed water collected during the experiment. Hence, from above formulation, the cost of water produced from proposed device is estimated as Rs. 10 per liter.

4 Conclusion

A solar-based device for generating water from moist atmospheric air is designed and fabricated. Device generates portable water for hot and humid water scare regions. In this work, moist air condensation experiments were performed in controlled ambient conditions and investigated the effect of various parameter on the performance of proposed atmospheric water harvesting device. Parameter under consideration were relative humidity, moist air temperature, and degree of subcooling. In addition, analysis was done on the quality of water which is obtained from moist air condensation. The present study concluded that the design of condenser unit, i.e., Al fins entrenched into series of array of Cu tubes enables more surface area, therefore increases condensation rates onto the surface. Condensation rates increases with increasing relative humidity, moist air temperature and degree of subcooling. The quality assessment of the atmospheric water harvesting device shows that the device generate water with turbidity of 40 PPM which is suitable for human consumption. Finally, the cost of water from present device is estimated as Rs. 10 per liter, which is reasonable price, however, the present cost can be further decreased by improving the chemo-physical properties of the condensing surface.

Abbreviations

- A :

-

Cross-sectional area of rectangular duct (mm2)

- \(\bar{C}\) :

-

Cost of solar energy in India (Rs.)

- C :

-

Cost of producing 1 L of water from the proposed device (Rs.)

- C p :

-

Specific heat capacity (J/kg K)

- dp:

-

Total pressure increased in the fan (N/m2)

- ΔT:

-

Degree of subcooling (℃)

- E total :

-

Total energy requirements of the device (kWh)

- m :

-

Condensation rate (l/h)

- m cond :

-

Amount of condensed water collected during the experiment (l)

- \(\dot{m}\) :

-

Mass flow rate of water-cooling unit (kg/s)

- M a :

-

Mass of air (28.963 kg/Kmol),

- M v :

-

Mass of water vapor (18.02 kg/Kmol),

- N max :

-

RPM of the fan at maximum speed

- N req :

-

RPM of the fan at required speed

- P 0 :

-

Total atmospheric pressure (bar)

- P fan :

-

Power requirement of fan modules (kW)

- P sat :

-

Pressure corresponding to saturation temperature (bar)

- P total :

-

Total energy requirement of the water harvesting device (kW)

- P WC :

-

Power requirement of water-cooling unit (kW)

- Q N :

-

Flow rate of moist air at the required speed (m3/s)

- Q max :

-

Flow rate of moist air at the maximum speed (m3/s)

- RH:

-

Relative humidity (%)

- t :

-

Total time of condensation experiment (hours)

- T :

-

Moist air temperature (℃)

- V max :

-

Maximum speed (m/s)

- a:

-

Properties of dry air

- m:

-

Properties of moist air

- v:

-

Properties of water vapor

- w:

-

Properties of water

- CFM:

-

Cubic feet per minute

- PPM:

-

Parts per million

- RPM:

-

Revolutions per minute

References

Wahlgren RV (2001) Atmospheric water vapour processor designs for potable water production: a review. Wat Res 35(1):1–22

Hamed AM, Kabeel AE, Zeidan ESB, Aly AA (2010)A technical review on the extraction of water from atmospheric air in arid zones. JP J Heat Mass Transf 4(3):213–228

El-Ghonemy AMK (2012) Fresh water production from/by atmospheric air for arid regions, using solar energy: review. Renew Sustain Energ Rev 16(8):6384–6422

Liu XH, Yi X, Jiang Y (2011) Mass transfer performance comparison of two commonly used liquid desiccants: LiBr and LiCl aqueous solutions. Energ Convers Manag 52:180–190

Ming T, Gong T, de Richter RK, Wu Y, Liu W (2017) A moist air condensing device for sustainable energy production and water generation. Energ Convers Manag 138:638–650. https://doi.org/10.1016/j.enconman.2017.02.012

Eslami M, Tajeddini F, Etaati N (2018) Thermal analysis and optimization of a system for water harvesting from humid air using thermoelectric coolers. Energ Convers Manag 174:417–429. https://doi.org/10.1016/j.enconman.2018.08.045

Jradi M, Ghaddar N, Ghali K (2012) Experimental and theoretical study of an integrated thermoelectric-photovoltaic system for air dehumidification and fresh water production. Int J Energ Res 36(9):963–974. https://doi.org/10.1002/er.1848

Bamisaye OS, Oke PK (2019) Modelling the condensed water discharge rate in air conditional system in south west, Nigeria. Curr J Appl Sci Technol 32(3):1–13

Suryaningsih S, Nurhilal O (2016) Optimal design of an atmospheric water generator (AWG) based on thermo-electric cooler (TEC) for drought in rural area

Gerard RD, Worzel JL (1972) Atmospheric water extraction over the ocean, beneficial modifications of the marine environment. In: Symposium sponsored by national research council and department of the interior, Washington DC, 11 Mar, 1968. National Academy of Sciences, Washington, DC, pp 66–84

Harrison LG (1996) Water recovery device for reclaiming and refiltering atmospheric water. Patent Appl 5,553,459

Rosenthal RA (1999) Atmospheric water extractor and method. Patent Appl 5,857,344

Tsilingiris PT (2008) Thermophysical and transport properties of humid air at temperature range between 0 and 100 ℃. Energ Convers Manag 49(5):1098–1110. https://doi.org/10.1016/j.enconman.2007.09.015

Kumari M, Mudgal LK, Singh AK (2013) Comparative studies of physico-chemical parameters of two reservoirs of Narmada river, MP, India. Curr World Environ J 8(3):473–478. https://doi.org/10.12944/cwe.8.3.18

Acknowledgements

The authors acknowledge the financial support from Science and Engineering Research Board (SERB), Department of Science and Technology (DST), Govt. of India (Project No. ECR/2016/000020).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Baghel, V., Sikarwar, B.S. (2021). Performance Investigation of Atmospheric Water Generating Device for Hot and Humid Conditions. In: Sikarwar, B.S., Sundén, B., Wang, Q. (eds) Advances in Fluid and Thermal Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0159-0_4

Download citation

DOI: https://doi.org/10.1007/978-981-16-0159-0_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0158-3

Online ISBN: 978-981-16-0159-0

eBook Packages: EngineeringEngineering (R0)