Abstract

The design, development and manufacturing of products inevitably involve environmental aspects (e.g., material and energy consumption) that lead to negative environmental impacts (Herrmann in Ganzheitliches Life Cycle Management, Nachhaltigkeit und Lebenszyklusorientierung in Unternehmen. VDI-Buch. Springer, Berlin, 2010, [1]). The awareness of these issues enables an understanding of the immediate effects that design and manufacturing have on the environment and how products can affect the ecosystems around them. We face many problems, and we can only solve if the design of products is geared to ecological requirements. This requires that product development is regarded as a holistic and interlinked process. This results in the consideration of processes such as recycling, downcycling as well as maintainability and material separation in our product life cycles. Hence, production and environmental problems were treated independently of each other for a long time, and the environment had received little attention in the phases of the product development process (Huang in Design for X, Springer, Netherlands, Dordrecht, 1996, [2]). Especially small- and medium-sized enterprises will increasingly face problems in aligning their innovation activities with ecological requirements. So far there is no practical approach to holistic and interlinked product development that sufficiently takes ecological requirements into account and is easy to adopt for SMEs.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

On January 1, 2016, the 17 United Nations goals for sustainable development (SDGs) came into force [3, 4]. In addition to economic and social goals, a major focus is on ecological goals. In order to measure its own achievement of these goals, Germany formulated a series of indicators that were adopted as part of the German Sustainability Strategy (DNS) 2016 [5], 6. A central goal of the sustainability strategy at the ecological level is the establishment of sustainable consumer and industrial products to reduce energy consumption and CO2 emissions (goal 12) [7]. This goal can only be achieved if the design of consumer and industrial products and also the business models for their economic exploitation are geared to ecological requirements. The design and development of the consumer or industrial product must therefore be adapted to the needs of the target group in line with the corporate objectives and capabilities.

Thus, this paper analyzes literature to find criteria for the selection of methods geared to the needs of SMEs. The selection of methods for the design and development of the consumer or industrial product must therefore be adapted to the needs of the companies’ circumstances, the ecological affordances, the target group in line with the corporate objectives.

2 Current Situation

Especially small- and medium-sized enterprises (SME), in contrast to large companies, will increasingly face problems in aligning their innovation activities with ecological requirements in terms of the DNS. In principle, many of these companies do not have a structured innovation process, as they lack research and development departments, budgeting, etc. Moreover, these companies do not have the necessary resources, capacities, innovation skills and sustainability expertise to develop ecological innovations completely independent [8]. For the federal state of Saxony-Anhalt in Germany in particular, the report on the SME offensive certifies [9] (p. 12) that there are “in many cases innovation-oriented small and medium-sized enterprises which do not have the structural and personnel prerequisites, or do not have them to the same extent, to be able to realise product innovations without support”. Consequently, it is necessary to support SMEs in structuring their innovation process and aligning it with ecological requirements in the sense of the DNS—an SME-oriented step-by-step approach can make a valuable contribution here. Therefore, context-sensitive methods can be used to reduce the need to use one specific approach. This means that the selection of methods for accomplishing a task within the process model depends on the type of project, the development status, the time resources and the available data [10].

If one looks only at the area of product development, some development concepts are frequently used both in university teaching and in business practice, such as Integrated Design Engineering [11], the Design Thinking [12,13,14], the Agile Project Management (among others in [13, 15,16,17]) the VDI2221 [18, 19]. However, these concepts are not geared to the consideration of ecological requirements yet.

According to PIGOSSO et al., in contrast very specific impact categories of sustainability are considered in the eco-design literature, in which a large number of methods and tools are published [20]. In the context of this literature strand, however, the intercompatibility of the presented methods and tools is hardly or not at all questioned, and it remains unclear to what extent they can be integrated into a superordinate product development concept. Also, the tailor-made selection of methods according to the context and needs within companies is not or only insufficiently considered [20, 21]. Consequently, some researchers see precisely this variety of methods and tools as a barrier to application in industry, since it is not clear in which situations which methods with the corresponding tools are relevant [20]. There is a lack of approaches and methodologies for accelerated and optimized application by industry [20].

The approaches shown in Table 74.1 come closest to a SME-oriented approach to product development, considering sustainability requirements. On the one hand, the above-mentioned approach of Integrated Design Engineering (IDE) [11] is also used at the OVGU in the context of industrial projects and teaching and on the other hand further approaches such as Design 4 Sustainability (D4S) [22], System Design for Sustainability (SDS) [22], Design for Base of Pyramid (DfBOP) [23, 24] and Human Centered Design (HCD) [25]. All approaches are practical concepts, some of which provide for a concrete step-by-step approach to product development (IDE, D4S, SDS) and some of which can also cover SME-specific R&D needs (D4S, SDS, HCD). In particular, D4S and SDS seem to be easy to implement even by people from outside the industry. Compared to the other approaches, HCD is widely used in the literature and offers product developers an extensive collection of methods, but its suitability for practical application is to be rated less highly here, as the approach offers little assistance in implementing the procedure. The implemented human-centered approach (IDE, HCD) or team orientation (IDE, D4S) shall also be emphasized in some approaches.

3 Take Precedence and Aim of Research

With regard to the weaknesses of the individual development approaches shown in Table 74.1, it is striking that with the exception of D4S, ecological requirements are only insufficient considered. In the case of SDS and DfBOP, social aspects of sustainability are primarily targeted, with economic and ecological requirements playing a subordinate role. Since the development of products that primarily address markets in developing countries requires an effort that is likely to exceed the available resources and capacities of many SMEs.

The necessity of implementing the needs of SMEs with regard on the ecological aspects of product development into a holistic approach has been recognized. Especially for SMEs, a specific step-by-step approach seems to be a good work practice. This can practically concretize the individual phases of the interlocking product development as well as the methods and tools to be used in the individual phases. In view of the strengths and weaknesses of the above-mentioned product development approaches, it can be concluded that individual aspects of these approaches (e.g., tools) can be combined in a synergetic way for such a step-by-step approach. In conclusion, it shall be noted that previous approaches only partially take into account the underlying vision or the economic, ecological and other goals of SMEs, especially with regard to the DNS. This is necessary in order to ensure that they are willing to apply them.

A core objective of the development work is the precisely fitting applicability of the procedural concept by SMEs. Accordingly, it shall be ensured that the concept can be integrated into the companies without the need for specialized personnel. In addition, the SME-specific framework conditions, such as scarce capacities and the partial lack of data on the product life cycle, are to be considered. For the development of the approach concept, this means that a decision support for SMEs will be necessary, which explains the individual development steps as well as the methods and tools applicable in each case in detail. On the one hand, it can be avoided that the multitude of methods and tools mentioned before overburdens the non-specialized user. On the other hand, the procedural concept enables a timely implementation of the product development by means of SME practice-oriented worksheets and tools and thus counteracts the shortage of time in SMEs. Therefore, it is necessary to identify fitting methods and tools which can be used in SMEs by apply identified criteria first. Therefore, it is needed to define measurable practice-oriented and sustainability criteria, which will be used to rate the methods and then to design the process concept. In the narrower sense of sustainable products, it is necessary to question the existing product range and also the inclusion of new products in the product range [35]. BERGMANN [36] mentioned that the first two steps are the thorough needs analysis and the examination of possible immaterialization strategies. In these two steps, it is checked whether a physical product is needed at all, whether it can be immaterialised alternatively and whether it is justifiable from a sustainability point of view. Only in the third step does the actual program policy, product conception and product development begin. On the basis of the steps contained therein a sustainable product offer is created. In this paper, it is assumed that the first two steps are already finished and that the focus is on the integration of possible methods into SME processes.

For the present within this research, the definition of criteria to determine the capability to integrate a method into a SMEs product development approach and whether is mature enough is based on a research paper written at OVGU [37]. VAJNA et al. derive from case studies different criteria for comparing methods with each other (General applicability, Innovation enabling, Complexity of the method, Complexity of the supported products, Exploitation of computer support, Integration of different domains, Applicable to different kind of products, Balancing of different product goals, Analogies to nature, Inclusion of economical influences, Consideration of social sciences, Support of communication, Support of single work, Support of teamwork Systematic and predetermined procedures, Opportunistic course of action, Parallelization of activities, Dynamic reaction to changes of conditions, Ongoing comparison and evaluation of actual results, Continuous feedback, Anticipation of results, Several equivalent, but not similar solutions, Teachability, Generality, Practicability) [37].

Other researchers also defined criteria for analyzing methods but use different vocabulary to describe the criteria. Ernzer et al. focused on methods for life cycle design based on the needs of a company and give an approach to a systematic analysis of the company to select suitable methods [38]. Hereby requirements arise from relations to the product, the surrounding environment and the company. Watty et al. point out the significance of criteria selection for the choice of quality methods to achieve a high-quality product as well as product development process at reasonable costs. They correlate the benefits of larger flexibility on the market and shorter time to market, less loops in the development process, less rejection or rework, better documentation and an increasing motivation to the selection of method [39]. They refer to the importance of considering different motives of quality at the selection of a method must regard the demands of the society, companies and the customer, while even intersecting demands may differ in their motive. EDER explores “the need for a formalized engineering design methodology” and reveals a higher level of guidance in an engineering design procedure when the problem is not seen as a routine or the expertise in the product as well as the process is lacking. Especially the expertise of novice and advanced beginners needs to be considered, not in the field of the company’s domain but in the field of applying new and more suitable methods of product development [40].

Within these reviews, the product, the surrounding environment, and the company itself are considered from different point of views and point out the importance of a substantial selection of criteria to select appropriate methods meeting all requirements. Within this research, the criteria have been reduced and it has also been considered to be necessary that the sustainable criteria group had to be implemented. This step needs further research and have to be validated within case studies. Baumann [41] in 2002 mentioned steps for communication are necessary for a good impact with regard to the applicability. The understanding of the role, impact and contribution of tools leads to a better learnability of methods.

A further distinction can be made between product-related and company-related criteria, both of which in turn surround criteria of legislation, standards and market-related criteria [38]. Product-related criteria include the complexity of products, the degree of ecological perfection, the number of pieces (product range) and the dominant life phases of the product. The company-related criteria are the competence in DfE (design for environment), the general method competence, the degree of innovation, resources of the DfE department, and the strategic targets of the company. Laws, standards, and the market define the surrounding criteria for methods which can be implemented into a product development process. Figure 74.1 shows an overview of the categorized criteria identified so far are structured according to priority and chronological order of the evaluation process to be carried out. Consequently, when evaluating a method for its applicability, sustainability is considered first. If this proves to be sustainable, the evaluation of the criteria can be advanced to the next category. Thus, the first evaluation step proves to be possible exclusion criteria. Furthermore, the categories of applicability and integratability have to be fulfilled in order that a method can be integrated into SME processes.

Thus, aspects of the category integratability such as learnability and practicability include a partial aspect of sustainability. These, in turn, are sometimes based on criteria from the category of applicability, such as low complexity, step-by-step approach and communication of the results. Consequently, a low complexity increases the learnability, thus a method that is easy to learn is re-applied with a higher probability, which can lead to a higher effect in the sustainability of companies. In this phase of the work, the criteria are assigned zero to five points and summed up to the categories. This results in a maximum of 25 points for the category of sustainability, 30 points for applicability and 15 points for integratability.

For the evaluation of the identified methods with regard to their general usability in the company, a minimum number of points will have to be assigned to the categories in the process of work. In addition, the criteria and their categories must also be checked and, if necessary, adjusted. In addition, the evaluation of a method can be carried out in comparison to another conceivable method in order to compare its applicability in the company and its processes as well as its situation. A semantic differential or a comparison in a table can be used for the evaluation among themselves.

In the development of the project, it will be determined which of these concepts and methods meet the previously defined criteria. Also, it needs to become evaluated to what extend they can be used for different types of product development, e.g., generally valid or context-sensitive, and to what extent they can be effectively combined. From this analysis, a development requirement for the procedural concept is derived, which is then processed conceptually.

4 Summary

Up to this point, criteria have been collected for the identification of applicable methods into SMEs in order to implement sustainable methods for product development. This will lead to the carefully selection of fitting methods according to the needs of SMEs with regard to sustainable aspects. The criteria identified in this paper are summed up within the criteria tree (Fig. 74.1) which could be seen as a requirements list for methods to implement ecological requirements of a product development within SMEs. The awareness of the methods capabilities enables an understanding of the immediate effects that lead to a holistic approach. SMEs can use the additional information and support designers with methods which fit to the actual the development task, a specific phase of product development and also can be used to compare different methods.

5 Outlook

This approach will be improved, detailed, and verified in further research by applying it within the extension of researching methods. For the next step to create a sustainable product development approach, more methods which can be used in SMEs will be identified and rated with the developed criteria. According to the guideline VDI 2221 [18, 19], the design process is divided into different stages. Bhamra and Lofthouse [27] grouped often used tools (see Table 74.2) into five sections; Environmental Assessment, Strategic Design, Idea Generation, User-centred Design, and Information Provision. To simplify the project- and SME-specific method selection process, the identified criteria can also be used as indicators for offering fitting methods within different development tasks.

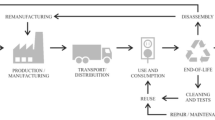

This grouping, as well as the variety of methods, is to be adopted in the following steps for the creation of the product development concept, but the group of environmental assessment is still insufficient and will be extended by some methods. These groups can be roughly assigned to the product development phases; see Fig. 74.2. What can be used to rate the criteria for phase assignment and to give the SME an overview in which phase the method can be used. After rating the methods and structure with regard to the phases, a holistic approach can be gathered. The transfer of the methods and also the criteria will be evaluated by implementing the methods within education and industry cooperations such as case studies. This leads to the opportunity to recognize not adapted characteristics of a company. What gives a view whether the methods and the criteria fit the capabilities of the company or not.

References

Herrmann, C.: Ganzheitliches life cycle management. Nachhaltigkeit und Lebenszyklusorientierung in Unternehmen. VDI-Buch. Springer, Berlin (2010)

Huang, G.Q.: Design for X. Springer, Netherlands, Dordrecht (1996)

United Nations publication issued by the Department of Economic and Social Affairs. In: Sustainable Development Goals Report, vol. 2019. United Nations, New York (2019)

Martens, J., Obenland, W.: Die agenda 2030. Globale Zukunftsziele für nachhaltige Entwicklung, 30th edn. Global Policy Forum; terre des hommes, Bonn, Osnabrück (2017)

BK-Amt: Deutsche Nachhaltigkeitsstrategie. Neuauflage 2016, 11044 Berlin (2016 (soweit nicht anders vermerkt), Kabinettbeschluss vom 2017)

BK-Amt: Deutsche Nachhaltigkeitsstrategie. Aktualisierung 2018, 11044 Berlin (2018 (soweit nicht anders vermerkt), Beschluss Bundeskabinett vom 2018)

Statistisches Bundesamt (Destatis): Nachhaltige Entwicklung in Deutschland - Indikatorenbericht 2018. Heike Becker, Jens Hoffmann (2018)

Hansen, E.G., Klewitz, J., Schaltegger, S.: Industrie Management 5/2013: Eco-Innovation. GITO mbH Verlag (2013)

Ministerium für Wirtschaft, Wissenschaft und Digitalisierung des Landes Sachsen-Anhalt: Mittelstandsoffensive Sachsen-Anhalt I3—Wachstum durch Innovationen, Investitionen und Internationalisierung. Hier ist der Mittelstand (2020)

Wiesner, M., Kokoschko, B., Bùi Duy, L., Augustin, L.: Card Sorting basierter Ansatz zur Erarbeitung einer nutzungsgerechten Methodensammlung am Beispiel des IDE-Toolkits. In: Krzywinski, J., Linke, M., Wölfel, C. (eds.) Entwerfen Entwickeln Erleben 2019, pp. 29–40. Dresden (2019)

Vajna, S. (ed.): Integrated design engineering. Ein interdisziplinäres Modell für die ganzheitliche Produktentwicklung. Springer Vieweg, Berlin (2014)

Brenner, W., Uebernickel, F.: Design thinking for innovation. Springer International Publishing, Cham (2016)

Naccari, F.: Enterprise integration in the user industries—needs and current solutions. In: Kosanke, K., Nell, J.G. (eds.) Enterprise Engineering and Integration. Building International Consensus Proceedings of ICEIMT ’97, International Conference on Enterprise Integration and Modeling Technology, Torino, Italy, October 28–30, 1997. Research Reports Esprit, pp. 27–33. Springer, Berlin, Heidelberg (1997)

Plattner, H., Meinel, C., Leifer, L.: Design thinking research. Springer International Publishing, Cham (2015)

Cockton, G., Lárusdóttir, M., Gregory, P., Cajander, Å.: Integrating user-centred design in agile development. Springer International Publishing, Cham (2016)

Kusay-Merkle, U.: Agiles Projektmanagement im Berufsalltag. Springer, Berlin Heidelberg (2018)

Schwaber, K., Sutherland, J.: The scrum guide. Die Spielregeln, Der gültige Leitfaden für Scrum (2017)

VDI: VDI 2221 Blatt 1. Entwicklung technischer Produkte und Systeme - Modell der Produktentwicklung, VDI 2221 Blatt 1. Verein Deutscher Ingenieure, Berlin (2018)

VDI: VDI 2221 Blatt 2. Entwicklung technischer Produkte und Systeme - Gestaltung individueller Produktentwicklungsprozesse, VDI 2221 Blatt 2. Verein Deutscher Ingenieure, Berlin (2018)

Pigosso, Daniela, C.A., Rozenfeld, H., McAloone, Tim, C.: Characterization of the state-of-the-art and identification of main trends for ecodesign tools and methods. Classifying three decades of research and implementation. J. Ind. Inst. Sci. 95(4), 405–426 (2015)

Johansson, G.: Success factors for integration of ecodesign in product development. Environ. Manage. Health 13(1), 98–107 (2002). https://doi.org/10.1108/09566160210417868

Vezzoli, C., Kohtala, C., Srinivasan, A., Xin, L., Fusakul, M., Sateesh, D., Diehl, J.C. (eds.): Product-service system design for sustainability, 1st edn. Taylor and Francis, Saltaire (2014)

Prahalad, C.K.: Der Reichtum der Dritten Welt. Armut bekämpfen, Wohlstand fördern, Würde bewahren, 1st edn. FinanzBuch-Verl., München (2006)

Prahalad, C.K.: The fortune at the bottom of the pyramid. Strategy + business 26 (2002)

IDEO: Human-Centered Design Toolkit: An Open-Source Toolkit To Inspire New Solutions in the Developing World (Lee, M.H. et al. Trans.), Edit the World. https://www.ideo.com/tools (2011)

Neutschel, B., Wiesner, M., Schabacker, M., Vajna, S.: Vorgehensweisen zum Einsatz universitärer Produktentwicklung als Innovationstreiber. In: Krzywinski, J., Linke, M., Wölfel, C. (eds.) Entwerfen Entwickeln Erleben 2016. Beiträge zum Industrial Design: Dresden 30. Juni-1. Juli 2016. Technisches Design, vol. 10. TUDpress, Dresden (2016)

Bhamra, T., Lofthouse, V.: Design for Sustainability. A Practical Approach, 1st edn. Design for Social Responsibility. Taylor and Francis, Abingdon, Oxon (2016)

Vezzoli, C., Kohtala, C., Srinivasan, A. (eds.): Product-service system design for sustainability. Greenleaf Publishing, Sheffield (2014)

Tukker, A., Tischner, U.: New business for old Europe. Product-service development, competitiveness and sustainability. Greenleaf Pub, Sheffield, South Yorkshire, England (2010)

Ceschin, F.: Sustainable product-service systems. Springer International Publishing, Cham (2014)

Ao, S.I. (ed.): International Multi Conference of Engineers and Computer Scientists, IMECS 2009. 18–20 March, 2009, Regal Kowloon Hotel, Kowloon, Hong Kong. Lecture Notes in Engineering and Computer Science. IAENG, Hong Kong (2009)

Castillo, L.G., Diehl, J.C., Brezet, J.C.: Design considerations for base of the pyramid (BoP) projects. In: Proceedings of the Nothern World Mandate: Culumus Helsinki Conference, pp. 24–26 (2012)

Simanis, E., Hart, S., Duke, D.: The base of the pyramid protocol: beyond “basic needs” business strategies. Innov. Technol. Govern. Global. 3(1), 57–84 (2008)

Larsen, M.L.M., Flensborg, A.: Market creation toolbox. DI International Business Development (2011)

Hopfenbeck, W., Jasch, C.: Öko-Design. Umweltorientierte Produktpolitik. Verlag Moderne Industrie, Landsberg/Lech (1995)

Bergmann, G.: Umweltgerechtes Produkt-Design. Management und Marketing zwischen Ökonomie und Ökologie. Luchterhand, Neuwied, Berlin (1994)

Vajna, S., Kittel, K.: An approach to compare product development methods. In: Norell Bergendahl, M. (ed.) Design has never been this cool. ICED 09, the 17th International Conference on Engineering Design; 24–27 August 2009, Stanford University, Stanford, California, USA; proceedings volume. DS / Design Society, vol. 58, pp. 313–324. Design Society, Glasgow (2009)

Ernzer, M., Birkhofer, H.: Selecting methods for life cycle design based on the needs of a company. In: DS 30: Proceedings of DESIGN 2002, the 7th International Design Conference, pp. 1305–1310. Dubrovnik (2002)

Watty, R., Binz, H., Enriquez-Geppert, J.: Systematic selection of appropriate methods in quality management. In: DS 58–5: Proceedings of ICED 09, the 17th International Conference on Engineering Design, vol. 5, Design Methods and Tools (pt. 1). Palo Alto, CA, USA, 24–27.08.2009 (2009)

Eder, W.E.: Design engineering and needs for methodology. In: DS 58-5: Proceedings of ICED 09, the 17th International Conference on Engineering Design, vol. 5, Design Methods and Tools (pt. 1). Palo Alto, CA, USA, 24–27.08.2009 (2009)

Baumann, H., Boons, F., Bragd, A.: Mapping the green product development field: engineering, policy and business perspectives. J. Clean. Prod. 10(5), 409–425 (2002)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kokoschko, B., Augustin, L., Schabacker, M. (2021). Identifying Criteria for the Selection of Ecodesign Methods to Integrate into SMEs Product Development. In: Chakrabarti, A., Poovaiah, R., Bokil, P., Kant, V. (eds) Design for Tomorrow—Volume 1. ICoRD 2021. Smart Innovation, Systems and Technologies, vol 221. Springer, Singapore. https://doi.org/10.1007/978-981-16-0041-8_74

Download citation

DOI: https://doi.org/10.1007/978-981-16-0041-8_74

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0040-1

Online ISBN: 978-981-16-0041-8

eBook Packages: EngineeringEngineering (R0)