Abstract

Solar energy is renewable sources of energy and more convenient to use it for heating purposes. Drying of food grains increases the shelf life and to preserve the excess food products in a season toward food security. Direct sun-drying is typically involving a slow process. Further, the quality of air at the site influences the quality of the dried products. Drying is not only applied to food grains, but also several industrial applications are using solar air heaters. This work mainly focused on effect of employing phase change materials (PCM) in dryer. The solar dryer produces hot air through natural or forced convection. The drying time is reduced by up to 60% with the help of PCM. The air velocity is to be around 1 m/s to provide uniform heat output from the PCM. The overall heat retention inside the dryer was found maximum when integrating PCM in the solar dryer.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

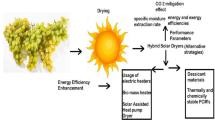

Solar energy is potentially available around 300 days annually in India. Solar energy utilization has increased in the past few decades due to the awareness of global warming by burning of fossil fuels for our thermal needs. Solar energy is primarily in the form of heat and readily available to heating applications with a selective energy conversion technique. Even though a diluted form, solar energy is effectively used with solar flat plate collectors toward low-temperature applications. Solar drying is popular in agriculture. The significant drawbacks of the open sun dryer are the longer dryer time, manual work and food quality affected by the varying solar radiation as well as atmospheric pollutants and weather. Mass production of dry products is in demand due to the excess production and low consumption. Solar dryer has typically employed a flat plate collector with or without secondary reflectors, dryer cabin where the food grains to be placed, the blower in the forced convection dryers. Absorber surface is one of the essential aspects to increase the temperature of flowing air. Absorber tubes are preferable in the liquid collectors due to higher specific heat and density. Extraction of heat energy by an air medium that is passing through the solar collector. Figure 1 shows the possible ways of employing PCM in solar air heater and dryer.

Heat transfer enhanced mainly due to an increase of collector area. The researchers tested various absorber designs. Reflectors and concentrators attached to solar dryer reduced the drying time and improved the efficiency of dryer [1]. Solar photovoltaic panels used to power the fans to make the airflow to be a forced convection dryer. Further, the chimney integrated into solar dryer improved the buoyancy of hot air through the food grains [2]. Sun-drying involves the open sun-drying at the place of harvest (in-situ) and elsewhere after post-harvest. Solar dryers are operating active and passive modes. Natural circulation of hot air occurs in the passive systems due to the buoyancy effects of air. In active systems, a blower circulates the airflow to the collector and dryer. The passive integral type of solar dryers is classified further into cabinet dryers and greenhouse dryers. PCM are used in the thermal management systems [3]. The operating temperature of suitable PCM for a dryer is around 60 °C. The selective PCMs are fatty acids, paraffin wax, salt hydrates, and eutectics. PCM possesses higher energy density than sensible storage systems. Thermal conductivity of PCM is the main drawback to the large-scale commercial deployment. In this article, the recent advances of solar dryer with PCM are discussed.

2 Previous Studies

Several researchers have been investigated solar dryers in the past decades. Varying solar intensity requires thermal energy storage (TES) to provide the required heat to applications. Sreerag and Jithish [4] investigated the solar dryer with PCM. The incorporation of PCM provides a continuous heat supply to dryer chamber through the heat discharge from the PCM. Agarwal and Sarviya [5, 6] studied PCM-based heat exchanger to provide hot air to dry the food products. Most of the studies of dryers with PCM involve paraffin and salt hydrates for drying of food products. Vásquez et al. [7] demonstrated the use of the proper TES control system with solar drying, the potential of energy savings could be around 80% when compared to conventional drying. Jain et al. [8] developed mixtures of fatty acids to melt in the range of 40–60 °C to solar dryers. Agarwal and Sarviya [9] characterized commercial-grade paraffin wax to utilize as PCM in solar dryer instead of technical grade PCM through differential scanning calorimetry. Commercial-grade PCM is found to be a cost-effective PCM for solar dryers. The energy stored in PCM is mainly latent heat-based. Solar collectors frequently involve an absorber surface, which exchanges the heat to the air.

Krishnan and Sivaraman [10] showed the thermal efficiency of solar dryer with TES was improved by 50% than that of the conventional dryer. The effect of thermal storage was observed to sustain the required temperature for 3 h after sunset, and then it decreased gradually. El Khadraoui et al. [11] investigated a solar dryer with the PCM cavity. PCM cavity introduced in the dryer to act as a solar energy accumulator. The temperature of the drying chamber was observed to be 4–16 °C higher than ambient all over the night due to PCM. A model was used to predict the drying kinetics and observed a reduction of drying time with PCM by 50% compared to the dryer without PCM [12, 13]. Kaewpanha et al. [14] investigated 28.35 kg of paraffin wax-based dryer to dry chilies during weak sunshine. Yadav and Chandramohan [15] investigated the effect of air velocity during phase change of PCM. Melting improved by higher airflow velocity, and the discharge process requires a lower air velocity to supply hot air at 68 °C. High flow velocity was not recommended for heat retrieval from PCM. Swami et al. [16] investigated a solar dryer with two PCM to dry fish. The selection of a PCM-based dryer is to make the drying of fish around a temperature of 62 °C. Temperature control inside the drying chamber was attained with the help of the TES unit. Yadav et al. [17] investigated the hot air coming from solar collectors with PCM for drying applications, and drying process was observed to be continued up to 10.00 pm due to heat stored in PCM. The preferable air flow velocity was 1–4 m/s for charging PCM and about 1 m/s for discharging PCM. Airflow velocity influenced heat transfer. Bhardwaj et al. [18] investigated sensible and latent heat materials and showed the PCM doubled the moisture removal rate. Elbahjaoui and Qarnia [19] investigated alumina oxide-based paraffin wax for the flat plate solar collectors. Reyes et al. [20] observed the overall efficiency of dryer with PCM in a range of 56–76%. Vásquez et al. [21] studied a dynamic model of a solar dryer for agricultural products with TES, using paraffin wax.

Babar et al. [22] studied the absorber temperature profile in the dryer to employ PCM. The average temperature of the chamber was observed to be 23.5% more because of PCM. Identification of thermal zones is essential to employ the PCM to act as a thermal energy reservoir for drying. Iranmanesh et al. [23] showed the overall drying efficiency with PCM was 39.9%. The incorporation of PCM to solar dryer improved the overall drying efficiency. Azaizia et al. [24] demonstrated PCM-based dryer was around 7.5 °C higher than the non-PCM dryer throughout the night. Reduction of moisture content of pepper about 95% was observed 30 h, 55 h, and 75 h for the non-PCM dryer, PCM-based dryer, and open sun dryer, respectively. The greenhouse solar dryer with PCM proves effective in drying.

Saw tooth-shaped absorber, along with PCM in the TES system, was investigated by Babu et al. [25]. The sawtooth shape absorbed solar radiation effectively, and the attached paraffin storage tank stores latent heat for a long time. A total of 20 aluminum pipes of 1 mm thick are used to provide hot water from 6 to 8 am. Srivastava and Shukla [26] carried out an experimental validation on solar dryer with PCM. The dryer with PCM stored heat and the drying is done for a long time with temperature regulation [27]. The temperature of PCM remains high after several cycles of operations. To make a solar air dryer reliable, the heat pipes were used during the day, containing water inside and in PCM [28]. The heat pipe helped to maintain a small temperature difference to PCM by making a flat plate solar air dryer contain heat pipes and PCM.

Atalay [29] compared a pebble-stone-based packed-bed with PCM storage in a solar dryer. The efficiency of the PCM-based dryer is minimal to the packed bed-based dryer, but the economic point of view packed-bed was about 10% lower. PCM usually is encapsulated into a container to increase the surface area available to the heat transfer. The container size and fin dimensions [30] and orientation play an essential role in the charging of PCM [31], and the arrangement of PCM is also essential to obtain the maximum benefits of TES [32, 33]. An increase in air temperature reduced the power consumption, but the mass flow rate increased the power [34]. A solar dryer using engine oil and PCM improved drying by 43.75% [35]. Khouya [36] investigated the method of reduction of drying time using several methods to dry the hardwood solar kiln. The drying time reduces with the decrease in thickness of wood-boards and increase in collector area. The use of TES reduces the drying time up to 60%. Lamrani and Draoui [37] showed a packed-bed storage reduced the drying time by about 15% and reduces the payback period by 33%. Four different concentrations of aluminum nanoparticle such as 0%, 0.5%, 1.0% and 1.55 with paraffin were used as heat energy storage element in hybrid-solar dryer [38]. The percentage reduction of drying time of dryer with and without PCM is illustrated in Fig. 2.

Heat energy storage capacity was improved for increased nanoparticle concentration up to 1.0% in PCM. As economics point of view, the 1.0% alumina with PCM was recommended, for drying agro-product, due to its reversibility. Ndukwu et al. [39] demonstrated wind-powered solar dryer with glycerol as PCM with lower drying time under the ambient temperature of 24–50 °C and humidity of about 10–52%. Poblete and Painemal [40] determined thermal efficiency of solar dryer with and without TES was 37.8% and 22.2%, respectively. The salient points are discussed in the next section.

3 Discussion

Utilization of PCM in dryer certainly improves the moisture removal rate from the food grains and agricultural crops. The dryer with PCM is observed to be safe and does not deteriorating the quality of food. Sometimes, the packed-bed storage using sensible heat materials like pebbles is observed economically effective when compared to PCM. However, the productivity due to longer duration for heat storage and compactness of the dryer is promising in the case of PCM. PCM with sensible heat medium and composite PCM were found to be useful to observe the faster rate of heat transfer in the TES. Most researched PCM with solar dryer is observed to be paraffin wax due to its optimum operating temperature of dryers and the organic nature as well as cost-effectiveness. The summary of the performance enhancement of solar dryer with PCM (paraffin wax) is given in Table 1.

The solar dryer with TES produced higher temperature and lower RH in dryer. Fluid flow velocity is to be optimized for the TES-based solar dryers to attain an effective drying rate. Due to low-temperature operation of solar dryers, copper tubes are preferring PCM side to enhance the heat transfer. TES unit is used as a supplementary heat source, storage for after sunshine hours, and thus, TES plays a vital role to improve the overall drying performance of solar dryers. Due to low-temperature operation, nanoparticles are added as thermal conductivity enhancers to PCM. The PCM behavior is to be improved to reach large-scale commercial applications of solar dryers with PCM.

4 Conclusions

From the literature, the PCM used in solar dryer was studied by several researchers. The major conclusions are given below.

-

PCM inclusion improved the drying performance of solar dryers. The reduction of drying duration was possible up to 60%.

-

Solar dryer with PCM is found to be safe for foods.

-

PCM container selection plays a vital role in providing heat transfer augmentation and the safety against the leakage of liquid PCM into the air.

-

Heat pipes inside the PCM are a useful enhancement method used in the PCM-based solar dryer.

-

Solar PV panels are used as the preheating sections for the solar dryers.

-

The airflow velocity influences the PCM behavior and drying rate. Higher and lower air velocities are desirable for heating and cooling of PCM, respectively. The air velocity could be optimized to obtain a longer drying time.

-

The solar dryers with TES are used for several applications ranges from domestic to industrial purposes.

-

Hybrid applications like wind and biomass-powered solar dryers are observed to be fully reliant on renewable sources of energy.

References

Sandali, M., Boubekri, A., Mennouche, D.: Improvement of the thermal performance of solar drying systems using different techniques: a review. J. Sol. Energy Eng. Trans. ASME 141(5), 050802 (2019). https://doi.org/10.1115/1.4043613

Fudholi, A., Sopian, K.: A review of solar air flat plate collector for drying application. Renew. Sustain. Energy Rev. 102, 333–345 (2019). https://doi.org/10.1016/j.rser.2018.12.032

Mofijur, M., Mahlia, T.M.I., Silitonga, A.S., Ong, H.C., Silakhori, M., Hasan, M.H., et al.: Phase change materials (PCM) for solar energy usages and storage: an overview. Energies 12(16), 3167 (2019). https://doi.org/10.3390/en12163167

Sreerag, T.S., Jithish, K.S.: Experimental investigations of a solar dryer with and without multiple phase change materials (PCM’s). World J. Eng. 13(3), 210–217 (2016)

Agarwal, A., Sarviya, R.M.: An experimental investigation of shell and tube latent heat storage for solar dryer using paraffin wax as heat storage material. Eng. Sci. Technol. Int. J. 19(1), 619–631 (2016). https://doi.org/10.1108/WJE-06-2016-028

Agrawal, A., Sarviya, R.M.: A review of research and development work on solar dryers with heat storage. Int. J. Sustain. Energy 35(6), 583–605 (2016). https://doi.org/10.1080/14786451.2014.930464

Vásquez, J., Reyes, A., Mahn, A., Cubillos, F.: Experimental evaluation of fuzzy control solar drying with thermal energy storage system. Dry Technol. 34(13), 1558–1566 (2016). https://doi.org/10.1080/07373937.2015.1137001

Jain, A., Kumar, A., Shukla, A., Sharma, A.: Development of phase change materials (PCMs) for solar drying systems. In: Prakash, O., Kumar, A. (eds.) Solar Drying Technology. Green Energy and Technology, pp. 619–633 (2017). https://doi.org/10.1007/978-981-10-3833-4_23

Agrawal, A., Sarviya, R.M.: Characterization of commercial grade paraffin wax as latent heat storage material for solar dryers. Mater. Today Proc. 4(2), 779–789 (2017). https://doi.org/10.1016/j.matpr.2017.01.086

Krishnan, S., Sivaraman, B.: Experimental investigations on thermal storage in a solar dryer. Int. Energy J. 17(1), 23–35 (2017)

El Khadraoui, A., Bouadila, S., Kooli, S., Farhat, A., Guizani, A.: Thermal behavior of indirect solar dryer: nocturnal usage of solar air collector with PCM. J. Clean Prod. 148, 37–48 (2017). https://doi.org/10.1016/j.jclepro.2017.01.149

El-Sebaii, A.A., Shalaby, S.M.: Experimental investigation of drying thymus cut leaves in indirect solar dryer with phase change material. J. Sol Energy Eng. Trans. ASME 139(6) (2017). https://doi.org/10.1115/1.4037816

Aumporn, O., Zeghmati, B., Chesneau, X., Janjai, S.: Numerical study of a solar greenhouse dryer with a phase-change material as an energy storage medium. Heat Transf. Res. 49(6), 509–528 (2018). https://doi.org/10.1615/HeatTransRes.2018020132

Kaewpanha, M., Wansungnern, W., Banthuek, S.: Development of thermal energy storage as a supplemental heat source for solar dryer. Key Eng. Mater. 777, 102–106 (2018). https://doi.org/10.4028/www.scientific.net/KEM.777.102

Yadav, S., Chandramohan, V.P.: Numerical analysis on thermal energy storage device with finned copper tube for an indirect type solar drying system. J. Sol. Energy Eng. Trans. ASME 140(3) (2018). https://doi.org/10.1115/1.4039273

Swami, V.M., Arun, T.A., Anil, T.R.: Experimental analysis of solar fish dryer using phase change material. J. Energy Storage 20, 310–315 (2018). https://doi.org/10.1016/j.est.2018.09.016

Yadav, S., Lingayat, A.B., Chandramohan, V.P., Raju, V.R.K.: Numerical analysis on thermal energy storage device to improve the drying time of indirect type solar dryer. Heat Mass Transf. 54(12), 3631–3646 (2018). https://doi.org/10.1007/s00231-018-2390-7

Bhardwaj, A.K., Kumar, R., Chauhan, R.: Experimental investigation of the performance of a novel solar dryer for drying medicinal plants in Western Himalayan region. Sol. Energy 177, 395–407 (2019). https://doi.org/10.1016/j.solener.2018.11.007

Elbahjaoui, R., El Qarnia, H.: Performance evaluation of a solar thermal energy storage system using nanoparticle-enhanced phase change material. Int. J. Hydrogen Energy 44(3), 2013–2028 (2019). https://doi.org/10.1016/j.ijhydene.2018.11.116

Reyes, A., Vásquez, J., Pailahueque, N., Mahn, A.: Effect of drying using solar energy and phase change material on kiwifruit properties. Dry Technol. 37(2), 232–244 (2019). https://doi.org/10.1080/07373937.2018.1450268

Vásquez, J., Reyes, A., Pailahueque, N.: Modeling, simulation and experimental validation of a solar dryer for agro-products with thermal energy storage system. Renew. Energy 139, 1375–1390 (2019). https://doi.org/10.1016/j.renene.2019.02.085

Babar, O.A., Arora, V.K., Nema, P.K.: Selection of phase change material for solar thermal storage application: a comparative study. J. Braz. Soc. Mech. Sci. Eng. 41(9) (2019). https://doi.org/10.1007/s40430-019-1853-1

Iranmanesh, M., Samimi Akhijahani, H., Barghi Jahromi, M.S.: CFD modeling and evaluation the performance of a solar cabinet dryer equipped with evacuated tube solar collector and thermal storage system. Renew. Energy 145, 1192–1213 (2020). https://doi.org/10.1016/j.renene.2019.06.038

Azaizia, Z., Kooli, S., Hamdi, I., Elkhal, W., Guizani, A.A.: Experimental study of a new mixed mode solar greenhouse drying system with and without thermal energy storage for pepper. Renew. Energy 145, 1972–1984 (2020). https://doi.org/10.1016/j.renene.2019.07.055

Babu, S., Abishraj, V.R., Suthagar, S.: Solar thermal energy storage on PCM based integrated saw tooth collector for institutions. In: 1st International Conference on Sustainable Green Buildings and Communities, SGBC 2016, 7936078 (2017)

Srivastava, A.K., Shukla, S.K.: Thermal modeling of indirect solar drying system: an experimental validation. Distrib. Gener. Altern. Energy J. 32(3), 19–51 (2017). https://doi.org/10.1080/21563306.2017.11878944

Gao, W.F., Lin, W.X., Liu, T., Li, M.: An experimental study on the application of polyalcohol solid-solid phase change materials in solar drying with cross-corrugated solar air collectors. IOP Conf. Ser. Earth Environ. Sci. 93(1), 012075 (2017). https://doi.org/10.1088/1755-1315/93/1/012075

Bhagwat, V.V., Salve, S.P., Debnath, S.: Experimental analysis of a solar dehydration with phase changing material. AIP Conf. Proc. 1998, 020003 (2018). https://doi.org/10.1063/1.5049099

Atalay, H.: Assessment of energy and cost analysis of packed bed and phase change material thermal energy storage systems for the solar energy-assisted drying process. Sol. Energy 198, 124–138 (2020). https://doi.org/10.1016/j.solener.2020.01.051

Senthil, R.: Effect of uniform and variable fin height on charging and discharging of phase change material in a horizontal cylindrical thermal storage. Therm. Sci. 23(3B), 1981–1988 (2019). https://doi.org/10.2298/TSCI170709239S

Senthil, R.: Effect of position of heat transfer fluid tube on the melting of phase change material in cylindrical thermal energy storage. Energy Sources Part A (2019). https://doi.org/10.1080/15567036.2019.1649751

Senthil, R., Cheralathan, M.: Enhancement of the thermal energy storage capacity of a parabolic dish concentrated solar receiver using phase change materials. J. Energy Storage 25, 100841 (2019). https://doi.org/10.1016/j.est.2019.100841

Senthil, R.: Effect of charging of phase change material in vertical and horizontal rectangular enclosures in a concentrated solar receiver. Case Stud. Therm. Eng. 21, 100653 (2020). https://doi.org/10.1016/j.csite.2020.100653

Bahammou, Y., Lamsyehe, H., Kouhila, M., Lamharrar, A., Idlimam, A., Abdenouri, N.: Valorization of co-products of sardine waste by physical treatment under natural and forced convection solar drying. Renew. Energy 142, 110–122 (2019). https://doi.org/10.1016/j.renene.2019.04.012

Alimohammadi, Z., Akhijahani, H.S., Salami, P.: Thermal analysis of a solar dryer equipped with PTSC and PCM using experimental and numerical methods. Sol. Energy 201, 157–177 (2020). https://doi.org/10.1016/j.solener.2020.02.079

Khouya, A.: Effect of regeneration heat and energy storage on thermal drying performance in a hardwood solar kiln. Renew. Energy 155, 783–799 (2020). https://doi.org/10.1016/j.renene.2020.03.178

Lamrani, B., Draoui, A.: Thermal performance and economic analysis of an indirect solar dryer of wood integrated with packed-bed thermal energy storage system: a case study of solar thermal applications. Drying Technol. (2020). https://doi.org/10.1080/07373937.2020.1750025

Bahari, M., Najafi, B., Aziz Babapoor, A.: Evaluation of α-Al2O3-PW nanocomposites for thermal energy storage in the agro-products solar dryer. J. Energy Storage 28, 101181 (2020). https://doi.org/10.1016/j.est.2019.101181

Ndukwu, M.C., Onyenwigwe, D., Abam, F.I., Eke, A.B., Dirioha, C.: Development of a low-cost wind-powered active solar dryer integrated with glycerol as thermal storage. Renew. Energy 154, 553–568 (2020). https://doi.org/10.1016/j.renene.2020.03.016

Poblete, R., Painemal, O.: Improvement of the solar drying process of sludge using thermal storage. J. Environ. Manage. 255, 109883 (2020). https://doi.org/10.1016/j.jenvman.2019.109883

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Senthil, R., Vijayan, G., Phadtare, G., Gupta, B. (2021). Performance Enhancements of Solar Dryers Using Integrated Thermal Energy Storage: A Review. In: Kumar, A., Pal, A., Kachhwaha, S.S., Jain, P.K. (eds) Recent Advances in Mechanical Engineering . ICRAME 2020. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-9678-0_31

Download citation

DOI: https://doi.org/10.1007/978-981-15-9678-0_31

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9677-3

Online ISBN: 978-981-15-9678-0

eBook Packages: EngineeringEngineering (R0)