Abstract

Rapid industrialization and urbanization have led to an increase in the economic rate of growth but adversely affected the environment. The generated by-products of different industrial processes are disposed of in an unhygienic manner, thus creating management problems for the environment. The urgent need is to procure the depleting natural resources and create new resources from industrial residues using engineering technologies. The bioconversion process of stabilization by earthworms is one such sustainable innovation that can solve the disposal issues of industrial wastes. This promotes organic farming and reduces the use of chemical fertilizers, thus maintaining good health of people as a whole. The final product of biotransformation results in nutrient-rich vermicompost and earthworms play a major role as stabilizing agents in the entire process. The present article discusses the suitability of large-scale implementation of stabilization of industrial wastes which are otherwise posing problems for the environment with their unsafe disposal.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Industrial solid waste management has been a rising concern with the growth of industrial sector and economy buildup of developing countries like India where standards of living are getting better each day resulting in destruction of green space and major demand for urbanization and adequate infrastructure leading to expanding industrialization. According to Central Statistics Office, Ministry of Statistics and Programme Implementation, Government of India, total 371, 336 polluting industries were in operation in India (Sugar; Pulp & Paper; Pharmaceutical; Pesticides; Iron & Steel; Fertilizer; Distillery; Soap & Detergent; Cement; Aluminium; Copper; Zinc), out of which 40,095 were large-scale and 331,241 were small-scale industries [1]. About 30% of 960 million tons solid waste generated in India comes from the industrial sector [2]. Different industries produce different levels of hydrocarbons, phenols, heavy metals, organic chemicals, and other effluents in different forms which pollute the overall environment through its unsafe disposal. Hazardous industrial wastes are destructive in all manners while non-hazardous industrial wastes are non-toxic by-products generated by commercial and industrial activities and are safe for recycling and other waste-to-energy processes. All the agro-based industries, pulp & paper industry, tanneries, food processing industries & textile industries, thus become a major source of raw materials as their by-products can be reused again.

In the current scenario of sustainable development where the population is increasing at an enormous rate and the natural resources are decreasing in an uncontrollable manner, the environment is facing the adverse effects of the overall human activities. The management of solid wastes is a major concern in the path of achieving sustainable needs that can be solved only by providing access to engineering innovations. The current methods available for solid waste management include landfilling, incineration, recycling, source reduction, and reuse [3]. The operation of incineration is least-preferred considering the toxic emissions, high capital costs, and Global Warming Potential. Landfilling has been the most dominant technique of disposing waste due to cheaper costs among all operations [4]. The problem of water & land contamination through leachate and greenhouse gas emissions arises in landfilling and is, therefore, not the best solution for managing waste [5, 6]. Recycling is slow and informal in developing countries like India which lacks in providing basic recycling facilities [7, 8]. As a result, reuse is the most feasible option for industrial waste management. Reuse can be done by both composting and vermicomposting. The cost-benefit analysis of reusing is much attractive as compared to other management technologies [7]. Therefore, the need of the hour is to adopt vermicomposting as a sustainable waste management strategy in bio-transforming industrial wastes into fertilizers.

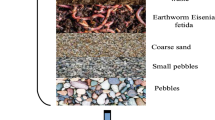

Vermicompost is the bio-oxidized and stabilized product formed by the combined action of earthworms and micro-organisms. Vermicomposting process is an eco-friendly process that is best suited for industrial waste bioconversion [9]. The earthworm species E. foetida is extensively used in vermistabilization process because of its high potential for bioconversion of organic wastes into vermin casts [10].

The cocoon production, the increase in biomass, and the low mortality rate of earthworms in the vermistabilization of paper mill wastewater sludge is an indication of the suitability of E. fetida in industrial waste stabilization [11]. Higher heavy metal concentration levels occur in different industrial waste by-products due to the involvement of chemicals in different processes. In the final vermicompost samples, the heavy metals content decreased as compared to the initial sewage sludge while that in the earthworms increased due to the bioaccumulation factor (BAF) [12]. This clearly depicts the efficiency of vermiconversion process in effectively removing the heavy metals content. An increase of 6.6 times the initial value of Total Nitrogen Content occurred in the finally stabilized tea coal factory ash vermicompost sample which clearly shows its high nutrient value [13]. The macronutrients and micronutrients are readily available to plants in vermicompost [14]. Therefore, in these adulteration times, the excessive use of inorganic fertilizers should be countered while the demand for organic fertilizers such as vermicompost should be given preference in agriculture. The existing resources should be used adequately and industrial wastes need to be utilized in a manner such that sustainability could be achieved. The main objective of this review is to focus on the potential of stabilization of industrial wastes by using earthworms and implementing this technology on a large-scale for sustainable agricultural development.

2 Vermicomposting

In the process of waste conversion, the waste material to be stabilized passes through the gut of the earthworms, where it gets transformed and is excreted out in the form of worm manure. These castings are not only helpful in regulating the growth of plants but also act as pest repellents thereby enriching microbial activity. This process of valorization of waste material is known by different names such as vermicomposting/vermitechnology/vermiconverion/vermistabilization. This process can work within a mesophilic temperature range of 10–32 °C and both microbes and earthworms survive and work effectively in this range [15]. Vermicomposting is a closed-loop renewable technology for amendment of waste materials into rich nutrients source for soil fertility and also enhances the water retention capacity of soil. It also results in compositional change of waste, decrease in C:N ratio due to decrease in organic content, and gain in nutrient content by the earthworm activity [16]. The earthworms not only aerate the substrate but also decompose it thereby increasing their biomass and overall microbial activity of the process [17]. The agro-industrial organic residues need to be transformed for use in food production by the addition of vermistabilized humus to soil instead of expensive disposal of such wastes [18]. The researchers have been managing the industrial wastes using earthworms extensively [19,20,21].

Industrial wastes cannot be directly fed to earthworms due to containment of hazardous chemicals as it can drastically affect the vermicomposting process. Amendments are bound to be added to the industrial wastes for successful working conditions. Cow dung was used as a bulking agent to stabilize bakery industrial sludge in vermicomposting trials [22]. Three bulking agents cow dung (CD), biogas plant slurry (BGS) and wheat straw (WS) were added to stabilize agro-industrial sludge procured from sugar mill [23]. Tea waste was stabilized in a short period of 28 days with the condition that it should be mixed with cow dung [24]. 50:50 combination of sludge obtained from beverage industry and cow dung was ideally suggested as nutrient-rich end product in terms of its earthworm growth and nutrient content [25]. Therefore, it is evident that a bulky material is necessary for the degradation of industrial wastes if they are mixed in suitable ratios.

Many researchers have also reported a decrease in toxicity levels of the industrial waste in the vermicomposting process on the basis of heavy metal bioaccumulation in the gut of earthworms. Vermicompost made from 1:1 combination of textile mill wastewater sludge and cow dung was reported ideal due to reduced bioavailability of toxic heavy metals after vermistabilizing it using two epigeic earthworm species Eudrilus eugeinae and Perionyx excavates [26]. The earthworm also contains a protein called metallothionein which is known to bind heavy metals such as Cu2+, Zn2+, and Mn2+ [27]. Detoxification of industrial wastes is done by chloragocyte cells and gut microbes available in earthworms [28]. A considerable increase in heavy metal content was also noticed [29, 30]. It is, therefore, crucial to study the behavior of heavy metals and their bioaccumulation in the vermistabilization process. The industrial waste should be properly utilized by using earthworms in order to obtain end product that can sustainably be used as a crop nutrient and reduce the use of inorganic fertilizers [31].

3 Biotransformation of Different Industrial Wastes

Non-hazardous industrial wastes that are otherwise disposed of unhygienically by the industries, have been successfully used by researchers in biotransformation for the preparation of vermicompost using earthworms of different species. Vermicomposting process depends on a variety of factors such as type of substrate material to be degraded, its physicochemical properties, species and number of earthworms added, temperature, moisture content, amendment material, mixing ratio of different added materials, aeration process in the material. Bioconversion by red earthworm Eisenia fetida on brewers’s spent grain (BGS) showed a decrease in C/N ratio whereas earthworm population increased at the end [32]. Increase in dehydrogenase activity also depicts the release of extra-cellular enzymes in the manure castings and the degrading ability of active microbial population [33]. Detoxification and recycling of brick kiln coal ash increased the nitrogen and phosphorus contents, thus decreasing the heavy metal content which resulted in less polluted vermicompost [34]. The vermiconversion process also involved the use of green plants such as Tephrosea purpurea (TEP) and Gliricidia sepium (GLS) that were utilized to stabilize paper industry sludge. PMS + CD + TEP/GLS (2:1:1) combination being ideal for sustainable agriculture [35]. The waste material maturity can also be indicated by dehydrogenase, urease, and phosphatases activities. The problem of leachates in landfills was also countered when Eisenia fetida were added to it which led accumulation of toxins in the tissues of earthworms enhancing their reproductive ability and detoxified the municipal leachate [36]. Potential of earthworms Eisenia fetida was also checked after transformation of citronella bagasse and paper mill sludge mixture (3:2) leading to nutrient content increase and bacterial population growth. Increase in ash content and decrease in humification index are indicative of better maturity of compost [37]. By-products of agricultural industry can be effectively converted into useful resource just like transformation of 2:1:1 ratio of pressmud of sugar industry with cow dung and green plants (Gliricidia sepium and Leucaena leucocephala) produced nutrient-rich manure [38]. Similarly, 60:40 combination of distillery sludge waste (DSW) and tea leaf residues (TLR) acquired favorable results in terms of casting activity of earthworms and depicted the preference of earthworms for less DSW content and more TLR content consumption when compared with 80:20 ratio [39]. Sewage sludge derived biochar (SSDB) was applied as an amendment in sewage sludge (SS) which increased the cocoon production with addition of SSDB and high bioaccumulation of heavy metals. The decrease in C/N ratio showed positive trends in good vermicompost transformation [40]. In a separate study, mushrooms were cultivated using tea factory waste (TFW), and the obtained product (mycotea waste) was completely transformed into vermicompost. The 1:1 mixture showed maximum cellulose reduction. High C/N ratio is said to be an outcome of high cow dung content [41].

Similarly, other industrial wastes that have successfully been used by various researchers include milk industry sludge; apple pomace waste; soft drink industry sludge; herbal pharmaceutical industry waste; paper mill sludge, tannery sludge and distillery waste each in combination with municipal solid waste [42,43,44,45,46]. Residues from palm oil mill; biomass of an oil yielding plant named java citronella; biosludge from beverage industry are some other by-products of industrial processes that were vermicomposted and proved to be beneficial for environment instead of harming when disposed of in a rendered manner [47,48,49]. The industrial wastes are stabilized and detoxified after bioconversion by earthworms and the end product brings nutrient value with it that adds to the effective yield of crops and soil conditioning. The vermitechnology is an environment-friendly technique of converting industrial wastes into resourceful manure and covers the ecological, social and economic dimensions of sustainable development.

4 Role of Earthworms in Bioconversion Process

Aristotle, the Greek philosopher, called earthworms “intestines of the earth”. Earthworms were also denoted as “ecosystem engineers” [50]. Earthworm castings are soil aggregates that help in the organic matter decomposition in the soil and also create soil porosity by humus formation [51, 52]. Many exogenic and endogenic enzymes are available in the gut of the earthworms for conversion of organic minerals into exchangeable forms for growth of plants and soil structural development [53].

The addition of organic fertilizer into the soil is advantageous for C and N mineralization and biomass of earthworm along with the availability and assimilation of nutrients such as Mg, K and P [54]. Poly-aromatic hydrocarbons (PAHs) are bioaccumulated to a great extent by earthworms [55]. The microbial and biochemical soil activities are facilitated by earthworms on the substrate and the environmental risks are also reduced by partial degradation of excretions of earthworms [56]. The ingestion of organic wastes in the gut of earthworms occurs including microflora present in it which is expelled out in the form of vermin castings (faecal matter) [57]. High bioaccumulation of heavy metals in earthworms can be observed due to worm activity whereas it may not be seen in substrates in which earthworms are absent [58, 59]. Earthworm castings are humus-like substances, enriched with certain hormones, enzymes, microbes and other complexes that are transferred to the soil through the gut of earthworm [60]. The feeding regime of the earthworm is also dependent on the selection of substrate for the nutrient pool soil [61].

The growth of earthworms and complete decomposition of organic matter is depicted by high levels of humic acid present in vermicomposts thereby indicating “hormone inducing activity” [62]. 25% increase was seen in the yield of crops when the earthworms are present in the agricultural-based ecosystem [63]. Aerobic conditions are maintained by earthworms through continuous mixing of soil, eliminating contaminants present in it. Both earthworms and their vermicast play a vital role in sustainable agriculture and food production by increasing the nutritional quality of the harvested crop. Therefore, the cheapest and permanent solution to make modern-day agriculture more sustainable and productive is vermitechnology.

5 Conclusions

-

The researches of almost all authors have indicated to comply with vermicomposting as a sustainable method to transform a variety of industrial wastes/sludges into useful end product. This reduces their toxicity and adds to the existing resources thus maintaining ecological balance.

-

Adequate recycling of by-products of industries by the most effective vermitechnology should be implemented on a larger scale to decrease the load on the environment and control the existing resources from depletion.

-

The investment cost of setting up a vermicompost system is lower as compared to other waste treatment methods. Additionally, it is considered clean and sustainable technology because waste is reused to produce organic fertilizer which could be applied to agricultural lands.

-

Biotransformation leads to zero waste production without the misuse or burning of organic wastes. As a result, the concept of circular economy is better achieved by less exploitation of virgin resources. It also aims at increasing the efficiency of materials, energy use, recycling and reuse, accompanied by low waste generation.

-

Vermicomposting is a sustainable method that works on the same principle of Waste-to-Energy (WTE) processes and is an energy-efficient process for waste to biomass conversion using engineering innovations.

References

https://unstats.un.org/unsd/envaccounting/londongroup/meeting20/LG20_7_4.pdf

Pappu A, Saxena M, Asolekar SR (2007) Solid wastes generation in India and their recycling potential in building materials. Build Environ 42:2311–2320

Wu TY, Lim SL, Lim PN, Shak KPY (2014) Biotransformation of biodegradable solid wastes into organic fertilizers using composting or/and vermicomposting. Chem Eng Trans 39:1579–1584

Laner D, Crest M, Scharff H, Morris JWF, Barlaz MA (2012) A review of approaches for the long-term management of municipal solid waste landfills. Waste Manag 32:498–512

Romero C, Ramos P, Costa C, Márquez MC (2013) Raw and digested municipal waste compost leachate as potential fertilizer: comparison with a commercial fertilizer. J Clean Prod 59:73–78

Pozza SA, Penteado CSG, Criscuolo VG (2015) A greenhouse gas inventory in the municipal landfill of the City of Limeira, Brazil. Chem Eng Trans 43:2083–2088

https://sustainabledevelopment.un.org/content/documents/126GER_synthesis_en.pdf

Song Q, Li J, Zeng X (2015) Minimizing the increasing solid waste through zero waste strategy. J Clean Prod 104:199–210

Bhat SA, Singh J, Vig AP (2016) Management of sugar industrial wastes through vermitechnology. Int Lett Nat Sci 55:35–43

Garg P, Gupta A, Satya S (2006) Vermicomposting of different types of waste using Eisenia foetida: a comparative study. Bioresour Technol 97:391–395

Negi R, Suthar S (2013) Vermistabilization of paper mill wastewater sludge using Eisenia fetida. Bioresour Technol 128:193–198

Liu F, Zhu P, Xue J (2012) Comparative study on physical and chemical characteristics of sludge vermicomposted by Eisenia Fetida. Procedia Environ Sci 16:418–423

Goswami L, Sarkar S, Mukherjee S, Das S, Barman S, Raul P, Bhattacharyya P, Mandal NC, Bhattacharya S, Bhattacharya SS (2014) Vermicomposting of Tea Factory Coal Ash: metal accumulation and metallothionein response in Eisenia fetida (Savigny) and Lampito mauritii (Kinberg). Bioresour Technol 166:96–102

Atiyeh RM, Arancon N, Edwards CA, Metzger JD (2001) The influence of earthworm processed pig manure on the growth and productivity of marigolds. Bioresour Technol 81:103–108

Adhikary S (2012) Vermicompost, the story of organic gold: a review. Agric Sci 3:905–917

Bhat SA, Singh J, Vig AP (2017) Amelioration and degradation of pressmud and bagasse wastes using vermitechnology. Bioresour Technol 243:1097–1104

Lavelle P, Decaens T, Aubert M, Barot S, Blouin M, Bureau F (2006) Soil invertebrates and ecosystem services. Eur J Soil Biol 42:3–15

Suthar S (2006) Potential utilization of guar gum industrial waste in vermicompost production. Bioresour Technol 97(18):2474–2477

Elvira C, Sampedro L, Benitez E, Nogales R (1998) Vermicomposting of sludges from paper mill and dairy industries with Eisenia ndrei: a pilot scale study. Bioresour Technol 63:205–211

Garg VK, Kaushik P, Dilbaghi N (2006) Vermiconversion of wastewater sludge from textile mill mixed with anaerobically digested biogas plant slurry employing Eisenia foetida. Ecotoxicol Environ Saf 65:412–419

Ravindran B, Dinesh SL, John Kennedy L, Sekaran G (2008) Vermicomposting of solid waste generated from leather industries using epigeic earthworm Eisenia foetida. Appl Biochem Biotechnol 151:480–488

Yadav A, Garg VK (2019) Biotransformation of bakery industry sludge into valuable product using vermicomposting. Bioresour Technol 274:512–517

Suthar S (2010) Recycling of agro-industrial sludge through vermitechnology. Ecol Eng 36:1028–1036

Kaur S, Kour G, Singh J (2014) Vermicomposting of tea leaves waste mixed with cow dung with the help of exotic earthworm Eisenia fetida. Int J Adv Res Biol Sci 1(9):229–234

Singh J, Kaur A, Vig AP, Rup PJ (2009) Role of Eisenia fetida in rapid recycling of nutrients from biosludge of beverage industry. Ecotoxicol Environ Saf 73:430–435

Yuvaraj A, Karmegam N, Tripathi S, Kannan S, Thangaraj R (2020) Environment-friendly management of textile mill wastewater sludge using epigeic earthworms: bioaccumulation of heavy metals and metallothionein production. J Environ Manag 254:109813

Irvine GW, Summers KL, Stillman MJ (2013) Cysteine accessibility during As3+ metalation of the α- and β-domains of recombinant human MT1a. Biochem Biophys Res Commun 433:477–483

Srivastava R, Kumar D, Gupta SK (2005) Bioremediation of municipal sludge by vermitechnology and toxicity assessment by Allium cepa. Bioresour Technol 96:1867–1871

Bhat SA, Singh J, Singh K, Vig AP (2017) Genotoxicity monitoring of industrial wastes using plant bioassays and management through vermitechnology: a review. Agric Nat. http://dx.doi.org/10.1016/j.anres.2017.11.002

Hait S, Tare V (2012) Transformation and availability of nutrients and heavy metals during integrated composting-vermicomposting of sewage sludges. Ecotoxicol Environ Saf 79:214–224

Bhat SA, Singh J, Vig AP (2017) Earthworms as organic waste managers and biofertilizer producers. Waste Biomass Valoriz. http://dx.doi.org/10.1007/s12649-017-9899-8

Saba S, Zara G, Bianco A, Garau M, Bononi M, Deroma M, Pais A, Budroni M (2019) Comparative analysis of vermicompost quality produced from brewers’spent grain and cow manure by the red earthworm Eisenia fetida. Bioresour Technol 293:122019

Benitez E, Sainz H, Nogales R (2005) Hydrolytic enzyme activities of extracted humic substances during the vermicomposting of a lignocellulosic olive waste. Bioresour Technol. 96:785–790

Mondal A, Goswami L, Hussain N, Barman S, Kalita E, Bhattacharyya P, Bhattacharya SS (2019) Detoxification and eco-friendly recycling of brick kiln coal ash using Eisenia fetida: a clean approach through vermitechnology. Chemosphere. S0045-6535(19)32710-9

Karmegam N, Vijayan P, Prakash M, John Paul JA (2019) Vermicomposting of paper industry sludge with cowdung and green manure plants using Eisenia fetida: a viable option for cleaner and enriched vermicompost production. J Clean Prod 228:718–728

Jóźwiak MA, Jóźwiak M, Kozłowski R, Żelezik M (2019) Zooremediation of leachates from municipal waste using Eisenia fetida (SAV). Environ Pollut 254:11287

Boruah T, Barman A, Kalita P, Lahkar J, Deka H (2019) Vermicomposting of citronella bagasse and paper mill sludge mixture employing Eisenia fetida. Bioresour Technol 294:122–147

Balachandar R, Baskaran L, Yuvaraj A, Thangaraj R, Subbaiya R, Ravindran B, Chang SW, Karmegam N (2019) Enriched pressmud vermicompost production with green manure plants using Eudrilus eugeniae. Bioresour Technol. S0960-8524(19)31808-5

Mahaly M, Senthilkumar AK, Arumugam S, Kaliyaperumal C, Karupannan N (2018) Vermicomposting of distillery sludge waste with tea leaf residues. Sustain Environ Res 2018(28):223–227

Krystyna M, Małgorzata G, Rafaela C, Agnieszka, R, Patryk W, Ślęzak E (2016) Biochar amendment for integrated composting and vermicomposting of sewage sludge—the effect of biochar on the activity of Eisenia fetida and the obtained vermicompost. S0960-8524(16)31564-4

Abbiramy KS, Ross PR, Paramanandham J (2015) Degradation of tea factory waste by mushroom cultivation and vermicomposting. J Environ Sci Eng 57(2):126–130

Singh S, Bhat SA, Singh J, Kaur R, Vig AP (2017) Earthworms converting milk processing industry sludge into biomanure. Open Waste Manag J 10:30–40

Hanc A, Chadimova Z (2014) Nutrient recovery from apple pomace waste by vermicomposting technology. Bioresour Technol. https://doi.org/10.1016/j.biortech.2014.02.031

Singh J, Kaur A (2013) Vermidegradation for faster remediation of chemical sludge and spent carbon generated by soft drink industries. J Environ Sci Sustain 1:13–20

Singh D, Suthar S (2012) Vermicomposting of herbal pharmaceutical industry waste: earthworm growth, plant-available nutrient and microbial quality of end materials. Bioresour Technol 112:179–185

Hemalatha B (2012) Recycling of industrial sludge along with municipal solid waste—vermicomposting method. Int J Adv Eng Technol 3:71–74

Singh RP, Embrandiri A, Ibrahim MH, Esa N (2011) Management of biomass residues generated from palm oil mill: vermicomposting a sustainable option. Resour Conserv Recycl 55:423–434

Deka H, Deka S, Baruah CK, Das J, Hoque S, Sarma H, Sarma NS (2011) Vermicomposting potentiality of Perionyx excavatus for recycling of waste biomass of java citronella—an aromatic oil yielding plant. Bioresour Technol 102:11212–11217

Singh J, Kaur A, Vig AP, Rup PJ (2010) Role of Eisenia fetida in rapid recycling of nutrients from bio sludge of beverage industry. Ecotoxicol Environ Saf 73:430–435

Jones CG, Lawton JH, Shachak M (1994) Organisms as ecosystem engineers. Oikos 69:373–386

Jouquet P, Dauber J, Lagerlof J, Lavelle P, Lepage M (2006) Soil invertebrates as ecosystem engineers: intended and accidental affects on soil and feedbackloops. Appl Soil Ecol 32:153–164

Lavelle P, Spain AV (2001) Soil ecology. Kluwer Academic Publishers, Dordrecht, p 654

Suthar S (2012) Vermistabilization of wastewater sludge from milk processing industry. Ecol Eng 47:115–119

Briones MJL, Barreal ME, Harrison AC, Gallego PP (2011) Earthworms and nitrogen application to improve soil health in an intensively cultivated kiwifruit orchard. Appl Soil Ecol 49:158–166

Jing YP, Liu MQ, Yin QP, Li HX, Hu F (2013) Effects of earthworms and ryegrass on the removal of fluoranthene from soil. Pedosphere 23:523–531

Coutino-González E, Hernández-Carlos B, Gutiérrez-Ortiz R, Dendooven L (2010) The earthworm Eisenia fetida accelerates the removal of anthracene and 9,10-anthraquinone, the most abundant degradation product, in soil. Int Biodeterior Biodegrad 64:525–529

Suthar S, Sajwan P, Kumar K (2014) Vermiremediation of heavy metals in wastewater sludge from paper and pulp industry using earthworm Eisenia fetida. Ecotoxicol Environ Saf 109:177–184

Rodriguez-Campos J, Dendooven L, Alvarez-Bernal D, Contreras-Ramos SM (2014) Potential of earthworms to accelerate removal of organic contaminants from soil: a review. Appl Soil Ecol 79:10–25

Suthar S, Singh S, Dhawan S (2008) Earthworm as bioindicators of metals (Zn, Fe, Mn, Cu, Pb and Cd) in soils: is metal bioaccumulation affected by their ecological categories. Ecol Eng 32:99–107

Tersic T, Gosar M (2012) Comparison of elemental contents in earthworm cast and soil from a mercury contaminated site (Idrija area, Slovenia). Sci Total Environ 430:28–33

Norgrove L, Hauser S (2000) Production and nutrient content of earthworm casts in a tropical agrisilvicultural system. Soil Biol Biochem 32:1651–1660

Atiyeh RM, Lee S, Edwards CA, Arancon NQ, Metzger JD (2002) The influence of humic acids derived from earthworms-processed organic wastes on plant growth. Bioresour Technol 84:7–14

Groenigen JWV, Lubbers IM, Vos HMJ, Brown GG, Deyn GBD, Groenigen KJV (2014) Earthworms increase plant production: a meta-analysis. Sci Rep 4:63–65. https://doi.org/10.1038/srep06365

Acknowledgements

The authors acknowledge Dr. Puneet Pal Singh Cheema, Assistant Professor, Department of Civil Engineering, Guru Nanak Dev Engineering College, Ludhiana for his guidance and the necessary research facilities provided in the Environment Engineering Laboratory.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Badhwar, V.K., Singh, S., Singh, B. (2021). Biotransformation of Industrial Wastes for Nutrient Rich Vermicompost—A Review of the Bioconversion Process by Earthworms. In: Singh, H., Singh Cheema, P.P., Garg, P. (eds) Sustainable Development Through Engineering Innovations. Lecture Notes in Civil Engineering, vol 113. Springer, Singapore. https://doi.org/10.1007/978-981-15-9554-7_23

Download citation

DOI: https://doi.org/10.1007/978-981-15-9554-7_23

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9553-0

Online ISBN: 978-981-15-9554-7

eBook Packages: EngineeringEngineering (R0)