Abstract

This chapter describes structural, kinetic, thermodynamic and viscoelastic aspects of how dispersions of small molecules (essentially 0-dimensional objects) aggregate into thermally reversible or thixotropic networks that immobilize large volumes of a liquid. When possible, the different properties of these molecular gels are correlated. The data are considered at different time and distance scales during the lives of the gels. A short history of molecular gels and challenges to advancing the field are also presented. The properties of some molecular gels with simple gelator structures, including long n-alkanes and derivatives of them, are described as well.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Hansen parameters

- Schröder-van Laar equation

- Ostwald ripening

- Storage and loss modulus

- Viscoelasticity

- Critical gelator concentration

- Avrami equation

7.1 Introduction: General Classifications

Gels are a part of almost all aspects of our materials world [1]. The processes by which gels form from particle structures are only one type of self-assembly. Others lead to a myriad of different phases which will not be discussed here, although each type depends on the relative magnitudes of enthalpic and entropic factors that are time-dependent [2]. Examples of hydrogels (i.e., gels based on aqueous liquid components) include aggregates of collagen (the most abundant protein in our bodies; when denatured, it can take the form of aspic or, as sold commercially with different additives in the US and elsewhere, Jell-O ©), amyloids (that have been linked to Alzheimer’s disease), and other protein-based gels with actin, clathrin, and tubulin as the non-aqueous component. Other common hydrogels are in human and other mammalian bodies and jelly fish, and in jellied sand worms. Many types of toothpaste, deodorants, cosmetics, soaps, pharmaceutical delivery agents, and foods [3] are gels, as are many non-edible materials such as silly-putty, paints, inks, dental materials and other adhesives, materials for producing new morphs of pharmaceuticals [4], and aluminum soaps that gelate hydrocarbons for ‘fracturing’ in oil wells [5] and for producing napalm [6].

When the liquid components are aqueous or organic, the gels are referred to hydrogels or organogels, respectively. IUPAC defines a gel as “a non-fluid colloidal network or polymer network that is expanded throughout its whole volume by a fluid” [7]. This definition not very useful and is incomplete because it does not address the viscoelastic properties of gels. Also, it does not provide insights into the gel network structures of molecular gels and responses to stress at different length scales, from the macroscopic to the nanometric. Additionally, it avoids important questions concerning how adaptable are gel systems to changes in their component structures and environments. Only some of the factors listed below will be considered here:

-

(1)

How amenable is a class of molecular gelators to small structural modifications and what are the consequences of those changes to the properties of the gels?

-

(2)

How wide a range of liquid types can be gelated by a single gelator?

-

(3)

What is the lowest concentration of a molecular gelator that can gelate successfully a liquid at or near room temperature [i.e., the critical gelator concentration (CGC)]?

-

(4)

How long can a gel be maintained at room temperature without phase separation?

-

(5)

What is the temperature range over which a gel phase can be maintained? Specifically, at what temperature does a gel ‘melt’ (Tg) and revert to its sol phase?

-

(6)

How strong or malleable is a particular gel? That is, what are its viscoelastic properties?

Common features of ‘gels’ are their compositions, at least two components—one of which is a solid and the other a liquid—their solid-like rheological behavior despite being mostly liquid [8], (i.e., they are non-Newtonian fluids), and their continuous microscopic structures with macroscopic dimensions that are permanent on the time scale of an analytical experiment [9]. Mechanical damping in gels is small: tanδ = G″/G′ ≪ 1, where G′ is the storage modulus and G″ is the loss modulus. The moduli are, respectively, measures of the energy stored and dissipated in a material in which a deformation has been imposed. Also, the oscillatory frequency dependence of the viscosity of a viscoelastic material under shear stress (i.e., the complex viscosity, η* = √(G′2 + G″2)/ω) is a useful parameter to assess the viscoelasticity of a soft material. In fact, each of these is useful in assessing quantitatively whether a sample meets the viscoelastic criteria to be called a gel. A typical response of a gel to oscillatory frequency changes is shown in Fig. 7.1 [10]. Although cavitational rheology is a newer and potentially more useful method for assessing whether a sample is a gel [11], it has not been used extensively.

It is important to emphasize that microscopically the liquid component maintains many of its bulk viscosity and diffusion properties in the gel phase. The diffusion constant of the liquid or of a solute dissolved in the liquid portion is slower than in the absence of the gelator, but it is not inconsequential [12]. Only a small fraction of the liquid molecules is in contact with the gelator network at any given time, and the liquid molecules are able to diffuse from one part of the gel to others. In addition, a constant fraction of the gelator molecules that are in the liquid phase (i.e., the aforementioned CGC) is also able to diffuse within the liquid component and exchange over time with molecules residing within the gelator networks. This equilibration and a thermodynamic preference for larger aggregates leads to Ostwald ripening over time that is observed in many gels. In fact, the liquid does not undergo macroscopic phase separation. Thus, destruction of a molecular gel, is principally a result of a lack of long-term balance between attractive and repulsive capillary and other interfacial forces; intrinsically, molecular gels are thermodynamically less stable than their phase-separated liquid and solid phases [13], although it may require years in some cases (and less than minutes, in others) to observe macroscopic phase separation A simple semi-quantitative method for determining the CGC and Tg of gels is the ‘falling drop’ method, in which a metal ball is placed on the surface of gel and the concentration of gelator or temperature at which the ball falls is recorded [14].

As a result, identifying gels can be complicated because the name also encompasses a number of other ‘soft matter’ materials (e.g., microgels, colloids [15], emulsions, liquid crystals, and micelles) [2], each with different properties that generally do not meet all of the criteria noted as requisite in this chapter, although there are specific examples that do. Specifically excluded is ‘hard matter’ with inelastic networks, such as aluminosilicates. special formulations of some of the other soft materials may adopt all of the characteristics of and be gels. Of these, the general class of materials that are microgels are closest to ‘true’ gels: although lacking a continuous network that permeates the material, they do possess small gel-aggregates that are separated by a non-gel medium. An edible example of a microgel is bubble tea made from gelled seeds of Hyptis suaveolens (L.) Poir [16]. In addition, aerogels and xerogels are not gels although they are produced from them by removing the liquid component, leaving behind a solvent-free 3D or collapsed network.

7.2 A Short (Prejudiced) History of Gels

Although materials known to be gels have been mentioned for more than 3 millennia [17], the time span during which gels have been studied scientifically is much shorter. The author’s prejudiced view of some of the most important observations and advances is summarized briefly below. In 1841, Lipowitz reported the first formal scientific molecular hydrogel ‘sighting’–the gelation of aqueous solutions by lithium urate [18]. In 1864, Thomas Graham, who became Master of the Mint in England, began his studies of sol-gel chemistry; although these are not true gels as noted above, mention of this work is seminal because the pathway leading to them can involve ‘true’ gels. In addition, he made some very important (and unusual!!) pronouncements, such as his support for the theory of ‘vitalism’: “While the rigidity of the crystalline structure shuts out external expressions, the softness of the gelatinous colloid partakes of fluidity, and enables the colloid to become a medium for liquid diffusion, like water itself …. The colloid possesses energia. It may be looked upon as the probable primary source of the force appearing in the phenomena of vitality.” [19].

In 1871, Maddox used ‘dry’ gelatin plates with silver salts for photography. In 1888. Eastman made silver halide dispersions in gelatin on cellulose nitrate rolls of film placed in a camera. In 1891, Meunier made gels with 1,3:2,4-di-O-benzylidene-D-sorbitol as the gelator. In 1896, Liesegang reported reactions of molecules, as well as their diffusion and crystallization, in gels. In 1899–1900, Hardy employed gel electrophoresis and recorded microscopic images of gel networks. In 1907, Foster and Jackson made organogels using camphoryl thioisemicarbazide as the gelator. In 1907, Cotton and Mouton performed studies of thixotropy in gels. In 1912, Zsigmondy and Bachmann reported gelation of aqueous and alcoholic liquids by fatty acid salts. Notably, in the same year, Hardy synthesized thermally-reversible gels with small organic molecules as the gelators and made serious attempts to formulate a theoretical basis for how rod-shaped objects aggregate into colloids and, in some cases, result in gels. Many discoveries have made in the field of gels, including molecular gels, in the intervening century [3, 20,21,22,23,24,25, 29]. They have been driven in part by advances in instrumentation which allows processes and structures to be interrogated at increasingly short time and length scales [26]. Despite these advances, some of the frustrations noted by Dorothy Jordon Lloyd nearly a century ago [27]—“The colloid condition, the gel, is one which is easier to recognize than to define”—persist today, and the field of molecular gels remains an active area of inquiry. Unfortunately, part of the reason for even greater progress is a lack of standardized, accepted methods for preparing and analyzing gels [28].

7.3 Molecular Gels and Approaches to Their Analyses

In this chapter, we focus on the structures and properties of molecular gels; the techniques for obtaining the structural information, usually indirect methods such, as neutron and X-ray scattering, or direct methods such as atomic force and electron microscopies will not be discussed here. For an excellent coverage of methods to determine gel structures at different distance scales, see Ref. [29]. Only in a very limited number of examples have the molecular packing arrangements of gelator molecules within their gel networks been determined. The difficulties to obtain this information arise from several factors: (1) many molecular gelators are polymorphous, so that the phase within a gel may be different from that obtained from single crystal X-ray analyses, even if an appropriate crystal can be grown; (2) the gels networks are dynamic, so that the molecules within them are not fixed ‘permanently’ in space; (3) the habit within the crystalline network may differ depending on the liquid from which it is grown; (4) objects within the network may include disordered liquid molecules; (5) removal of the liquid from a gel risks changing the morph of the xerogel left behind; (6) intrinsically, the individual gelator objects within the gel network are very small, despite the gelator molecular sizes, shapes and conformational labilities varying over a wide range. An example of the latter is the family of acyclic to pentacyclic triterpenes whose structures and gelation properties have been compared [30]. Despite these difficulties, methods for determining the crystalline organization of gelator molecules within the gel networks are being developed and there is promise of others [31]. They rely on solid state (magic-angle) NMR techniques [32], synchrotron radiation analyses [33], and correlations between powder diffraction patterns from intrinsic gels and derived from single crystal data [34]. Also, the orientation of gelator molecules within a single gel fiber can be determined, in principle, from linearly polarized radiation and knowledge of the direction of the transition dipoles of the chromophores or lumophores [35]. Although this method holds great promise, it is still in a state of development and will not be applicable to all molecular gelator assemblies.

The structural analyses have been and continue to be aided by calculations at different levels of sophistication on single gelator molecules and ensembles of them. In that regard, density functional theory (DFT), molecular dynamics, statistical mechanical, and other types of calculations are being used to discern details of association between molecular gelators at the early and latter stages of aggregation, and to correlate the results of those calculations with experimental observations [36,37,38,39].

Even with these data, additional structural challenges will remain. By necessity, gelator networks must be 3-dimensional in order to immobilize the liquid component (usually by attractive short-range interfacial and capillary forces and longer-range repulsive interactions [23, 40]). Those networks rely on a fusion of the objects at ‘junction zones’ (i.e., at the intersection points between the constituent objects). Even though more information is forthcoming about the shapes and properties of the objects within the gelator networks, and they constitute the vast majority of the mass of the networks, very little is known about the nature of the molecular organizations within zones, despite their playing a crucial role in determining the strength, elastic properties and longevity of the gels. Unfortunately, there does not appear to be a general means to assess the molecular packing within junction zones at this time, and it will be difficult to do so in the future because of their low concentrations and (presumably) greater disorder than within the gelator objects.

Their gel networks are comprised of molecules in which the networks responsible for providing the viscoelastic properties are linked physically through non-covalent interactions (usually, ionic, H-bonding and/or molecular dispersion forces). Many of them can be cycled with their corresponding sol/solution phases by heating above and cooling below their characteristic gelation temperatures; they are reversible thermally even if the non-covalent bonds are broken. Of course, there is a critical gelator concentration, usually defined at ambient temperqature, below which percolation of the gelator molecules into fibrillar or other objects does not lead to a 3D network and gelation of the liquid component. Polymer gels, in which the networks responsible for providing the viscoelastic properties are from monomers held together by covalent bonds (i.e., linked chemically), will not be discussed except as needed to provide context for molecular gels. As opposed to many molecular gels (i.e., physical gels), polymer gels are not reversible thermally with their corresponding sol/solution phases if the covalent bonds of the polymer network are broken. In fact, Flory included molecular gels almost as an afterthought, presumably in his fourth class of gels [41]: (1) well-ordered lamellar structures; (2) cross-linked polymeric networks swollen with solvent; disordered polymer chains; (3) polymer networks in which the chain-chain interactions are physical; (4) particulate disordered structures.

7.4 Making Molecular Gels

As mentioned above, the most common method to make molecular gels is by cooling their sols/solutions and by heating molecular gels to make sols/solutions. However, in each case, the shapes and sizes of the objects constituting the gel network depend on the rate of cooling of the sol phase (Fig. 7.2) [42] and critically on the detailed nature of solvent-gelator molecular interactions during the aggregation process leading to D in Fig. 7.3 [43]. The potential sensitivity of the gelator aggregation mode to cooling rate and liquid composition is clearly displayed by 1.5 wt% 3β-cholesteryl 4-(2-anthryloxy)butanoate (CAB) gels (Fig. 7.4) [44, 45]: they exhibit Tg values and fluorescence maxima at ~39 ℃ and 421 nm, respectively, in hexadecane and ~60 ℃ and 427 nm, respectively, in 1-octanol; the hexadecane-like or the 1-octanol-like gel network can be formed repeatedly and reproducibly when the sol phases are fast–cooled or slow-cooled and then reheated to the sol phase and re-cooled within a specific, intermediate range of liquid compositions. Neutron diffraction and X-ray scattering studies demonstrate that the packing arrangement of the CAB molecules and the shapes of the constituent fibers are different in the networks prepared by the different cooling protocols [46].

Polarized optical micrographs of gels at room temperature comprised of 2 wt% N,N′-dimethylurea in carbon tetrachloride that were formed by rapidly (spherulites; left) and very slowly (rods; right) cooling the sol phase. The scale bars are 200 μm.

Cartoon representation of bullet-shaped molecules in a sol phase (a) aggregating to effect bulk crystallization (b) in competition with selective growth into a rod-like 1D structures (c) and then into 3D (d) networks. The liquid is represented by the squiggly-shaped lines.

Other physical methods [47] include relieving or imposing a mechanical stress on thixotropic sols (vide infra), shining light on photoresponsive sols [48] (Fig. 7.5 [49]), effecting chemical changes to potential gelators by in situ enzymatic reactions [50], and placing sols under ultrasound to promote aggregation by conformational changes [51]. Thixotropic gels become fluid when disturbed (as by shaking) and then recover their viscoelasticity when left at rest. Some other chemical and physical methods to make or destroy molecular gels—some of which are reversible and some are irreversible–include changing the pH, adding or removing metal or other ions, initiating host-guest complexation, effecting redox processes, applying magnetic fields, and inducing in situ reversible or irreversible chemical reactions [52].

7.5 How Do Aggregation and Growth of Molecular Gelator Networks Occur?

The actual shapes of the micron-scale objects constituting the gelator network depend on the shape, chirality [53], and solubility of the gelator molecules [54] and kinetic factors (such as the rate of super-cooling) [10, 55], along the kinetic pathway leading to aggregates and their epitaxial growth into axially symmetric objects with large aspect ratios. The objects may have uniform or poly-disperse cross-sections as rods, straight or helically twisted tapes and fibers, tubules, spherulites, etc. In fact, helically twisted tapes can be produced even by achiral molecular gelators [56]! Several types of gelator networks, including those comprised of tetraoctadecylphosphonium salts, have been used as templates to make silicate objects [57] with tetraethyl orthosilicate (TEOS) precursors [58].

In fact, one can envision several mechanisms by which small molecules in sol phases aggregate into the 3D networks requisite for gel formation. A cartoon representation of one possible mode from a sol phase is shown in Fig. 7.3. The bullet-shaped molecules prefer to associate along one axis, leading to preferential 1D growth of rod-like objects shown in C. A macroscopic analogy is how Lego blocks interact preferentially along only their crenelated surfaces. Rather empirical treatments of the formation and structures of gel networks based on kinetic parameters have been devised by Avrami (Eq. 7.1) [59] and Dickinson (Eq. 7.2) [60]. The original articles describe the specific conditions for applying them to molecular gels. X is the volume fraction of the gelator participating in the gel network at time t, K is a type of rate constant, n is the ‘Avrami exponent’ which characterizes the type of object growth, Df is the fractal dimension of the gelator network, and C is a constant. The variable X has been measured as a function of time by absorption and fluorescence spectroscopies, as well as by rheological and small angle neutron diffraction measurements; any technique which measures rapidly the changes in gelator aggregation may be employed. Other, more detailed approaches to aggregation/nucleation/growth mechanisms are based on isodesmic and cooperative modes of aggregation [61] and a combination of kinetic and thermodynamic considerations [62].

7.6 Experimental Determination of What Is and Is Not a Gel

A simple and preliminary (but sometimes inaccurate) method to determine what is and what is not a gel is ‘the inverse flow method’ [63] in which a sample consisting of a liquid and a small fraction of solid is inverted with respect to gravity. If no flow is observed after a protracted period, the sample may be assumed to be a gel. A more accurate and detailed assessment of the gel status of a sample is available from measurements of endotherms and exotherms in differential scanning calorimetry thermograms. An example is the thermal behavior of 1 and 3 wt% n-dotriacontane (C32H66) in safflower oil rich in trioleins [64]. From the thermograms obtained on cooling the sol (Fig. 7.6a) and heating the gel (Fig. 7.6b) at 1 or 10 ℃, it was possible to calculate the initial crystallization and melting temperatures, the temperatures of maximum heat flow for crystallization/melting (TCr and TM, respectively), and the heats of crystallization/melting (ΔHCr and ΔHM, respectively). These data allow interesting and mechanistically informative comparisons between thermodynamic and rheological changes (the latter obtained in separate experiments). They also provide insights into the validity of applying the Schröder-van Laar equation [65] (Eq. 7.3), which assumes ideality in melting-nucleation phenomena during the sol-gel phase transitions (i.e., the interactions between gelator and liquid molecules is the same in the sol and gel phases) over a range of concentrations). In Eq. 7.3, x is the gelator solubility under conditions of ideal solution behavior, T is the equilibrium temperature, R is the ideal gas constant, and ΔHM and TM–available from DSC measurements—are, respectively, the molar melting enthalpy and the melting temperature of the neat gelator. Because the assumption of ideality is frequently not valid, the use of this equation is useful in a limited number of gel systems.

Reprinted with permission from European Journal of Lipid Science and Technology, 2009, 111, 207. Copyright (2009) Wiley-VCH

Cooling (a) and heating (b) thermograms at 1 or 10 ℃/min of dotriacontane (C32H66) in a triolein-rich safflower oil. The arrows in A indicate the initial (TCr = 45.7 ℃) crystallization and maximum heat flow (TCr = 40.0 ℃) temperatures. The heat of crystallization, ΔHCr, is obtained from the area under the exotherm. In B, the arrows show the melting temperatures (TM), and the areas under the corresponding endotherms provide the heats of melting, ΔHM.

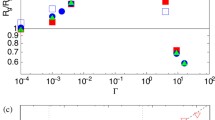

Thixotropic gels are especially interesting because they can be destroyed by application of excessive stress and reformed when the sample is left under conditions within the linear viscoelastic region, which is determined by oscillatory rheological measurements of the moduli as a function of oscillation frequency and applied stress. The values of the moduli, as a sample is cycled periodically between the linear viscoelastic (LVR) and the destructive strain (DS) regions, can yield valuable insights into the dynamics of the isothermal reformation step and the degree (if any) of irreversible destruction of the gelator structure upon repeated application of destructive strain. In the example shown in Fig. 7.7 with the gelator (R)-12-hydroxy-N-(2-hydroxyethyl)stearamide (HS–2–OH), there is no discernible loss of gel structure after repeated exposure to destructive strain [66]. That is usually not the case: the magnitudes of the moduli decrease as the number of cycles or the magnitude of the applied strain increases. The recovery time constant τ after cessation of destructive strain can be calculated from Eq. 7.4 (where m is a constant that depends on the gel being examined).

Reprinted with permission from Soft Matter 2015, 11, 5010. Copyright (2015) Royal Society of Chemistry

G′ (■) and G″ (▲) versus time and application of different strains and frequencies (LVR = linear viscoelastic region; DS = destructive strain region) of a 2.0 wt% HS–2–OH in isostearyl alcohol sample at 20 ℃.

7.7 The Role of the Liquid Component

Despite the gelator being a much smaller portion of a gel than the liquid, the properties of the latter are frequently given less attention. To discern how to characterize the properties of the liquid, it is necessary to consider the interactions between the two components at various stages during gel formation. Unfortunately, methods to assess gelator-liquid interactions in sol phases, for example, are not well developed. Thus, most approaches concentrate on whether a particular liquid is gelated by a specific gelator molecule and comparisons of the properties of the two.

Several of those approaches have been compared recently [67b]. Here, the one of Hansen will be discussed as it applies to gels [67], comparing it with the more traditional Hildebrand solubility parameter [Eq. 7.5, where \(\Delta E_{i}^{v}\) is the energy of vaporization and Vi is the molar volume; includes dispersion forces and polar interactions (including H-bonding)] that emphasizes enthalpy without considering equally entropy. Then, Eq. 7.6 applies for a mixture containing 2 different components (e.g., a solvent and a gelator) where is the volume of the mixture and ϕi is the volume fraction of component i.

Hansen solubility parameters (HSPs) consider specific intermolecular interactions as 3 separate components for the energy of vaporization as the cohesive energy. They are London (atomic) dispersion forces \((E_{d} )\), (molecular) permanent dipole-dipole, quadrupole-quadrupole, ion-ion etc. forces (Ep), and (molecular) hydrogen bonding \((E_{h} )\) and \(E_{total} = E_{d} + E_{p} + E_{h}\) Then, \(E_{total} /V({\text{in}}\,{\text{J}}/{\text{cm}}^{3} = {\text{MPa)}}\) is a pressure and the sum of squares of the individual HSP components (i.e., the Hildebrand solubility parameter) is \(\delta_{total}^{2} = \delta_{d}^{2} + \delta_{p}^{2} + \delta_{h}^{2}\). From this, one can calculate Hansen spheres by calculating \(\delta_{d} ,\delta_{p} \,{\text{and}}\,\delta_{h}\) as the center of a sphere \(R_{ij}\) (Eq. 7.7; where i is a solvent and j is a gelator) on a group summation basis, using data from Hansen’s book [67] or empirically if a sufficient number of gelated and non-gelated liquids have been employed.

An attractive alternative to the Hansen solubility parameters is Teas plots, another empirical relationship between liquid properties and gelator (or other species) solubilities, [67a, 68], from which triangles of solubility can be constructed [69, 70].

7.8 Organic Gelator Molecules and Their Assemblies. Starting from the Simplest Molecular Structures and Increasing the Complexity

A short synopsis of a limited number types of molecular gelators and their aggregate gel structures are presented below. The examples have been selected to give the reader a ‘flavor’ of the myriad of known molecular gels. Two of the most efficient molecular gelators, in terms of the range of liquids gelated and the CGCs (~ .03 to .05 wt%) required, are methyl 4,6-O-p-nitrobenzylidene-α-D-galactopyranoside and methyl 4,6-O-benzylidene-α-D-mannopyranoside [71]. For a more comprehensive treatment of this topic, see the books and reviews cited.

7.8.1 n-Alkanes and Their Simple Derivatives

Very short n-alkanes melt to their isotropic liquid phases at sub-ambient temperatures and, therefore, are inappropriate candidates to form useful assemblies for gelation of other liquids. However, longer n-alkanes exhibit neat solid phases with more than one type of organization and super-ambient melting temperatures [72]. For example, n-heneicosane (C21H44) undergoes transitions from orthorhombic (Phase I) to hexagonal-rotator (Phase II) layers at 32.5 ℃ and from Phase II to its isotropic (liquid) phase at 40.2 ℃ [73]. Even in solid Phase II, due to thermal fluctuations, there is some disordering and gauche chain conformations which are less probable in a layer middle than at the layer ends [72]. In fact, very long n-alkanes are able to gelate short n-alkanes and a variety of liquids by forming networks consisting of 2D platelets [74].

The added disorder caused by inserting a carboxy group between carbons 4 and 5 of the n-heneicosane chain, yielding n-butyl stearate, induces formation of a smectic B liquid-crystalline phase between 15 and 26 ℃ [75]. Addition of a carboxylic acid group to a chain end of a long n-alkane reduces the disorder, and layered surfactant hydrogels are formed when water is added to the salts. For example, stearic acid (mp ~157 ℃) is the carboxylic acid derivative of octadecane (mp 28 ℃). Its potassium or rubidium salt or mixtures of potassium stearate and 1-octadecanol form well organized lamellar hydrogels [76].

In fact, a large number of other end groups have been appended to long alkyl chains as a means to modify the melting temperature (i.e., making them well above room temperature) and solubility of potential gelators [77]. They, especially in combination with addition of a hydroxyl [78] or carbonyl group [79] near the chain middle (N. B.: at C12), have been shown to yield molecules capable of gelating a wide variety of liquids.

Whereas HS–2–OH [66] gelates several liquids by creating twisted ropes whose the pitch = 130 ± 30 nm in silicone oil (Fig. 7.8), and 60 ± 5 nm in isostearyl alcohol, [66] the shape of the objects responsible for the network of carbon tetrachloride gels supplied by the smallest molecular organogelator known to date, N,N′-dimethyl urea (MW 88), can be changed from spherulites (fast-cooling of sols) to rods (slow-cooling of sols) (Fig. 7.2) [42]. Even more surprising is the observation that the gel networks of achiral oligoureas can be various types of braided fibers. For example, the pentaurea 5UR has been shown to form a variety of chiral braids in N,N-dimethylformamide (Fig. 7.9) as its sols are cooled to room temperature [80]. A detailed explanation for the different motifs has been reported, along with a caveat that an excess of one of the handedness within the braids can be attributed to traces of chiral species advertently (or inadvertently!) present in the sols. The gross aspects of their formation can be explained by a mathematical model reported more than 70 years ago [81]. Similar approaches have been employed to explain the change from fibers of sodium oleate/oleic acid in buffered aqueous media that are <100 mm-long helices to >1 cm long helical assemblies with a regular pitch and radius when small amounts of N-decanoyl-L-alanine are added to the initial solutions/sols [82]. Less dramatic (but clear) elongation of the fibers was also found when some shorter saturated alkanoate salts were added in place of the N-decanoyl-L-alanine.

7.8.2 Some Tubule Assemblies of More Complex Alkane-Derived Surfactants

Nanotubules can offer an especially interesting mode of aggregation and growth leading to gel networks [53]. For example, the modes of growth and detailed structures of nanotubes from L-dodecanoylserine, a structurally simple molecule with a long alkyl chain and a polar head group, are very dependent on the liquid from which they are grown (Fig. 7.10) [83]. In water, aggregation proceeds from micelles and helical ribbons, leading eventually to tubules (mp 17–20 ℃) in which the polar head groups pointed outward. When grown from toluene, the progression is from inverted micelles and vesicles and the lipophilic tails are pointed outward in the eventual tubules (mp 60–62 ℃). Also, the ribbons are not twisted if the dodecanoylserine is racemic. Another detailed example uses cryo-TEM to follow the sequential transformation of aqueous dispersions of N-α-lauryl-lysyl-aminolauryl-lysyl-amide (LLALA), a molecule comprised of two dodecyl chains and two charged lysine groups, into 1D objects—from thin fibers/ribbons to twisted ribbons to coiled ribbons to closed nanotubes (Fig. 7.11) [84]. The observations of the separate objects are made possible by the very different rates for the transformation steps.

Temporal progression of LLALA to nanotubes (B5) by self-assembly in aqueous media at 25 ℃: B1—thin micrometer-long fibrils; B2—twisted ribbons of various widths; B4—alternating arrowheads highlight a cylindrical curvature. Bars = 100 nm. Reprinted with permission from J Am Chem Soc 2011, 133, 2511.

7.8.3 Some Tubule Assemblies of Steroidal Surfactants

Tubules with monodisperse diameters have been made by adding a simple bile acid, lithocholic acid, to an aqueous sodium hydroxide solution [85]. Single-walled tubules (52 and 49 nm outside and inside diameters) can be observed from the closure of twisted ribbons shortly after mixing (Fig. 7.12a). They are easily aligned and become multi-layered over longer times (Fig. 7.12b). They have been transformed into silica and titanium oxide objects with very large aspect ratios via sol-gel processes and calcination using tetraethyl orthosilicate (TEOS) and titanium(IV) isopropoxide (Ti(OiPr)4), as the precursors [86].

7.9 Final Thoughts About the Scope and Intent of This Chapter

Unapologetically, this chapter relies more heavily on reports from research in the author’s laboratory than a balanced rendering of the references warrants. That reliance is a result only of the author’s familiarity and is not intended to be a balanced assessment of the importance of the contributions of others to the field.

With that in mind, this chapter is intended to describe what molecular gels are structurally and mechanically, and the known limits of both properties, and to describe the clear challenges to advancing the field; it is not intended to be a comprehensive treatise. It presents a description of what molecular gels are and how one can ascertain the difference them and other phases that depend on aggregation. It also describes some of the challenges confronting our ability to characterize them and, more importantly, how to design molecular gelators a priori and their interactions with the liquid components along the pathways starting from sols. Although molecular gels, comprised of (‘0-D’) gelator molecules, are intrinsically weaker mechanically than their polymeric gel analogues (in which at least one-dimension of the gel structure is always present through covalent intermolecular interactions among ‘monomers’), they offer some potential advantages and opportunities. Foremost among these is their ease of reversibility that makes possible many interesting applications, some of which are described in several of the references cited here.

References

Smith, D.K.: In: Weiss, R.G. (ed.) Molecular Gels. Royal Society of Chemistry, United Kingdom, chap 9 (2018)

(a) Hamley, I. W.: Introduction to Soft Matter. Wiley: Chichester. (b) Liu, X.Y., Li, J.L. (eds) Soft Fibrillar Materials. Wiley, Singapore (2013). (c) Doi, M.: Soft Matter Physics. Oxford University Press, Oxford (2013). (d) Miller, W.L., Cacciuto, A.: Exploiting classical nucleation theory for reverse self-assembly. J. Chem. Phys. 133, 234108 (2010)

Marangoni, A.G., Garti, N. (eds.): Edible Oleogels, 2nd edn. AOCS Press, London (2018)

Ruiz-Palomero, C., Kennedy, S.R., Soriano, M.L., Jones, C.D., Valcarcel, M., Steed, J.W.: Pharmaceutical crystallization with nanocellulose organogels. Chem. Commun. 52, 7782–7785 (2016)

Clark, J.B.: US Patent 2,596,844 13 May 1952

Fieser, L.F., Harris, G.C., Hershberg, E.B., Morgana, M., Novello, F.C.: Putnam ST Napalm. Ind. Eng. Chem. 38, 768–773 (1946)

McNaught, A.D., Wilkinson, A.: IUPAC. Compendium of Chemical Terminology (the “Gold Book”), 2nd edn. Blackwell Scientific, Oxford (1997)

Dawn, A., Kumari, H.: Low Molecular Weight Supramolecular Gels Under Shear: Rheology as the Tool for Elucidating Structure-Function Correlation. Chem. Eur. J. 24, 762–776 (2018)

Marangoni, A.G.: Kinetic Analysis of Food Systems. Springer, Switzerland, p. 161ff (2017)

Huang, X., Raghavan, S.R., Terech, P., Weiss, R.G.: Distinct Kinetic Pathways Generate Organogel Networks with Contrasting Fractality and Thixotropic Properties. J. Am. Chem. Soc. 128, 15341–15352 (2006)

Fuentes-Caparrós, A.M., Dietrich, B., Thomson, L., Chauveau, C., Adams, D.J.: Using cavitation rheology to understand dipeptide-based low molecular weight gels. Soft Matter. 15, 6340–6347 (2019)

(a) Li, J.-J., Zhang, M., Weiss, R.G.: (R)-12-Hydroxystearic acid hydrazides as very efficient gelators: Diffusion, partial thixotropy, and self-healing in self-standing gels. Chem. Asian J. 11, 3414–3422 (2016). (b) Song, J., Wang, H., Li, M.: An NMR study on the gelation of N,N′-bis(4-N-alkylo-xybenzoyl) hydrazine (4Dn) in two aromatic solvents. New. J. Chem. 39, 2711–2719 (2015)

Feng, L., Cavicchi, K.A.: Investigation of the relationships between the thermodynamic phase behavior and gelation behavior of a series of tripodal trisamide compounds. Soft Matter 8, 6483–6492 (2012)

Takahashi, A., Sakai, M., Kato, T.: Melting temperature of thermally reversible gel. VI. Effect of branching on the sol–gel transition of polyethylene gels. Polym. J. 12, 335–341 (1980)

Weiss, C.K., Toca-Herrera, J.L. (eds.): Colloid Chemistry. Basel, MDPI (2018)

Hsu, F.C., Tsai, S.F., Lee, S.-S.: Chemical investigation of Hyptis suaveolens seed, a potential antihyperuricemic nutraceutical, with assistance of HPLC-SPE-NMR. J. Food Drug Anal. 27, 897–905 (2019)

(a) Dresel, W., Heckler, R.P.: Lubricating greases in lubricants and lubrication. In: Mang, T., Dresel, W. (eds) Lubricants and Lubrication. Wiley, Weinheim (2017). (b) Mortier, R.M., Fox, M.F., Orszulik, S.T.: Chemistry and Technology of Lubricants, 3rd edn. Springer, Dordrecht (2010)

Lipowitz, A.: Versuche und Resultate über die Löslichkeit der Harnsäure. Liebigs Ann Chem Pharm 38, 348–355 (1841)

Graham, T.: X. liquid diffusion applied to analysis. Phil. Trans. Roy Soc. 151, 183–224 (1861)

te Nijenhuis, K.: Thermoreversible networks. Adv. Polym. Sci. 130 (Springer Verlag, Berlin) (1997)

Escuder, B., Miravet, J.F. (eds.): Functional Molecular Gelators. RSocietyC Publishing, Cambridge (2014)

Liu, X.Y., Li, J.L. (eds.): Soft Fibrillar Materials: Fabrication and Applications. Wiley-VCH Verlag, Weinheim (2013)

Weiss, R.G., Terech, P. (eds.): Molecular Gels. Materials with Self-Assembled Fibrillar Networks. Springer, Dordrecht (2006)

Weiss, R.G. (ed.): Molecular Gels. Royal Society of Chemistry, United Kingdom (2018)

Loh, X.J., Scherman, O.A. (eds.): Polymeric and Self Assembled Hydrogels. RSC Publishing, Cambridge (2013)

Weiss, R.G.: The past, present, and future of molecular gels. What is the status of the field and where is it going? J. Am. Chem. Soc. 136, 7519–7530 (2014)

Lloyd, D.J.: The problem of gel structure. In: Alexander, J. (ed.) Colloid Chemistry, vol. 1, pp. 767–782. The Chemical Catalog Co, New York (1926)

Weiss, R.G.: Controlling variables in molecular gel science. How can we improve the state of the art? Gels 4, 25ff (9 pages) (2018)

Guenet, J.M.: Organogels. Thermodynamics, structure, solvent role, and properties. Springer Nature, Switzerland (2016)

Bag, B.G., Majumdar, R.: Self-assembly of renewable nano-sized triterpenoids. Chem. Rec. 17, 841–873 (2017)

Das, U.K., Banerjee, S., Dastidar, P.: Remarkable shape-sustaining, load-bearing, and self-healing properties displayed by a supramolecular gel derived from a bis-pyridyl-bis-amide of L-phenyl alanine. Chem. Asian J. 9, 2475–2482 (2014)

Nonappa, Lahtinen M., Behera, B., Kolehmainen, E., Maitra, U.: Unraveling the packing pattern leading to gelation using SS NMR and X-ray diffraction: direct observation of the evolution of self-assembled fibers. Soft Matter 6, 1748–1757 (2010)

Takeno, H., Mochizuki, T.: A structural development of an organogel explored by synchrotron time-resolved small-angle X-ray scattering. Colloid Polym. Sci. 291, 2783–2789 (2013)

Ostuni, E., Kamaras, P., Weiss, R.G.: Novel X-ray method for in situ determination of Gelator strand structure. Cholesteryl Anthraquinone-2-carboxylate. Angew. Chem. Int. Ed. Engl. 35, 1324–1326 (1996)

Giansante, C., Raffy, G., Schafer, C., Rahma, H., Kao, M.T., Olive, A.G.L., Del Guerzo, A.: White-light-emitting self-assembled nano fibers and their evidence by microspectroscopy of individual objects. J. Am. Chem. Soc. 133, 316–325 (2011)

Dou, C.D., Li, D., Gao, H.Z., Wang, C.Y., Zhang, H.Y., Wang, Y.: Sonication-induced molecular gels based on mono-cholesterol substituted Quinacridone derivatives. Langmuir 26, 2113–2118 (2010)

Vujicic, N.S., Glasovac, Z., Zweep, N., van Esch, J.H., Vinkovic, M., Popovic, J., Zinic, M.: Chiral hexa- and nonamethylene-bridged bis(L-Leu-oxalamide) Gelators: The first oxalamide gels containing aggregates with a chiral morphology. Chem. Eur. J. 19, 8558–8572 (2013)

(a) Gránásy, L., Pusztai. T., Borzsonyi, T., Warren, J.A., Douglas, J.F.: A general mechanism of polycrystalline growth. Nat. Mater. 3, 645–650 (2004). (b) Raghavan, S.R., Douglas, J.F.: The conundrum of gel formation by molecular nanofibers, wormlike micelles, and filamentous proteins: gelation without cross-links? Soft Matter. 8, 8539–8546 (2012)

Sanz, E., White, K.A., Clegg, P.S., Cates, M.E.: Colloidal gels assembled via a temporary interfacial Scaffold. Phys. Rev. Lett. 103, 255502 (2009)

Terech, P., Weiss, R.G.: Low-molecular mass gelators of organic liquids and the properties of their gels. Chem. Rev. 97, 3133–3159 (1997)

Flory, P.: Thermodynamics of polymer solutions. Disc Faraday Soc. 49, 7–29 (1970)

George, M., Tan, G., John, V.T., Weiss, R.G.: Urea and Thiourea derivatives as low molecular-mass organogelators. Chem. Euro J. 11, 3243–3254 (2005)

(a) Lan, Y., Corradini, M.G., Weiss, R.G., Raghavan, S.R., Rogers, M.A.: To gel or not to gel: Correlating molecular gelation with solvent parameters. Chem. Soc. Revs. 44, 6035–6058. (b) Hirst, A.R., Coates, I.A., Boucheteau, T.R., Miravet, J.F., Escuder, B., Castelletto, V., Hamley, I.W., Smith, D.K.: Low-molecular-weight gelators: elucidating the principles of gelation based on gelator solubility and a cooperative self-assembly model. J. Am. Chem. Soc. 130, 9113–9121 (2008). (c) Edwards, W., Lagadec, C.A., Smith, D.K.: Solvent-gelator interactions-using empirical solvent parameters to better understand the self-assembly of gel-phase materials. Soft Matter. 7, 110–117 (2011). (d) Chen, J., Kampf, J.W., McNeil, A.J.: Comparing molecular gelators and nongelators based on solubilities and solid-state interactions. Langmuir 26, 13076–13080 (2010) (e) Muro-Small, M.L., Chen, J., McNeil, A.J.: Dissolution parameters reveal role of structure and solvent in molecular gelation. Langmuir 27, 13248–13253 (2011). (f) Jonkheijm, P., van der Schoot, P., Schenning, A.P.H.J., Meijer, E.W.: Probing the solvent-assisted nucleation pathway in chemical self-assembly. Science 313, 80–83 (2006). (g) De Greef, T.F.A., Smulders, M.M.J., Wolffs, M., Schenning, A.P.H.J., Sijbesma, R.P., Meijer, E.W.: Supramolecular polymerization. Chem. Rev. 109, 5687–5754 (2009). (h) Aggeli, A., Nyrkova, I.A., Bell, M., Harding, R., Carrick, L., McLeish, T.C.B., Semenov, A.N., Boden, N.: Hierarchical self-assembly of chiral rod-like molecules as a model for peptide beta-sheet tapes, ribbons, fibrils, and fibers. Proc. Natl. Acad. Sci. USA 98, 11857–11862 (2001). (i) Van derHart, D.L., Douglas, J.F., Hudson, S.D., Antonucci, J.M., Wilder, E.A.: NMR characterization of the formation kinetics and structure of di-o-benzylidene sorbitol gels self-assembled in organic solvents. Langmuir 27, 1745–1757 (2011). (j) De Yoreo, J.J., Vekilov, P.G.: Principles of crystal nucleation and growth. In: Dove, P.M., De Yoreo, J.J., Weiner, S. (eds.) Biomineralization (Reviews in Mineralogy and Geochemistry). Mineralogical Society of America, Washington DC 54, 57–93 (2003)

(a) Lin, Yc., Weiss, R.G.: A novel gelator of organic liquids and the properties of its gels. Macromolecules 20, 414–417 (1987). (b) Lin, Yc, Kachar, B., Weiss, R.G.: A novel family of Gelators of organic fluids and the structure of their gels. J. Am. Chem. Soc. 111, 5542–5551 (1989)

Furman, I., Weiss, R.G.: Factors influencing the formation of thermally reversible gels comprised of cholesteryl 4-(2-Anthryloxy)butanoate in hexadecane, 1-octanol, or their mixtures. Langmuir 9, 2084–2088 (1993)

Terech, P., Furman, I., Weiss, R.G.: Structures of organogels based upon cholesteryl 4-(2-anthryloxy)butanoate, a highly efficient luminescing gelator: Neutron and X-ray small-angle scattering investigations. J. Phys. Chem. 99, 9558–9566 (1995)

Caran, K.L., Lee, D.C., Weiss, R.G.: Molecular gels and their fibrillar networks In: Liu, X.Y., Li. J.L. (eds.) Soft Fibrillar Materials: Fabrication and Applications. Wiley-VCH Verlag, Weinheim, chap 1 (2013)

Murata, K., Aoki, M., Suzuki, T., Harada, T., Kawabata, H., Komori, T., Ohseto, F., Ueda, K., Shinkai, S.: Thermal and light control of the sol-gel phase transition in cholesterol-based organic gels. novel helical aggregation modes as detected by circular dichroism and electron microscopic observation. J. Am. Chem. Soc. 116, 6664–6676 (1994)

Kumar, R., Raghavan, S.R.: Photogelling fluids based on light-activated growth of zwitterionic wormlike micelles. Soft Matter 5, 797–803 (2009)

(a) Zhang, Y., Kuang, Y., Gao, Y., Xu, B.: Versatile small-molecule motifs for self-assembly in water and the formation of biofunctional supramolecular hydrogels. Langmuir 27, 529–537 (2011). (b) Du, X., Zhou, J., Xu, B.: Supramolecular hydrogels made of basic biological building blocks chem Asian J. 9, 1446–1472 (2014)

(a) Caran, K.L., Lee, D.C., Weiss, R.G.: Molecular gels and their fibrillar networks. In: Liu, X.Y., Li, J.L. (eds.) Soft Fibrillar Materials: Fabrication and Applications. Wiley-VCH Verlag, Weinheim chap 1.32, p. 40ff (2013). (b) Liu, J., He, P., Yan, J., Fang, X., Peng, J., Liu, K., Fang, Y.: An organometallic super-gelator with multiple-stimulus responsive properties. Adv. Mater. 20, 2509–2511 (2008). (c) Naota, T., Koori, H.: Molecules that assemble by sound: An application to the instant gelation of stable organic fluids. J. Am. Chem. Soc. 127, 9324–9325 (2005). (d) Wang, C., Zhang, D., Zhu, D.: A low-molecular-mass Gelator with an electroactive Tetrathiafulvalene group: Tuning the gel formation by charge-transfer interaction and oxidation. J. Am. Chem. Soc. 127, 16372–16373 (2005). (e) Bardeling, D.: Ultrasound Induced Gelation: A Paradigm Shift, vol. 5, pp. 1969–1971 (2009). (f) Ogata, K., Naota, T., Takaya, H.: Metal array fabrication based on ultrasound-induced self-assembly of metalated dipeptides. Dalton Trans. 42, 15,953–15,966 (2013)

Mishra, R.K., Das, S., Vedhanarayanan, B., Das, G., Praveen, V.K., Ajayaghosh, A.: Stimuli-responsive supramolecular gels In: Weiss, R.G. (ed.) Molecular Gels. Royal Society of Chemistry, United Kingdom, chap 7 (2018)

(a) Selinger, J.V., Spector, M.S., Schnur, J.M.: Theory of self-assembled tubules and helical ribbons. J. Phys. Chem. B 105, 7157–7169 (2001). (b) ten Eikelder H.M.M., Huub, M.M., Markvoort, A.J., de Greef, T.F.A., Hilbers, P.A.J.: An equilibrium model for chiral amplification in supramolecular polymers. J. Phys. Chem. B 116, 5291–5301

(a) Yu, R., Lin, N.B., Yu, W.D., Liu, X.Y.: Crystal networks in supramolecular gels: formation kinetics and mesoscopic engineering principles. CRYSTENGCOMM 17, 7986–8010 (2015). (b) Yan, N., Xu, Z.Y., Diehn, K.K., Raghavan, S.R., Fang, Y., Weiss, R.G.: Correlations of gel properties with gelator structures and characterization of solvent effects. Langmuir 29, 793–805 (2013). (c) Yan, N., Xu, Z., Diehn, K.K., Raghavan, S.R., Fang, Y., Weiss, R.G.: How Do Liquid Mixtures Solubilize Insoluble Gelators? Self-Assembly Properties of Pyrenyl-Linker-Glucono Gelators in Tetrahydrofuran-Water Mixtures. J. Am. Chem. Soc. 135, 8989–8999 (2013). (d) Liu, S.J., Yu, W., Zhou, C.: Solvents effects in the formation and viscoelasticity of DBS organogels. Soft Matter. 9, 864–874 (2013)

(a) Huang, X., Terech, P., Raghavan, S.R., Weiss, RG (2005) Kinetics and structure during 5α-Cholestan-3β-yl N-(2-Naphthyl)carbamate/n-alkane organogel formation. J. Am. Chem. Soc. 127, 4336–4344. (b) Li, J.L., Yuan, B., Liu, X.Y., Wang, R.Y., Wang, X.G.: Control of crystallization in supramolecular soft materials engineering. Soft Matter. 9, 435–442 (2013). (c) Filobelo, L.F., Galkin, O., Vekilov, P.G.: J. Chem. Phys. 123, 014904 (2005)

Liu, Y., Jia, Y., Zhu, E., Liu, K., Qiao, Y., Che, G., Yin, B.: Supramolecular helical nanofibers formed by an achiral monopyrrolotetrathiafulvalene derivative: water-triggered gelation and chiral evolution. New. J. Chem. 41, 11060–11068 (2017)

(a) Jung, J.H., Ono, Y., Shinkai, S.: Sol-gel polycondensation of tetraethoxysilane in a cholesterol-based organogel system results in chiral spiral silica. Angew. Chem. Int. Ed. 39, 1862–1865 (2000). (b) Jung, J.H., Ono, Y., Sakurai, K., Sano, M., Shinkai, S.: Novel vesicular aggregates of crown-appended cholesterol derivatives which act as gelators of organic solvents and as templates for silica transcription. J. Am. Chem. Soc. 122, 8648–8653 (2000)

Huang, X., Weiss, R.G.: Silica structures templated on fibers of tetraalkylphosphonium salt gelators in organogels. Langmuir 22, 8542–8552 (2006)

(a) Avrami, M.: Kinetics of phase change. I General Theory. J. Chem. Phys. 7, 1103–1112 (1939). (b) Avrami, M.: Kinetics of phase change. II Transformation‐time relations for random distribution of nuclei. J. Chem. Phys. 8, 212–224 (1940)

Dickinson, E.: On gelation kinetics in a system of particles with both weak and strong interactions. J. Chem. Soc., Faraday Trans. 93, 111–114 (1997)

Smulders, M.M.J., Nieuwenhuizen, M.M.L., de Greef, T.F.A., van der Schoot, P., Schenning, A.P.H.J., Meijer, E.W.: How to distinguish isodesmic from cooperative supramolecular polymerisation. Chem. Eur. J. 16, 362–367 (2010)

Douglas, J.F., Dudowicz, J., Freed, K.F.: Lattice model of equilibrium polymerization. VII. Understanding the role of “cooperativity” in self-assembly. J. Chem. Phys. 128, 224901 (2008)

Raghavan, S.R., Cipriano, B.H.: Gel fornation: Phase diagrams using tabletop rheology and calorimetry. In: Weiss, R.G., Terech, P. (eds.) Molecular Gels. Materials with Self-Assembled Fibrillar Networks. Kluwer Academic Publishers, Dordrecht chap 8 (2006)

Morales-Rueda, J.A., Dibildox-Alvarado, E., Charó-Alonso, M.A., Weiss, R.G., Toro-Vazquez, J.F.: Thermo-mechanical properties of safflower oil organogels with candelilla wax or hentriacontane as gelator. Eur. J. Lipid Sci. Tech. 111, 207–215 (2009)

(a) Beckman, W.: Crystallization: Basic Concepts and Industrial Applications, pp. 37–74. Wiley, Weinheim. (2013). (b) Feng, L. Ph.D. thesis. Investigation of the relationships between the thermodynamic phase behavior and gelation behavior of a series of tripodal trisamide compounds. University of Akron, pp. 13–16 (2012)

Mallia, V.A., Weiss, R.G.: Structural bases for mechano-responsive properties in molecular gels of (R)-12-hydroxy-N-(ω-hydroxyalkyl)octadecanamides. Rates of formation and responses to destructive strain. Soft Matter. 11, 5010–5022 (Correction: 2015, 11, 5168) (2015)

(a) Hansen, C.M.: Hansen Solubility Parameters, 2nd edn. CRC Press, Boca Raton. (2007). (b) Lan, Y., Corradini, M.G., Weiss, R.G., Raghavan, S.R., Rogers, M.A.: To gel or not to gel: Correlating molecular gelation with solvent parameters. Chem. Soc. Revs. 44, 6035–6058 (2015). (c) Singh, A., Auzanneau, FI, Corradini, M.G., Grover, G., Weiss, R.G., Rogers, M.A.: Molecular nuances governing the self-assembly of 1,3:2,4-dibenzylidene-D-sorbitol. Langmuir 33, 10907–10916 (2017). (d) Xu, H.Q., Song, J., Tian, T., Feng, R.X.: Estimation of organogel formation and influence of solvent viscosity and molecular size on gel properties and aggregate structures Soft Matter. 8, 3478–3486 (2012)

Zhao, C.X., Wang, H.T., Li, M.: Research progress in the correlation between gelation properties and solvent parameters. Acta Phys-Chim Sinica 30, 2197–2209 (2014)

Barton, A.F.M.: Handbook of solubility parameters and other cohesive parameters. CRC Press, Boca Raton, Fl, 2nd edn (1991)

Vila, A.S., Garcia, J.M.B.: Extended abstract—computer applications and cleaning: teas fractional solubility parameter system. Conserv. Smithson. Contrib. Conserv. Sci. 35–38 (2012). https://pdfs.semanticscholar.org/610c/be33953b4b1b88a31ff259cf9c897aacbb1c.pdf

(a) Luboradzki, R., Gronwald, O., Ikeda, A., Shinkai, S.: Sugar-integrated “Supergelators” which can form organogels with 0.03–0.05% [g mL−1]. Chem Lett. 29, 1148–1149 (2000). (b) Gronwald, O., Shinkai, S.: Sugar-integrated gelators of organic solvents. Chem Eur. J. 7, 4328–4334 (2001)

Maroncelli, M., Strauss, H.L., Snyder, R.G.: The distribution of conformational disorder in the high-temperature phases of the crystalline n-alkanes. J. Chem. Phys. 82, 2811–2824 (1985)

Schaerer, A.A., Busso, C.J., Smith, A.E., Skinner, L.B.: Properties of pure normal alkanes in the C17 to C36 Range. J. Am. Chem. Soc. 77, 2017–2019 (1955)

Abdallah, D.J., Weiss, R.G.: n-Alkanes Gel n-Alkanes (and Many Other Organic Liquids). Langmuir 16, 352–355 (2000)

Krishnamurthi, D., Krishnamourthy, K.S., Shashidar, R.: Thermal, optical, X-ray, infrared and NMR’ studies on the a-phase of some saturated aliphatic esters. Mol. Cryst. Liq. Cryst. 8, 339–366 (1969)

(a) Vincent, J.M., Skoulios, A.: ‘Gel’ et ‘coagel’. I. Identification. Localisation dans un diagramme de phases et détermination de la structure du ‘gel’ dans le cas du stéarate de potassium. Acta Cryst. 20, 432–441 (1966). (b) Vincent, J.M., Skoulios, A.: ‘Gel’ et ‘coagel’. II. Etude comparative de quelques amphiphiles Acta Cryst. 20, 441–447 (1966). (c) Vincent, J.M., Skoulios, A.: ‘Gel’ and ‘coagel’. III. ‘Gel’ investigation in the equimolecular mixture potassium stearate-n-octadecanol. Acta Cryst. 20, 447–451 (1966)

George, M., Weiss, R.G.: Molecular organogels. Soft matter comprised of low molecular-mass organic gelators and organic liquids. Acc. Chem. Res. 39, 489–497 (2006)

(a) Mallia, V.A., George, M., Blair, D.L., Weiss, R.G.: Robust organogels from nitrogen-containing derivatives of (R)-12-hydroxystearic acid as gelators. Comparisons with gels from stearic acid derivatives. Langmuir 25, 8615–8625 (2009). (b) Mallia, V.A., Terech. P., Weiss. R.G.: Correlations of properties and structures at different length scales of hydro- and organo-gels based on N-alkyl-(R)-12-hydroxyoctadecylammonium chlorides. J Phys. Chem. B 115, 12401–12414 (2011). (c) Mallia, V.A., Weiss, R.G.: Self-assembled fibrillar networks and molecular gels employing 12-hydroxystearic acid and its isomers and derivatives. J. Phys. Org. Chem. 27, 310–315 (2014). (d) Abraham, S., Lan, Y., Lam, R.S.H., Grahame, D.A.S., Kim, J.J.H., Weiss, R.G., Rogers, M.A.: Influence of positional isomers on the macroscale and nanoscale of aggregates of racemic hydroxyoctadecanoic acids in their molecular gel, dispersion and solid states. Langmuir 28, 4955–4964 (2012). (e) Zhang, M., Selvakumar, S., Zhang, X., Sibi, M.P., Weiss, R.G.: Structural and solubility parameter correlations of gelation abilities for dihydroxylated derivatives of long-chained, naturally-occurring fatty acids. Chem. Eur. J. 21, 8530–8543 (2015)

(a) Pal, A., Abraham, S., Roger, M.A., Dey, J., Weiss, R.G.: Comparison of dipolar, h-bonding, and dispersive interactions on gelation efficiency of positional isomers of keto and hydroxy substituted octadecanoic acids. Langmuir 29, 6467–6475 (2013). (b) Zhang, M., Weiss, R.G.: Mechano-responsive, thermo-reversible, luminescent organogels derived from a long-chained, naturally-occurring fatty acid. Chem. Eur. J. 22, 8262–8272 (2016). (c) Zhang, M., Weiss, R.G.: Mechano-switchable, luminescent gels derived from salts of a long-chained, fatty-acid gelator. Phys. Chem. Chem. Phys. 18, 20399–20409 (2016)

Jones, C.D., Simmons, H.T.D., Horner, K.E., Liu, K.Q., Thompson, R.L., Steed, J.W.: Braiding, branching and chiral amplification of nanofibres in supramolecular gels. Nat. Chem. 11, 375–381 (2019)

Artin, E.: Theory of braids. Ann. Math. 48, 101–126 (1947)

Kageyama, Y., Ikegami, T., Hiramatsu, N., Takeda, S., Sugawara, T.: Structure and growth behavior of centimeter-sized helical oleate assemblies formed with assistance of medium-length carboxylic acids. Soft Matter 11, 3550–3558 (2015)

Boettcher, C., Schade, B., Fuhrhop, J.H.: Comparative cryo-electron microscopy of noncovalent N-dodecanoyl- (D- and L-) serine assemblies in vitreous toluene and water. Langmuir 17, 873–877 (2001)

Ziserman, L., Lee, H.Y., Raghavan, Mor A., Danino, D.: Unraveling the mechanism of nanotube formation by chiral self-assembly of amphiphiles. J. Am. Chem. Soc. 133, 2511–2517 (2011)

(a) Terech, P., de Geyer, A., Struth, B., Talmon, Y.: Self-assembled monodisperse steroid nanotubes in water. Adv. Mater. 14, 496–498 (2002). (b) Terech, P., Talmon, Y.: Aqueous suspensions of steroid nanotubules: Structural and rheological characterizations. Langmuir 18, 7240–7244 (2002)

Huang, X., Weiss, R.G.: Rodlike silica and titania objects templated on extremely dilute aqueous dispersions of self-assembled sodium lithocholate nanotubes. J. Coll. Interface Sci. 313, 711–716 (2007)

Acknowledgements

RGW is extremely grateful to the many students in his laboratory and collaborators throughout the world who have helped to advance the field of this research and have been his educational guides. Much of the research from the lab at Georgetown would not have been possible without the financial support of the US National Science Foundation, most recently Grant CHE-1502856. This chapter is dedicated to the memory of two recently deceased outstanding scientists whose research in fields related to molecular gels has been inspirational to those directly in it. They are Kailasam Venkatesan of India (29 April 1932–31 December 2019) and Faruk Jose Nome Aguilera of Brazil who was born in Chile (29 May 1947–24 September 2018).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Weiss, R.G. (2021). A Primer on Gels (with an Emphasis on Molecular Gels). In: Liu, XY. (eds) Frontiers and Progress of Current Soft Matter Research. Soft and Biological Matter. Springer, Singapore. https://doi.org/10.1007/978-981-15-9297-3_7

Download citation

DOI: https://doi.org/10.1007/978-981-15-9297-3_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9296-6

Online ISBN: 978-981-15-9297-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)