Abstract

The inflation of clean, efficient, sustainable, effective, secure, and reliable electricity demand has been triggered much interest for Microgrid (MG) at a miraculous and quickened pace. The necessity of reliability enhancement, diversity of fuel, cutback of greenhouse gases, severe weather fluctuation, etc. has stimulated the inclusion of MG concept not only in utility level but also in customer and community level. Incorporation of solar photovoltaic (SPV) and thermoelectric (TE), termed as Solar photovoltaic-thermoelectric (SPV-TE) hybrid system is found to be a very promising technique to broadening the utilization of solar spectrum and enhancing the power output effectively-cum-efficiently. This hybrid architecture caters electrical energy with additional thermal energy that signifies upon harnessing of solar insolation in an exceptional way. But in order to retain the voltage profile in the permissible level, MG needs storage mechanism for smoothening of renewable-based power inconstancy, catering significantly high active power and dodging the long-term reactive power rising. This paper illustrates the comparative analysis of two systems such as Conventional MG; TE coupled Conventional MG defining the necessity of employment of energy storage system (ESS). The superiority of proposed system has been outlined in terms of lesser complexity in source integration, mitigating the detriment of WES and FCT integration in real-life application, delivery of higher active power and lesser reactive power absorbance over the other system. The studied system is modeled in MATLAB/Simulink environment and the results are presented to support, verify, and validate the analysis.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Solar PV system

- TEG

- Nonconventional distribution generation

- Wind energy system

- Reactive power

- Active power

1 Introduction

Supplementary energy resources are becoming mandatory upon the enduring energy reserves to cope with the energy demand of surging population and technological advancement in the world [1]. Though the Sun is a boundless energy resource which also clean as well as unreservedly available energy resource from nature, it suffers from the curse of having lower efficiency upon the most used renewable energy resources. Concentrated solar photovoltaic modules (CPV) are also sunlight based energy generator that converts a portion of solar irradiance into electrical energy having much more efficient than traditional solar PV system. Several portions of the solar irradiation has wasted as heat while converting sunlight into electricity. SPV system suffers from having lower quantum efficiency as it dissipates greatly (around more than half) of the solar irradiation as heat. Hence, by utilizing the dissipated heat into conversion of electricity the power generation and ultimately efficiency can be increased. Many researchers have been working on the hybridization of solar PV-Wind energy system (WES)-FCT, its control aspect, storage. In source side design of MPPTs for SPV and WES such as optimization-based MPPT, Modified MPPT that raises the system cost as well as mathematical complexity [2]. As per our knowledge, Implementation of SPV-TEG based system has not been employed in non-conventional distribution generation yet. Most of the researchers have been working upon the hybridization of solar PV, WES, and FCT based power generating sources in Microgrid resulting substantial generation of active power and reactive power [3,4,5]. These papers lag the complete use of the solar irradiation for extracting significant amount of power from the solar PV array resulting in higher electrical efficiency. But as far as our concern, implementation of solar PV-TEG based hybrid system in conventional Microgrid has not been studied yet. The novelty of the paper lies in employment of aforementioned technique (SPV-TEG hybrid system) for availing higher active power and lesser reactive power from the traditional Microgrid. Finally, system performance has been studied in this paper for employment of SPV-TEG-based system in non-conventional distribution generation system under zero fault and numerous faulty conditions.

2 System Modeling and Description

The modeling of thermoelectric generator (TEG) and solar PV modules (SPV) has been performed by insertion of corresponding number of modules in parallel and series as per the requirement. After being designed individually, both the systems have been combined in order to perform the study upon the hybrid system. The model is described in individual subsection namely:

-

Modeling of Solar PV array

-

Modeling of TEG

-

Modeling of WES

-

Modeling of DC-DC Converter

-

Modeling of VSC (Voltage Source Converter)

-

Modeling of Control Algorithm

-

Modeling of Filter

-

Modeling of Electrolyzer and its bidirectional converter.

2.1 Modeling of Solar PV Array

Solar irradiation and temperature on the solar PV module surface are solely responsible for the characteristics of SPV array. As the solar irradiance upon the SPV array is increased, the power generated from SPV array is also increased. In order to construct an SPV array, number of SPV modules need to combine in a particular fashion either in series or parallel to obtain the requisite power. The equivalent circuit of the solar cell is shown in Fig. 1 where \(I_{\text{ph}}\) Defines the function as current source, \(R_{\text{sh}}\) defines the internal shunt resistance, \(R_{\text{se}}\) is the series resistance and a diode connected in parallel with the current source [6]. The output current of the solar PV module

where k = Boltzmann’s constant = 1.3805 × \(10^{ - 5}\) J/K, A = ideality factor of the solar PV cell depend on PV manufacturing technology, some of them are presented in Table 1. T = operating temperature of the module, q = 1.6 × \(10^{ - 19}\) C.

2.2 Modeling of Thermoelectric Generator

The working of TEG constitutes of three elementary thermoelectric effects with two accessorial effects. The three elementary effects are named as Seebeck effect, Peltier effect, and Thomson effect while the accessorial effect can be named as: Joule effect and Fourier effect. Seebeck effect is responsible for electromotive force (EMF) and Peltier heat, Thomson heat and Joule heat are caused by the effect of Peltier, Thomson, and Joule, respectively. As a matter of fact Peltier effect is not an interface effect; it produces heat only at the end sides of the semiconductors. Volumetric effects like Thomson and Joule heat production are pretended to be uniformly transferred to the cold and hot junctions of the semiconductor elements [7]. Though Thomson effect is very small it is often neglected in many cases.

For steady-state analysis at cold and hot junction of TEG an energy balance equation is used which can be expressed as follows:

Mathematically’

The electrical current can be expressed as follows:

The short circuit current is the maximum current at a load voltage of zero i.e. \(V_{\text{L}} = 0\). Hence can be written as follows:

Finally, the voltage of TEG can be expressed by using Ohm’s Law, and the corresponding equation obtaining short circuit current and current through TEG, i.e.,

A model of TEM specified by TEPI-12656-0.6 has been used over here to model the hybrid system and the behavioral analysis has been conducted. The parameter specifications of the thermoelectric Module (TEM) have been listed in Table 1. The constraints that have been considered for modeling are presented in Table 2.

2.3 Modeling of Wind Turbine

About 350–400 W power is generated from a permanent magnet based self-regulated variable speed wind turbine at a wind speed of 12 m/s. Stall control or self-control can be achieved by adjustment of wind turbine blades in a particular direction. At a wind speed of 17 m/s, this wind turbine can be able to extract power from the wind.

The aerodynamics of the rotor can be stated as

where \(P_{\text{w}}\) = wind power,

\(C_{\text{p}}\) = power coefficient.

2.4 Modeling of Electrolyzer

A resistor (contact resistance) connected in series with the controlled voltage source (CVS) is considered for modeling of an Electrolyzer. A shepherd’s model has been used for representation of nonlinear voltage which varies with amplitude of current and amplitude of the actual voltage. The CVS can be represented mathematically as:

where E is No Load Voltage, Eo is Constant Electrolyzer Voltage, K is the Polarization Voltage.

Q is the Capacity of Electrolyzer, A is the Exponential Voltage, B is the Exponential Capacity, i is the Current of the Electrolyzer. Bidirectional converter is an integral part of connecting an Electrolyzer with a system. As the name suggests the flow of power is in both the directions. Generally, system integrated with Fuel Cell, Supercapacitors use bidirectional converter for power flow in both directions.

2.5 Modeling of DC-DC Converter

In order to stepping up the voltage at the output of the terminal, dc-dc converter is used which is also termed as boost converter.

It can be stated as

where Vo denotes Output Voltage of the System

Vs denotes Input/Source Voltage of the System

D denotes Duty Cycle (it varies from 0 to 1).

2.6 Modeling of Voltage Source Converter (VSC)

For mitigation of power quality issues, converting dc side voltage into ac voltage for feeding it to the grid; VSC is connected to the system. This can also be acted as an active shunt filter. Natural a-b-c reference frame has been considered for modeling of the VSC. The following equations have been used in order to model the VSC.

Mathematically,

where, Sa, Sb, Sc define Three-phase Switches;

S1, S3, S5 define switching state of switches;

Via, Vib, Vic define voltage output of inverter;

Vdc define DC link voltage.

2.7 Modeling of Control Strategy of VSC

There is a self-uniqueness of this control strategy for operation during healthy as well as faulty conditions. The control strategy thus used is found to be efficient as after the clearance of fault, it brings the system back to the steady-state. No controller will be going to work during fault; hence the control strategy is designed in such a way that as soon as the fault is cleared the system comes back to the initial position as soon as possible. Whatever non-conventional sources are proposed to integrate this strategy holds well every time. A multiplication factor of 0.0045 is considered for phase voltages. The control strategy thus used can be shown in block diagram in Fig. 2.

2.8 Filter Modeling

Though the system uses many power electronics based switches there is the chance of generation of harmonics in the system. In order to lessen the harmonics filter circuits have been implemented. The Synchronous reference frame (SRF) has been used in order to model the filter circuit that can be explained below.

where, Rf denotes Resistance of Filter;

Lf denotes Inductance of Filter;

\(\omega_{e}\) Denotes Angular Frequency;

id, iq denotes d and q-axis inverter currents;

Vid, Viq denotes d and q-axis inverter voltages.

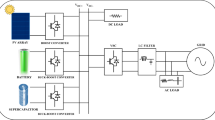

3 Proposed System Configuration

Figure 3 represents the proposed system of employing thermoelectric generator (TEG) in NDG. The newness of this work lies in integrating TEGs with solar PV array so that the power generation from the RE sources could be maximized in a significant manner. As per our knowledge, implementation of TEGs has not yet been considered for Microgrid. Hence the proposed system is compared with conventional NDG to infer the superiority of employing TEGs to NDG.

4 Results and Discussion

The system is subjected to healthy conditions as well as several variations (fault conditions). The reliability of the whole NDG system is studied for several parameters such as active power delivered to the system by the RE sources (P) and Reactive power supplied to the system (Q). The control strategy applied to the system has been studied precisely during variations. Because the main aim of control strategy will be defined best when the fault is cleared means as soon as the fault is cleared the control strategy starts its action in order to retain the system back to the initial condition. Thus the applicability of the proposed system is verified for healthy conditions (during zero faults), and faulty conditions such as Line-to-Ground (L-G) fault (Figs. 4).

4.1 During Healthy Condition (Zero Fault Condition)

The electrolyzer integration plays a vital role in mitigating higher reactive power absorbance and lower active power delivery for the system. The higher active power delivery is due to the presence of an additional DC source i.e. an Electrolyzer that provides power in both directions. It supplies power to the load and grid and charged through grid during off sunshine hours in order to retain the system operation and without interrupting the power supply to the load. The solar PV receives sunlight for electricity generation during these sunshine hours and also charges the Electrolyzer to mitigate the power demand during peak hours as well as off sunshine hours.

4.2 During Line to Ground Fault Condition

The proposed system is studied under fault conditions in order to check the reliability of the controller during disturbances. The system fault is created in virtual scenario. In the above studied single L-G fault active power, reactive power (Fig. 5).

About 1.297 times higher active power has been delivered to the system when the EESS has integrated whereas about 1.281 times lower reactive power has been absorbed without integration of EESS in case of SPV-FCT system, 1.213 times higher active power delivery whereas 1.24 times lower reactive power absorbed in SPV-TEG-FCT system (Fig. 6).

5 Observational Analysis

See Table 3.

6 Conclusion

Thermoelectric Generators (TEG) are integrated with solar PV system in order to process the lost heat by thermoelectric effect. The conversion of light energy into electricity by photoelectric effect and converting heat into electricity by thermoelectric effect combinedly generate a significant amount of power from solar PV array. Also, it can be observed that presence of EESS affects less to the system during disturbances to its compensating nature. The system is less affected in case of EESS integration as during power fluctuations the EESS itself serves as an auxiliary power source at the time of dynamic variation.

References

Jena S, Kar SK (2019) Setting a fostered energy network by decarbonizing the grid: Hybridization, control, and future solutions upon storage. Int J Energy Res 43(1):455–474

Jena S, Kar SK. Demonstrating the benefits of thermoelectric-coupled solar PV system in microgrid challenging conventional integration issues of renewable resources. Int J Energy Res

Jena S, Kar SK (2019) Employment of solar photovoltaic‐thermoelectric generator‐based hybrid system for efficient operation of hybrid nonconventional distribution generator. Int J Energy Res

Jena S, Kar S, Satpathy PR. Encapsulating the challenges of storage in solar PV based microgrid. ISBN:97-3-659-35285-0

Senthilkumar J, Charles Raja S, Srinivasan D, Venkatesh P (2018) Hybrid renewable energy-based distribution system for seasonal load variations. Int J Energy Res 42(3):1066–1087

Wu YY, Wu SY, Xiao L (2015) Performance analysis of photovoltaic–thermoelectric hybrid system with and without glass cover. Energy Convers Manag 93:151–159

Beeri O, Rotem O, Hazan E, Katz EA, Braun A, Gelbstein Y (2015) Hybrid photovoltaic-thermoelectric system for concentrated solar energy conversion: Experimental realization and modeling. J Appl Phys 118(11):115104

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Jena, S., Patro, S., Barik, S.S., Kar, S.K. (2021). Differentiating Storage Essentiality in Thermoelectric and Non-thermoelectric Integrated Conventional Microgrid. In: Mahapatra, S., Shahbaz, M., Vaccaro, A., Emilia Balas, V. (eds) Advances in Energy Technology. Advances in Sustainability Science and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-15-8700-9_9

Download citation

DOI: https://doi.org/10.1007/978-981-15-8700-9_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-8699-6

Online ISBN: 978-981-15-8700-9

eBook Packages: EnergyEnergy (R0)