Abstract

Ceria nanoparticle synthesizes by nanotechnology by using cerium chloride and sulfuric acid by the precipitations method which is evaluated as an adsorbent for the evacuation of Cr(VI) detachment from wastewater. Experimentation was done using the simple batch process where all the experiments were conducted to verify the efficiency of the nanoparticle for the removal of Cr(VI). Adsorption achieved balance inside at some point and was autonomous of starting chromium (VI) focus. The hybrid material was found to have maximum efficiency for the removal of hexavalent chromium with 94–95.6%, pH at 7, adsorbent dose of 0.1 mg and temperature of 28 ± 2 °C and initial concentration of 50 ppm. The mathematical modeling has done for the experimental data. The experimental data clearly fitted the Langmuir isotherm and Freundlich adsorption isotherm; the adsorption information was examined; and the adsorption instrument was explored utilizing X-beam diffraction by SEM.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Water contamination is turning into the most significant issue that imperils and impacts on all living being and getting to be intense consistently. The impact of water contamination has consequences for the delicate equalization of nature. Overwhelming metals like mercury, chromium, nickel, lead, cadmium, copper are present in the debased water, and they present at low fixation in well equalization water. Anyway, these are available at high focus in terms of tainted water. Among these overwhelming metals, chromium hexavalent is viewed as a need. Cr(VI) turn out in the effluent of tanning, dye, fertilizer, electroplating, material assembling, jewels water, steel generation processing plants, and so on. The chromium hexavalent levels released might run from ten to several mg/l which are the most significant anthropogenic wellspring of chromium (VI) [1, 2]. Chromium is a heavy metal that is generally found in the environment. Natural chromium has three stable isotopes, namely 52Cr, 53Cr and 54Cr. It happens for the most part in the chromium (III) from as chromite mineral, which contains oxygen, chromium (III) and different metals. Chromium occurs in environments as trivalent chromium structure. Hexavalent chromium is exceptionally lethal to vegetation. The system of danger is pH subordinate. It is just because of human exercises that significant measures of hexavalent chromium become present. Trivalent chromium mixes are not exceptionally harmful and are a fundamental supplement that encourages the body to utilize sugar, protein, fat and so on, and deficiencies may cause heart issues, interruptions of digestion systems and diabetes [3]. However, the take-up of an excessive amount of trivalent chromium can cause well-being impacts also, for example skin rashes. Hexavalent chromium mixes are partitioned up in water risk class 3 and are viewed as harmful. The unnecessary presentation to tidies or fogs of Cr(VI) mixes produces dermatitis, ulceration and puncturing of the nasal septum, just as liver and kidney harm. With long haul introduction to Cr(VI) mixes, human lung malignant growth increases.

Nanotechnology is getting created in a few dimensions: materials, gadgets and frameworks. The nanomaterials level is the most progressive at present, both in logical information and in commercial applications. Nanoparticles are not exactly a couple of 100 nm. This decrease in size achieves huge changes in their physical properties as for those saw in mass materials. They can be metallic, mineral, polymer-based or a blend of materials. A large portion of these progressions are identified with the presence of quantum impacts as the size reductions and are the birthplace of marvels, for example the super paramagnetism, Coulomb barricade, surface plasmon reverberation and so on. The expansion in the surface region to volume proportion is likewise a result of the decrease in size. It prompts the presence of surface impacts identified with the high number of surface iota’s, just as to a high explicit territory, which is significant from the down to earth perspective.

2 Materials and Methods

Ceria synthesize using cerium chloride and sulfuric acid by the precipitations method [4]. Chemical and compounds utilized in this examination was of expository review and secured from E-Merck India Ltd and Aldrich are listed cerium chloride (CeCl2), sulphuric acid (H2SO4), Potassium di-chromate (K2Cr2O7), Nitric acid (HNO3), Ammonium hydroxide (NH4OH). 1:1 ratio was prepared for the synthesis of Ceria with a solution of various cerium chloride and sulfuric acid. 2 M cerium chloride solution is stirred with 300 rpm with 2 gm of ammonium bicarbonate in which dropwise 3 M sulfuric acid is added with pH adjusted by the base. The precipitate was kept for 24 h and washed with distilled water and dried at 50 °C for 3–4 h in the oven. The standard chromium (VI) solution of 10–100 ppm was treated with 0.02–0.1 gm ceria nanopowder. Adsorption experiments were done for different parameters contact time, the concentration of adsorbate and pH. The evolution of 220 UV-Visible spectrophotometers is used for the analysis of a sample at a wavelength of 540 nm. Evacuation of Cr(VI) from wastewater and uptake capacity was found as follows

where C0 = initial concentration of Cr(VI), \( C_{t} \) = concentration of Cr(VI) at time t, \( V \) = volume of solution, M = mass of adsorbent.

2.1 SEM Micrographs of Ceria Nanopowder

The surface morphology of the material studied by SEM is shown in (Fig. 1). The SEM is made for understanding the surface morphology from figure that the material is having identifiable pores. It is done at 10.00 kV and at 50,000 magnification. This mainly shows the pores structures where adsorption of ceria nanopowder can take place.

3 Result and Discussion

3.1 Effect of Contact Times

Batch investigation of Cr(VI) at various time intervals is considered for beginning chromium (VI) centralization of 10–100 mg/L at pH 7 and the adsorbent portion of 0.1 mg, keeping every single other parameter consistent. The outcome is spoken to in (Fig. 2). It is comprehended from (Fig. 3) that more than 95.5% evacuation happens in 120 min. The modification in the rate of expulsion may be because of the way that at first all adsorbent locales are idle, and in addition, the solute, center of attention inclination is soaring. Chromium (VI) uptake capacity rate by adsorbent is diminished provocatively, because of the reduction in the quantity of empty adsorption locales present in the nanomaterial which is decreases in the adsorption.

3.2 Effect of Adsorbent Weight

The impact of the adsorbent portion on the evacuation of chromium (VI) and uptake capacity is examined under the constant parameter (pH 7), at encompassing temperature (28 ± 2 °C) and contact time of 120 min for Cr (VI) centralization of 10–100 ppm. The outcomes are shown in Figs. 4 and 5. The expulsion of Cr(VI) is high at the 0.1 mg adsorbent dose of 95.5% at 50 ppm but the uptake capacity is decreases as adsorbent dose is increases. It is seen that after measurement of 0.07 mg/100 mL, there is stable change in the level of the evacuation of Cr(VI). It might be because of the covering of dynamic locales at higher measurements and the combination of the reciprocity. Along these lines, 0.1 mg/100 mL for 50 ppm is viewed as ideal portion and is utilized for more examination.

3.3 Adsorption Isotherms

3.3.1 Langmuir Adsorption Isotherm Model

Langmuir model points toward the character stability of adsorbate distribution on the adsorbent shell. During this research, we tried to investigate the obtained results using the Langmuir model. Langmuir model shows the good fit for the data found from the calculation. Langmuir isotherm model gives best fit than that of other. The following equation represents the Langmuir adsorption model.

where

- qe:

-

Equilibrium adsorbed at the time (mg/g),

- Ce:

-

Equilibrium concentration (mg/L),

- qm:

-

Maximum adsorption capacity in (mg/g),

- Ka:

-

Langmuir isotherm constant in (L/mg).

This is the Langmuir adsorption model for a 0.1 mg adsorbent dose of ceria nanopowder. At 5 to 50 ppm of chromium (VI) stock solution concentration at contact time of 120 min (Table 1).

3.3.2 Freundlich Adsorption Isotherm Model

Many faceted adsorptions are shown in the Freundlich model for heterogeneous adsorption surfaces. With this model, it is assumed that the adsorbate is incessantly maintained obligatory to the adsorbent and obligatory energy required for adsorption varies exponentially distributed. This model can be represented by the below equations (Fig. 6, and Tables 2 and 3).

where

- qe:

-

Equilibrium adsorbate at time (mg/g),

- Ce:

-

Equilibrium concentration of adsorbate (mg/L),

- kf:

-

Capacity of the adsorbent (mg/g)

- n:

-

Adsorption constant (L/mg).

4 Conclusion

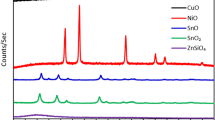

Ceria is the impending adsorbent for the execution of Cr(VI) from aqueous systems for the purification of the wastewater. This nanopowder is allowed the traditional adsorption methods to eliminate the water contents. The ceria nanopowder is found to be partially amorphous in nature as marked in the XRD data. The adsorption model Langmuir isotherm gives the adsorbate molecular distribution on the adsorbent shell, and Freundlich isotherm model reflects the multilayer adsorption and applicable for heterogeneous adsorption surfaces. The adsorption data fitted best in the Langmuir isotherm than that of the Freundlich isotherm model. The execution efficiency of the Cr(VI) is optimized by varying the parameters. It is seen that ceria is appropriate material for evacuation of Cr(VI) from wastewater.

References

Ramasubramaniam S, Govindarajan C, Gomathi T, Sudha PN Removal of chromium (VI) from aqueous solution using chitosan-starch blend. Scholar Res Library ISSN 0975–5071

Gallios GP, Vaclavikova M (2008) Removal of chromium (VI) from water streams: a thermodynamic study. Environ Chem Lett. https://doi.org/10.1007/s10311-007-0128-8

National Research Council (U.S.) (1974) Committee on biologic effects of atmospheric pollutants Chromium. Natl Acad Sci 155. ISBN 978-0-309-02217-0

Li R, Li Q, Gao S, Shang JK (2012) Exceptional arsenic adsorption performance of hydrous cerium oxide nanoparticles: part A. Adsorption capacity and mechanism. Chem Eng J 185–186:127–135

Acknowledgements

Financial support from DST (SERB)-New Delhi under empowerment equality opportunities for excellence in science (Project Sanction file number SB/EMEQ-373/2014) is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Deore, H., Sardare, M., Nemade, P. (2021). Experimental Modeling and Evacuation of Cr(VI) from Wastewater by Using Nanostructured Ceria. In: Gupta, L.M., Ray, M.R., Labhasetwar, P.K. (eds) Advances in Civil Engineering and Infrastructural Development. Lecture Notes in Civil Engineering, vol 87. Springer, Singapore. https://doi.org/10.1007/978-981-15-6463-5_39

Download citation

DOI: https://doi.org/10.1007/978-981-15-6463-5_39

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6462-8

Online ISBN: 978-981-15-6463-5

eBook Packages: EngineeringEngineering (R0)