Abstract

The aim of this study was to develop Cellulose Nano Crystal (CNC)-based sustainable biocomposite film. CNC was extracted from medical absorbent cotton using alkali and acid hydrolysis. The composite films were produced by reinforcing CNC in PVA/Chitosan polymer using solvent casting method. Films were characterized by XRD, contact angle, hemocompatibility, protein adsorption. CNC dispersed in PVA/Chitosan affects the surface properties and it enhanced the hydrophilicity of the composite film. The percentage of hemolysis of both composites was less than 5% which confirmed it as hemocompatible material. The percentage of protein adsorption of CNC-based composite was 39% higher compared to control. This result suggests that CNC is a good reinforcing material for biopolymer composite preparation.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Transdermal drug delivery is a potential means to deliver active ingredients into the circulatory system through skin into blood because it is safe, effective, and comfort to patients (Shankar et al. 2018). Transdermal patches deliver drugs at a preset controlled rate to systemic circulation when applied to intact skin. It provides sustained and controlled delivery of molecules to body. Generally high dosage drug is administered into the patch and as the concentration of drug is higher in patch compared to blood, the drug will come into blood through diffusion process through skin for a long period that maintains constant drug concentration into blood (Ravichandiran and Manivannan 2015). There are several biopolymers like gelatin, silk, starch, polyvinyl, alcohol, chitosan which are used to prepare transdermal wound healing patches (Khamrai et al. 2017).

Cellulose is one of the most profuse biopolymer, which is commonly used as reinforcing elements for fabrication of composite biopolymer (Noshirvani et al. 2018). Cellulose is a polymer having glucose monomer, linked by β (1, 5) glycosidic bonds. Cellulose nanocrystal (CNC) is a promising biomaterials exhibiting many advantages like biocompatibility, mechanical properties, high water absorption capacity, low cost, renewability, etc., (Bajpai et al. 2017) and therefore it is attractive to use in bionanocomposites. CNCs has been used to prepare different types of biocomposites using polypropylene, polyvinyl alcohol, polyurethane, etc. Noshirvani et al. (2018) prepared CNC loaded starch/PVA nanocomposite film using solvent casting method for biodegradable packaging application. Bajpai et al. (2017) developed CNC-based chitosan films along with curcumin and silver nano particles for wound dressing application. They observed good results in terms of wound reduction in rat model. Wang et al. (2018) prepared antioxidant films using chitosan and epigallocatechin-3-gallate with bacterial cellulose as reinforcement element. They observed bacterial cellulose improved tensile strength and reduced water solubility and it offered sustained release of drugs for long time. CNC and metallic nano particle-based composite nanomaterials showed good antibacterial properties against pathogenic bacteria (Perumal et al. 2018). Generally acid hydrolysis method is used for preparation of CNC (Singh et al. 2017). CNCs are available in different morphology depending on the source and method of extraction (George and Sabapathi 2015). Thambiraj and Shankaran (2017) extracted CNC from cotton with needle-shaped morphological structure. They did a preliminary experiments on fabrication of CNC-based film using cotton-based CNC. It is evident that there is no dearth of literature on extraction of CNC from cotton using hydrochloric acid, composite preparation, and its detailed characterization.

The aim of this study was to develop CNC-reinforced wound dressing film using chitosan and polyvinyl alcohol. For this, CNC was isolated from medical absorbent cotton using hydrochloric acid hydrolysis. The efficiency of CNC-loaded film was compared with control (film without CNC). The water absorption, swelling properties, contact angles and protein adsorption studies were performed for both film with and without CNC.

2 Materials and Method

2.1 Materials

The chemicals used for preparation of CNC and CNC composite films and for their characterization are given in Table 1

2.2 Preparation of Film

Cellulose nanocrystals were extracted from medical absorbent cotton using alkali and acid hydrolysis as described in literature (Thambiraj and Shankaran 2017; Abu-Danso et al. 2017). Briefly, cotton was carefully cleaned using distilled water and ethanol to eliminate any type of unwanted residues. After that, it was treated with 2% NaOH and acid hydrolysis was performed using hydrochloric acid. After that, CNC was centrifuged and washed with distilled water. Finally, it was dried at 60 °C for 12 h and the dried powder was used for film preparation.

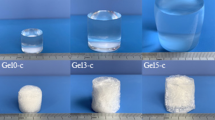

For the preparation of film solvent casting method was used. For this, 10 w/v% PVA solution was prepared using distilled water at 70 ℃. 1 w/v% chitosan solution was prepared in distilled water containing acetic acid (1 v/v%) at 40 ℃. After cooling, both solutions were mixed at the ratio of 70:30 in constant stirring followed by ultrasonication for one hour. For CNC loaded film, 3 wt% CNC powder according to dry weight of PVA and chitosan was added before ultrasonication. Both solutions were poured in glass Petri dish followed by drying at 40 ℃ for 12 h. PVA/Chitosan film was coded as film 1 and CNC/PVA/Chitosan composite was coded as film 2. The optical micrograph of as-prepared film is shown in Fig. 1. The color of both films was white and transparent.

2.3 Characterization

Thickness. Thickness of composite films were measured using a micrometer screw gauge to nearest 0.01 mm. Thickness was measured at three random places of composite films and it was observed that thickness of films were same in each point of measurement. There was no difference between film 1 and film 2 and the thickness of each film was 1 mm.

X-Ray Diffraction (XRD). XRD of dried specimens was performed by X-ray diffractometry (XRD; Brukerdiffractometer, D8 advance, Japan) using Cu radiation with wavelength λ = 0.154 nm. The XRD scan was performed in range of 2θ angle of 0–80° and scan speed of 1° per min.

Porosity. Porosity of the CNC films was determined by means of the liquid displacement method. The films were dipped in ethanol (99.9%) for 5–10mins and the wet weight was taken. The percentage of porosity was determined as,

where, WD and Ww are dry weight and wet weight of films, ρ = 0.789 g/cm3 (density of ethanol) and V is volume of films.

Contact Angle. Contact angle was determined by conventional sessile drop technique (phoenix 300 instrument). Distilled water was dropped on the surface of the film and photo of drop and the film was captured by CCD camera.

Protein Adsorption Studies. For protein adsorption studies, specimens of equal weight were immersed in ethanol (99.9%) for one hour and then washed thrice with PBS (pH 7.4) for 30 min. After that, the films were placed in glass test tube containing 2 ml of bovine serum albumin (BSA) (BSA conc. 1 mg/ml) for one hour. After one hour, the films were taken out and the solution was tested for unadsorbed proteins left in it. Proteins present in the solutions were estimated by folin-lowry method using BSA as standard. Absorbance (660 nm) was measured in UV-V is spectrophotometer (Shimazdu, Japan).

Hemolysis Study. In vitro hemocompatibility test was conducted by hemolysis assays described in literature (Samanta and Chanda (2018)). Briefly, human blood was diluted in normal saline in 4:5 ratio. 2–3 g of films were taken in glass test tubes containing 10 ml saline and incubated at 37 ℃ for 30 min. After that, 0.2 ml diluted blood was mixed in both test tubes and again it was incubated for additional 60 min. Positive control and negative control were prepared by adding 0.2 ml diluted blood in 0.1% sodium bicarbonate (10 ml) and normal saline (10 ml), respectively. Both positive and negative controls were incubated at 37 ℃ for 60 min.

After that, centrifugation (500 g) was carried for all test tubes for 5minutes, the supernatant was cautiously collected, and optical density was determined using spectrophotometer (Sl 177, ELICO, India) at 545 nm. The hemolysis (%) was determined using the following formula:

2.4 Statistical Analysis

All data were presented as mean ± standard deviation (SD). All specimens were in triplicate (n = 3), unless stated otherwise. One way analysis of variance (ANOVA) with a Tukey's post hoc test was carried out by using ORIGIN software. Significant differences were considered as: (p < 0.001; **p < 0.01; *p < 0.05).

3 Results and Discussion

Thickness. The biocomposite films were prepared by using PVA/chitosan and PVA/Chitosan/CNC were uniform without any bubbles. The thickness of both samples measured as 1 mm. Thickness measurement is important because the physical properties of films depend on thickness of the film. There are no significant differences between two films.

Porosity. The porosity of film 1 was calculated as 25.34 ± 17% and it was observed that after addition of CNC the porosity was reduced (17 ± 7.3%). The reduction of porosity of film 2 results in increase in apparent density. The density is beneficial for the mechanical property of scaffold. An optimum porosity is necessary for cell attachments and the movement of nutrients and it ultimately increases the implant’s bioactivity. For controlled release of drugs from scaffold, the porosity should be optimum without adversely affecting the structural or mechanical behavior of scaffold (Rambhia and Ma 2015). The release of drugs is generally occurs through diffusion process and after implantation scaffold exhibits strong burst release. Therefore, it is important to reduce initial burst release of drugs and maintain sustained release for longer period.

Contact angle. Contact angle test is generally performed to determine the surface hydrophilicity of any biomaterial. Contact angle depends on the hydrophilic group, which is exposed on the surface of the material. The data of water contact angle of film 1 was 65.23° ± 0.54°. When CNC was added in PVA-chitosan-based films, it showed reduction in contact angle (54.53° ± 1.41°). The increase in hydrophilicity of CNC-based films may affect the cell adhesion, cell proliferation (Fig. 2).

XRD study. The XRD spectra of both films are presented in Fig. 3. PVA displayed a semi-crystalline structure for hydrogen bond between the OH− groups of the PVA chains. Both films exhibited peak at 2θ angle of 20° for superimposed peak of chitosan and PVA (Amaral et al. 2013). Film 2 exhibited peak at 2θ angle of 22.74° for cellulose nanocrystal.

Hemocompatibility study. Toxic materials can destroy erythrocytes and release hemoglobin. Hemocompatibility is considered one of key concerns in tissue engineering, particularly for scaffolds that will come into direct contact with blood. The percentage of hemolysis is important feature in assessment of biocompatibility of materials (Liu et al. 2014). The percentage of hemolysis of film 1 was 2.8 ± 0.49% and for film 2 it was 3.66 ± 0.19%. As both samples showed hemolysis less than 5%, therefore both films were highly hemocompatible according to the ASTM F756 standard (Samanta and Chanda 2018). The data suggested that CNC-based composite meets the requirement for medical biomaterials.

Protein adsorption study. Protein adsorption is significant in controlling cell reaction to biomaterials (Saravanan et al. 2017). Biomaterials adsorb proteins on their surface to anchor osteoblast cells via integrins (Shankar et al. 2018). Initial protein adsorption is important because it determines the success of any biomaterials (Shankar et al. 2018). When a material is exposed to cell, proteins spontaneously adsorb on the surface of the materials. The adsorption of protein is mainly dependent on the surface chemistry, surface wettability, surface morphology, etc. (Le et al. 2013). In our study, we studied protein adsorptionability for one hour. It was observed that protein adsorption was higher in film 2 compared to the control (Figure 4). Inclusion of CNC in PVA/Chitosan film enhanced protein adsorption by 38%. As we found in contact angle analysis, film 2 showed more hydrophilicity and it can be related to enhanced protein adsorption rate.

4 Conclusion

CNC was prepared from medical absorbent cotton in order to reinforce the PVA/Chitosan matrix with content 3 wt% by casting method. Films were uniform with no bubbles and the porosity of CNC composite film was reduced compared to PVA/chitosan matrix. Also, the hydrophilicity, hemocompatibility, and protein adsorptionability were enhanced due to CNC reinforcement. The improved proterties of CNC composite was mainly due to the inter-molecular hydrogen bonding interaction between CNC and polymer matrix.

References

Abu-Danso E, Srivastava V, Sillanpää M, Bhatnagar A (2017) Pretreatment assisted synthesis and characterization of cellulose nanocrystals and cellulose nanofibers from absorbent cotton. Int J Biol Macromol 102:248–257

Amaral IF, Sousa SR, Neiva I, Marcos-Silva L, Kirkpatrick CJ, Barbosa MA, Pêgo AP (2013) Kinetics and isotherm of fibronectin adsorption to three-dimensional porous chitosan scaffolds explored by 125I-radiolabelling. Biomatter 3(2):e24791

Bajpai SK, Ahuja S, Chand N, Bajpai M (2017) Nano cellulose dispersed chitosan film with Ag NPs/Curcumin: An in vivo study on Albino Rats for wound dressing. Int J Biol Macromol 104:1012–1019

George J, Sabapathi SN (2015) Cellulose nanocrystals: synthesis, functional properties, and applications. Nanotechnol Sci Appl 8:45

Khamrai M, Banerjee SL, Kundu PP (2017) Modified bacterial cellulose based self-healable polyeloctrolyte film for wound dressing application. Carbohyd Polym 174:580–590

Le X, Poinern GEJ, Ali N, Berry CM, Fawcett D (2013) Engineering a biocompatible scaffold with either micrometre or nanometre scale surface topography for promoting protein adsorption and cellular response. Int J Biomater

Liu Y, Cai D, Yang J, Wang Y, Zhang X, Yin S (2014) In vitro hemocompatibility evaluation of poly (4-hydroxybutyrate) scaffold. Int J Clin Exp Med 7(5):1233

Noshirvani N, Hong W, Ghanbarzadeh B, Fasihi H, Montazami R (2018) Study of cellulose nanocrystal doped starch-polyvinyl alcohol bionanocomposite films. Int J Biol Macromol 107:205–2074

Perumal AB, Sellamuthu PS, Nambiar RB, Sadiku ER (2018) Development of polyvinyl alcohol/chitosan bio-nanocomposite films reinforced with cellulose nanocrystals isolated from rice straw. Appl Surf Sci 449:591–602

Rambhia KJ, Ma PX (2015) Controlled drug release for tissue engineering. J Control Release 219:119–128

Ravichandiran V, Manivannan S (2015) Wound healing potential of transdermal patches containing bioactive fraction from the bark of Ficusracemose. Int J Pharm PharmSci 7(6):326–332

Samanta SK, Chanda A (2018) Study on the structure and properties of crystalline pure and Doped β-tri calcium phosphate ceramics. Mater Today: Proc 5(1):2330–2338

Saravanan S, Chawla A, Vairamani M, Sastry TP, Subramanian KS, Selvamurugan N (2017) Scaffolds containing chitosan, gelatin and graphene oxide for bone tissue regeneration in vitro and in vivo. Int J Biol Macromol 104:1975–1985

Shankar S, Oun AA, Rhim JW (2018) Preparation of antimicrobial hybrid nano-materials using regenerated cellulose and metallic nanoparticles. Int J Biol Macromol 107:17–27

Singh S, Gaikwad KK, Park SI, Lee YS (2017) Microwave-assisted step reduced extraction of seaweed (Gelidiellaaceroso) cellulose nanocrystals. Int J Biol Macromol 99:506–510

Thambiraj S, Shankaran DR (2017) Preparation and physicochemical characterization of cellulose nanocrystals from industrial waste cotton. Appl Surf Sci 412:405–416

Wang X, Xie Y, Ge H, Chen L, Wang J, Zhang S, Feng X (2018) Physical properties and antioxidant capacity of chitosan/epigallocatechin-3-gallate films reinforced with nano-bacterial cellulose. Carbohyd Polym 179:207–220

Acknowledgments

The authors sincerely acknowledge the help and facilities provided by the Department of Biomedical Engineering, Department of Biotechnology, Department of chemical Engineering, Department of Physics, and Department of Metallurgy, NIT Raipur, India for conducting this research work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sen, S., Agrawal, R., Begam, H. (2021). Preparation and Characterization of Cellulose Nano Crystal/PVA/Chitosan Composite Film for Wound Healing Application. In: Rizvanov, A.A., Singh, B.K., Ganasala, P. (eds) Advances in Biomedical Engineering and Technology. Lecture Notes in Bioengineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-6329-4_25

Download citation

DOI: https://doi.org/10.1007/978-981-15-6329-4_25

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6328-7

Online ISBN: 978-981-15-6329-4

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)