Abstract

Coal gangue, a residue obtained during the coal mining process, accounts for 10–15% of raw coal produced. Usually, this coal gangue is transported and stacked loosely in the nearby areas. Long term piling up of this mine waste can volatilize large amounts of potentially toxic heavy metals which have the ability to infiltrate surrounding ecosystems. In the present study, coal gangue from an open cast mining area in Bhupalpally in Telangana state, India, has been analyzed for its physical and chemical characteristics. Further, column leaching test was performed to evaluate the leachability of selected heavy metal ions simulating field conditions using deionized double distilled water. The column tests proved that the selected heavy metal ions from coal gangue can be easily mobilized.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Mining of coal is often associated by generation of huge volumes of natural rock masses, popularly known as ‘Coal gangue’ which usually accompany the carboniferous beds. Coal gangue is characterized by great diversity in grain size and petrographic composition and amounts to more than 20% of the total solid waste generated during the mining (Keefer and Sajwan 1993; Plewa and Mysłek 2001; Malhotra and Mehta 2002; Asokan et al. 2005). Among the various solid wastes generated by different industries, it is identified as the largest with relatively higher impact on the environment (Wu et al. 2017).

Among the Coal Combustion Residues, a lot of study has been focused on coal and fly ash. Coal ash has been successfully utilized for many years in various applications (Yao et al. 2015) and fly ash has been used as fill material, liner material for waste containment, to stabilize toxic and heavy metal diced soils, as subbase material, as soil additives to increase crop productivity (Moghal and Sivapullaiah 2011, 2012, 2013; Moghal 2017). But, relatively lesser attention has been given to coal gangue.

The current avenues of coal gangue utilization include re-combustion for power generation, in the production of fertilizers, bricks, concrete, and cement (Wu et al. 2017). Though the rate of coal gangue has spiked in the recent times, its huge volume of generation with relatively higher rate of generation necessitates the identification of alternative utilization approach (Ashfaq et al. 2019). Previous researchers have established the application of coal gangue in retrospective backfilling of abandoned mine sites as a sustainable solution to reduce the problem of subsidence and disposal of solid waste. Wu et al. (2017) and Jabłonska et al. (2017) have identified the potential of coal gangue as an adsorbent and landfill liner material. However, new applications of coal gangue are still sought. In this context, in the present study, physical and chemical analyses of coal gangue and presence of heavy metal have been evaluated. Also, column leaching test on coal gangue has been performed to assess the leaching potential of selected heavy metals from coal gangue.

2 Materials and Methodology

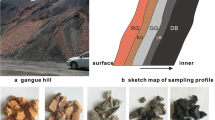

Coal gangue has been procured from Kakatiya Coal mines, Bhupalpally, Telangana. Post procurement, to avoid possible alteration in the chemical and physical properties, the samples were sealed in a zip pouches. Air-dried samples were grounded using jaw crusher and subsequently were allowed to pass through 1 mm mesh sieve to maintain consistency and uniformity of the tested samples.

Acid digestion technique was used to evaluate the initial concentrations of selected trace metal concentration. A liquid-to-solid ratio of 20 was maintained during the leaching tests performed in the column apparatus. The physical properties studied include natural moisture content, specific gravity, pH, total dissolved solids (TDS) and electrical conductivity (TDS). All the tests were performed in accordance with their respective ASTM codes.

3 Results and Discussion

3.1 Physical Properties

Moisture Content

The natural moisture content of coal gangue calculated after oven drying the sample was in the range of 2–5%. This variation in value might be due to the heterogeneity of coal gangue.

Specific Gravity (Gs)

The average specific gravity value of coal gangue was found to be 2.50. The lower value of specific gravity may be due to varying iron content and presence of entrapped air. This lower ‘Gs’ leads to lower unit weight and thus coal gangue finds application as a backfill material.

Grain Size Distribution

The crushed portion of coal gangue was uniformly mixed to make a representative sample of 1 kg for performing sieve analysis test. The particle size distribution curve of the samples used in the study is presented in Fig. 1. Based on the Unified Classification system (USC), the coal gangue samples are comparable to silty sands (SM).

3.2 Chemical Properties

pH

The pH was determined at varying liquid-to-solid ratios (4–100) and is presented in Fig. 2. Prior to test, the pH meter was calibrated using three different buffer solutions with pH of 4, 7 and 9.2. From the results, it is evident that the natural coal gangue has a neutral pH of about 7. With the increase in L/S ratio, coal gangue exhibited acidic pH with proportionate increase in acidity with the liquid content. The linear increase in acidity with the L/S ratio can be attributed to the attack of H+ ions on the mineral phases of the coal gangue.

EC and TDS

The instrument used for measuring pH was used for measuring EC and TDS. From results presented in Fig. 3, it was observed that EC and TDS exhibited an identical behavior with the change in L/S ratio. It was noted that with the increasing L/S ratio, both EC and TDS linearly decreased. Similar to the observations made for pH, the highest fall in EC and TDS was noted at L/S ratio of 20. The sudden fall can be related to the abrupt decrease in the pH of the leachate. Due to lack of EC and TDS data for the coal gangue from other regions in India, validation of the obtained results could not be done.

3.3 Leaching Behavior of Heavy Metals

The leached concentrations of selected heavy metals at liquid-to-solid ratio of 20 are presented in Table 1. The concentration of leachate is compared with US EPA regulatory to evaluate the level of toxicity of the selected heavy metals. From the results presented in Table 1, it is evident that except Cadmium (Cd), all other selected heavy metals were found to be more than regulatory limits prescribed by US EPA.

Further it can be observed that heavy metals have the potential to mobilize from coal gangue, subsequently contaminating surrounding surface and ground-water bodies. The observations made are in consistency with previous studies by Cao et al. (2016) and Wang et al. (2016).

4 Conclusions

In the present study, the physical and chemical characteristics of coal gangue were examined. Also, the leaching behavior of heavy metals from coal gangue was studied under column leaching experiments. The following conclusions were drawn from the study.

-

The moisture content and specific gravity of coal gangue were found to be lesser than general value of soils and other combustion residues.

-

Gradation distribution curve of coal gangue is analogous to that of silty sand.

-

Both electrical conductivity values and total dissolved solids content decreased consistently with increase in L/S ratio.

-

pH of coal gangue leachate extracted relying on double distilled water reduces with increase in L/S ratio.

-

Barring cadmium (Cd), all other elements showed higher mobilization levels from coal gangue when deionised distilled water was used as extractant.

References

Ashfaq M, Heeralal M, Moghal AAB, Murthy VR (2019) Carbon footprint analysis of coal gangue in geotechnical engineering applications. Indian Geotech J. https://doi.org/10.1007/s40098-019-00389-z

Asokan P, Saxena M, Asolekar SR (2005) Coal combustion residue environmental implications and recycling potentials. Resour Conserv Recycl 43(3):239–262

Cao Z, Cao Y, Dong H, Zhang J, Sun C (2016) Effect of calcination condition on the microstructure and pozzolanic activity of calcined coal gangue. Int J Miner Process 146:23–28

Jabłonska B, Kityk AV, Busch M, Huber P (2017) The structural and surface properties of natural and modified coal gangue. J Environ Manage 190:80–90

Keefer RF, Sajwan K (1993) Trace element in coal and coal combustion residues. Advances in trace substances. Research. Lewis Publishers, CRC Press, Florida

Malhotra VM, Mehta PK (2002) High-performance high-volume fly ash concrete. Marquardt Printing Ltd., Ottawa

Moghal AAB (2017) A state-of-the-art review on the role of fly ashes in geotechnical and geoenvironmental applications. J Mater Civ Eng 29(8):11

Moghal AAB, Sivapullaiah PV (2011) Effect of pozzolanic reactivity on compressibility characteristics of stabilised low lime fly ashes. Geotech Geol Eng 29(5):665–673

Moghal AAB, Sivapullaiah PV (2012) Retention characteristics of Cu2+, Pb2+ and Zn2+ from aqueous solutions by two types of low lime fly ashes. Toxicol Environ Chem 94(10):1941–1953

Moghal AAB, Sivapullaiah PV (2013) Role of lime leachability on the geotechnical behaviour of fly ashes. Int J Geotech Eng 6(1):43–51

Plewa F, Mysłek Z (2001) Industrial waste management in underground mining technologies

Wang JM, Qin Q, Hu SJ, Wu KN (2016) A concrete material with waste coal gangue and fly ash used for farmland drainage in high groundwater level areas. J Cleaner Prod 112(1):631–638

Wu H, Wen Q, Hu L, Gong M, Tang Z (2017) Feasibility study on the application of coal gangue as landfill liner material. Waste Manage 63:161–171

Yao ZT, Ji XS, Sarker PK, Tang JH, Ge LQ, Xia MS, Xi YQ (2015) A comprehensive review on the applications of coal fly ash. Earth Sci Rev 141:105–121

Acknowledgements

The authors are indebted to Singareni Collieries Company limited authorities for help rendered by permitting the procurement of coal gangue from Kakatiya coal mines, Bhupalpally.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ashfaq, M., Heera Lal, M., Moghal, A.A.B. (2021). Characterization of Heavy Metals from Coal Gangue. In: Latha Gali, M., Raghuveer Rao, P. (eds) Problematic Soils and Geoenvironmental Concerns. Lecture Notes in Civil Engineering, vol 88. Springer, Singapore. https://doi.org/10.1007/978-981-15-6237-2_8

Download citation

DOI: https://doi.org/10.1007/978-981-15-6237-2_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6236-5

Online ISBN: 978-981-15-6237-2

eBook Packages: EngineeringEngineering (R0)