Abstract

Being a challenge to deal with structural foundations in soft clays, several techniques were promulgated across the world. This paper presents the load–settlement behaviour of soft clay provided with soil-cement columns in test tanks. Based on the experimental work performed on 10% cement mixed single clay column resting on hard stratum simulating end bearing condition, it is revealed that load-carrying capacity of clay bed increased by 3–4 times that of virgin clay. Also, the load-carrying capacity of clay bed increased 5–7 times that of virgin clay with the group of three columns arranged in triangular pattern with centre to centre spacing of two times the diameter of column. Group capacity of soil-cement column is 1.5–2 times of single column which is not multiplicative of single column. UCC tests were carried to find out the optimum fibre content by varying the fibre content from 0 to 3%. From UCC test, it is observed that 2% fibre content is suitable for the present study considering the strength improvement and ease of mixing. It is observed from the tests that with the addition of 2% fibre in soil-cement column, load-carrying capacity of clay bed increased by 5.5–7.5 times when tested with group of columns. There is 10–20% increase in ultimate load-carrying capacity of soil-cement column after addition of fibre and the mode of failure of columns changed from brittle to bulging failure.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The soft clay deposits spread along the shore lines of many world nations are characterized by high compressibility and low shear strength. This coupled weakness of these deposits pose a challenge to the geotechnical engineers while designing suitable foundation system to support the infrastructure. Several foundation systems were developed to support the structural loads. Most of these systems come partly underground improvement which subsequently supports the loads. Despite several advancements made on various aspects of improvement or supporting systems in these soft clay beds, there still exist several unknowns with respect to load transfer mechanisms and settlements. In the recent times, deep mixing using lime or cement has been widely used to improve these beds within short time periods (Faro et al. 2015). In this process, the cemented soil columns are surrounded by soft clay and understanding the overall improvement requires a great deal of experimental work (Yao et al. 2016). In the present work, an attempt is made to study the addition of fibre reinforcement along with cement on the load-carrying capacity of the improved system. This system is beneficial when the deep mixed columns are extended up to the stiffer stratum, whereby higher load-carrying capacity of deep mixed columns with fibre reinforcement can be utilized (Consoli et al. 2003; Xiao et al. 2013, 2015; Farouk and Shahien 2013). For this, the experimental studies are carried out in the test tanks with end bearing columns.

2 Experimental Study

2.1 Materials Used

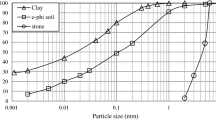

Soil: the locally available soil is used to make soft clay. The properties of soil are: G = 2.71, gravel = 1%; sand = 30%; silt = 30%; clay = 39%; liquid limit = 63%; plastic limit = 20%; plasticity index = 43% and IS classification = CH.

Cement: OPC-53 grade cement is used in this study.

Fibre: polypropylene fibre is used. The properties of fibre are: length = 6 mm, diameter = 26 μm, aspect ratio = 231, E = 7 GPa, tensile strength = 540 MPa, ρ = 910 kg/m3.

2.2 Test Procedure

The load tests were carried out in model test tanks of 30 cm diameter and 30 cm height and also in test tank of 50 cm × 50 cm × 60 cm. The test tank is placed on the pedestal of loading frame centrally. The soft clay is prepared corresponding to the required consistency indices of 0.1, 0.25 and 0.5. 50 mm diameter (d) and PVC pipes are used to form 25 cm long soil-cement columns within soft clay.

The soft clay prepared corresponding to a given consistency is placed in the test tank is layers of 5 cm by marking on the sides of test tank. PVC pipes are placed at the desired spacing (2d) and soil-cement mix or soil-cement-fibre mix as per the test condition is placed and pressed while gradually withdrawing the PVC pipe by rotation by maintaining adequate overlapping with respect to the placement of clay around the pipes. The process is repeated till the test specimen with soil-cement columns is formed. At the top of soil-cement columns, a levelling course of 2 cm thick sand is placed before placing the 12 cm diameter test plate over them. The system is allowed for 7 days curing by covering it with a polythene bag and at the end of curing period, load test was carried out. The load was applied in increments of and the corresponding settlements were recorded with the help of dial gauges. The load-settlement plots were drawn and the ultimate loads were obtained by drawing tangents to the initial and final straight-line portions (Fig. 1).

3 Results and Discussion

The load tests were carried out on end bearing soil-cement columns of 50 mm diameter and 25 cm long at different consistencies of clay. The pressure-settlement curves are presented below.

3.1 Influence of Different Fibre Content on the Soil-Cement Column

For the calculation of optimum fibre content, UCC test is performed by varying fibre content from 0 to 3% by weight of soil. For this test, samples of size 50 mm × 100 mm are used. Different samples are prepared for different consistencies, i.e. Ic = 0.1, Ic = 0.25, Ic = 0.5. These samples are tested after 14 days of curing.

From Figs. 2 and 3, it can be seen that both strength and deformation is increasing after addition of fibre. Deformation is increased by about 1.2–2 times after addition of fibre. Strength is increased by about 20% after addition of fibre.

From Figs. 4 and 5, it can be seen that without fibre failure of sample is brittle and with addition of fibre, and sample fails due to bulging which is an indication of ductile behaviour. From all the above observations and considering the ease of mixing, 2% fibre content by weight was used in the present study.

3.2 Influence of Consistency on Soil-Cement Column Capacity

The load tests are carried out on soil-cement columns of 5 cm × 25 cm at different consistencies of clay.

It can be seen from this Fig. 6 that the settlements are considerably higher with decrease in consistency for any load increment. The ultimate load-carrying capacity values are obtained from the intersection points of tangents drawn along the initial and final straight-line portions of load-settlement plots (Table 1).

The pressure-settlement plots for a 3 column group at different soil consistency indices (Ic) are presented in Fig. 7. It can be observed from this figure that the initial consistency of clay has significant influence on the load-carrying capacity of column group. The ultimate load-carrying capacity of the group is about 180 kPa at Ic = 0.5 and its 120 kPa, 50 kPa at 0.25 and 0.1, respectively. These values indicate that the ultimate capacity is increased around 3 times when the consistency index is increased from 0.1 to 0.5.

3.3 Effect of Soil Consistency on Behaviour Soil-Cement Columns

Pressure-settlement plot for the initial consistency of 0.1, 0.25 and 0.5 is shown in Figs. 8, 9 and 10 (Table 2).

From above observations, we can conclude that capacity of single column is around 3 times that of original soil and capacity of group of column of three is 5–7 times that of original soil. Also, the capacity of group of column of three is 1.7–2.1 times that of single column.

From this, it can be concluded that group capacity is not multiplicative of single column.

3.4 Effect of Fibre Addition on Soil-Cement Column Behaviour

Pressure-settlement curves for the different initial consistencies with fibre-reinforced single soil-cement column and group of columns are plotted in order to compare its capacity with original soil is shown in Figs. 11, 12 and 13 (Table 3).

From this, it can be concluded that capacity of fibre-reinforced single column is 3.5–4 times of original soil and capacity of group of column is 5.5–7.5 times of original soil. Whereas capacity of fibre-reinforced group of column is around 1.5–2 times that of single column.

3.5 Comparison Between Soil-Cement Columns and Fibre-Reinforced Soil-Cement Columns

It can be observed from Table 1 that increase in ultimate load capacity of soil after addition of fibre is about 15–20%. Figure 14 indicates the failure pattern of soil-cement columns and Fig. 15 indicates the failure pattern of fibre-reinforced soil-cement column. From Fig. 14, it can be observed that failure of soil-cement column brittle as it was broken into pieces, whereas from Fig. 15, it can be observed that when fibre is added column is showing bulging failure which indicates ductile behaviour. From above observations, we can conclude that addition of fibre improves the ductility of soil-cement column (Table 4).

4 Conclusions

The following conclusions are drawn from the experimental work carried out in this study.

-

1.

The load-carrying capacity of soil-cement columns is significantly increased with increasing initial soil consistency.

-

2.

In case of soil-cement columns, the increasing cement content has shown marginal increase in load-carrying capacity.

-

3.

The group capacity of end bearing soil-cement columns is found to be not multiplicative value of a single column capacity.

-

4.

There is increase in ultimate load-carrying capacity of soil-cement column after addition of fibre by 15–20% and mode of failure of column changes to ductile from brittle.

References

Consoli NC, Vendruscolo MA, Prietto PDM (2003) Behavior of plate load tests on soil layers improved with cement and fiber. J Geotech Geoenviron Eng ASCE 129(1):96–101

Faro VP, Consoli NC, Schnaid F, Thomé A, Lopes LDS (2015) Field tests on laterally loaded rigid piles in cement treated soils. J Geotech Geoenviron Eng ASCE 141(6):601–605

Farouk A, Shahien MM (2013) Ground improvement using soil–cement columns: experimental investigation. Alexandria Eng J 52(4):733–740

Xiao HW, Lee FH, Zhang MH, Yeoh SY (2013) Fiber reinforced cement treated clay. In: Pierre D, Jacques D, Roger F, Alain P, Francois S (eds) 18th Soil mechanics and geotechnical engineering. Proceedings of the 18th international conference on soil mechanics and geotechnical engineering, Paris, vol 2–6, pp 2633–2636

Xiao HW, Lee FH, Goh SH (2015) Fibre distribution effect on behavior of fibre-reinforced cement-treated clay. In: Proceedings of 15th Asian regional conference of soil mechanics and geotechnical engineering, Nov, Fukuoka, Japan, vol 2(60), pp 2063–2068

Yao K, Yao Z, Song X, Zhang X, Huc J, Pan X (2016) Settlement evaluation of soft ground reinforced by deep mixed columns. Int J Pavement Res Technol 9:460–465

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Mahesh, L., Pillai, R.J., Kumar, G.S., Murthy, V.R. (2021). Improvement of Soft Clay Bed Using Fibre-Reinforced Soil-Cement Columns. In: Latha Gali, M., Raghuveer Rao, P. (eds) Problematic Soils and Geoenvironmental Concerns. Lecture Notes in Civil Engineering, vol 88. Springer, Singapore. https://doi.org/10.1007/978-981-15-6237-2_57

Download citation

DOI: https://doi.org/10.1007/978-981-15-6237-2_57

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6236-5

Online ISBN: 978-981-15-6237-2

eBook Packages: EngineeringEngineering (R0)