Abstract

Lower leg–foot orthoses (AFOs) are assistive contraptions supported for different physical and neurological messes impacting the flexibility of the lower members. Added substance manufacturing item has been researched as an elective method; regardless, it has ended up being inefficient cost-wise. This work intends to explore the potential results of making specific AFO parts, explicitly, calf, shank and footplate, with the kept composite stronghold that aides in the streamlining of the device to the extent convenience, style, inflexible nature and cost. This work shows the insignificant exertion 3D printing with fortress approach as an elective course for the arranging and amassing of orthotic contraptions with complex shapes. This assessment looked into the fields related to 3D checking, 3D printing aided sketching out for the collecting of an unbending AFO.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

13.1 Introduction

Pre-assembled orthotic gadgets are reasonable and intended to fit a scope of patients. Because of this restricted plans, it would not give redid solace and usefulness. Be that as it may, delivering a custom-fit orthosis is an arduous and tedious manual process achieved just by master orthotist. The technique to make a give can take up a role as much as four long stretches of manufacture time per unit whenever performed by an accomplished expert. To make the orthotics in light of the cast, it will take days. The cast will likewise consume room while putting away and must be kept for a couple of months, and after, that another cast must be made [1,2,3,4].

In present-day focused world, makers need to discharge an as good as ever item to the market as quick as conceivable to have the capacity to contend in the worldwide market. The presentation of fast prototyping in the beginning periods of item improvement has extraordinarily decreased the advancement time span and cost engaged with model assembling. Quick prototyping (RP) is the way toward creating a three-dimensional parts or models straightforwardly from CAD illustrations. The uses of fast prototyping are progressing at quick pace. They have moved from making models for parts to a few building applications. Among the advancing RP applications are the making of molds for bite the dust throwing and making of parts to be utilized in the gathering of items. Regarding medicinal utilize, RP is utilized to make models utilizing three-dimensional designs from X-beam gear and these models are utilized to study and plan medical procedure. Techniques are being created to lead remote medical procedure by virtual reality utilizing RP models. Notwithstanding the past application, quick prototyping is additionally being utilized to make body parts known as orthotics and prosthetics [5]. This investigation work is focused on illustrating lower leg–foot orthoses (AFOs) through making sense of and produces by quick prototyping. An orthosis is described by the International Standards Organization as a remotely associated device used to adjust the fundamental and useful qualities of the neuromuscular and skeletal structure. Lower leg–foot orthoses cannot avoid being orthoses that encompass the lower leg joint and the whole or part of the foot. AFOs are wanted to control development, correct distortion or conceivably compensate for deficiency of the leg [6,7,8,9,10]. With our present advancement, we can quicken the amassing method by using making sense of to assemble 3D CAD data on the patient’s foot. Remedial reverse engineering is required to use the reverse engineering advancement to revamp 3D models of the anatomical structures and biomedical things for plan and amassing of therapeutic things. Making sense of is generally portrayed as a methodology of separating an inquiry or existing system, to recognize its fragments and their interrelationships, and investigate how it works remembering the ultimate objective to update or convey a copy without access to the arrangement from which it was at first made.

Through figuring out, we can dissect the 3D examined information and outline the most appropriate orthoses for the patient. The way toward outlining orthoses utilizing figuring out programming would allow changes in the standard plan to meet the correct needs of every patient. Moreover, the utilization of 3D scanner and modernized programming in manufacturing understanding particular orthotic gadgets can possibly convey exceptional solace because of the precise information gave through 3D checking. Quick prototyping is the name given to an expansive gathering of related advances which might be used to make physical inquiries especially from CAD information assets. These systems are stand-out in that they incorporate and protection substances in layers to define items. Such structures are furthermore regarded by using the names included substance advent, three-dimensional printing, and stable unfastened-form advent and layered amassing [11,12,13,14]. They provide purposes of enthusiasm for various programs stood out from standard subtractive fabricate structures, as an instance, getting ready or turning:

-

i.

Objects may be framed with any geometric multifaceted nature or unpredictability without the requirement for make bigger system setup or last get together;

-

ii.

Objects may be produced the use of various substances, or as composites, or substances may even be fluctuated in a controlled manner at any place in a protest;

-

iii.

Additive creation frameworks lessen the improvement of complicated articles to a sensible, clean and commonly quick manner. These homes have resulted of their extensive use as a manner to lessen time to marketplace in production. Today’s systems are heavily used by engineers to higher understand and speak their product designs in addition to make speedy tooling to fabricate the ones products. Surgeons, architects, artists and people from many other disciplines also robotically use the technology.

13.1.1 Background

Foot drop is a misleadingly dependable requires a likely snared bother. It tends to be depicted as a basic deficiency of decay leg and toe dorsiflexion. The foot and decrease leg dorsiflexors incorporate the tibialis the front, the extensor hallucis longus (EHL) and the extensor digitorum longus (EDL). These solid tissues engage the body to clean the foot amidst swing stage and control plantar flexion of the foot on back zone strike [15,16,17,18]. Weakness in this storing up of muscle tissue brings about an equinovarus distortion. This is some of the time insinuated as steppage walk, in gentle of reality that the patient tends to stroll with a distorted flexion of the hip and knee to save the feet from getting at the ground in the midst of swing level. In the midst of walk, the power of foot bottom spot strike outperforms body weight, and the course of the floor reaction vector goes at the back of the lower leg and acknowledgment (see the photo underneath knee) (Fig. 13.1).

13.1.1.1 Anatomy

Strands from the dorsal pieces of the ventral rami of L4-S1 are found in the peroneal nerve, which is encouraged with the tibial nerve to fuse the sciatic nerve. The sciatic nerve leaves the pelvic pit at the more basic sciatic foramen, essentially unremarkable showed up diversely in connection to the piriformis. It bifurcates to shape the peroneal and tibial nerves either in the distal third of the thigh or at the midthigh level.

The lower leg partitioning shallow and gigantic branches. The shallow branch goes between the two pioneers of the peronei and continues down the lower leg to lie between the peroneal tendon and the sidelong edge of the gastrocnemius [19,20,21,22,23] (Fig. 13.2).

13.1.1.2 Causes

Foot drop is because of inadequacy or absence of development of the muscle tissue drew in with lifting the front bit of the foot [24]. The concealed purposes behind foot drop are moved and may include:

-

i.

Nerve hurt.

The most extreme broadly analyzed purpose behind foot drop is strain of a nerve in your leg that controls the muscle tissues related with lifting the foot. This nerve can in like manner be hurt in the midst of hip or knee substitution clinical way, which may reason foot drop. Nerve root hurt (“crushed nerve”) in the spine can similarly reason foot drop.

-

ii.

Muscle or nerve issue.

Various types of solid dystrophy, an obtained ailment that causes dynamic muscle weakness, may add to foot drop. Diverse disarranges, for example, polio or Charcot-Marie-Tooth issue, in like manner would motive be able to foot drop.

-

iii.

Cerebrum and spinal string inconvenience. Scatters that influence the spinal string or cerebrum—for instance, amyotrophic parallel sclerosis (ALS), diverse sclerosis or stroke—may purpose foot drop.

13.1.1.3 Symptoms

Foot drop makes it difficult to support the front bit of your foot, so it might defer the floor when you walk. To counter this, you can raise your thigh while you walk, around despite the fact that you have been mountaineering stairs (steppage walk), to allow your foot to clear the floor. This unconventional walk may likewise make you smack your foot down onto the floor with each movement you are taking. On occasion, the skin on the absolute best purpose of your foot and feet can likewise encounter numb [25,26,27,28,29,30].

Foot drop often affects just a single foot. Contingent upon the hidden reason, be that as it can, it is possible for the two feet to be influenced.

13.1.1.4 Definition

Foot drop, from time to time called drop foot, is a general term for burden lifting the front piece of the foot. On the off chance that you have foot drop, you may drag the front of your foot on the ground when you walk. Foot drop is not an infection. Or then again potentially, foot drop implies that a covered neurological, solid or anatomical issue [31].

A part of the time foot drop is transient. In different cases, foot drop is endless. In the event that you have foot drop, you may need to wear a prop on your lower leg and foot to hold your foot in a typical position.

13.1.1.5 Tests and Diagnosis

Foot drop is usually dismembered amidst a physical test. Your lord should watch you walk and may check a part of your leg muscles for shortcoming. The individual may in addition check for deadness on your shin and on the most critical motivation behind your foot and toes. Sometimes, extra testing is recommended [32,33,34,35].

13.1.1.6 Imaging Tests

Foot drop is a part of the time realized by an extra of bone in the spinal channel or with the guide of a tumor or irritates pushing at the nerve inside the knee or spine. Imaging tests can help pinpoint these sorts of issues [36].

-

I.

X-bars. Plain X-shafts make use of a low degree of radiation to acknowledge a delicate tissue mass or a bone harm that would reason your pointers.

-

II.

Ultrasound. This headway uses sound waves to make photographs of inward systems. It might be associated with check for pimples or tumors that may push at the nerve.

-

III.

Modernized tomography (CT) filters through. Electronic tomography joins X-shaft photos taken from an expansive extent of edges to framework pass-sectional points of view of structures inside the packaging.

-

IV.

Attractive resounding imaging (MRI). This research makes use of radio waves and a strong engaging field to make isolated sneak peaks. X-bar is expressly prized in envisioning sensitive tissue disasters that could a nerve.

13.1.1.7 Nerve Tests

Electromyography (EMG) and nerve conduction considers measure electrical action in the muscles and nerves. These tests can be ungainly; at any rate, they are extremely helpful in picking the region of the harm along the affected nerve [37].

13.1.1.8 Treatments and Drugs

Treatment for foot drop relies upon the hidden reason. In the event that the simple motive is successfully dealt with, foot drop may additionally beautify or maybe vanish [23]. On the off threat that the essential cause cannot be treated, foot drop might be lasting. Particular remedy for foot drop may encompass:

-

i.

Braces or helps. A prop in your decrease leg and foot or guide that fits into your shoe can assist maintain your foot in an average function.

-

ii.

Physical remedy. Activities that enhance your leg muscle mass and help you hold up the scope of motion for your knee and lower leg may also beautify stroll troubles related with foot drop. Extending practices are especially critical to keep the improvement of solidness within the foot sole vicinity.

-

iii.

Nerve incitement. In a few instances, empowering the nerve that lifts the foot enhances foot drop.

-

iv.

Surgery. Contingent on the cause, and in case your foot drop is normally new, nerve clinical process is probably useful. In the occasion that foot drop is lengthy-standing, your expert might also advise scientific system that wires decrease leg or foot bones or a method that exchanges an operating ligament to a change function (Fig. 13.3).

13.2 Ankle–Foot Orthosis

An AFO can be used for foot drop even as cautious fix is not supported or all through cautious or neurologic recovery. The specific explanation behind an AFO is to offer toe dorsiflexion inside the course of the swing territory, normal or flat adequacy at the lower leg for the range of position, and, if urgent, push off affectation at some stage in the past due position divide. An AFO is profitable elegant if the foot can advantage plantigrade limit when the patient is status. Any equinus contracture obstructs its productive use [38].

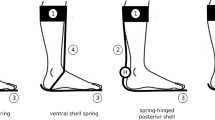

The best commonly used AFO in foot drop is created of polypropylene and increases into a shoe. If its miles slice to fit front to the malleoli, it gives rigid immobilization. This instrument is used meanwhile as lower leg precariousness or spasticity is astounding, much the same as the case in sufferers with best motor neuron sicknesses or stroke [39].

If the AFO suits back to the malleoli (back leaf spring type), plantar flexion at effect point strike is permitted, and push off returns the foot to free for the swing segment. This gives dorsiflexion help with times of out of shape or slight spastic equinovarus mutilation. A shoe-get orthosis that associates explicitly to the heel counter of the shoe besides may be used. A view through Menotti et al. suggested that front AFOs are related to decay power expenses of by strolling and favored degrees of saw comfort over back AFOs are and thusly may likewise enable people with foot drop to walk longer divisions while utilizing less genuine undertaking.

13.3 Methodology

13.3.1 Manufacturing Techniques of AFO

The process will be used to create orthotic devices is additive manufacturing. Computer-assisted design (CAD) systems have also being used to assist in creating the positive improving consistency and repeatability of this process, but the process remains slow and complex and it requires considerable input from experienced craftsmen. Furthermore, in these traditional processes, the possibilities for innovation or product development are limited. With CAD systems, it will be observed that orthoses rejection ratio has been reduced combined with time reduction up to 50% and cost saving up to 25–50% [26,27,28,29,30] as shown in Fig. 13.4.

A standard AFO was characterized to best understand the performance characteristics required of a spring ankle–foot orthotic. These characteristics, in combination with the study of human biomechanics, were used to choose optimum material and size. The flowchart shown below details the steps in the prototype development process

Each of the individual work flows shown in Fig. 13.5 above merged to create the final prototype through use of the best process. Upon completion of the final prototype comparative testing was done to show the similarities in performance between the standard AFO and the prototype.

13.3.2 3D Scanning Techniques of Foot Drop Patients

During the scanning process as shown in Fig. 13.6, numerous 3D outputs of the question are gained from different bearings and every one of the information is consolidated naturally into a solitary and finish 3D surface model. Normal examining times extend from a couple to 15 min; the moderately long aggregate filtering time is less significant, since the full robotization of the procedure gives the administrator flexibility to perform different undertakings amid the checking procedure. Likewise, no particular specialized know-how in 3D checking is required to play out the procedure. The 3D profiles procured progressively by the laser scanner can be moved into the reference framework characterized by the receptor. The filtering procedure is in this way extremely straightforward and natural: the administrator move, totally unreservedly, the hand-held scanner over the protest, while the obtained 3D profiles are appeared continuously on the screen.

The essential system for all quick prototyping strategies can be compressed as takes after:

-

i.

A CAD show is built and afterward changed over to STL design. The determination can be set to limit stair venturing.

-

ii.

The RP machine forms the STL document by making cut layers of the model.

-

iii.

The first layer of the physical model is made. The model is then brought down by the thickness of next layer, and the procedure is then rehashed until consummation of the model.

-

iv.

The demonstration and any backings are expelled. The surface of the model is then completed and cleaned.

The phases of 3D scanning as shown in Figs. 13.7 and 13.8 and CAD designing the production of an AFO, with a reasonable quality of image in terms of its resolution, before sending it to a 3D printer. Based on the observed result, the project purpose is feasible but further refinement of the process is necessary at this stage. It was concluded that using a 3D laser scanner can provide a high quality of image of scanning for the AFO making purposes comparing to those that used in previous studies. The CAD tools were suitable to reduce the size of the original, large scan, mesh making and offsetting.

13.4 Clinical Gait Anyalsis of Foot Drop Patients

The term gait refers to the pattern of walk of an individual. Gait analysis consists of the various scientific measurement and analysis linked with locomotion. The gait measurement techniques used in the Gait Laboratory of the Physical and Rehabilitation Medicine Department at PGIMER Chandigarh are broadly classified into four types [40,41,42].

-

i.

Camera motion analysis,

-

ii.

16 force plate-based force analysis,

-

iii.

Biometrics EMG analysis,

-

iv.

Sway analysis.

-

i.

Three markers on each shank: head of fibula, lateral malleulus, lateral bar (same way for the bar on the tight, see Fig. 13.9);

-

ii.

One marker on each foot:

Fifth metatarsal joint and emispherical markers: b1 marker on each heel: (only for standing trial) be careful that the two markers on the fifth metatarsal joint and on the heel have to stay on the same plane (see Figs. 13.10 and 13.11).

Subject with the markers positioning on his skin (i) back view, (ii) lateral view, (iii) frontal view (Figures from Motion and Gait Analysis Laboratory at PGIMER, Chandigarh), (iv) the method in order to find the Posterior Iliac crests and (v) the positioning of “sacral” marker, (vi) positioning of the bars

13.4.1 Gait Analysis of Foot Drop Patients

The trial of foot drop patients in clinical gait laboratory is done as shown in Fig. 13.12. Which will help to check how much improvement of gait cycle with 3D printed ankle–foot orthosis?

The clinical gait analysis trial with old and customized design 3D printed ankle–foot orthosis is performed as shown in Fig. 13.13 to check ankle joint stability in foot drop patients.

13.5 Significant Findings

The different phases of 3D scanning and CAD designing the production of an AFO, with a reasonable quality of the image in terms of its resolution, before sending it to a 3D printer. Based on the observed result, the research purpose is feasible but further refinement of the process is necessary at this stage.

It was concluded that using a 3D laser scanner can provide a high quality of image of scanning for the AFO making purposes comparing to those that used in previous studies. The CAD tools were suitable to reduce the size of the original, large scan, mesh making and offsetting the mesh in order to make 5 mm thickness for the final AFO design.

-

1.

In show off AFO layout patients stands as a great deal as blood course circulate to foot and cannot walk truly are being long past up in competition to inside the midst of complete deal make use of. Another arrangement of AFO for foot drop patients has been made to conquer this issue and restrained detail displaying and expand exam has in like way been executed.

-

2.

Utilization of 3D human accessible scanner (Artec Eva) to get accurate measurements of foot drop patients.

-

3.

New format of AFO is created with the aid of 3D printing technology (SLS) which is greater time and cost. It examinations the shape and lead of fabric of modern-day usable AFO and 3D published AFO.

-

4.

By making use of 3D printing (SLS) innovation AFO shape some other fabric Nylon-Poly Amide (type of Plastic) has been made.

-

5.

Selective laser sintering (SLS) three-dimensional printing having the principle advantage is that the manufactured fashions are permeable (generally 60% of the thickness of normal factors), as an end result weakening their great and ground wrap up.

-

6.

Considering its heartiness and capability to supply complicated entire elements, SLS can deliver massive money and time saving blessings for little run components that would normally require some collecting with popular assembling. It is an ideal marriage of usefulness, high-quality and unpredictability.

-

7.

It continues up the focal point of weight line of motion in nonpartisan position (center of base of help). And furthermore balances out the foot, which as a consequence decreases the danger of harm and improves stride strength and adjust.

-

8.

It can lessen plantar weight by redistribution of plantar weight. It moreover assists to upgrade ordinary probability dispersion of plantar stacking, which is fundamental importance to decrease carry down furthest point torment amid taking walks.

13.6 Scope of Future Works

Future works of the design of Artec Eva Studio 12 Professional will focus on optimization of the computerized design process. Improvement of image processing for the 3D scanned data will be researched so as to simplify current processes. The mechanical structure of compliant finger joint will be further developed, and algorithms of parameter optimization will be developed. The thumb joint will be designed and tested. More materials and embedded sensors could be tested and optimized. Software interface will be developed. In the future, the AFOs with sensor can provide accuracy indicate that when do they need to replace the AFOs. Future works on the development of the AFO test bed will focus on the design of the clamp elements so as to provide quantitative body weight during the gait. Actual human gait cycle data and ankle stiffness could be implemented into the control system so as to verify the functional analysis of the AFO. Further study of the energy return in gait will be analysis in this AFO test bed. Control system will be developed in the real-time machine so as to improve the performance.

References

Abboud RJ (2002) Relevant foot biomechanics. Curr Orthop 6:165–179

Alexander MA, Xing SY, Bhagia SM (2011) Lower limb orthotics [Online]. Webmd Llc. (2011). Available http://Emedicine.Medscape.com/Article/314838-Overview#Aw2aab6b5. Accessed 22 Sept 2011

American Orthotic and Prosthetic Association Inc. Evidence Note (2008) The use of ankle–foot orthoses in the management of stroke. 5(12):120–128

Banga HK, Parveen K, Belokar RM, Kumar R (2014) Rapid prototyping applications in medical sciences. Int J Emerg Technol Comput Appl Sci (IJETCAS) 5(8):416–420

Banga HK, Belokar RM, Madan R, Dhole S (2017) Three dimensional gait assessments during walking of healthy people and drop foot patients. Defence Life Sci J 2(1):14–20

Banga HK, Belokar RM, Kalra P, Madan R (2018) Fabrication and stress analysis of ankle foot orthosis with additive manufacturing. Rapid Prototyping J 24(1):301–312

Banga HK, Belokar RM, Kumar R (2017) A novel approach for ankle foot orthosis developed by three dimensional technologies. In: 3rd International conference on mechanical engineering and automation science (ICMEAS 2017), University of Birmingham, UK, vol 8(10), pp 141–145

Boehler W, Marbs A (2002) 3D scanning instruments. In: Proceedings of the CIPA WG 6 international workshop on scanning for cultural heritage recording, Ziti, Thessaloniki, vol 3(12), pp 9–18

Brackx B, Van Damme M, Matthys A, Vanderborght B, Lefeber D (2012) Passive ankle–foot prosthesis prototype with extended push-off. Int J Adv Robotic Syst 1(10):19–28

Bennett BC, Russell SD, Abel MF (2012) The effects of ankle foot orthoses on energy recovery and work during gait in children with cerebral palsy. Clin Biomech (Bristol, Avon) 27(3):287–291

Bregman DJJ, Rozumalski A, Koops D, De Groot V, Schwartz M, Harlaar J (2009) A new method for evaluating ankle–foot orthosis characteristics. Gait Posture 30(6):144–149

Brehm M-A, Harlaar J, Schwartz M (2008) Effect of ankle–foot orthoses on walking efficiency and gait in children with cerebral palsy. J Rehabil Med 4(9):529–534

Bowker P (1993) Biomechanical basis of orthotic management. Oxford England 2(10):19–28

Chen C-L, Yeung K-T, Wang C-H, Chu H-T, Yeh C-Y (1999) Anterior ankle–foot orthosis effects on postural stability in hemiplegic patients. Arch Phys Med Rehabil 8(5):1587–1592

Chu TM, Reddy NP, Padovan J (1995) Three-dimensional finite element stress analysis of the polypropylene, ankle–foot orthosis: static analysis. Med Eng Phys 17(5):372–379

Cook D, Gervasi V, Rizza R, Kamara S, Xue-Cheng L (2010) Additive fabrication of custom pedorthoses for clubfoot correction. Rapid Prototyping J 16:189–193

Mavroidis C, Ranky RG, Sivak ML, Patritti BL, Dipisa J (2011) Patient specific ankle–foot orthoses using rapid prototyping. J Neuroeng Rehabil 1(5):252–259

Crabtree CA, Higginson JS (2009) Modeling neuromuscular effects of ankle foot orthoses (AFO’s) in computer simulations of gait. Gait Posture 29:65–70

De Burgh J (2003) The human body—an essential guide to how the body works. Grange Books, Rochester

Schrank ES, Stanhope SJ (2011) Dimensional accuracy of ankle–foot orthoses constructed by rapid customization and manufacturing framework. J Rehabil Res Dev 48:31–42

Edelstein JE, Bruckner J (2002) Orthotics: a comprehensive clinical approach. Wiley, Slack, New Jersey

Fan GAO, Carlton W, Kapp S (2009) Development of a motorized device for quantitative investigation of AFO’s. In: 4th International conference on bioinformatics and biomedical engineering, vol 15(3), pp 112–119

https://www.mayoclinic.org/diseases-conditions/foot-drop/diagnosis-treatment/drc-20372633

Singh H, Singh S, Prakash C (2019) Current trends in biomaterials and bio-manufacturing. In: Biomanufacturing. Springer, Singapur

Foot Drop Disease Pictures. www.epainassist.com

Anatomy of ankle nerve system. www.epainassist.com

Poomathi N, Singh S, Prakash C, Patil RV, Perumal PT, Barathi VA, Balasubramanian KK, Ramakrishna S, Maheshwari NU (2018) Bioprinting in ophthalmology: current advances and future pathways. Rapid Prototyping J

Silva P, Silva MT, Martins J (2009) A review of thermoplastic ankle–foot orthoses adjustments/replacements in young cerebral palsy and spina bifida patients. JPO J Prosthet Orthot 7:15–22

Singh S, Singh M, Prakash C, Gupta MK, Mia M, Singh R (2019) Optimization and reliability analysis to improve surface quality and mechanical characteristics of heat-treated fused filament fabricated parts. Int J Adv Manuf Technol: 1–16

Singh S, Singh N, Gupta M, Prakash C, Singh R (2019) Mechanical feasibility of ABS/HIPS-based multi-material structures primed by low-cost polymer printer. Rapid Prototyping J 25(1):152–161

Singh S, Prakash C, Ramakrishna S (2019) 3D printing of polyether-ether-ketone for biomedical applications. Eur Polym J (2019)

Milusheva SM, Tosheva EY, Toshev YE, Taiar R (2012) Ankle foot orthosis with exchangeable elastic elements series on biomechanics. 23(1):322–330

Milusheva S, Tochev D, Stefanova L, Toshev Y (2011) Virtual models and prototype of individual ankle foot orthosis. In: Isb Xxth congress—Asb 29th annual meeting, 31 July–5 Aug, Cleveland, Ohio

South BJ, Fey NP, Bosker G, Neptune RR (2009) Manufacture of energy storage and return prosthetic feet using selective laser sintering. J Biomech Eng 132:015001

Staats TB, Kriechbaum MP (1989) Computer aided design and computer aided manufacturing of foot orthoses. JPO J Prosthet Orthot 1:182–186

Sungjae H, Jungyoon K, Jinbock Y, Kisik T, Kihong R, Youngho K (2006) Development of an active ankle foot orthosis for the prevention of foot drop and toe drag. Biomed Pharm Eng 1:418–423. International Conference on ICBPE

Chu T-M, Reddy NP (1995) Stress distribution in the ankle–foot orthosis used to correct pathological gait. J Rehabil Res Dev 32(4):349–360

Tortora GJ, Derrickson BH (2008) Principles of anatomy and physiology. Wiley, USA

Waters RL, McNeal D, Perry J (1975) Experimental correction of footdrop by electrical stimulation of the peroneal nerve. J Bone Joint Surg 8(57):1047–1054

Whittle M (2007) Gait analysis: an introduction. Butterworth-Heinemann Elsevier, Philadelfia

Winter DA (2009) Biomechanics and motor control of human movement. Wiley, New Jersey

Ai YW, Yan H, Jian WZ, Yang W (2014) A new method of digital manufacturing of orthoses. Comput Model New Technol 3(18):271–275

Declaration of Conflicting Interests

No potential conflicts of interest with respect to the research, authorship and publication of this article as declared by author(s).

Funding

The author(s) received no financial support for the research, authorship and publication of this article.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Banga, H.K., Kalra, P., Belokar, R.M., Kumar, R. (2020). Improvement of Human Gait in Foot Deformities Patients by 3D Printed Ankle–Foot Orthosis. In: Singh, S., Prakash, C., Singh, R. (eds) 3D Printing in Biomedical Engineering. Materials Horizons: From Nature to Nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-15-5424-7_13

Download citation

DOI: https://doi.org/10.1007/978-981-15-5424-7_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-5423-0

Online ISBN: 978-981-15-5424-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)