Abstract

Trace metals are involved in many metabolic pathways of marine phytoplankton, and are involved in regulating their growth and productivity, thereby influencing the community structure and function of the marine ecosystem. As such, trace metals play important roles in the marine biogeochemical cycles of carbon and nitrogen. However, due to the low solubility in seawater, the bio-availability of trace metals such as Zn, Co, and especially Fe may limit the growth of phytoplankton in many oceanic areas.

On the one hand, shipboard and laboratory culture environments are very likely to cause trace metal contamination. Therefore, trace metal clean culture techniques are necessary during studies of phytoplankton uptake of trace metals and trace metal limited culture experiments, and during the sampling and analysis procedures in these experiments. On the other hand, trace metal ion buffer reagents are usually required in seawater media in order to provide a sufficient but nontoxic supply of trace metals necessary for phytoplankton growth, and to precisely adjust the trace metal availability in the laboratory culturing experiments. This chapter is primarily intended to set forth trace metal clean culture techniques for the study of trace metal–phytoplankton interactions. In addition, the chapter also provides information on how to prepare seawater culture media used in laboratory and shipboard trace metal clean incubation experiments.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

The growth of phytoplankton requires not only a sufficient supply of elements of macronutrients (C, N, P, and Si), but also a variety of micronutrient metals (such as Fe, Mn, Co, Cu, Mo, Zn, and Co). The solubility of some metal elements tends to be low, with only low concentrations of free ions present in seawater environment, and so they are classified as micro- or trace elements (concentrations lower than 50 and 0.05 μmol kg−1, respectively). Among these trace metals, Fe is required by all photosynthetic organisms and has been most studied by oceanographers, as it plays important roles in phytoplankton biochemical electron transfer. Fe is involved in reactions of both photosynthesis and respiration, and the reduction of nitrate, nitrite and sulfate, as well as nitrogen fixation processes. In high-nutrient and low-chlorophyll (HNLC) regions, such as the Southern Ocean, subpolar and equatorial Pacific, and some Pacific eastern boundary upwelling regions, the bioavailability of iron is the limiting factor of phytoplankton growth and regulates primary productivity and ecosystem structure, thus influencing the global carbon cycle (Martin et al. 1993; Sunda and Huntsman 1995a; Coale et al. 1996; Hutchins and Bruland 1998; Boyd et al. 2000). The trace metal Mn is an essential element in the water-oxidizing complex of photosystem II (PSII), and so is required for the growth of all marine phytoplankton groups. It has been observed that the availability of Mn can limit phytoplankton growth, especially under low irradiance conditions (Sunda and Huntsman 1998). Zn is an important component in carbonic anhydrase synthesis, and so is essential in the processes of inorganic carbon transport and fixation, and is also involved in the production of alkaline phosphatase for organic phosphorus uptake (Morel et al. 1994). Co (and Cd) can be used as a substitute element for Zn in the alkaline phosphatase synthesis (Morel et al. 1994; Sunda and Huntsman 1995b), and are essential for the growth of some cyanobacteria and haptophytes (Sunda and Huntsman 1995b; Saito et al. 2002). Unlike Fe, these other trace metals such as Zn, Co, and Mn only limit marine phytoplankton growth in certain oceanic regions or under particular environmental conditions. Because the requirements of trace metals are species specific among different phytoplankton groups, the bioavailability of these trace metals may also play important roles in shaping natural phytoplankton community structure.

With the development of analytical chemistry and modern instrumental analysis techniques such as atomic absorption spectrometry, electrochemical technology, and inductively coupled plasma (ICP) mass spectrometry, chemical oceanographers are able to analyze seawater trace metal concentrations more precisely. In contrast to the low concentrations of trace metals in seawater, these metals are ubiquitous in the shipboard or laboratory environment from dust, rust, paint, etc., easily contaminating the seawater samples or the culture media used for incubation. Therefore, in order to precisely determine or control the concentrations of trace metals in seawater samples or culture experiments, it is important to adopt trace metal clean sampling and culture techniques in the studies of trace metal–phytoplankton interactions. These techniques include but are not limited to separating a clean operational space, using experimental containers made of special materials, special cleaning of the labware, and removing the trace metal residues in the chemicals used for the incubation media with ion-exchange methods.

In addition, seawater is a weak alkaline solution containing various salts, with low concentrations of free metal ions. A major fraction of many trace metals in natural seawater are present as chelates with organic ligands. The presence of these organic ligands also increases the solubility and bioavailability of trace metals in the marine environment (Bruland and Lohan 2003). Eukaryotic phytoplankton mainly take up dissolved inorganic metal elements (such as Fe, Cu, Zn, and Mn) from the seawater medium through cell membrane-bound transport proteins. These transporters on the surface of the cell membranes are able to bind to either the free metal ions, or metals bound to organic ligands in the seawater through ligand exchange processes. The metal can then be transported into cells across the membrane to be utilized in different metabolic pathways. As a result, the degree to which the chelators bind to trace metals can affect the uptake and utilization efficiency of these elements by phytoplankton. Therefore, in order to provide sufficient trace metal elements for phytoplankton growth, or to precisely control the trace metal concentrations in the study of trace metal limitation or enrichment experiments, it is necessary to add ligands (chelators) to the seawater medium in marine phytoplankton cultures (Morel et al. 1979; Price et al. 1989; Sunda 1988). Ethylenediaminetetraacetic acid (EDTA) is the most widely used inorganic chelator in these studies. The addition of EDTA and metal ions in culture medium can be treated as a trace metal ion buffer system to regulate the trace metal ion concentration and bioavailability. On the one hand, EDTA binds the free metal ions in the solution through the chelation process. On the other hand, as the free metal ions are utilized by phytoplankton, the complex can release metal ions back to the seawater medium.

This chapter mainly summarizes the trace metal clean culture techniques and the preparation of seawater culture media used in laboratory and shipboard trace metal clean incubation experiments. This is mainly intended to benefit readers who are especially interested in the study of trace metal uptake by marine phytoplankton, the mechanisms of trace metal limitation in phytoplankton, and trace metal enrichment incubations.

1 Methods

1.1 Trace Metal Clean Culture Techniques

1.1.1 Setup of Clean Laboratory Space

The concept of a “trace metal clean” laboratory was first established by Professor Patterson at the California Institute of Technology. It is well known that ambient air tends to contain high numbers of particles. The concentration of airborne particles in a laboratory without cleaning procedures is about 200 μg m−3 and even higher in industrial areas, with percentages of the metal elements of 10%, 3%, 1.5%, 1.5%, and 0.5% for Ca, Fe, Al, Ni, and Cu, respectively. In contrast, the concentrations of some metals in seawater are extremely low, with units of ppm or even ppb. Therefore, the ubiquitousness of trace metals in the regular shipboard or laboratory environments may easily cause trace metal contamination of seawater. In order to lower the chance of contamination, some of the algal culture operations need to be performed in a special clean laboratory area. These procedures include the preparation of seawater culture medium, and the sampling and analyses of seawater and phytoplankton samples. The clean laboratory/room is a contained space with a high-efficiency particulate air (HEPA) filtration system to trap the airborne particles that are 0.3 μm or larger in size. Especially for the procedures involved in trace metal analyses, a class 100 HEPA filter is usually required (less than 100 particles with size larger than 0.3 μm in an air volume of 1 m3). All of the air delivered to a clean laboratory/room should pass through the HEPA filters, with positive pressure in the whole clean space. It needs special attention that the degree of cleanliness usually decreases with the airflow direction, which is also the principle used to decide the position for HEPA filter installation. If restrained by space or logistical conditions, a laminar flow hood mounted with HEPA filters may be used in substitution of a clean laboratory. In shipboard incubation experiments, a separate trace metal clean laboratory container is the best option. In some circumstances, a temporary clean laboratory container established by wrapping trace metal clean plastic with HEPA-filters/laminar flow can also be used.

In general, metal labware is not allowed in a clean laboratory/room. The walls and ceilings of the laboratory should be kept tightly closed, and the materials such as the test benches that come into contact with the samples should be relatively clean and made of inert materials, such as polypropylene (PP), polyethylene (PE), or polytetrafluoroethylene (PTFE, also known as Teflon). No metal materials should be exposed in the whole laboratory space; therefore, the walls, ceilings, faucets, and cabinet handles should be replaced with plastic fixtures, otherwise metal-free plastic wraps or a relative clean and inert epoxy paint are needed for the best coverage, to avoid metal contamination. The personnel who work in the clean laboratory/room are also required to wear clean attire, including clean-room shoes, hats, gowns, and plastic gloves. These clothes should not be worn outside the clean room. Plastic gloves should be replaced regularly whenever they come in contact with possible contamination sources. Clean-room apparel is usually lint-free and non-shedding, and mostly made of Tyvek, microporous (MP) fabric and Spunbond–Meltblown–Spunbond (SMS) tri-laminate materials. Cosmetics and hair spray are not recommended to wear in the clean room. When feasible, a separate changing room should be constructed between the trace metal clean room as a transitional place for personnel who enter the clean room or for materials/samples transported from the dirty general laboratory environment.

1.1.2 The Requirements and Cleaning of Labware

Trace metal clean incubation should avoid the use of metal utensils. The culture flasks and reagent bottles used in the experiments should be made of PE, PP, polycarbonate (PC), or PTFE as needed. The water for making solutions and cleaning should be ultrapure such as Milli-Q water, with a resistivity of 18.2 MΩ cm−1 at 25 °C. Prior to use, the reagent bottles and culture flasks and all the other labware that directly contact the samples and cultures need to be soaked and acid-washed to remove contaminants that may be adsorbed onto the surface. These major procedures are described below.

Newly purchased appliances should be cleaned first with solvents or special detergents such as Decon®-Clean and Micro® reagents. After removal of coarse impurities, all utensils require further cleaning by acid washing. In phytoplankton culture experiments, a 10% HCl solution is generally used. All utensils need to be immersed in a 10% HCl acid bath at least for 3 days, and then rinsed with ultrapure water about five times until the HCl remaining on the surface of the container is removed. For the tubing used in some continuous culture devices, which are difficult to clean by soaking, 10% HCl solution is usually pumped into the lines for rinsing, and then ultrapure water is thoroughly pumped through for cleaning. For field research work, in order to avoid contamination during the transportation for scientific expedition cruises, these instruments are generally brought in small sealed containers and kept immersed in 10% HCl solution, until they are washed with ultrapure water in the shipboard clean laboratory just before the beginning of the culture experiment. For the culture flasks and experimental tubing directly used in the culture experiment, it is necessary to use uncontaminated filtered in situ seawater for the final rinsing step right before the culture experiment.

For some extremely strict analysis experiments, according to the NBS standard, multi-step acid-washing procedures are required:

For PTFE containers, after washing with detergent at 77 °C, add concentrated HCl, concentrated HNO3, and ultrapure water in a mixed solution with volume ratio of 12:5:18 for several days and then rinse several times with ultrapure water.

For PE containers, after soaking them in concentrated HCl for 3 days at room temperature and washing with ultrapure water, immerse them in 1% HCl solution at 55 °C for 3 days, followed by rinsing with ultrapure water and soaking in 1% HCl solution at room temperature for 3 days, and finally rinse the containers with ultrapure water.

1.1.3 Trace Metal Clean Procedures During Incubation and Sampling

The sampling of seawater (including phytoplankton) used in shipboard incubation experiments also requires trace metal clean operations. PTFE-lined water samplers should be used to avoid potential metal contamination. The hydro-wire rope should be painted with non-metallic materials (such as PTFE and PE) or replaced with plastic line. In order to minimize contamination from the steel body of the research vessel, the sampling should be conducted while the ship is facing upwind and upstream. Another method is to rapidly throw a sample collector at the bow to immerse it in the water for sample collection, which should be conducted after the engine of the research vessel has been shut down but while the hull is still slowly moving forward. To collect large volumes of seawater, a trace metal clean pumping system is generally used, made by attaching trace metal clean hose to a towfish that is deployed at the desired depth of seawater. Special devices (such as supporting rods) are applied to keep the water inlet as far away as possible from the hull to minimize possible contamination. When feasible, a small boat sampling method can be used by sailing a Zodiac made of non-metallic materials hundreds of meters away from the research vessel for sample collection, and then taking the collected water back to the shipboard laboratory for incubation experiments.

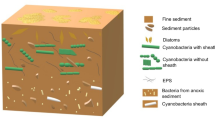

In both shipboard and laboratory culture experiments, culture systems especially need to be sealed to reduce metal contamination from the surrounding environment. During the sampling process, any opening of the culture caps need to be performed only in a clean laboratory or a clean hood. Plastic apparatus that directly come into contact with the samples must be acid-washed in advance. For shipboard incubations, Hutchins et al. (2003) designed a temperature-controlled continuous culture device (Fig. 36.1), which is appropriate for trace metal clean incubations.

The schematic diagram of a trace metal clean shipboard natural community continuous incubation system (Hutchins et al. 2003). The system is composed of the following parts: (a) Carboys are used to contain culture medium made of cleanly collected filtered seawater in a class 100 clean area. (b) Adjustable peristaltic pumps are used to pump medium from the carboys through Teflon tubing to the incubation bottles located inside the shipboard incubators. (c) The shipboard incubator is mounted with Plexiglas holders to hold polycarbonate bottles for phytoplankton incubation. The Teflon fittings are placed on the cap for inflow and neck for outflow of each incubation bottle. These incubation bottles are shaken periodically by an air-pressurized arm. (d) The outflow collecting bottles are connected outside the incubator

1.1.4 Trace Metal Clean Operations in Reagent Preparation

The reagents used in trace metal clean culture experiments need to be prepared with ultrapure water. Chemicals with high purity (guaranteed reagent, chromatographically pure or ultrapure reagent, etc.) are preferred as well. The solutions used for making seawater culture medium require special metal removal treatments, usually by the use of a chelating ion exchange resin. The most commonly used in practice is Chelex® 100 ion exchange resin, which has good selectivity for heavy metal ions such as iron and copper. Chelex® 100 ion exchange resin is a copolymer of divinyl-styrene containing iminodiacetic acid ions that acts as a chelation group to bind multivalent metal ions. Due to its carboxylic acid group, Chelex® 100 ion exchange resin has weak acidity, good metal ion selectivity, and strong binding ability, which is an advantage over other conventional exchange resins.

Special purification processes are required before the use of Chelex® 100 ion exchange resin (Price et al. 1989), as listed as below.

-

1.

Weigh a certain amount of Chelex® 100 ion exchange resin as needed. The general rule is to use 5 g of resin for every 100 mL of solution. Soak it in methanol at room temperature (with resin mass to methanol volume ratio of 1:5 w/v) 3–4 h, and then rinse with 750 mL of Milli-Q water.

-

2.

Next, soak the rinsed resin in 1 M HCl solution overnight and rinse with 1 L Milli-Q water.

-

3.

Soak the resin in 3 M NH4OH solution for 1 week, and then rinse with 1 L Milli-Q water.

-

4.

After soaking for 10 min in 0.1 M HCl solution, rinse with 2 L Milli-Q water, and then rinse with 200 mL of artificial seawater.

-

5.

Add 200 mL of the solution to be purified, resuspend the resin, and slowly titrate the medium solution to pH 8.1 with 1 M NaOH solution.

-

6.

Finally transfer the resin to the container using a batch method or column method for the final purification of solutions.

-

(a)

Batch method: Directly add the Chelex® 100 ion exchange resin purified after the steps 1–5 to the solution requiring removal of heavy metal ions and stir or shake the mixture continuously for 1 h using a magnetic stir plate or laboratory shaker. Finally, the resin is filtered away to obtain the trace metal clean solution. Special attention should be paid to maintain clean operations during filtration (e.g., acid washing of containers and stirrers in a clean room).

-

(b)

Column method: The purified resin suspension is filled in an exchange column, which can be performed in several steps to ensure there are no air bubbles in the column. Then gently pour the solution to be purified into the packed column, taking care to avoid agitation of the resin in the column. Finally, discard the initial 500 mL of solution has passed through the column, and then start collecting the purified solution from the outflow of the packed column.

-

(a)

The applications of Chelex® 100 ion exchange resin for the removal of specific metals is referred to in the reference list in Table 36.1.

1.2 Preparation of Seawater Media in Trace Metal Clean Culture Experiments

1.2.1 Aquil* Medium

The Aquil* medium is a one of the most commonly used synthetic seawater culture media. The preparation of Aquil* medium usually includes enriching the artificial seawater with macro- and micronutrients used to support the growth of many coastal and oceanic phytoplankton taxa. The Aquil* medium described here is a modification by Sunda et al. (2005) from the original Aquil medium (Morel et al. 1979; Price et al. 1989). The modification contains a final concentration of 100 μM of EDTA and eightfold lower iron concentration to minimize the precipitation of hydrous ferric oxides. In the preparation of Aquil* medium, all the stock solutions except for the trace metal and vitamin solutions need to pass through the Chelax® iron exchange column to remove potential metal contamination. The addition of EDTA is used to control the metal speciation and concentrations.

Synthetic ocean water (SOW) is prepared by mixing separate solutions of anhydrous salts and hydrous salts, with a final salinity of 35, as listed in Table 36.2. For making the SOW, first dissolve each of the anhydrous salts individually into 600 mL of Milli-Q water. And then use 300 mL of Milli-Q water to dissolve each of the hydrous salts. For the best dissolution, the salts need to be added into the solutions in order. Only add new salt into the solution after the previous salt is fully dissolved. Then combine the two salt solutions and bring the final volume to 1 L using Milli-Q water.

The preparation of macro-nutrient solution described in Table 36.3 includes making stock solutions of each individual nutrient. Add 1 mL of each of the stock solutions into SOW for each 1 L final volume of Aquil* medium.

For the preparation of trace metal stock solutions (Table 36.4), prepare the individual stock solutions using Milli-Q water first. Then dissolve EDTA in 950 mL of Milli-Q water and add 1 mL of each stock solution. Next bring the volume to 1 L for the trace metal stock solution, and use 1 mL of the stock solution for preparing each liter of final Aquil* medium.

The preparation of mixed vitamin stock solution is listed in Table 36.5. First, the stock solutions of vitamin B12 and vitamin H are prepared individually. 1 mL of each of the vitamin B12 and vitamin H solutions are added next into 950 mL of Milli-Q water. Then add 100 mg vitamin B1 into the solution and use Milli-Q water to bring the final volume up to 1 L. Use 1 mL of the stock solution for 1 L of Aquil* medium.

1.2.2 YBC-II Medium

The YBC-II medium is an artificial seawater culture medium, developed for culturing the nitrogen-fixing cyanobacterium Trichodesmium without a nitrogen source (Chen et al. 1996). To make the artificial seawater used for the medium, first fully dissolve all the salts listed in Table 36.6 using 900 mL of Milli-Q water, next add the metal and f/2 vitamin stock solutions into the artificial seawater, and finally bring the volume to 1 L with Milli-Q water. Adjust the pH of the medium to 8.15–8.2 by adding NaOH solution. The medium is sterilized by filtration instead of autoclaving (Tables 36.7 and 36.8).

It requires special attention that the seawater growth medium used in laboratory culture experiments in general needs to be autoclaved. However, in order to avoid metal contamination from the autoclave, in the trace metal clean incubations culture media are usually sterilized using a microwave, or by filtration through 0.2 μm pore-size filters.

2 Problems and Precautions

Due to the higher concentration of trace metals in atmospheric particulate matters compared to the oceanic environment, and the ubiquitousness of trace metal contamination in many laboratory and shipboard incubation areas, phytoplankton cultures and samples are easily exposed to potential contamination. Therefore, the culture bottles need to be kept sealed during the incubation experiments to minimize contamination. All the operations that require exposure of cultures or seawater to the ambient air should be carried out in the class 100 clean area, such as the processes of inoculation, filling seawater and cultures into bottles, nutrient enrichment and sampling.

Moreover, in the same incubation experiment, the culture flasks should be from similar batches, and the acid-washing processes of these containers should also be uniform to minimize the errors caused by contamination between different treatments and duplicate samples. This is mainly because the culture flasks are made of different materials that may have different capacities to adsorb/release trace metal ions, and the new ones are generally more contaminated.

During the whole experimental process, it should be always kept in mind that potential metal contamination can be ubiquitous. Thus, the personnel should take caution to prevent and minimize the contamination from each step of the experimental operations.

Last but not least, the requirement of trace metals by phytoplankton may also be affected by other environmental conditions. For example, it has been reported that the irradiance and light/dark cycle affected phytoplankton uptake and utilization of Fe and Mn; that the nitrogen source played an important role in the Fe, Mo, and Ni uptake; and that the CO2 supply may regulate Zn limitation and uptake in marine diatoms and iron availability to marine phytoplankton (Sunda 1988; Sunda and Huntsman 1995a, b, 1998, 2005; Shi et al. 2010). Therefore, in future research and new experimental designs to study trace metal and phytoplankton interactions, the condition of these other environmental parameters are also needs to be carefully considered.

References

Boyd PW, Watson AJ, Law CS et al (2000) A mesoscale phytoplankton bloom in the Polar Southern Ocean stimulated by iron fertilization. Nature 407:695–702

Bruland KW, Lohan MC (2003) Controls of trace metals in seawater. Treatise Geochem 6:23–47

Chen Y-B, Zehr JP, Mellon M (1996) Growth and nitrogen fixation of the diazotrophic filamentous nonheterocystous cyanobacterium Trichodesmium sp. IMS 101 in defined media: evidence for a circadian rhythm. J Phycol 32:916–923

Coale KH, Johnson KS, Fitzwater SE et al (1996) A massive phytoplankton bloom induced by a ecosystem-scale iron fertilization experiment in the equatorial Pacific Ocean. Nature 383:495–501

Guillard RRL (1975) Culture of phytoplankton for feeding marine invertebrates. In: Smith WL, Chanley MH (eds) Culture of marine invertebrate animals. Plenum Press, New York

Guillard RRL, Ryther JH (1962) Studies of marine planktonic diatoms. I. Cyclotella nana Hustedt and Detonula confervacea Cleve. Can J Microbiol 8:229–239

Hutchins DA, Bruland KW (1998) Iron-limited diatom growth and Si:N uptake in a coastal upwelling regime. Nature 393:561–564

Hutchins DA, Pustizzi F, Hare CE et al (2003) A shipboard natural community continuous culture system for ecologically relevant low-level nutrient enrichment experiments. Limnol Oceanogr Methods 1:82–91

Kingston HM, Greenberg RR (1984) An elemental rationing technique for assessing concentration data from a complex water system. Environ Int 10(2):153–161

Kingston HM, Barnes IL, Brady TJ et al (1978) Separation of eight transition elements from alkali and alkaline earth elements in estuarine and seawater with chelating resin and their determination by graphite furnace atomic absorption spectrometry. Anal Chem 50(14):2064–2070

Martin JH, Fitzwater SE, Gordon RM et al (1993) Iron, primary production and carbon–nitrogen flux studies during the JGOFS North Atlantic Bloom Experiment. Deep-Sea Res 40:115–134

Morel FMM, Reuter J, Anderson D et al (1979) Aquil: a chemically defined phytoplankton culture medium for trace metal studies. Limnol Oceanogr 36:27–36

Morel FMM, Reinfelder JR, Roberts SB et al (1994) Zinc and carbon co-limitation of marine phytoplankton. Nature 369:740–742

Mykytiuk AP, Russell DS, Sturgeon RE (1980) Simultaneous determination of iron, cadmium, zinc, copper, nickel, lead, and uranium in sea water by stable isotope dilution spark source mass spectrometry. Anal Chem 52(8):1281–1283

Paulson AJ (1986) Effects of flow rate and pretreatment on the extraction of trace metals from estuarine and coastal seawater by Chelex-100. Anal Chem 58(1):183–187

Price NM, Harrison GI, Hering JG et al (1989) Preparation and chemistry of the artificial algal culture medium Aquil. Biol Oceanogr 6:443–461

Rasmussen L (1981) Determination of trace metals in sea water by chelex-100 or solvent extraction techniques and atomic absorption spectrometry. Anal Chim Acta 125:117–130

Saito MA, Moffett JW, Chisholm SW, Waterbury JB (2002) Cobalt limitation and uptake in Prochlorococcus. Limnol Oceanogr 47:1629–1636

Shi D, Xu Y, Hopkinson BM, Morel FMM (2010) Effect of ocean acidification on iron availability to marine phytoplankton. Science 327:676–679

Sturgeon RE, Berman SS, Desaulniers JAH et al (1980) Comparison of methods for the determination of trace elements in seawater. Anal Chem 52(11):1585–1588

Sunda WG (1988) Trace metal interactions with marine phytoplankton. Biol Oceanogr 6:411–442

Sunda WG, Huntsman SA (1995a) Iron uptake and growth limitation in oceanic and coastal phytoplankton. Mar Chem 50:189–206

Sunda WG, Huntsman SA (1995b) Cobalt and zinc inter replacement in marine phytoplankton: biological and geochemical implications. Limnol Oceanogr 40:1404–1407

Sunda WG, Huntsman SA (1998) Interactive effects of external manganese, the toxic metals copper and zinc, and light in controlling cellular manganese and growth in a coastal diatom. Limnol Oceanogr 43:1467–1475

Sunda WG, Huntsman SA (2005) Effect of CO2 supply and demand on zinc uptake and growth limitation in a coastal diatom. Limnol Oceanogr 50:1181–1192

Sunda WG, Price N, Morel FMM (2005) Trace metal ion buffers and their use in culture studies. In: Andersen RA (ed) Algal culturing techniques. Academic Press/Elsevier, Amsterdam, pp 35–63

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Science Press and Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Feng, Y., Fu, F., Hutchins, D.A. (2021). Trace Metal Clean Culture Techniques. In: Gao, K., Hutchins, D.A., Beardall, J. (eds) Research Methods of Environmental Physiology in Aquatic Sciences. Springer, Singapore. https://doi.org/10.1007/978-981-15-5354-7_36

Download citation

DOI: https://doi.org/10.1007/978-981-15-5354-7_36

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-5353-0

Online ISBN: 978-981-15-5354-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)