Abstract

Chlorophenols (CPs) have been detected as contaminants causing groundwater and potable water pollution. Toxicity of CPs increases with the increase in the degree of chlorination. This study aimed at investigating the efficiency of Nickel coated iron (Ni/Fe) bimetal for CP dechlorination water treatment. The emphasis was on the effect of degree of chlorination, Nickel coating, and iron oxide films on possible removal mechanisms of CPs such as dechlorination and sorption, co-precipitation, physical entrapment with iron oxides (i.e. incorporation). Batch experiments were conducted with Ni/Fe and four CPs [pentachlorophenol (PCP), 2,3,4,6-tetrachlorophenol (2,3,4,6-TeCP), 2,4,6-trichlorophenol (2,4,6-TCP), 2,4-dichlorophenol (2,4-DCP)], single CP at a time, under identical, and anoxic conditions. Reactivity of CPs with Ni/Fe was PCP > 2,3,4,6-TeCP > 2,4,6-TCP ≈ 2,4-DCP with 55, 46, 34, and 30% of the respective compounds initially introduced to each system removed from the solution after 25 days. Dechlorination of PCP and 2,3,4,6-TeCP resulted in accumulation of lower CPs and trace amounts of phenol with 93–96% mass balance. The 2,4,6-TCP and 2,4-DCP concentrations decreased over time, but a noticeable increase in the corresponding dechlorination products was not observed. Furthermore, the reaction of 2,4,6-TCP and 2,4-DCP resulted in the formation of iron oxides (akaganeite, hematite, lepidocrocite, goethite, and wustite) causing Ni/Fe surface passivation. Incorporation with such iron oxides was a significant removal process of 2,4,6-TCP and 2,4-DCP by Ni/Fe. The higher pKa of 2,4,6-TCP (5.97-7.42) and 2,4-DCP (7.68) and passive oxides could lead to 2,4,6-TCP and 2,4-DCP and their degradation products towards a greater affinity for incorporation with the iron oxides. In conclusion, dechlorination potential of Ni/Fe was greater for CPs with a high number of chlorine (PCP, TeCP). The CPs with a low number of chlorine (TCP, DCP), when reacted with Ni/Fe, demonstrated a low preference for dechlorination but a greater affinity for removal by incorporation with the iron oxides.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Chlorophenols (CPs) are manufactured organochlorine compounds and contain phenol (an aromatic compound) with chlorines (between one and five). Phenol is manufactured with the addition of a hydroxy group to a carbon in benzene replacing a hydrogen. The group of CPs includes mono-CPs, di-CPs, tri-CPs, tetra-CPs, and pentachlorophenol and altogether 19 different chlorophenol isomers (ATSDR 1999).

CPs are often used as chemicals for wood preservation, disinfectants, pesticides, and herbicides (ATSDR 1999). Use of CPs is causing extensive groundwater and drinking water contamination because of improper disposal of CP containing waste, leaching from landfills containing CP-treated waste, evaporation from treated wood products, waste generated during paper production and bleaching of wood pulp with chlorine, and burning of wastes with CPs (ATSDR 1999). In addition, CPs can be dissolved in drinking water because of the chlorination of trace levels of phenolic compounds present in water, if any, during the disinfection process, as complex compounds formed if hypochlorite acid reacts with phenolic acids and phenoxy herbicides degradation products (WHO 2003).

The United States Environment Protection Agency has listed some of the CPs as priority toxic pollutants (USEPA 2019, 2018a, b). Toxicity of CPs increases with increasing degree of chlorination (Czaplicka 2004). Among all CPs, pentachlorophenol (PCP), a wood preservative and biocide (UNEP 2014), is reported as the most toxic CP (Tanjore and Viraraghavan 1994). Further, PCP is listed as a human carcinogen (IARC 2019; USEPA 2010), priority pollutant (USEPA 2019, 2018a, b; EC 2016), and toxic to aquatic organisms (UNEP 2014). The maximum contaminant level of PCP in drinking water has been imposed as 1 ppb (USEPA 2018a, b). Increased awareness about the toxicity and environmental impacts of CPs has led to banning or restricting the use of PCP worldwide (UNEP 2014). However, persistence of CPs leads to the continued ubiquitous presence of CP compounds as contaminants in surface water, groundwater, soil, and sediments. Dechlorination and removal of PCP have gained attention in contaminated groundwater treatment. However, degradation/removal of tetrachlorophenol (TeCP), trichlorophenol (TCP), and dichlorophenol (DCP) have received only little attention. Treatment and removal of CPs has become a difficult task due to their inherent characteristics such as hydrophobic nature and aromaticity linked stability.

Degradation of various CPs has been reported using different technologies in the literature. Reductive dechlorination of CPs with zero-valent iron (ZVI) has been reported by Gunawardana et al. (2018) and Kim and Carraway (2000); photocatalysis process has been tested by Lan et al. (2011), Li et al. (2011) and Ma et al. (2019); microbial degradation-assisted dechlorination was reported by Xu et al. (2018), Yang and Chen (2016); use of membrane biofilm reactors was reported by Long et al. (2018). Among the various treatment techniques available, ZVI is popular as a reactive medium for dechlorination of chlorinated contaminants because of the aspects such as economical, relatively highly reactive, and pose minimal environmental impact (Choi et al. 2008; Gunawardana et al. 2011; Kim and Carraway 2000). Use of permeable reactive barriers (PRBs) is a passive treatment and a financially feasible method for the treatment of contaminated groundwater (Henderson and Demond 2007; Fu et al. 2014; Furukawa et al. 2002). ZVI with a variety of particle sizes can be used as the reactive medium in PRB applications. However, microscale ZVI has been commonly tested and popular for dechlorination of chlorinated organic contaminants (Cheng et al. 2007; Choi et al. 2008; Chun et al. 2010; Gillham and Ohannesin 1994; Feng and Lim 2005; Kim and Carraway 2000; Klausen et al. 2003; Matheson and Tratnyek 1994; Nardo et al. 2010; Patterson et al. 2016; Phillips et al. 2010).

The reductive dechlorination process of chlorinated organics by ZVI is dependent on a number of variables. The contaminant transformation when in contact with ZVI in the aqueous medium is led by various species which act as reducing agents that are simultaneously present in the aqueous system and lead to, (1) direct contaminant reduction by the electrons released from Fe0 (primary reductant), and (2) indirect contaminant reduction by other reductants such as electrons released by adsorbed/structural FeII (secondary reductants), H/H2 and Fe3O4 and green rust (tertiary/quaternary reductants) (Hu et al. 2018). Previous studies have reported various factors that influence the reactivity, longevity, and dechlorination potential of ZVI (Gunawardana et al. 2018, 2019; Henderson and Demond 2007, 2011; Jeen 2005; Jin suk et al. 2009; Li and Benson 2010). Among the many factors, the inherent characteristics of the iron oxide phases cause a major influence on the reactivity of ZVI and dechlorination potential (Gunawardana et al. 2018, 2019). Such iron oxide phases can be the oxides initially present on the ZVI surface before reaction with CPs as well as the oxides continuously evolving during the reaction of CPs in the CP-ZVI system. In general, different iron oxide phases are present as a combination on an as-received unmodified ZVI particle surface that is formed because of the exposure of ZVI to atmospheric O2 during many stages of ZVI processing such as the production process and storage conditions (Cornell and Schwertmann 2003). In addition, when ZVI is introduced to an aqueous medium, various iron oxides and/or oxyhydroxide precipitates continuously evolve and accumulate on the ZVI surface because of Fe0 oxidation and ZVI corrosion occurring in the ZVI/H2O environment (Matheson and Tratnyek 1994). The iron oxides initially present or form during the reactions can also affect the ZVI performance over time. There are several competing mechanisms by which the iron oxides formed on ZVI can either enhance or inhibit ZVI reactivity. These oxides can act as (1) reactive or non-reactive sorption sites for contaminant molecules, (2) incorporate the contaminants and entrap within an oxide film during its formation, (3) affect the number of effective reactive sites and surface area available on ZVI for dechlorination, and (4) impede the electron transfer process, especially when these oxide phases formed on the ZVI are non-conducting passive oxide layers (Davenport et al. 2000; Gotpagar et al. 1999; Noubactep 2007; 2013; Ritter et al. 2002; Scherer et al. 1999).

The characteristics of different iron oxide phases on the ZVI surfaces (initially present and that are formed while reacting with the CPs) play a significant role on the ZVI reactivity for dechlorination (Gunawardana et al. 2018). Magnetite is known to comprise a high electrical conductivity with a low bandgap between its valence and conduction bands (0.1 eV;) Cornell and Schwertmann (2003) and lead to an enhancement in the electron transfer (Liu et al. 2006). In contrast, some FeIII oxides and oxyhydroxides claim for a higher bandgap between the valence and conduction bands (e.g. lepidocrocite 2.06 eV; goethite 2.10 eV; maghemite 2.03 eV; and wustite 2.30 eV) (Cornell and Schwertmann 2003). These oxides result in ZVI surface passivation and hinder the ability of electrons and contaminant molecules transfer process through the interfaces of solid and liquid (Farrell et al. 2000). ZVI surface passivation has been observed when non-conducting oxides (haematite, 2.20 eV; lepidocrocite, wusite) form on the ZVI surface which seems to hinder the electron transfer process from the Fe0 to CP molecules (Gunawardana et al. 2019). Therefore, the application of ZVI in PRBs for CP dechlorination is limited by various factors such as (1) decrease in degradation rates during the reaction period because of reduction in ZVI surface reactivity as a result of passive oxide phases formation, and (2) build up of degradation products during the reaction which may be competitors simultaneously present in the aqueous medium competing as co-contaminants for the same reactive sites and electrons for dechlorination (Gunawardana et al. 2018).

The application of bimetals synthesized with the combination of another secondary metal such as Ni, Pd, or Pt [comprise of a high reduction potential than ZVI; ZVI, −0.44 V; Ni, −0.257 V; Pd, 0.915 V; or Pt, 1.188 V; Arning and Minteer (2007)] on the ZVI surface has been tested to mitigate the limitations to the use of ZVI to remove chlorinated organic compounds (Choi et al. 2008; Gunawardana et al. 2019; Kim and Carraway 2000; Ko et al. 2007; Shih et al. 2011; Wang et al. 2008; Zhang et al. 2006). Enhanced hydrodechlorination of chlorinated phenols was reported by bimetals (Choi et al. 2008; Ko et al. 2007; Liu et al. 2001; Xu et al. 2012; Zhou et al. 2010) and aliphatic compounds (Feng and Lim 2005; Schrick et al. 2002). On the other hand, some studies did not observe any PCP degradation when using unmodified ZVI (Hou et al. 2009; Morales et al. 2002), while Pd/Fe, Pd/Mg (Morales et al. 2002), and Ni/Fe (Cheng et al. 2010; Zhang et al. 2006) partially dechlorinated PCP with build up of lower degree CPs and phenol. The nanoscale bimetals (e.g. Pd/Fe) showed high reactivity and transformed 4-CP, 24-DCP, and 246-TCP to phenol (Zhou et al. 2010). In contrast, Kim and Carraway (2000) reported a significant reduction in PCP dechlorination when using bimetals such as Pd/Fe, Pt/Fe, Ni/Fe, Cu/Fe compared to unmodified ZVI. The increased reactivity of bimetals could be attributed to the (1) secondary metal acting as a catalyst and enhancing the CP hydrogenation reaction and (2) formation of galvanic cells and enhances the electron transfer process (Tian et al. 2009). The cost of Pd or Pt is high, thus limiting the field application potential. Hence, Ni as an effective and economical alternative secondary metal is preferable for actual field application of bimetals as the reactive medium in PRB systems (Kim and Carraway 2000).

During the reactions, dechlorination is the preferred mechanism. However, other than the dechlorination process, incorporation of CP molecules with the oxides during their evolution throughout the reaction claims a crucial role in the CPs removal from water by bimetal/water systems (Gunawardana et al. 2018, 2019; Noubactep 2008). Interestingly, CPs incorporation, that is sorption, co-precipitation, and/or physical entrapment, with the iron oxide phases occurs concurrently with the dechlorination (Gunawardana et al. 2019). The incorporated CP molecules with the oxide layers limit the availability of CPs in the aqueous phase in direct contact with the bimetals for dechlorination, thus such incorporated CPs cannot be further degraded. Further, the incorporation process could be influenced by the physical–chemical properties of CPs and affect the efficiency of bimetals for the CPs dechlorination process. Increased amounts of ligand sorption on to iron oxides have been observed with the increase in pKa values of the ligand compounds (Song et al. 2008). Thus, it can be hypothesized that the affinity for incorporation of CPs with the oxide phases will increase with the decrease in the degree of chlorination of CPs; pKa of 2,4-DCP, 2,4,6-TCP, 2,3,4,6 TeCP, and PCP are 7.68, 5.97–7.42, 5.22–5.62, 4.60–5.25, respectively (Olaniran and Igbinosa 2011; Shiu et al. 1994). In addition, the changes in the morphology of the ZVI or bimetal surface due to the formation of various iron oxide phases over time under different conditions can change the surface properties/reactivity of iron and dramatically affect the CP removal processes from solution (Gunawardana et al. 2018, 2019).

The degradation of CPs using ZVI, other metals or bimetals and a comparison between CP degradation efficiencies have been studied by previous researchers (Choi et al. 2008; Kim and Carraway 2000; Ko et al. 2007; Liu et al. 2001; Xu et al. 2012). Previous studies have concentrated on comparing the reactivity of different metals or bimetals (with Pd, Ni as the catalyst) for CP degradation. Although these studies had reported that the ZVI materials used were obtained from different suppliers, comprehensive studies have not been carried out to identify the potential role of ZVI surface characteristics (e.g. oxide phases) on the reactivity for CP dechlorination.

Further, PCP sorption using one type of ZVI has been quantified (Kim and Carraway 2000) as well as sorption with bimetals (Ni/Fe, Pd/Fe, Pt/Fe, Cu/Fe, Mg/Ag, Pd/Mg) (Kim and Carraway 2000; Patel and Suresh 2006; 2007). Nonetheless, there are no comprehensive studies reported in the literature which uses ZVI-based bimetals to investigate incorporation levels of different CPs with different degree of chlorination. The sorption onto iron oxides could be influenced by the physical–chemical properties of CPs, which could lead to concerns with CPs dechlorination efficiency by ZVI and bimetals. Previous research also provides evidence that ligands with a greater pKa value resulted in increased sorption onto iron oxides such as ferrihydrite (Song et al. 2008). Based on this concept, it may be expected that the tendency for incorporation will increase as the degree of chlorination decreases, given that the pKa of 2,4-DCP, 2,4,6-TCP, 2,3,4,6 TeCP and PCP are 7.68, 5.97–7.42, 5.22–5.62, 4.60–5.25, respectively. Consequently, the possible relationship between iron oxide formation, CP dechlorination and/or incorporation as well as the effect of degree of chlorination on CPs incorporation/dechlorination processes when using bimetals remains uncertain and requires proper studies to understand the underlying mechanisms.

Therefore, in view of the gaps in the literature, this study aimed at investigating the effectiveness and efficiency of bimetallic particles for CP dechlorination and the effect of degree of chlorination and iron oxide phases on CPs incorporation and dechlorination when using Ni/Fe bimetallic system. Four model contaminants (PCP, 2,3,4,6-TeCP, 2,4,6-TCP, 2,4-DCP) were chosen for the study. These CPs were selected as they are common degradation products of PCP dechlorination and due to the toxic concerns of these CPs in the environment (ATSDR 1999; Tanjore and Viraraghavan 1994). Both dechlorination and incorporation processes of selected CPs were examined using Ni/Fe bimetal. The present study also focused on the distinct role CP removal mechanisms (dechlorination and incorporation) in removing CPs from the aqueous phase as a function of the different variables considered during the present study.

2 Materials and Methods

2.1 Materials

High purity chemicals such as PCP powder (ACS grade, 98%), 2,3,4,6-tetrachlorophenol (2,3,4,6-TeCP, Supelco, 98%), 2,4,6-trichlorophenol (2,4,6-TCP, Aldrich, 98%), 2,4-dichlorophenol (2,4-DCP, Aldrich, 99%), analytical standards of PCP, phenol, chlorophenol isomers in methanol and nickel sulphate (NiSO4.6H2O, >98%) were purchased from Sigma-Aldrich. Analytical grade solvents (ethyl acetate, acetone), sulphuric acid (H2SO4), and hydrochloric acid (HCl) were obtained from Ajax Finechem. A stock solution (5000 mg/L) of individual CPs, i.e. PCP, 2,3,4,6-TeCP, 2,4,6-TCP, and 2,4-DCP was prepared with the use of ethyl acetate as the solvent. Deionized (DI) water with resistivity of 18.20 MΩcm was prepared using a Millipore-Q system and used for all the experiments. For the preparation of deoxygenated DI water (DW), the DI water was first degassed at 80 °C and 100 kPa for one hour using a vacuum pump and then sparged with O2-free N2 gas for half an hour (dissolved oxygen level <0.2 mg/L).

The bimetal particles, i.e. nickel-coated ZVI (Ni/Fe) were synthesized as explained by.Kim and Carraway (2000) The ZVI used for the preparation of Ni/Fe particles was electrolytic iron powder (<100 mesh, North American Höganäs). Before using for Ni/Fe synthesis, the ZVI particles were pre-treated with H2SO4 (Liu et al. 2006). For the acid pre-treatment, as-received ZVI particles (500 g) were added to 1 N H2SO4 solution (1.5 L), the mixture was agitated for 30 minutes at 100 rpm and room temperature using a rotary shaker, and rinsed with DW. Post-rinsing of the particles with DW, they were dried under continuous purging of N2 gas for 4 hours at 100 °C and then stored under N2 gas environments until use for the synthesis of Ni/Fe bimetals. The Ni/Fe particles were prepared using a reductive adsorption method (Kim and Carraway 2000). A reaction solution with Ni was prepared by adding a known volume of a Ni stock solution (2 ml of 2.4% Ni solution prepared with NiSO4.6H2O and 10% H2SO4) to 200 ml of DW water (pH of the prepared solution = 1.60). Then, 100.0 (±0.01) g of acid pre-treated ZVI was added to the solution (Kim and Carraway 2000). The mixture containing the Ni and ZVI was placed on a rotary shaker and agitated for one hour at 100 rpm and followed by rinsing with DW and acetone, air-dried at room temperature, and stored under O2-free N2 gas to use for the experiments. The Ni2+ solution was analysed for total Ni concentration pre- and post-exposure to acid-washed ZVI using the atomic absorption spectroscopy (AAS). The AAS results showed 92% Ni removal from the solution after Ni/Fe synthesis. Hence, based on the AAS analysis, the content of Ni deposited on the Ni/Fe bimetallic particles was calculated to be 442 ppm (mg of Ni per kg of Fe).

2.2 Experimental Procedure

Batch experiments were performed using Wheaton amber vials (30 ml) under identical experimental settings and anoxic conditions over the 25 day reaction period. Individual stock solution of PCP, 2,3,4,6-TeCP, 2,4,6-TCP, and 2,4-DCP (5000 mg/L) was prepared using ethyl acetate. Each CP was added and tested as a single compound in each vial. The initial concentration of each CP introduced to the batch reactors was 5 mg/L. This was equivalent to 19 μM of PCP, 22 μM of 2,3,4,6-TeCP, 25 μM of 2,4,6-TCP, and 31 μM of 2,4-DCP being initially introduced and available in each system before reaction with Ni/Fe bimetal. In each batch reactor, 1.00 (±0. 01) g of Ni/Fe and 10 ml DW were added and 10 μl of the respective CP stock solution was spiked. The high purity O2-free N2 gas was used as the headspace gas and the batch reactors were continuously purged with high purity O2-free N2 gas during the addition of deoxygenated water, CP stock solution, and during setting up the batch experiments to keep the reactors under anoxic conditions. The batch reactors were immediately sealed with aluminium caps with PTFE/silicone septa after the addition of respective CP solution and continuously agitated at 100 rpm on a rotary shaker at 23 (±1) °C until each sampling time. The control vials were prepared in a similar procedure without the addition of Ni/Fe bimetal particles. Duplicate experiments were conducted. At every sampling time over 25 days reaction duration, the pH of the reaction solution was monitored. At each sampling time, four reactors with Ni/Fe and two control vials without Ni/Fe were used for analyses.

The remaining concentration of parent CPs and the corresponding degradation products (Total CP concentration) as well as the aqueous concentrations of the parent CPs (dissolved CP concentration) in each reactor was determined at each sampling time using separate vials. A liquid–liquid extraction method with acid modification was used to extract the CPs from the Ni/Fe solids and the reaction solutions (Gunawardana et al. 2018; Kim and Carraway 2000). The total concentrations, which is the dissolved plus incorporated concentration of parent CPs and its degradation products, were determined after extracting the Ni/Fe bimetal/water mixture with ethyl acetate and concentrated HCl. In order to measure the concentration of total CP and degradation products, ethyl acetate (5 ml) was added to each batch reactor (containing the reaction solution and Ni/Fe particles). The mixture was continuously agitated for 30 minutes on a rotary shaker at 100 rpm, and then 1 ml concentrated HCl was added and the mixture was agitated for another ten minutes (Kim and Carraway 2000). The aqueous concentration (i.e. dissolved) of the parent CPs was determined after extracting the filtered reaction solutions with ethyl acetate and concentrated HCl. For the quantification of dissolved CPs in the solution, aqueous solution (9 ml) filtered by 0.2 μm regenerated cellulose (RC) membrane filters was used to along with the liquid–liquid extraction procedure using ethyl acetate/HCl as explained above for the quantification of total CP concentrations. After the liquid–liquid extraction procedure, 1.5 ml of the ethyl acetate layer was extracted, filtered (0.2 μm RC) and then stored in GC/MS autosampler vials for CPs and degradation product analysis. The solid contents (Ni/Fe particles) from the batch reactors sacrificed for quantification of the dissolved CP concentration were kept and utilized for the characterization of the iron oxide phases formed and present during the reaction period using Raman analysis.

2.3 Analysis

Quantification of CPs and its degradation products was carried out using the gas chromatography–mass spectrometer (Shimadzu model GCMS-QP2010S, Japan) (Gunawardana et al. 2018, 2019). A capillary column (ZEBRON ZB5-msi) with the dimensions of 30 m L × 0.25 mm ID × 0.25 μm thickness was used for the analysis. Selected ion monitoring (SIM) method was used with split mode injection of two μl of the sample at a ratio of 80:1 for separation and quantification of parent CP and degradation products. The carrier gas was high purity helium (1 ml/min), injection temperature 250 °C, column temperature program: 70 °C for 2 minutes, ramped at 5 °C minute−1 to 200 °C and held for 2 minutes, and ramped at 10 °C min−1 to 300 °C, and held for 5 minutes. A gas chromatograph (GC—SRI 8610C) with a column (HayeSep Q 80/100, Alltech, 6′ × 1/8″× 0.085″ SS) coupled with a thermal conductivity detector (TCD) was used for quantification of the amount of hydrogen gas accumulated in the headspace of batch reactors during the reaction period. The operating conditions of the GC/TCD were: column temperature—24 °C; carrier gas—N2 with a 10 ml/min flow rate.

2.4 Solid-Phase Characterization

The specific surface area of the unmodified ZVI, acid-washed ZVI, and Ni/Fe bimetallic particles were determined using the Brunauer–Emmett–Teller (BET) N2 method and a Micromeritic Tristar 3000 (USA). The morphology, characteristics, and elemental information on selected regions of the ZVI and Ni/Fe surfaces and the presence of Ni on the Ni/Fe particle surface were obtained using FEI Quanta 200 F environmental scanning electron microscope (ESEM) coupled with a SiLi (lithium drifted) energy dispersive spectroscopy (EDS) (USA). A back-scattered detector was used with a 20 kV beam potential to collect the images.

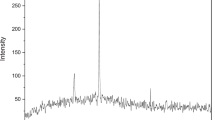

Raman spectroscopy (Renishaw Raman system 1000 spectrometer, Australia) was used to identify (1) the specific iron oxides present on the Ni/Fe particles prior to exposure to CP solutions and (2) the specific iron oxides formed on the Ni/Fe particles post-exposure to CP solutions. Eight oxide phases typically present on iron surfaces (akaganeite, maghemite, haematite, magnetite, lepidocrocite, goethite, feroxyhyte, ferrihydrite) were considered, synthesized as the reference iron oxides (Cornell and Schwertmann 2003), and characterized using Raman spectroscopy (Gunawardana et al. 2018). A natural wustite mineral specimen was characterized by EDS and Raman analysis and confirmed with the literature (Nadoll and Mauk 2011). During the Raman analysis, of all Ni/Fe samples reacted with CPs, it was observed that the spectra of different iron oxides present overlapped extensively, which indicated the presence of a mixture of oxide phases. The presence of a mixture of oxide phases made it complex for clear identification of individual oxide phases in the observed spectra. Therefore, multivariate curve resolution with alternating least squares (MCR-ALS) within MATLAB (Mathworks®) was used for quantification of specific iron oxides (Jaumot et al. 2005). The green rust oxides were excluded and not considered for the group of reference spectra, as they are reported as unstable and subject to transformation to other oxides under the conditions used in the present study.

The effect of Ni/Fe treatment on the concentration of different CPs degraded after 25 days reaction period was compared using statistical analysis (one-way and two-way analysis of variance) and SPSS statistical software (IBM SPSS Statistics version 20.0.0 [SPSS Inc., USA]). The effect of Ni/Fe treatment on the amount of CP degraded, levels of extractable CPs incorporated as well as H2 gas accumulated after 25 days reaction were compared. The differences were considered as significant at 95% confidence level.

3 Results and Discussion

3.1 Dechlorination of Chlorophenols Using Ni/Fe

The degradation of four CPs (PCP, 2,3,4,6-TeCP, 2,4,6-TCP, 2,4-DCP) using Ni/Fe and the subsequent formation of daughter compounds is presented in Fig. 12.1. After 25-day reaction period, the CPs reactivity with Ni/Fe in the order of highest to lowest was: PCP > 2,3,4,6-TeCP > 2,4,6-TCP ≈ 2,4-DCP (Fig. 12.1). After 25 days reaction, approximately 55% of PCP, 46% of 2,3,4,6-TeCP, 34% of 2,4,6-TCP, and 30% of 2,4-DCP, which was initially introduced to each system, were removed from the aqueous phase (Fig. 12.1). Among the four CPs tested, PCP showed a significantly higher amount of dechlorination (p < 0.05), whereas 2,4,6-TCP showed a significantly lower amount of dechlorination (p < 0.05) after 25 days of reaction with Ni/Fe.

a Ni/Fe bimetal degradation of Pentachlorophenol

, 2,3,4,6-tetrachlorophenol

, 2,3,4,6-tetrachlorophenol

, 2,4,6-trichlorophenol

, 2,4,6-trichlorophenol

and 2,4-dichlorophenol

and 2,4-dichlorophenol

; b Ni/Fe bimetal degradation of pentachlorophenol

; b Ni/Fe bimetal degradation of pentachlorophenol

and formation of TeCPs

and formation of TeCPs

, TCPs

, TCPs

, DCPs

, DCPs

, MCPs

, MCPs

, and phenol

, and phenol

; c Ni/Fe bimetal degradation of 2,3,4,6-tetrachlorophenol

; c Ni/Fe bimetal degradation of 2,3,4,6-tetrachlorophenol

and formation of TCPs

and formation of TCPs

, DCPs

, DCPs

, MCPs

, MCPs

, and phenol

, and phenol

; d Ni/Fe bimetal degradation of 2,4,6-trichlorophenol

; d Ni/Fe bimetal degradation of 2,4,6-trichlorophenol

and formation of DCPs

and formation of DCPs

and MCPs

and MCPs

, and e Ni/Fe bimetal degradation of 2,4-dichlorophenol

, and e Ni/Fe bimetal degradation of 2,4-dichlorophenol

and formation of MCPs

and formation of MCPs

; control

; control

; mass balance

; mass balance

. Error bars indicate ± one standard deviation. Total TeCPs were the sum of all the TeCPs measured, total TCPs were the sum of all the TCPs measured, total DCPs were the sum of all the DCPs measured and total MCPs were the sum of all the MCPs measured

. Error bars indicate ± one standard deviation. Total TeCPs were the sum of all the TeCPs measured, total TCPs were the sum of all the TCPs measured, total DCPs were the sum of all the DCPs measured and total MCPs were the sum of all the MCPs measured

Dechlorination of PCP and 2,3,4,6-TeCP using Ni/Fe resulted in accumulation of CPs with a lower degree of chlorination, with trace amounts of phenol being detected (Fig. 12.1b, c).

The CPs with a lower degree of chlorination continuously forming and accumulating in the system during the reaction of PCP or TeCP with Ni/Fe bimetal (Fig. 12.1b, c) can create a competition for the same electrons and reactive sites on the Ni/Fe and ZVI surfaces for dechlorination. Hence, the formation and gradual accumulation of CPs with a lower degree of chlorination may create adverse impacts on the rate of dechlorination of PCP or TeCP by Ni/Fe. Such a competitive effect between the parent CP and daughter CPs (with a lower degree of chlorination) can lead to partial dechlorination of PCP or TeCP. On the other hand, when 2,4,6-TCP was reacted with Ni/Fe, small concentrations of DCPs and monochlorophenols (MCPs) were observed as the main degradation products (Fig. 12.1d). Degradation of 2,4-DCP using Ni/Fe resulted in the accumulation of minute concentrations of MCPs as the end product (Fig. 12.1e).

The mass balance recoveries obtained for PCP and 2,3,4,6-TeCP with Ni/Fe bimetallic system were within 93–96% of the amount of respective CP initially added to the solution (Fig. 12.1). The remaining two CPs (2,4,6-TCP and 2,4-DCP) demonstrated high mass balance recoveries (91–97%) during the initial reaction period (Fig. 12.1). The 2,4,6-TCP and 2,4-DCP concentrations decreased over the reaction time, and however, a noticeable increase in the corresponding dechlorination products was not observed resulting in a gradual decrease of mass balance of these two CPs over time (Fig. 12.1). Despite the greater mass balance recoveries demonstrated by 2,4,6-TCP and 2,4-DCP at the beginning of the reaction period, these mass recoveries decreased considerably to between 70 and 80% during the later stages of the reaction period (Fig. 12.1d, e). As such, it could be suggested that CPs incorporation must have been a significant process of removal of 2,4,6-TCP and 2,4-DCP from solution when using Ni/Fe. The incomplete recovery of the parent CPs with a lower degree of chlorination and/or their degradation products could possibly be attributed to the formation of iron oxides with different characteristics, strong incorporation of CP molecules with the oxides formed during the reaction and lack of extraction/recovery of CPs and the degradation products during the extraction process (these aspects are elaborated in the subsequent sections).

The CPs dechlorination reaction with Ni/Fe bimetal demonstrated pseudo-first-order behaviour with Ct = C0e−kt, where C0 is the initial CP concentration (μM), Ct is the CP concentrations at reaction time t (μM), and k is the first-order observed reaction rate constant (day−1). The observed reaction rate constants were 0.0594 day−1, 0.0275 day−1, 0.0180 day−1, and 0.0170 day−1 for PCP, 2,3,4,6-TeCP, 2,4,6-TCP and 2,4-DCP, respectively. The trend of the observed rate constants (highest to lowest) further supports the observed reactivity of the CPs with Ni/Fe (PCP > 2,3,4,6-TeCP > 2,4,6-TCP > ≈ 2,4-DCP). The behaviour and observed rate constants are consistent with previous research reports where the batch experiment results proved first-order behaviour when chlorinated phenols were degraded with bimetallic systems (Choi et al. 2008; Kim and Carraway 2000; Ko et al. 2007; Liu et al. 2001). The general trend of CP reaction rates with Ni/Fe bimetal (1) did not comply with the data presented by Ko et al. (2007) who reported increased reaction rates using Ni/Fe with the decreased degree of chlorination and (2) agree with Patel and Suresh (2006) findings, who reported a decrease in reaction rates with the decreased degree of chlorination using Mg/Ag bimetal. This discrepancy between the reaction rates of this study and previous studies could be due to the differences in, (1) experimental conditions, (2) ZVI characteristics, (3) type/quantity of catalyst used, and (4) method of reaction rates estimation. The surface area normalized dechlorination reaction rate constants (KSA) of CPs in water-Ni/Fe bimetal system was calculated based on the BET specific surface area of Ni/Fe and found to be 0.02 × 10−2 Lm−2 day−1 for PCP and 0.01 × 10−2 Lm−2 day−1 for 2,3,4,6-TeCP, 2,4,6-TCP and 2,4-DCP. It was not possible to estimate the area of only the reactive sites on the Ni/Fe surface; the measured BET specific surface area of Ni/Fe metal surface is an absolute measurement representing the total area of Ni/Fe metal surface. Hence, the reactivity of Ni/Fe bimetal for CP dechlorination could be assessed only based on the observed dechlorination reaction rates.

It was anticipated that the use of Ni as a catalyst would result in enhanced CPs dechlorination by Ni/Fe bimetal. However, the use of Ni/Fe bimetal resulted in only partial dechlorination of CPs tested. Partial dechlorination of CPs observed with Ni/Fe could be a result of the formation of a permanent Ni coating as a thin film on the ZVI surface during Ni/Fe preparation, which could cover the ZVI reactive sites thus restricting the electron and CP molecules transfer process for effective dechlorination. These aspects are discussed under Sect. 12.3.2-Ni/Fe characterization.

3.2 Characterization of ZVI and Ni/Fe Material

The analysis of specific surface area of various materials showed that the specific surface area of unmodified ZVI, acid pre-treated ZVI, and Ni/Fe were 0.212 ± 0.002, 0.910 ± 0.003, 2.696 ± 0.011 m2/g, respectively. An increase in the ZVI surface area after each modification indicates the possibility of variations and changes of the composition or morphology between the materials after respective modifications, which could have influenced the CP dechlorination potential (Cwiertny et al. 2007).

The surface morphology and elemental distribution on the ZVI, Ni/Fe surfaces and the presence and distribution of Ni on the bimetal particles were obtained using the ESEM-EDS analysis (Fig. 12.2). The EDS analysis showed Fe, O, and C as the main elements on the unmodified and acid pre-treated ZVI surfaces (Fig. 12.2a, b). The EDS scans done in many small regions on the surface of the Ni/Fe bimetallic particles did not show any evidence of scattered deposition of Ni over the ZVI surfaces. An example of an EDS scans done on small areas on the Ni/Fe particles are shown in Fig. 12.2c [Fig. 12.2c; (i), (ii), and (iii) areas marked in red)]. However, the EDS scans done on a wide area on the Ni/Fe surface demonstrated the presence of deposited Ni [Fig. 12.2c (iv) area marked in red]. Prior to using for the preparation of Ni/Fe bimetallic particles, the acid-washed ZVI surface was initially mainly covered with magnetite. Due to magnetite’s high conductivity, Ni0 could be rapidly deposited as a thin layer on the surface of the acid pre-treated ZVI particles during the synthesis of Ni/Fe. The assumption underlying this hypothesis is that due to the high conductivity of magnetite, the reduction of Ni2+ to Ni0 occurs instantaneously and rapidly on a magnetite surface. Accordingly, based on the observations of this study, we hypothesize that during the Ni/Fe synthesis and reductive Ni deposition process (Fe0 + Ni2+ → Ni0 + Fe2+), Ni has deposited on the ZVI, not as clusters/scattered deposition of Ni particles scattered/dispersed in parts of the ZVI surface but as a thin Ni film over the ZVI surface. A schematic diagram illustrating the behaviour of the ZVI and oxide phases during the acid washing and Ni/Fe preparation is presented as Fig. 12.3.

The oxides present on the Ni/Fe bimetallic surfaces pre- and post-reaction with CPs were determined by Raman spectroscopy and MCR-ALS analysis. Typical Raman patterns of the reference oxide phases considered during the study are shown in Fig. 12.4. The typical Raman spectra of unmodified ZVI, acid pre-treated ZVI, unreacted Ni/Fe bimetal, and Ni/Fe bimetal after 25 days reaction with the four CPs are shown in Fig. 12.5.

The relative amounts of oxides present on the Ni/Fe (estimated by MCR-ALS analysis) before and after reaction with CPs are presented in Table 12.1. Prior to reaction with CPs, only magnetite was present on the Ni/Fe surface. However, during the reaction of each CP with Ni/Fe, a decrease in the relative amount of magnetite was observed (Table 12.1). In contrast, while magnetite amount was decreasing, several other iron oxides (akaganeite, haematite, lepidocrocite, wustite, goethite, ferrihydrite) were detected on the Ni/Fe surface during the 25 days reaction period with each CP tested (Table 12.1).

The changes in the iron surface morphology due to the formation of various iron oxide phases over time under different conditions can change the surface properties/reactivity of iron and dramatically affect the CP removal processes from solution (Gunawardana et al. 2011, 2018). In addition, the reactivity of the Ni/Fe bimetallic iron surfaces could be affected by the electric conductivity of oxide phases present and formed on the Ni/Fe and iron surfaces.

Findings showed that the dechlorination of CPs could be limited by the formation of akaganeite, haematite, goethite, lepidocrocite, and wustite (Table 12.1) as they have low conductivities at room temperature compared to magnetite (Cornell and Schwertmann 2003). The passive oxides formed seemed to decrease the number of redox reactive sites on the Ni/Fe surface and impede the electron transfer and transport of CP molecules. Such phenomenon could hinder the CP dechlorination leading to partial dechlorination and accumulation of lower degree CPs (Fig. 12.1), and possibly increased the CPs incorporation process (especially, 2,4,6-TCP and 2,4-DCP) with the iron oxides.

The relative amounts of passive oxide phases detected on the Ni/Fe surface showed a progressive growth over the reaction duration, especially when 2,4,6-TCP or 2,4-DCP was introduced as the testing CP in the reactors (Table 12.1). This progressive growth of passive oxides as well as their ageing could lead to further entrapment of the adsorbed CPs in the oxides/oxyhydroxides structures and reduce desorption of such CP molecules to the aqueous phase. Lack of availability of CPs in the aqueous phase could further limit the dechlorination of CPs by Ni/Fe.

CPs with higher pKa values (2,4-DCP: pKa of 7.68 and 2,4,6-TCP: pKa of 5.97–7.42) seemed to have a higher tendency for incorporation with the oxides hindering the dechlorination process. Furthermore, when 2,4,6-TCP and 2,4-DCP were reacting with Ni/Fe, detection of lower amounts of magnetite and greater amounts of passive oxides (akaganeite, haematite, lepidocrocite, wustite, goethite, ferrihydrite), compared to the amounts of respective oxides detected with PCP and 2,3,4,6-TeCP, provides evidence of decreased reactivity of 2,4,6-TCP and 2,4-DCP observed with the Ni/Fe bimetal. During the reaction of 2,4,6-TCP and 2,4-DCP with Ni/Fe, various passivating oxides started accumulating on the ZVI surface immediately during the initial reaction period of 1 day when in contact with Ni/Fe. Furthermore, Raman analysis showed continuous accumulation of such passivating oxides on the Ni/Fe surface throughout the 25-day reaction period of 2,4,6-TCP and 2,4-DCP with Ni/Fe. This progressive growth of passive oxides as well as their ageing could lead to strong entrapment of the adsorbed CP molecules with the oxides/oxyhydroxides structures and reduce the extraction/desorption potential of such CPs during the chemical extraction process resulting in poor mass balance recoveries. Based on the literature, FeII oxides have a greater solubility compared to that of FeIII oxides and magnetite has a greater solubility compared to Fe(OH)2 (Cornell and Schwertmann 2003). Thus, the incorporated CP and/or degradation products with the passive iron oxides seemed to be difficult to extract using HCl and ethyl acetate leading to poor CP mass balance (Fig. 12.1).

On the other hand, during the reaction of PCP and 2,3,4,6-TeCP with Ni/Fe bimetal, magnetite was the dominant oxide phase at the beginning and throughout the reaction period although some passive oxides started accumulating on the Ni/Fe towards the later part of the 25 days reaction period (Table 12.1). Presence of low levels of passivating oxides on the Ni/Fe surface during the reaction of PCP and 2,3,4,6-TeCP could potentially result in (1) lower levels of incorporation of the degradation products (i.e. CPs with lower degree of chlorination) with such oxide phases and (2) greater desorption and extraction efficiency of such lower degree CP degradation products (2,4,6-TCP and 2,4-DCP) and higher mass balance.

Nonetheless, the exact reasons for the variations observed in the formation/accumulation of different oxide phases during the reaction of Ni/Fe with various CPs of different degree of chlorination (i.e. PCP, 2,3,4,6-TeCP, 2,4,6-TCP, and 2,4-DCP) could not be explained by the findings of the present study. Therefore, specific studies need to be conducted to understand the behaviour and surface chemistry of ZVI and Ni/Fe bimetallic reactions when reacting with the CPs with different degree of chlorination.

3.3 Accumulation of Hydrogen Gas in Batch Reactors

Hydrogen gas accumulated in batch reactors was measured at each sampling time. The data of hydrogen gas formed during the reaction of the four CPs (PCP, 2,3,4,6-TeCP, 2,4,6-TCP, and 2,4-DCP) with Ni/Fe bimetal is presented in Fig. 12.6a. The hydrogen gas formation was observed with all the treatments, although the total hydrogen pressure remained <0.5 atm even after 25 days of reaction.

In a Ni/Fe bimetal system, Ni can perform as a catalyst to enhance the formation of atomic hydrogen or a metal hydride phase on the iron surface. Hence, Ni can potentially enhance the CP degradation via hydrodechlorination (Ko et al. 2007; Tian et al. 2009). Also, the catalytic activity of Ni is known to enhance the H2 gas production as a result of enhanced ZVI corrosion and encourage H2 to react as a reductant (Feng and Lim 2005; Matheson and Tratnyek 1994). However, in this study, low hydrogen gas accumulation (Fig. 12.6a) and partial CP dechlorination were observed (Fig. 12.1). The lower hydrogen gas formation with Ni/Fe is indicative of (1) lower reactivity of Ni/Fe, (2) inhibition of production of H2 gas due to the deposition of Ni possibly as a thin layer concealing the reactive sites on the ZVI surface, or (3) formation of passive oxides blocking the ZVI reactive surfaces. Less hydrogen gas formation with the Ni/Fe (Fig. 12.6) is consistent with the lower/partial CP degradation observed using this system (Fig. 12.1).

The rate of hydrogen gas formation may vary depending on the characteristics of the ZVI surface as well as the electron acceptors present in the systems. However, the results showed that the rate of hydrogen gas accumulation with each CP was approximately the same with some fluctuations observed with 2,4-DCP and seems to be independent of the type of CP present in the system (Fig. 12.6).

The solution pH was measured at each sampling time with Ni/Fe and each CPs and the data is presented in Fig. 12.6b. In general, an increase in the solution pH was observed over the reaction duration. An increase in pH from 5.6 or 6.1 to 6.1 or 7.1 was noted during the initial reaction period (1–2 days) followed by a pH decrease over the remaining duration of the experiment. After 25 days of reaction, the pH levels between 6.3 and 6.9 were observed with all treatments (Fig. 12.6b). An increase in solution pH occurs due to a consumption of protons during CP dechlorination and production of hydroxide ions during metal corrosion. In addition, some studies attributed the change in solution pH to the accumulation of daughter compounds with different acid dissociation constants during the degradation of parent CP compound using zero-valent metals (Kim 1999; Liu et al. 2001). Previous studies also have reported an increase in solution pH during interaction of CPs with ZVI and/or ZVI-based bimetals (Choi et al. 2008; Kim and Carraway 2000; Liu et al. 2001; Wei et al. 2006).

3.4 Incorporation of Chlorophenols onto Ni/Fe Solid Phase and Iron Oxides

Removal of the tested CPs from solution with Ni/Fe occurred due to concurrent dechlorination and incorporation. The amount of extractable CP incorporated per unit mass of Ni/Fe (Cs, μmole CP/g of Ni/Fe) was calculated in each system as follows: CS = [(CT − CW) *VW)]/MNi/Fe, where CT = total system CP concentration [μmole/l]; CW = aqueous phase CP concentration [μmole/l]; VW = volume of aqueous solution [l]; and MNi/Fe = initial amount of Ni/Fe used in the batch reactor [g]. The amounts of extractable CP incorporated in the Ni/Fe solid phase are presented in Fig. 12.7.

A rapid increment in the amount of incorporated CPs was observed during the initial reaction period up to 5 days (Fig. 12.7), which could be due to sorption of CPs on to the reactive and/or non-reactive sites of Ni/Fe particles and/or physical entrapment/co-precipitation of CPs with the iron oxides (Noubactep 2009; Noubactep 2008). In addition, the compounds present in the Ni/Fe bimetallic-water system as well as the iron oxide phases forming on the Ni/Fe surface subject to continuous change, thus could affect the amount of CPs incorporated with the oxide phases during the reaction period. Approximately constant levels of incorporated and extracted CP concentration demonstrated by some CPs at the later stages of the reaction (Fig. 12.7) could be attributed to strong incorporation of such CPs with the oxide phases formed during the reaction and lack of recovery of these incorporated CP molecules.

Noticeable amounts of lower degree CPs and/or phenol would be expected to be detected in the Ni/Fe systems as end products when dechlorination is the principal process. However, as illustrated in Fig. 12.1, when 2,4,6-TCP and 2,4-DCP reacted with Ni/Fe, only minute levels of CPs were detected as end products in the respective systems. Consequently, incorporation must have been a significant removal process of 2,4,6-TCP and 2,4-DCP by Ni/Fe from solution. Nevertheless, the detected minute levels of CPs as end products in these systems provide evidence of dechlorination; however, a majority of these end products may have also been incorporated with the iron oxides during the reaction.

This study does not facilitate the identification of the specific incorporation process such as sorption, co-precipitation, or physical entrapment with the oxide phases. However, the findings of this research provide evidence of a decrease in the mass recovery with the decrease in the degree of chlorination of CPs (Fig. 12.1). This is expected based on the theory of decrease in sorption affinity of CPs for an iron oxide with the degree of chlorination increases (as illustrated in Fig. 12.1). The fact that the lower degree CPs had the lowest recovery during extraction supports the possibility that oxide phases remaining after extraction strongly retain some of the CPs.

4 Conclusions

The effect of degree of chlorination on dechlorination and incorporation of four CPs (PCP, 2,3,4,6-TeCP, 2,4,6-TCP, and 2,4-DCP) was investigated using Ni/Fe bimetallic iron particles. Ni/Fe treatment resulted in partial CPs dechlorination and accumulation of lower CPs. In general, CPs with a higher degree of chlorination demonstrated greater CP dechlorination. The reactivity of CPs with Ni/Fe bimetallic system followed the sequence of PCP > 2,3,4,6-TeCP > 2,4,6-TCP ≈ 2,4-DCP over the 25 days reaction. As the degree of chlorination of the CPs decreased, the CPs showed an increased affinity for incorporation (sorption, co-precipitation and/or physical entrapment of CP and/or degradation products) with the iron oxides, incomplete mass recovery of CPs, and decreased dechlorination. In particular, 2,4,6-TCP and 2,4-DCP demonstrated a greater tendency for incorporation with the iron oxides. This effect of 2,4,6-TCP and 2,4-DCP may be attributed to the higher pKa values of these two CPs leading to a greater affinity for incorporation with the oxides thus lack of availability of these two CPs in the aqueous phase hindering the dechlorination. Furthermore, relatively high amounts of passive oxides (akaganeite, haematite, lepidocrocite, wustite, goethite, ferrihydrite) along with relatively low amounts of magnetite (compared to that with PCP and 2,3,4,6-TeCP) was detected during the reaction of 2,4,6-TCP and 2,4-DCP with Ni/Fe bimetal. The passive oxides seemed to hinder the dechlorination of 2,4,6-TCP and 2,4-DCP, but possibly increased CPs incorporation with the oxides.

References

Arning MD, Minteer SD (2007) Electrode potentials. In: Handbook of electrochemistry. In: Zoski CG (ed). Elsevier Science, p 934

ATSDR (Agency for Toxic Substances and Disease Registry) (1999) Toxicological profile for chlorophenols. Agency for toxic substances and disease registry. U.S Department of Health and Human Services, p 260

Cheng R, Wang Jl, Zhang W-x (2007) Comparison of reductive dechlorination of p-chlorophenol using Fe0 and nanosized Fe0. J Hazard Mater 144:334–339

Cheng R, Zhou W, Wang J-L, Qi D, Guo L, Zhang W-X, Qian Y (2010) Dechlorination of pentachlorophenol using nanoscale Fe/Ni particles: Role of nano-Ni and its size effect. J Hazard Mater 180:79–85

Choi JH, Choi SJ, Kim YH (2008) Hydrodechlorination of 2,4,6-trichlorophenol for a permeable reactive barrier using zero-valent iron and catalyzed iron. Korean J Chem Eng 25:493–500

Chun CL, Baer DR, Matson DW, Amonette JE, Penn RL (2010) Characterization and reactivity of iron nanoparticles prepared with added Cu, Pd, and Ni. Environ Sci Technol 44:5079–5085

Cornell RM, Schwertmann U (2003) The iron oxides structure, properties, reactions, occurrences, and uses. Wiley-VCH, Weinheim, p 659

Cwiertny DM, Bransfield SJ, Roberts AL (2007) Influence of the oxidizing species on the reactivity of iron-based bimetallic reductants. Environ Sci Technol 41(10):3734–3740

Czaplicka M (2004) Sources and transformations of chlorophenols in the natural environment. Sci Total Environ 322:21–39

Davenport AJ, Oblonsky LJ, Ryan MP, Toney MF (2000) The structure of the passive film that forms on iron in aqueous environments. J Electrochem Soc 147:2162–2173

EC (2016) List of priority substances in the field of water policy. European Commission. http://eceuropaeu/environment/water/waterframework/priority_substances.htm. Accessed 12 July 2017

Farrell J, Kason M, Melitas N, Li T (2000) Investigation of the long-term performance of zero-valent iron for reductive dechlorination of trichloroethylene. Environ Sci Technol 34:514–521

Feng J, Lim T-T (2005) Pathways and kinetics of carbon tetrachloride and chloroform reductions by nano-scale Fe and Fe/Ni particles: comparison with commercial micro-scale Fe and Zn. Chemosphere 59:1267–1277

Fu F, Dionysiou DD, Liu H (2014) The use of zero-valent iron for groundwater remediation and wastewater treatment: a review. J Hazard Mater 267:194–205

Furukawa Y, Kim J-w, Watkins J, Wilkin RT (2002) Formation of ferrihydrite and associated iron corrosion products in permeable reactive barriers of zero-valent iron. Environ Sci Technol 36:5469–5475

Gillham RW, Ohannesin SF (1994) Enhanced degradation of halogenated aliphatics by zero valent iron. Ground Water 32:958–967

Gotpagar J, Lyuksyutov S, Cohn R, Grulke E, Bhattacharyya D (1999) Reductive dehalogenation of trichloroethylene with zero-valent iron: surface profiling microscopy and rate enhancement studies. Langmuir 15:8412–8420

Gunawardana B, Singhal N, Swedlund P (2011) Degradation of chlorinated phenols by zero valent iron and bimetals of iron: a review. Environ. Eng. Res. 16:187–203

Gunawardana B, Swedlund PJ, Singhal N, Nieuwoudt MK (2018) Pentachlorophenol dechlorination with zero valent iron: a Raman and GCMS study of the complex role of surficial iron oxides. Environ Sci Pollut Res 25:17797–17806

Gunawardana B, Swedlund PJ, Singhal N (2019) Effect of O2, Ni0 coatings, and iron oxide phases on pentachlorophenol dechlorination by zero-valent iron. Environ Sci Pollut Res 26:27687–27698

Henderson AD, Demond AH (2007) Long-term performance of zero-valent iron permeable reactive barriers: a critical review. Environ Eng Sci 24:401–423

Henderson AD, Demond AH (2011) Impact of solids formation and gas production on the permeability of ZVI PRBs. J Environ Eng 137:689–696

Hou M, Wan H, Zhou Q, Liu X, Luo W, Fan Y (2009) The dechlorination of pentachlorophenol by zerovalent iron in presence of carboxylic acids. Bull Environ Contam Toxicol 82:137–144

Hu R, Cui X, Gwenzi W, Wu S, Noubactep C (2018) Fe0/H2O systems for environmental remediation: the scientific history and future research directions. Water 10:1739

IARC (2019) Monographs on the evaluation of carcinogenic risks to humans: pentachlorophenol and some related compounds, Vol 117. International Agency for Research on Cancer, World Health Organization, Lyon, France

Jaumot J, Gargallo R, De Juan A, Tauler R (2005) A graphical user-friendly interface for MCR-ALS: a new tool for multivariate curve resolution in MATLAB. Chemometr Intell Lab Syst 76:101–110

Jeen S-W (2005) Effects of mineral precipitation on long-term performance of granular iron permeable reactive barriers: column experiments and numerical simulation. Ph.D., University of Waterloo (Canada)

Jin suk O, Jeen S-W, Gillham RW, Gui L (2009) Effects of initial iron corrosion rate on long-term performance of iron permeable reactive barriers: Column experiments and numerical simulation. J Contam Hydrol 103:145–156

Kim YH (1999) Reductive dechlorination of chlorinated aliphatic and aromatic compounds using zero valent metals: modified metals and electron mediators. PhD, Texas A & M University

Kim YH, Carraway ER (2000) Dechlorination of pentachlorophenol by zero valent iron and modified zero valent irons. Environ Sci Technol 34:2014–2017

Klausen J, Vikesland PJ, Kohn T, Burris DR, Ball WP, Roberts AL (2003) Longevity of granular iron in groundwater treatment processes: solution composition effects on reduction of organohalides and nitroaromatic compounds. Environ Sci Technol 37:1208–1218

Ko SO, Lee DH, Kim YH (2007) Kinetic studies of reductive dechlorination of chlorophenols with Ni/Fe bimetallic particles. Environ Technol 28:583–593

Lan Q, Liu H, Li FB, Zeng F, Liu CS (2011) Effect of pH on pentachlorophenol degradation in irradiated iron/oxalate systems. Chem Eng J 168:1209–1216

Li L, Benson CH (2010) Evaluation of five strategies to limit the impact of fouling in permeable reactive barriers. J Hazard Mater 181:170–180

Li Y, Niu J, Yin L, Wang W, Bao Y, Chen J, Duan Y (2011) Photocatalytic degradation kinetics and mechanism of pentachlorophenol based on Superoxide radicals. J Environ Sci 23:1911–1918

Liu Y, Yang F, Yue PL, Chen G (2001) Catalytic dechlorination of chlorophenols in water by palladium/iron. Water Res 35:1887–1890

Liu CC, Tseng DH, Wang CY (2006) Effects of ferrous ions on the reductive dechlorination of trichloroethylene by zero-valent iron. J Hazard Mater 136:706–713

Long M, Ilhan ZE, Xia S, Zhou C, Rittmann BE (2018) Complete dechlorination and mineralization of pentachlorophenol (PCP) in a hydrogen-based membrane biofilm reactor (MBfR). Water Res 144:134–144

Ma H-Y, Zhao L, Guo L-H, Zhang H, Chen F-J, Yu W-C (2019) Roles of reactive oxygen species (ROS) in the photocatalytic degradation of pentachlorophenol and its main toxic intermediates by TiO2/UV. J Hazard Mater 369:719–726

Matheson LJ, Tratnyek PG (1994) Reductive dehalogenation of chlorinated methanes by iron metal. Environ Sci Technol 28:2045–2053

Morales J, Hutcheson R, Cheng IF (2002) Dechlorination of chlorinated phenols by catalyzed and uncatalyzed Fe(0) and Mg(0) particles. J Hazard Mater 90:97–108

Nadoll P, Mauk JL (2011) Wüstite in a hydrothermal silver-lead-zinc vein, Lucky Friday mine, Coeur d'Alene mining district, U.S.A. Am Mineral 96(2–3):261–267

Nardo AD, Natale, MD, Erto A, Musmarra D, Bortonea I (2010) Permeable reactive barrier for groundwater PCE remediation: the case study of a solid waste landfill pollution. In: Pierucci S, Ferraris GB (eds) Computer aided chemical engineering, Vol 28. Elsevier, pp 1015–1020

Noubactep C (2007) Processes of contaminant removal in “Fe0-H2O” systems revisited: the importance of co-precipitation. Open Environ J 1:9–13

Noubactep C (2008) A critical review on the process of contaminant removal in Fe0-H2O systems. Environ Technol 29:909–920

Noubactep C (2009) An analysis of the evolution of reactive species in Fe0/H2O systems. J Hazard Mater 168:1626–1631

Noubactep C (2013) Metallic Iron for water treatment: a critical review. CLEAN—Soil, Air, Water, pp 1–9

Olaniran AO, Igbinosa EO (2011) Chlorophenols and other related derivatives of environmental concern: Properties, distribution and microbial degradation processes. Chemosphere 83:1297–1306

Patel UD, Suresh S (2006) Dechlorination of chlorophenols by magnesium-silver bimetallic system. J Colloid Inter Sci 299:249–259

Patel UD, Suresh S (2007) Dechlorination of chlorophenols using magnesium-palladium bimetallic system. J Hazard Mater 147:431–438

Patterson BM, Lee M, Bastow TP, Wilson JT, Donn MJ, Furness A, Goodwin B, Manefield M (2016) Concentration effects on biotic and abiotic processes in the removal of 1, 1, 2-trichloroethane and vinyl chloride using carbon-amended ZVI. J Contam Hydrol 188:1–11

Phillips DH, Van Nooten T, Bastiaens L, Russell MI, Dickson K, Plant S, Ahad JME, Newton T, Elliot T, Kalin RM (2010) Ten year performance evaluation of a field-scale zero-valent iron permeable reactive barrier installed to remediate trichloroethene contaminated groundwater. Environ Sci Technol 44:3861–3869

Ritter K, Odziemkowski MS, Gillham RW (2002) An in situ study of the role of surface films on granular iron in the permeable iron wall technology. J Contam Hydrol 55:87–111

Scherer MM, Balko BA, Tratnyek PG (1999) The role of oxides in reduction reactions at the metal-water interface In: Mineral-Water Interfacial Reactions, Chapter 15, vol 715. ACS Symposium Series, pp 301–322

Schrick B, Blough JL, Jones AD, Mallouk TE (2002) Hydrodechlorination of trichloroethylene to hydrocarbons using bimetallic nickel-iron nanoparticles. Chem Mater 14:5140–5147

Shih Y-h, Chen M-Y, Su Y-F (2011) Pentachlorophenol reduction by Pd/Fe bimetallic nanoparticles: Effects of copper, nickel, and ferric cations. Appl Catal B 105:24–29

Shiu W-Y, Ma K-C, Varhanícková D, Mackay D (1994) Chlorophenols and alkylphenols: a review and correlation of environmentally relevant properties and fate in an evaluative environment. Chemosphere 29:1155–1224

Song Y, Swedlund PJ, Singhal N (2008) Copper(II) and cadmium(II) sorption onto ferrihydrite in the presence of phthalic acid: some properties of the ternary complex. Environ Sci Technol 42:4008–4013

Tanjore S, Viraraghavan T (1994) Pentachlorophenol—Water pollution impacts and removal technologies. Int J Environ Stud 45:155–164

Tian H, Li J, Mu Z, Li L, Hao Z (2009) Effect of pH on DDT degradation in aqueous solution using bimetallic Ni/Fe nanoparticles. Sep Purif Technol 66:84–89

UNEP (2014) Pentachlorophenol and its salts and esters: draft risk management evaluation, UNEP/POPS/POPRC.10/2, persistent organic pollutants review committee, United Nations Stockholm Convention on Persistent Organic Pollutants

USEPA (2010) Toxicological review of pentachlorophenol: in support of summary information on the integrated risk information system (IRIS). United States Environmental Protection Agency, Washington, DC

USEPA (2018a) Drinking water contaminants—standards and regulations. National Primary Drinking Water Regulations. https://www.epa.gov/dwstandardsregulations. Accessed 18 March 2019

USEPA (2018b) Groundwater & drinking water. National primary drinking water regulations. https://www.epa.gov/ground-water-and-drinking-water/national-primary-drinking-waterregulations#Organic. Accessed 18 Mar 2019

USEPA (2019) Priority pollutant list. Toxic and priority pollutants under the clean water act. http://water.epa.gov/scitech/methods/cwa/pollutants.cfm. Accessed 10 July 2019

Wang X, Chen C, Liu H, Ma J (2008) Characterization and evaluation of catalytic dechlorination activity of Pd/Fe bimetallic nanoparticles. Ind Eng Chem Res 47:8645–8651

Wei J, Xu X, Liu Y, Wang D (2006) Catalytic hydrodechlorination of 2,4-dichlorophenol over nanoscale Pd/Fe: reaction pathway and some experimental parameters. Water Res 40:348–354

WHO (2003) Chlorophenols in drinking-water. Background document for development of WHO Guidelines for Drinking-water quality. WHO/SDE/WSH/03.04/47. In: Guidelines for drinking-water quality, 2nd ed. Vol. 2. Health criteria and other supporting information. World Health Organization, Geneva, 1996

Xu F, Deng S, Xu J, Zhang W, Wu M, Wang B, Huang J, Yu G (2012) Highly active and stable Ni–Fe bimetal prepared by ball milling for catalytic hydrodechlorination of 4-chlorophenol. Environ Sci Technol 46:4576–4582

Xu Y, Xue L, Ye Q, Franks AE, Zhu M, Feng X, Xu J, He Y (2018) Inhibitory effects of sulfate and nitrate reduction on reductive dechlorination of PCP in a flooded paddy soil. Front Microbiol 9:567

Yang BR, Chen AH (2016) Effects of pentachlorophenol on the bacterial denitrification process. Chem Speciat Bioavailab 28:163–169

Zhang W, Quan X, Wang J, Zhang Z, Chen S (2006) Rapid and complete dechlorination of PCP in aqueous solution using Ni-Fe nanoparticles under assistance of ultrasound. Chemosphere 65:58–64

Zhou T, Li Y, Lim T-T (2010) Catalytic hydrodechlorination of chlorophenols by Pd/Fe nanoparticles: Comparisons with other bimetallic systems, kinetics and mechanism. Sep Purif Technol 76:206–221

Acknowledgements

Authors would like to thank Dr. Michel Nieuwoudt for the technical assistance provided with the Raman spectroscopic analysis. The research funding was provided by the New Zealand International Doctoral Research Scholarship, New Zealand Foundation for Research, Science and Technology and the University of Auckland, New Zealand.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Gunawardana, B., Singhal, N., Swedlund, P.J. (2021). Chlorophenols Dechlorination Water Treatment Using Ni-Iron Bimetallic Systems: Implications of the Degree of Chlorination, Nickel Coating, and Iron Oxide Phases. In: Kumar, M., Snow, D., Honda, R., Mukherjee, S. (eds) Contaminants in Drinking and Wastewater Sources. Springer Transactions in Civil and Environmental Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-4599-3_12

Download citation

DOI: https://doi.org/10.1007/978-981-15-4599-3_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-4598-6

Online ISBN: 978-981-15-4599-3

eBook Packages: EngineeringEngineering (R0)