Abstract

We design a refractive index (RI) based triple core photonic crystal fiber sensor, which works on the principle of surface plasmon resonance. The analyte to be sensed is placed inside all the three cores. The middle core is surrounded by a layer of graphene, followed by a layer of Indium tin oxide (ITO). ITO is used as the bio-sensing layer for operating in the infrared region. The graphene layer is used to enhance the sensitivity of the proposed sensor. Numerical results corroborate that the proposed sensor exhibits a maximum sensitivity of 2000 nm/RIU when refractive index of the analyte, na is increased from 1.44 to 1.48.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

For the first time, R. W. Wood observed the surface plasmon resonance (SPR) phenomena in 1902 [1]. In this technique, when the plane polarized light is incident at the interface between the dielectric and metal region, electrons get excited and they undergo oscillation along the interface [2]. Such waves are called as surface plasmon (SP) waves. When the light is incident at an angle greater than the critical angle, the excitation of SPs results in a reduced reflected light intensity. The angle at which a dip is observed in the reflected intensity of light is known as the resonant angle. It is well known that the propagation of light in a fiber optic medium is based on the principle of total internal reflection and so is the excitation of SPs. A resonance occurs when the frequency of the incident wave matches with the frequency of the SP waves. This process ultimately results in a considerable loss in the reflected light intensity. The resonance condition depends on the thickness and the dielectric constants of both metal and dielectric. A minimal change in the RI of the surrounding medium leads to change in the intensity of the SPR signal, which can be used to detect the biomolecules and to study the interaction of surface molecules in real time.

Photonic crystal fiber (PCF) is one of the special optical fibers which possesses a series of unique properties which are not available in conventional optical fibers [3]. It is well known that PCF combines the properties of optical fibers and photonic crystals. PCF is made up of a low-loss cladding region where in the air holes are periodically arranged. The core region is formed by creating a defect in the periodic arrangement of air holes. In this paper we choose a single mode fiber to enhance the excitation of surface plasmons. The number of air holes is increased in order to get a tight confinement at the core.

Graphene is an allotrope of carbon which is thinnest and strongest man made inorganic compound. It has large carrier mobility, large field enhancement and large surface area which helps in higher absorption of biomolecules. More over fabrication of graphene is relatively cheap and easy. Thus graphene is used to enhance the sensing property of the proposed sensor.

Majority of the available SPR sensors are constructed in the visible region by using gold and silver as the active materials [4]. Gold and silver have their peak absorptions in the visible region. Most of the bio-molecules have their absorption in the infrared (IR) region [5] and Indium tin oxide (ITO) also has its absorption wavelength at IR region. So we use ITO as an active metal layer. With the change in doping concentration of tin oxide and indium oxide, the plasma frequency of ITO can be tuned in the desired operating wavelength range [6].

2 Structure and Theoretical Modeling

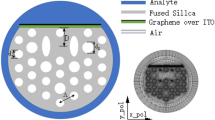

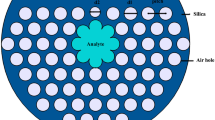

In this paper, we design a triple core PCF. The geometry of the triple core sensor is shown in Fig. 1. There are three cores filled with liquid that form a straight line with the central core. It has numerous air holes with a diameter of 0.95 µm. The air holes are arranged in a triangular lattice with a pitch value of Λ = 1.90 µm. The diameter of all the three cores is 1.52 µm. The center core is coated by a 3 nm graphene layer followed by a 30 nm Indium tin oxide layer. The RI of sample is changed from 1.44 to 1.48 [7]. The surface plasmon resonance occurs at the center core. The plasmonic mode occurs at the Indium tin oxide-graphene layer interface and the analyte.

The RI of the silica cladding is calculated using the Sellmeier’s equation [8]

The Sellmeier constants a_1, a_2, a_3, b_1, b_2 and b_3 for fused silica are 0.69616300, 0.407942600, 0.897479400, 0.00467914826, 0.0135120631 and 97.9340025, respectively. The refractive index of Indium tin oxide was computed by the Drude model [9] as follows

Here, λp and λc are the dispersion coefficients in micrometres. λp is the plasma frequency for the corresponding wavelength (λp = 0.56497) and λc is the collision wavelength (λc = 11.21076) and is loss related. Here the wavelength λ is measured in micrometres.

The graphene RI is obtained using following equation,

Here λ denotes wavelength and \(C_{1} \approx 5.446 \space \mu m^{-1} \).

The PCF has been designed in such a way to enhance detection accuracy and for maximum confinement. We employ finite element method to study the mode propagation of the proposed sensor, by including a perfectly matched layer boundary conditions to minimise the scattering radiation. We designed the PCF with COMSOL multiphysics v4.4.

Figures 2 and 3 represent the electric field distribution of the fundamental and the surface plasmon mode, respectively. These modes are highly useful to compute the loss spectra for analyte of RI, na = 1.44 at 1.5 μm wavelength.

3 Results and Discussions

Confinement loss is calculated using the following expression.

Here, Im(neff) represents the imaginary part of the effective RI of the fundamental mode which accounts for the loss and λ is the operating wavelength.

Figure 4 depicts the variation of the confinement loss for different values of the analytes (n = 1.44, 1.45, 1.46, 1.47, 1.48). It is clearly seen that the loss peak shifts towards the higher wavelength for the increase in the RI of analyte (Table 1).

The spectral sensitivity is calculated by using the following formula.

Here,

- Δλpeak:

-

shift in peak wavelength

- Δna:

-

change in RI of analyte

The proposed sensor exhibits maximum sensitivity of 2000 nm/RIU.

4 Conclusion

We have proposed a triple core PCF based SPR sensor. The sensitivity of the proposed sensor has been studied for five different analytes of 1.44, 1.45, 1.46, 1.47 and 1.48. The maximum sensitivity of 2000 nm/RIU has been observed for the designed sensor. The proposed fiber sensor can be further optimized for a wide range of analytes in the IR region which would be a promising tool for sensing applications.

References

Wood RW (1902) On a remarkable case of uneven distribution of light in a diffraction grating spectrum. Proc Phys Soc London 18:26. https://doi.org/10.1088/1478-7814/18/1/325

Gupta BD, Verma RK (2009) Surface plasmon resonance based fiber optic sensors: principle, probe designs, and some applications. J Sens. https://doi.org/10.1155/2009/979761

Russel PJ (2003) Photonic crystal fibers. Science: 358–362. https://doi.org/10.1126/science.1079280

Sharma AK, Jha R, Gupta BD (2007) Fiber-optic sensors based on surface plasmon resonance: a comprehensive review. IEEE Sens J 7(8):1118–1129. https://doi.org/10.1109/jsen.2007.897946

Barth A (2007) Infrared spectroscopy of proteins. Biochim Biophys Acta 1767(9):1073–1101. https://doi.org/10.1016/j.bbabio.2007.06.004

Rhodes C, Cerruti M, Efremenko A, Losego M, Aspnes DE, Maria JP, Franzen S (2008) Dependence of plasmon polaritons on the thickness of indium tin oxide thin films. J Appl Phys 103(9):0931081–0931086. https://doi.org/10.1063/1.2908862

Rifat AA, Mahdiraji GA, Chow DM, Shee YG, Ahmed R, Adikan FRM (2015) Photonic crystal fiber-based surface plasmon resonance sensor with selective analyte channels and graphene-silver deposited core. Sensors 15:11499–11510. https://doi.org/10.3390/s150511499

Adams MJ (1981) An introduction to optical waveguides, 14. Wiley, New York

Singh S, Gupta BD (2010) Simulation of a surface plasmon resonance-based fiber-optic sensor for gas sensing in visible range using films of nano composites. Meas Sci Technol 21(11):1152021–1152028. https://doi.org/10.1088/0957-0233/21/11/115202

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sambathu, N., Krishnamoorthy, S. (2021). Surface Plasmon Resonance-Based Photonic Crystal Fiber Sensor with Selective Analyte Channels and Graphene-Indium Tin Oxide Deposited Core. In: Rushi Kumar, B., Sivaraj, R., Prakash, J. (eds) Advances in Fluid Dynamics. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-4308-1_73

Download citation

DOI: https://doi.org/10.1007/978-981-15-4308-1_73

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-4307-4

Online ISBN: 978-981-15-4308-1

eBook Packages: EngineeringEngineering (R0)