Abstract

We discovered an ancient art of using charcoal for agriculture by the Indians living in the Amazon basin. Old to new technologies exist in thermal conversion (pyrolysis) of dense biomass to stable biochar. Unstable biochar derived from straw was the challenge undertaken in France. A straw pyrolyzer of 1 Mg/h was designed, fabricated, and operated. Attempts were made to transfer the technology to Sri Lanka, and a patent was obtained in 1994 to replace 70% of urea usage. Small and medium-sized pyrolyzers were developed for producing fertilizer and envisaged energy by also converting the organic fraction of municipal solid wastes into biochar fertilizers, making it attractive to farmers and policymakers. Research was also focused on reducing the amount of char needed. It was found that a mixture of biochar, compost, and 30% recommended quantity of urea gave best results in most of the field trials. Important findings of cyclic effects of phosphorus in the nutrient regulation mechanisms of biochar paved the way for developing biochar biocatalysts to replace inorganic fertilizers with much less biochar. Thus, sustainable agriculture can be achieved by improving biomass generation, gathering, and processing systems for manufacture of biochar biocatalyst fertilizer, in all different ecological regions in the country.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

We were learning the art of cultivating a “chena,” when we stumbled on an abandoned one, way back in 1979. It was a revelation. We called it the “Kala Pola” (jungle market). It had flourishing and lushes growth of many types of peppers, tomato, pumpkin, and aubergine in clusters. They were from seeds that had sprouted from the previous cultivations. The immediate response was to examine the soil, and we were astonished to find the soil rich in very small particles of char and nuggets of char sparsely spread across these dense clusters. The Center for Agricultural Machinery, Land, Water, and Forestry Management (CEMAGREF) in France welcomed the idea of making char from agricultural wastes. They were interested in using it for fueling gasifiers to run tractors, while our intention was for replacing fertilizer for increasing agriculture productions.

At that time, commercial use of charcoal was not known, but there had been the use of it throughout history. The well-known discovery in the Amazon basin of Terra Preta de Indio (Black Soils of the Indians) by the Spaniards came to light only in the recent past in 2001 (Bezerra 2015), because that civilization got wiped out contracting diseases that the Spaniards had brought with them from Europe. It is believed that the ancient Indians engineered the poor tropical soils with the additions of biochar, or they crafted the properties of char into biochar. These soils have biochar, pot pieces, and animal skeletons; thus, they were formed under the trash piles of the indigenous people 2 m deep, 7000 years old, much more fertile than the surrounding soil (Fig. 1). There are reports of replenishing back soils of the Indians. These fertile soils are mined for commercial use now, and they find that these soils are especially helpful as a natural growing medium. In other words, the soils expand. Perhaps the microcosms in those soils have evolved to recycle and also adsorb CO2 from the atmosphere as the substrate, perhaps undergoing at some later stage anaerobic conditions in this Amazon basin to utilize CO2 as an energy source as well as for cell growth, a mechanism for their survival.

Oxisol and Terra Preta. (Source: B. Glaser cited by https://www.geozentrum-hannover.de/DE/Gemeinsames/Nachrichten/Veranstaltungen/2009/Hauskolloquium_2009_2010/2009_10_06_abstracts.html)

Although we do not have historical evidence of char use in Sri Lankan agriculture, the influence of Portuguese in Sri Lanka was similar to the report of Francisco de Orellana, the Spanish conquistador in 1542. He had ventured along the Rio Negro, one of the Amazon basin’s great rivers, hunting for a hidden city of gold, and his expedition found a network of farms, villages, and even huge-walled cities (https://www.youtube.com/watch?v=0Os-ujelkgw). According to Sanderatne and de Alwis (2018), in Sri Lanka, the high death rate in the nineteenth century and early twentieth century was primarily due to several infective and parasitic diseases, unhygienic living conditions, and inadequate medical services. Incidences of dysentery, tuberculosis, cholera, typhoid, and malaria were exceedingly high. One should wonder, what happened in the fifteenth century? We would have lost the actual craft of engineering very similar ferruginous soils like in the Amazon basin and the know-how of making charcoal. Instead, they were driven to clearing jungles, and they cultivated a chena in isolation, preventing diseases from spreading. One of the farmers, whom we met in Kalawewa many years ago, recounted his experiences of settling in Kalawewa from a village in Kandy after the restoration of the reservoir during the time of British rule. When they found many of the settlers succumbing to numerous diseases, including malaria, they fled and survived in the forest, cultivating chenas. He was not surprised when we narrated the observations of “Kala Pola,” and we still find that most farmers are aware of the importance of char, but they are unable to quantify its exact value to cultivation. So are most scientists, researchers, students, and administrators or some are not willing to accept alternatives to inorganic fertilizers because of self-interests in exploiting farmers for monetary gains.

This review is a testimony in quantifying the importance of biochar for sustainable agricultural productions. It entails laboratory investigations to determine kinetic properties, testing of an “engineering model” to determine the gas flow characteristics of straw bales with and without pyrolytic conditions. Mathematical expressions from these results were developed for simulating the pyrolysis front in the design of a 1 Mg/h pyrolyzer. Test runs were done to optimize the thermal process conditions and the products. We describe the potential use of the technology by arresting the polluting practice of straw burning and the twin benefits of biochar and power generations from paddy straw. We describe the development of pyrolyzers in Sri Lanka and the issues related to investments for promoting the developed technologies. From a scientific point of view, it was necessary to examine the quality of biochar in relation to the behavior of nutrients, particularly nitrogen and phosphorus. We describe field experimentations that were conducted firstly in order to reduce the use of inorganic fertilizer and secondly to demonstrate the role of biochar in enhancing phosphorus movements in rice cultivation. We then conclude convincingly that biochar is essential for sustainable agriculture productions in poor tropical soils of Sri Lanka.

2 Development of a Mobile Pyrolyzer (Carbonization)

Pyrolysis is a thermal decomposition process, requiring a supply of heat, preferable without oxygen or any excess oxidizing agent in the media of supplying heat until the biomass is converted to char, pyrolysis gases, pyrolysis products, and water. The product yield during the thermochemical conversion of biomass depends on temperature, pressure, time, reaction conditions, rate of heating, and added reactants or catalysts (Paul 1982; Demirbas and Kucuk 1997). The degree of equilibrium attained between these products will depend on the rate of heat supplied. Fast thermal transfer at higher temperatures maximizes the production of bio-oil and/or gases, while slow thermal transfer at lower temperatures maximizes the yield of carbon/charcoal. The rate of heating of 10 °C/s, <500 °C, is ideal for biochar productions. It is an endothermic reaction requiring the supply of heat at a specific rate of heating or variable, which will depend on the reactor configuration. In the thermal decomposition process, depending on the temperature regime as given in Table 1, the biomass undergoes drying, torrefaction, carbonization, and gasification. We find that the structure of the biomass, consisting of hemicelluloses, cellulose, lignin, and other substances, including various inorganic matter, vastly influences the quality of the char and the pyrolysis products. In the design of equipment required for any of these processes, it is important to determine the kinetics of pyrolysis, including the rate of pyrolysis at a given supply of heat, and it will depend on the size of particles, isothermal or non-isothermal reactor configurations, and the type of biomass. We can observe the mass reductions in an isothermal thermobalance (Fig. 2) at a given temperature of different particle sizes as shown in Fig. 3 (Basnayake 1986).

An isothermal thermobalance (Basnayake 1986)

The mass reductions in an isothermal thermobalance at a given temperature of different particle sizes (mass % vs time (s) of straw at 600 °C) (Basnayake 1986)

Each of these particles has undergone a first-order rate reaction, and we can express the unit mass reduction for a single run as:

where Mi = initial mass, Mf = final mass, and Mt = mass reduction at time t.

The first-order rate reaction is expressed as

where k = the rate constant.

Integrating Eq. 2 gives

We can substitute Eq. 3 in Eq. 1 to give

We can then plot a graph of ln(m) vs time. The slope of the straight line gives –k for that temperature, and we could denote it as k1. If we then do the same for the same mass of particle for different temperatures, k2, k3, k4, … ..kn can be obtained. The energy activation value can be obtained if ln(k) is plotted against 1/T, where T1, T2, T3, T4… ..Tn are the temperatures corresponding to k1, k2, k3…kn values. The slope of the straight line is equal to \( \frac{-\Delta E}{RT} \), and the factor of frequency is the intercept, thus giving

Therefore, Eq. 5 can now be inserted in Eq. 4 to replace k. We found that the energy of activation is about 1050 kJ/kg for most materials. But it will depend on heat transfer characteristics of the materials under investigation. The pyrolysis products can be used for supplying the required energy. Therefore, the products leaving the reaction zone can be written as

If the required quantity of the products is recycled and combusted to provide adequate energy for the endothermic reactions of pyrolysis, a system can be designed to continuously produce char from biomass. We wanted to develop a carbonization reactor to pyrolyze bales of straw, and we needed to find out the pressure losses encountered to send high-temperature flow of fumes using a high-temperature centrifugal fan. At high temperatures, there could be preferential passages through a bale of straw, but if the bales are replenished on a continuous basis, the preferential paths get filled with char or fresh straw. It was conceptually perceived to have a pyrolysis front as shown in Fig. 4.

Conceptual pyrolysis front (Basnayake, 1986)

Therefore, we built an engineering model to determine the characteristics of the gas flow. In the first instance, ambient air was used to determine the pressure loss, and it amounted to

where ΔP = pressure loss in N/m2 and v = velocity of air flow m/s and λ1 and λ2 are coefficients describing porosity of the material.

The first term depends on the potential energy, thus along the length of the passage and average diameter of the passages of the straw bales. The second term is the kinetic energy of entry and exit losses. λ1 and λ2 get modified, if the temperature increases due to changes in viscosity, the average diameter of passages through the bales, Reynolds number, and the changes in density ρ. We verified the predicted pressure losses with combusted gasses being sent through the bales. The pyrolysis front should be a diagonal, if there is a cross flow as shown in Fig. 5. The energy contents as given in Table 2 were used to determine the mass balances of the reactor, and the predicted performances were found to be similar to the experimental results of the mobile pyrolyzer. Test runs were done to optimize the thermal process conditions and the products by observing the pyrolysis front for automation of feeding. The granulation techniques of small particles were one of the aspects of product development.

Experimental pyrolysis front (Basnayake 1986). (Note: ti initial time, Tin inflow temperature, Tout outflow temperature)

3 Potential Use of Technology in Sri Lanka

We were very keen in transferring these developed technologies and know-how to interested parties in Sri Lanka. Unfortunately, none of the companies in Sri Lanka were interested in the production and conversion of char into fertilizer. A concerted effort was made to popularize and industrialize the processes by conducting trials and even obtaining the first patent titled “Discovery of a process to retard the release of nitrogen fertilizer by using charcoal and manioc” (Basnayake 1994). Although the Department of Agriculture advocates use of straw for composting, the necessary technology transfer of straw baling and know-how to store and preserve it have not been forthcoming. Therefore, farmers still continue to burn the straw by spreading the cut straw over the stubble. This practice seems to have some major effects, namely, weed suppression, pest control (John 2013), and the stubble getting converted to char. It is estimated that 50% of the paddy straw is burnt in Sri Lanka. The remaining 50% is now converted to compost, animal feed, and other uses with 20% decomposing in the fields contributing to methane productions. Therefore, residue burning is still widely practiced although officially banned in most countries, including Sri Lanka. However, most of the straw is burnt and blown away, and the amount of char remaining in the field is less than 10%, considering the high ash content in paddy (Ariyawansha et al. 2014). The burning is contributing to air pollution (Putun et al. 2004), human health problems (Iranzo et al. 2004; Kadam et al. 2000), and substantial nutrient losses (Haefele et al. 2011). There is a valid case for using straw for biochar productions and the excess heat used for power generation. It was estimated that just over 100 MW of power generation from small power plants within a radius of a collection area of 5 km can be a feasible project for Sri Lanka. The environmental costs of 108.5 million USD annually can be avoided in this twin system. Most of all, the saving on fertilizer applications is 153 million USD annually (Ariyawansha et al. 2014).

We were hoping to introduce straw balers to Sri Lanka and launch the long-awaited project of making char with a similar but more advanced reactor than an earlier one at CEMAGREF. We even experimented on several smaller units to convert paddy husk to char. It was an inclined reactor without recycling of pyrolysis gases and tar/oil by giving just about enough air for combusting part of those products as illustrated in Fig. 6 (Manel 2010; Gamage et al. 2012). A much larger unit was designed and was made operational with selected materials from municipal solid waste (MSW). It had a capacity of 100 kg/hr (Fig. 7). A gasifier was used to supply energy for drying and pyrolysis, such that the pyrolysis gases were to be used for even a larger reactor, thus having a series of them (Fig. 8). In the unit that was built, recycling of gases was tried by cooling and filtering the pyrolysis products. The tars/oils that condensed within input materials were pyrolyzed once more in the tall reactor, thus encountering fewer problems in blockages of pipes and valves. It was necessary to maintain temperatures >150 °C inside the reactor to continuously drive off moisture out of the reactor so that water will not accumulate but condense in the heat exchanger pipes. A steam-releasing system was incorporated to ensure safety. We eventually used a very old cast iron-cased centrifugal fan, discarded from a tea estate because the un-condensable gases still had some considerable amount of sensible heat, causing problems for most low-temperature fans readily available in the market.

Unfortunately, the government agencies and private companies turned down biochar proposals. It became very apparent that industries, agricultural officials, and academics preferred chemical applications rather than promoting effective cultivation techniques with biochar applications for sustainable development. It was naive in their part because throughout history, charcoal has been used in agriculture. At the same time of the work at CEMAGREF, a handful of scientists recognized the value of charcoal and had published few papers on the subject (Kishimoto and Sugiura 1985; Santiago and Santiago 1989). However, after the advent of discovering biochar use in ancient civilizations of the Amazon region in 2001, there have been considerable research and development to industrialize the processes and apply biochar (Lehmann and Joseph 2009). In most of the research studies, particularly in the tropical belt, benefits of biochar applications are well documented. Nevertheless, there are pessimistic points of view on biochar use cited in one or two review papers (Mukherjee and Lal 2014).

4 Quality of Biochar

Different points of view on the use of biochar arise from fundamental principles of defining the quality parameters for biochar. In our experience, if we use newly made char, particularly with condensed tar, having high concentrations of polyphenolic compounds, there will be detrimental effects of phytotoxicity of charcoal on establishing or growth of plants. We perform a bioassay to determine the level of phytotoxicity using germination tests for very sensitive seeds by using different proportions of char to sand contents as shown in Fig. 9. Therefore, very tarry chars require much more mixture of soil than chars with very high porosities and specific surfaces. However, such types of char mixed in correct proportions can be used to deter insects and pests. Pyrolysis of highly dense feedstock at low temperature as mentioned before will produce char with less porosity and low specific surface than straw. The latter produces unstable char but is very useful in the seeding and planting stages of growth. These chars made under very high compression of impact loading become dense and behave similar to chars made from materials like coconut shells. However, the coconut shell chars can last for decades or even thousands of years. Also curing of stable (dense) char with soil over a period of time reduces phytotoxicity and increases the nitrogen content. Such chars can then be termed biochar. The microbial actions in the mixture of char and soil are enhanced with a carbon source like compost. If we use green manure mixed with char and soil, and then cured, it will have very different properties. Whenever a phase of curing has taken place or by allowing the char to remain in the soil for a period without causing phytotoxicity, we could use the term “biochar.” However, it is best to define the terms as accepted by the international community. According to Lehmann and Joseph (2009), biochar is a charcoal carbon product derived from biomass that can enhance soils, sequester or store carbon, and provide useable energy. Biochar is produced by thermal decomposition of organic material under limited supply of oxygen (O) and at relatively low temperatures (<700 °C) (Lehmann and Joseph 2009). Therefore, it is defined as charcoal made for the application in soils.

Relationship between charcoal percentage and germination of lettuce (Lactuca sativa L.) seeds (Manel 2010)

Rice husk charcoal-coated urea can potentially be used as a slow-releasing nitrogen fertilizer which reduces leaching losses of urea. It also helps to reduce the phosphate and potassium from leaching. The cyclic effect of phosphate release is an important finding, which could be the central issue in defining microbial behavior in soils. The fluctuations of phosphate may have cyclic effects of 28 days. Charcoal-coated urea also increased the pH and redox potential value of the soil up to the desired levels (Gamage 2015). Sometimes, municipal solid waste compost cannot be used directly as a fertilizer, due to the presence of pathogens, unwanted materials, and toxic compounds such as heavy metals (Zucconi et al. 1985; Gajdos 1997), but it can be pyrolyzed to char reducing the mobility of heavy metals (Paz-Ferreiro et al. 2014) and getting rid of pathogens (Bond et al. 2017). The proximate analysis for this study is given in Table 3. The inorganic content in this charcoal showed a higher pH value of 9.1 due to a high ash content.

We did an interesting experiment to develop a biocatalyst char (BCC) activated with market wastes and Eppawala rock phosphate (ERP) in aerobic and anaerobic reactors mixed in water and then applied to garden wastes to make compost. The addition of charcoal when needed was the method used to control the pH; thus, the activation level of the digesting slurry was controlled, before adding the slurry into garden wastes. The catalyst-added compost was relatively high in nutrients compared to the control compost. In addition, aerobic catalyst-added compost had high phosphorus content than anaerobic catalyst-added compost, but the ammonium nitrogen content was high in anaerobic catalyst-added compost than others. The level of decomposition was higher in the compost with the aerobic catalyst (Gunasekara 2014). Biochar and biochar-biocatalyzed fertilizer notably having high pH can be used to neutralize acidic soils in most parts of the country and world, thus eliminating the use of lime which is an abiotic resource or transportation of alkaline soils that have less nutrient value than biochar-based fertilizers. In other words, such fertilizer neutralizes acid soils while providing nutrients in one application.

5 Field Experimentations

Apart from the differences in biochar quality, it was essential to determine the effect of char as a replacement for urea. Therefore, we undertook a study knowing the fact that the rice cultivars in Sri Lanka require very high nitrogen contents and thus respond best to inorganic fertilizers. It certainly did for the plots with recommended inorganic fertilizers (1) giving highest yields in the Yala season (Table 4), whereas the plots with inorganic fertilizers mixed with compost (3) gave a better yield than inorganic alone in the Maha season (Table 5). In that season, the plots with charcoal and 30% w/w recommended inorganic fertilizers (2) performed better than inorganic alone but with much less nitrogen. The yields were not significantly different in the Yala season between (1), (3), and (4). Namely, (4) were the plots with charcoal, paddy straw compost, and 30% (w/w) recommended inorganic fertilizers in the Yala season (Gamage 2015). The paddy straw compost was processed in a simulation lysimeter of a landfill bioreactor (Thivyatharsan et al. 2012). The study aimed at maximizing methane emission from a mixture of rice straw, cow dung, and green materials and evaluating the quality of the resulting compost. The color of the compost was very dark brown, and it did comply with SLS guidelines for quality of compost. The study shows that there is a high potential of producing compost from landfill bioreactors using rice straw (Gamage et al. 2010).

We wanted to promote vegetable cultivation with biochar that can be grown under coconut in the Hambantota district. We selected Amaranthus oleraceus for the field experiment with six treatments including soil as control (Ariyawansha et al. 2013). The charcoal was prepared using the traditional pit method; thus, lighter materials oxidize to form ash that get mixed with made char. We observed that the quality of biochar had an influence on plant growth and yield. There were considerable differences between treatments. The best performance including the highest yields of plant growth was observed from treatment 3, biochar made from coconut shells, and it has followed an ideal growth curve as shown in Fig. 10. Such high yields obtained from inter-cultivation under coconut have symbiotic benefits, such as it increases the productivity of coconut lands and consumption of Amaranthus oleraceus, thus reducing the extent of cultivation required in a small country like Sri Lanka. Both the statistical analysis and kinetic studies indicate a significant difference of biochar application with organic and inorganic fertilizer applications. The biochar which was produced with coconut husk and Gliricidia sepium sticks showed growth retardations due to inhibitions caused by high ash content. Total fresh weight recorded per plot can be ranked as highest from being from coconut shell biochar (CSB) (4.36 kg) followed by coconut husk biochar (CHB) (2.78 kg), then biochar made from Gliricidia sepium sticks (2.4 kg), recommended fertilizer (2.08 kg), compost (1.82 kg), and lowest the control (1.27 kg). This study proved that a localized production of nutrient supply by biochar applications reduces the cost of production.

Relationship between average plant height and days after planting (Ariyawansha et al. 2013)

We conducted another study to investigate the possibility to use coconut-based biochar as soil amendments in integrated Zea mays cultivation in a coconut land (Waduge 2011). There were five treatments. The best mean yield was obtained from CSB with recommended fertilizer (RF), and it reduces in the order of RF, CHB with RF, CHB, and least of all CSB (Table 6). The results show that the quantity of fertilizer can be reduced. This study also revealed that we can optimally use the applied chemical fertilizers by adding a stable form of biochar to the soil (Ariyawansha et al. 2013).

We conducted a field experiment with ten treatments to evaluate the effect of biochar applications with 30% of recommended inorganic fertilizer on Cucumis sativus growth (Weerasekara et al. 2013). It was a collaborative research project with HJS Condiments Limited. The combined effect of biochar and inorganic fertilizer gave the best yield (Fig. 11) in comparison to other treatments as a result of reduction of N fertilizer leaching from the soil, similar to reported by Chan et al. (2009). Several mechanisms contribute to the decrease in nutrient leaching which are related to increased nutrient use efficiency by increased water and nutrient retention (residence time in the root zone) and availability. It is likely to be related to an increase in internal reactive surface area of the soil-biochar matrix, thus decreasing water percolation below the root zone. Notably, the conditions were favorable for increased plant water use (increased evaporative surface) and increased plant nutrient use through enhanced crop growth (Basnayake et al. 2011). In relation to pest and disease attacks, the biochar treatments withstood well to aphid attack and downy mildew in comparison to the use of inorganic fertilizers. The least of the attacks was observed in the biochar with inorganic recommended fertilizers. Biochar may have a positive impact on plant resistance to disease due to its suppressive effect on soil pathogens (Matsubara et al. 2002).

Grade 1 (export quality) yields of the treatments in Block 4 (Weerasekara et al. 2013). Note: T1 = control (growing on soil), T2 = standard practices recommended by HJS Condiments Ltd., T3 = soil + inorganic fertilizer (IF) recommendation, T4 = soil + BC (BC replacing all recommended inputs on dry weight basis (db)), T5 = soil + BC + compost (BC replacing all IF on db), T6 = soil + BC + IF (replace compost with BC on db), T7 = soil + BC + compost + IF – urea (replace urea with BC), T8 = soil + BC + IF – urea (replace compost + urea with BC), T9 = soil +70% BC+ 30% IF and compost, and T10 = soil + BC + compost + IF

The replacement of inorganic nitrogen with nitrogen-rich plants or even trapping available nitrogen in composting processes was the focus of recent research. The field experiments conducted with developed fertilizer of granules made with active phase composting with biochar show very promising results. In a pot experiment, we grew Solanum lycopersicum (tomato) (Chularathna 2015). The plant heights were best with the developed fertilizer (1) and in order of lesser heights were 70% developed fertilizer with 30% recommended fertilizer (2), recommended fertilizer (3), and lastly the control with only soil (4). However, the mixed treatment gave highest yields followed by developed organic fertilizers and then recommended fertilizers and finally the control. The high vegetative growth could be attributed to available nitrogen, but the phosphorus and potassium would have been limiting for producing more fruits. As we have reported, the cyclic effect of phosphorus could be the central issue in defining microbial behavior in soils. Soil microorganisms act as sink and source of phosphorus (P) and mediate key processes in the soil P cycle, e.g., P mineralization and immobilization (Oberson and Joner 2005). The genetic and biochemical mechanisms of these transformations are not yet completely understood (Ohtake et al. 1996).

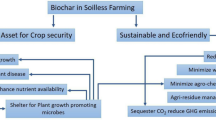

6 Sustainable Agriculture Productions with Biochar Applications

The sustainability of agriculture is very much dependent on the availability of phosphorus. In fact, the cumulative annual yields of paddy plotted against cumulative annual phosphorus and potassium applications follow a hyperbolic function than a straight line indicating exhaustion and degrading soils and poor cultivation practices (Basnayake et al. 2011). In applying biochar, we can overcome reductions in yields and increase productions, because our finding of cyclic effect of phosphorus is the key factor in differentiating soils ameliorated with biochar being better and more effective media for plant growth as opposed to only soil. The results of the studies throughout the world indicate that the role of biochar can be defined as materials with varying degrees of promoting optimum soil microcosms to provide nutrients while functioning as a “receptor,” which makes it a “nutrient regulator.” It has many diverse properties unlike the effects of one-way nutrient supply in inorganic fertilizer applications. Therefore, it requires in-depth research to find the mechanisms of fixing both carbon and nitrogen in biochar at required levels of nutrients like phosphorus availability to the plant while mobilizing it from the soil. In response to enhancing the property of “nutrient regulator,” the development of new biochar-based fertilizers should focus on finding types of substrates needed for microcosms to anchor phosphorus in the matrix of biochar structures and release it when needed by the plant, thus functioning as supplier and receptors. It is then necessary to introduce new cultural practices rather than rely on continuous fertilizer applications, since the buildup of receptors every season will eventually fix adequate nitrogen and carbon from the atmosphere, while phosphorus remains available to microcosms, like Terra Preta de Indio.

In view of disseminating the findings, it will depend on biomass generation, gathering and processing systems, making available enough feedstocks for advanced thermal conversions in different ecological regions in the country. Increasing the biomass generations of intercropping, including so-called weeds between cultivation seasons, is useful in fixing large quantities of nitrogen, which are mostly lost in current cultivation practices. We hope that the academics, scientists, researchers, engineers, administrators, and politicians understand the usefulness of land consolidation in sustainable development and formulate a policy with a sound strategy and a planning process to implement large-scale use of paddy straw for making fertilizer. Therefore, the use of paddy straw bales, cow dung, and green manure is a “need of the hour” for firstly producing energy and refrigeration requirements for preserving seeds and processing of food and secondly extracting valuable compost from landfill bioreactors for making biochar-based fertilizer that can contribute toward self-sustainability of the farming communities. Moreover, the findings in 1994 are still valid and proven beyond doubt with enhanced and matured knowledge bases in the country to assist small and medium enterprises in partnership with the farming communities to generate electricity that can be supplied to the national grid while producing fertilizer. It is better than relying on large trading companies to drive the miserable and ailing third world economy of this country.

References

Ariyawansha RTK, Basnayake BFA, Vijenayaka DMGP, Waduge NS, Gamage DAS (2013) Biochar applications for enhancing nutrient availability in tropical soils. In: Proceedings of the international conference on solid waste 2013 – Innovation in Technology and Management, Hong Kong SAR, P.R. China, 5 – 9 May 2013, pp 676–679

Ariyawansha RTK, Senevirathne SADN, Basnayake BFA (2014) Potential of converting paddy straw to bio-char and electricity in Sri Lanka. In: Proceedings of 11th Asia Pacific Roundtable on Sustainable Consumption and Production (APRSCP). 19–20 May 2014 in Plaza Athénée, Bangkok, Thailand, pp 207–222

Basnayake BFA (1986) Conception and functioning of a multi-product pyrolyzer (Conception et fonctionnement D’un carbonisateurmultiproduits). DEng Thesis. Université de Pierre et Marie Curie, Paris, France

Basnayake BFA(1994) Patent of discovery of a process to retard the release of nitrogen fertilizer by using charcoal and manioc. No: 10665

Basnayake BFA, Ariyawansha RTK, Senevirathne SADN (2011) A mathematical predictions on poor response to fertilizer applications for increased paddy and tea productions and remedial measures with biochar and integrated pest management programmes in Sri Lanka. In: International symposium on agriculture and environment, On November 9th 2011, at Faculty of Agriculture, University of Ruhuna, Sri Lanka

Bezerra J (2015) Chapter 2: Terra Preta de Índio and Amazonian History. In: The Brazilian Amazon world forests 21. Springer, Cham

Bond T, Tse Q, Chambon CL, Fennell P, Fowler GD, Templeton MR (2017) The feasibility of char and bio-oil production from pyrolysis of pit latrine sludge. Environ Sci Water Res Technol 3(6):1171

Chan KY, Van Zwieten L, Meszaros I, Downie A, Joseph S (2009) Agronomic values of green waste biochar as a soil amendment. Aust J Soil Res 45:629–634

Chularathna WGGS (2015) Evaluation and characterization of organic biochar fertilizer produced through active phase composting. Undergraduate thesis. Department of Natural Resources, Faculty of Applied Sciences, Sabaragamuwa University of Sri Lanka

Demirbas A, Kucuk M (1997) Biomass conversion processes. Energy Convers Manage 38(2):151–161

Gajdos R (1997) Effects of two composts and seven commercial cultivation media on germination and yield. Compost Sci Util 5:16–37

Gamage DAS (2015) Development of nutrient management technologies for sustainable rice farming for mitigating water and atmospheric pollution. PhD thesis, Postgraduate Institute of Agriculture, University of Peradeniya, Peradeniya, Sri Lanka

Gamage DAS, Sarachchandra NL,Basnayake BFA, Costa WAJM (2010) Lysimeter simulation of paddy straw landfill bioreactor to generate biogas and minimize ground water pollution. In: 9th Asia Pacific Roundtable for Sustainable Consumption and production 10th – 12th June 2010. Colombo Sri Lanka

Gamage DAS, Basnayake BFA, Costa J, Vidanagamage K (2012) Evaluation of total N, P, K and organic matter contents of soil amended with paddy husk charcoal coated urea and comparison of the yield of paddy. In: Proceedings of international conference on sustainable built environment, Sri Lanka

Gunasekara NS (2014) Development of an effective organic fertilizer through a novel approach of biocatalyst derived from biochar. B.Sc. thesis, Department of Agricultural Engineering, Faculty of Agriculture, University of Peradeniya, Sri Lanka

Haefele SM, Konboon Y, Wongboon W, Amarante S, Maarifat AA, Pfeiffer EM, Knoblauch C (2011) Effects and fate of bio-char from paddy residues in paddy-based systems. Field Crop Res 121:430–440

https://www.geozentrum-hannover.de/DE/Gemeinsames/Nachrichten/Veranstaltungen/2009/Hauskolloquium_2009_2010/2009_10_06_abstracts.html. Accessed on 28 Apr 2018

https://www.youtube.com/watch?v=0Os-ujelkgw. Accessed on 01 May 2018

IEA Bioenergy (2007) Biomass pyrolysis. http://www.ieabioenergy.com/wp-content/uploads/2013/10/Task-34-Booklet.pdf. Accessed on 01 May 2018

Iranzo M, Canizares JV, Roca-Perez L, Sainz-Pardo I, Mormeneo S, Boluda R (2004) Short communication: characteristics of paddy straw and sewage sludge as composting materials in Valencia (Spain). Bioresour Technol 95:107–112

John A (2013) Alternatives to open-field burning on paddy farms. Options 18

Kadam KL, Forrest LH, Jacobson WA (2000) Paddy straw as a lignocellulosic resource: collection, processing, transportation, and environmental aspects. Biomass Bioenergy 18:369–389

Kishimoto S, Sugiura G (1985) Charcoal as a soil conditioner. In: Symposium on forest products research, international achievements for the future, vol 5, pp 12–23

Lehmann J, Joseph S (2009) Biochar for Environmental Management, Earthscan, Dunstan House, 14a St Cross Street, London, ECIN 8XA, UK

Manel UGE (2010) Development of a municipal solid waste pyrolyzer for producing high quality charcoal. B.Sc. thesis, Department of Agricultural Engineering, Faculty of Agriculture, University of Peradeniya, Sri Lanka

Matsubara Y, Hasegawa N, Fukui H (2002) Incidence of Fusarium root rot in asparagus seedlings infected with arbuscular mycorrhizal fungus as affected by several soil amendments. J Jpn Soc Hortic Sci 71:370–374

Mukherjee A, Lal R (2014) The biochar dilemma. Soil Res 52:217–230

Oberson A, Joner EJ (2005) Microbial turnover of phosphorus in soil. In: Turner BL, Frossard E, Baldwin DS (eds) Organic phosphorus in the environment. CABI, Wallingford, pp 133–164

Ohtake H, Kato J, Kuroda A, Taguchi K, Sakai Y (1996) Chemolactic signal transduction in pseudomonas aeruginosa in pseudomonas. In: Nakazawa T, Furukawa K, Hass D, Silver S (eds) Molecular biology and biotechnology. American Society for Microbiology, Washington DC, pp 188–194

Paul S (1982) Bio-energy re-news. J Energy Biomass Recycl 1:1–48

Paz-Ferreiro J, Lu H, Fu S, Méndez A, Gascó G (2014) Use of phytoremediation and biochar to remediate heavy metal polluted soils: a review. Solid Earth 5:65–75

Putun EA, Apayd E, Putun E (2004) Paddy straw as a bio-oil source via pyrolysis and steam pyrolysis. Energy 29:2171–2180

Sanderatne N, de Alwis S (2018) The demographic transition in Sri Lanka: A socio-economic analysis. Marga Institute, 941/1, Jayanthi Mawatha, Kotte Road, Ethul Kotte

Santiago A, Santiago L (1989) Charcoal chips as a practical substrate for container horticulture in the humid tropics. Acta Hortic 238:141–147

Thivyatharsan R, Gunarathna HAYR, Basnayake BFA, Kuruparan P (2012) Performance and suitability of a landfill bioreactor with low cost biofilm contained clay-waste polyethylene-clay composite liner system for tropical climates of Asian countries. J Mater Cycles Waste Manage. https://doi.org/10.1007/s10163-011-0039

Waduge NS (2011) Use of coconut based biochar as soil amendment for integrated maize cultivation in coconut lands. Directed study report. Postgraduate Institute of Agriculture, University of Peradeniya, Sri Lanka

Weerasekara IACS, Ariyawansha RTK, Basnayake BFA, Karunarathne AK, Pathirage AC, Basnayake CA (2013) Evaluation of biochar influence on nutrient regulation for growth and yield improvements of gherkin (Cucumis sativus L.). In: Proceedings of the international conference on solid waste 2013 – Innovation in Technology and Management, Hong Kong SAR, P.R. China, 5–9 May 2013, pp 684–686

Zucconi F, Monaco A, Forte M, Bertoldi MD (1985) Phytotoxins during the stabilization of organic matter. In: Gasser JKR (ed) Composting of agricultural and other wastes. London/New York, Elsevier Applied Science, pp 73–88

Acknowledgments

The authors thank CEMAGREF and France for the financial and technical support given for R&D activities and Kandy Municipal Council, Coconut Cultivation Board, HJS Condiments Ltd., and academic and nonacademic staff of the Department of Agricultural Engineering and Postgraduate Institute of Agriculture, University of Peradeniya for supporting the research and development efforts. We wish to thank Aurora Basnayake for English corrections and valuable comments on comprehension.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Basnayake, B.F.A., Ariyawansha, R.T.K., Gamage, D.A.S., Karunarathna, A.K. (2020). Experiences of Biochar Applications for Sustainable Agriculture in Sri Lanka. In: De Silva, R.P., Pushpakumara, G., Prasada, P., Weerahewa, J. (eds) Agricultural Research for Sustainable Food Systems in Sri Lanka. Springer, Singapore. https://doi.org/10.1007/978-981-15-3673-1_12

Download citation

DOI: https://doi.org/10.1007/978-981-15-3673-1_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-3672-4

Online ISBN: 978-981-15-3673-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)