Abstract

In this paper, an analysis of exergy of an air conditioner having condenser of air-cooled type is presented. The prime objectives of this paper are to analyse all the four main components (condenser, expansion valve, compressor and evaporator) of vapour compression refrigeration system individually and then to quantify and identify the sites having the largest exergy losses. The exergy efficiency is also calculated at different ambient conditions, i.e. (30, 32, 34, 36 and 38 °C) with different volume flow rates of air, i.e. (0.08, 0.1, 0.12, 0.14 and 0.16 m3s).The results showed that exergy loss is highest in the compressor. The order of exergy loss is (Exergy Destruction)compressor > (Exergy Destruction)condenser > (ExergyDestruction)evaporator > (ExergyDestruction)expansionvalve. In addition, the exergy efficiency of the system varies from 31.10 to 34.52%.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

55.1 Introduction

The atmospheric temperature has increased so much because of the adverse effects of global warming. Thus, even in the rural areas, air conditioners and refrigerators have become an integral part of human life [1,2,3]. Human comfort is much important to the extent for the industrial and domestic areas are concerned and due to which air conditioning bears a heavy cost. To make a such system more efficient and environment-friendly, main difficulty is to utilise few energy and to have the minimum losses [4, 5]. To predict all the thermodynamic cycles and determination of irreversibility attached to all processes is very important [6, 7]. Thus, irreversibility associated with a process is qualitatively determined by exergy analysis. It helps the engineers and scientists to focus on the areas where the improvement can be done and the effectiveness of vapour compression refrigeration system can also be further improved [8]. The exergy losses can be determined by the second law-based analysis [9, 10]. Padilla et al. [11] performed exergy analysis of domestic VCRS with R413a and R12. They investigated that the performance in terms of irreversibility, power consumption and exergy efficiency of R413a is finer as that of R12, so R12 can be changed with R413a in domestic VCRS. The way to determine different losses as well as COP and exergetic efficiency of the cycle has been described by proper example. Yumrutas et al. [12] performed exergy analysis-based exploration of the effect of evaporator and condenser temperature on VCRS cycle in terms of COP, pressure losses, exergy losses and second law efficiency. He concluded that disparity in temperature of condenser has very less effect on exergy losses of expansion valve and compressor. Also, exergy efficiency and first law efficiency increase but total exergy losses of system decrease on increasing the operating temperature of condenser and evaporator. Park et al. [13] described through EEVs mass flow features of R410a and R22. They showed that with the increase in sub-cooling, EEV opening and inlet pressure, the mass flow rates passing through EEVs also increase. Nikolaidis and Probert [9] studied two-stage vapour compression refrigeration plant and determined the effect of change in temperatures of evaporator and condenser analytically. Venkataramanamurthy et al. [14] conducted an experimental test for vapour compression refrigeration system and analysed the energy flow and comparisons of the second law efficiency of R22 and its replacement R-436b.

In this paper, the exergy analysis of all the four main components (condenser, expansion valve, compressor and evaporator) of VCRS is individually analysed. The exergy loss and efficiency are calculated at different ambient conditions with different volume rates of air.

55.2 Experimental Set-up

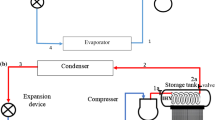

Figure 55.1 represents the experimental set-up of an air conditioner. In this experimental set-up, R-410a is used as refrigerant. The chief components of an air conditioning system are compressor, condenser, throttling device and evaporator.

Formulae Used:

Exergy balance for the control volume can be described as:

The component-wise exergy balance equation is as follows:

-

(1)

Compressor:

-

(2)

Condenser:

-

(3)

Expansion device:

-

(4)

Evaporator:

The total exergy destruction in the VCRS is the sum of exergy destruction in the four main components of the VCRS and is expressed as follows:

-

(5)

Total exergy destruction:

-

(6)

Exergy effiency:

55.3 Results

Tables (55.1, 55.2, 55.3, 55.4 and 55.5) show the exergy losses at different ambient temperatures with different volume flow rates of air.

55.4 Graphs and Discussion

From Figs. 55.2 and 55.3, it can be seen that exergy loss of compressor is maximum among all other components but it decreases with increase in volume flow rate while increases with increase in ambient temperature. But among all the parts of air conditioning system, exergy loss is minimum in expansion valve.

From Fig. 55.4, it can be found that total exergy loss increases continuously with increment in ambient temperature. As with increase in the ambient temperature, COP of system decreases.

From Fig. 55.5, it conveys that total exergy loss increases with volume flow rate of refrigerant but it obtains an optimum value of nearly 0.1 m3/s.

55.5 Conclusions

Exergy analysis is a method to describe the process and this further helps in reducing the thermodynamic losses happening in these processes. It is a salient feature in explaining the different energy flows in the process and in the final run helps to reduce losses happening in the main system. The following results are drawn:

-

However, the volume flow rate and ambient temperature do affect the exergy losses for all components, but highest losses occur in compressor for all the cases. The order of exergy loss is (EXD)compressor > (EXD)condenser > (EXD)evaporator > (EXD)expansion valve.

-

The exergy efficiency of the VCRS varies from 31.10 to 34.52% at different ambient conditions for different volume rates of air.

Abbreviations

- Wc:

-

Compressor work

- Qc:

-

Refrigerating effect

- Mr:

-

Refrigerant mass flow rate

- h1:

-

Refrigerantenthalpy at exit of evaporator or inlet of compressor in kJ/kg

- h2:

-

Refrigerant enthalpy at exit of compressor or inlet of condenser in kJ/kg

- h3:

-

Refrigerant enthalpy at exit of the condenser or inlet of expansion valve in kJ/kg

- h4:

-

Refrigerantenthalpy at exit of expansion valve or entry of evaporator in kJ/kg

- S1:

-

Refrigerantentropy at the exit of evaporator or inlet of compressor in kJ/kg-K

- S2:

-

Refrigerantentropy at exit of compressor or inlet of condenser in kJ/kg-K

- S3:

-

Refrigerant entropy at exit of condenser or inlet of expansion valve in kJ/kg-K

- S4:

-

Refrigerantentropy at exit of expansion valve or entry of evaporator in kJ/kg-K

- Te:

-

Evaporator temperature

- Tc:

-

Condenser temperature

- To:

-

Ambient temperature

- ηexergy:

-

Exergy efficiency

References

Ansari, A.A., Goyal, V., Yahya, S.M., Hussain, T.: Experimental investigation for performance enhancement of a vapor compression refrigeration system by employing several types of water-cooled condenser. Sci. Technol. Built Environ. 24(7), 793–802 (2018)

Hughes, B.R., Chaudhry, H.N., Ghani, S.A.: A review of sustainable cooling technologies in buildings. Renew. Sustain. Energy Rev. 15(6), 3112–3120 (2011)

Duan, Z., Zhan, C., Zhang, X., Mustafa, M., Zhao, X., Alimohammadisagvand, B., Hasan, A.: Indirect evaporative cooling: past, present and future potentials. Renew. Sustain. Energy Rev. 16(9), 6823–6850 (2012)

Caliskan, H., Dincer, I., Hepbasli, A.: Exergoeconomic, enviroeconomic and sustainability analyses of a novel air cooler. Energy Build. 55, 747–756 (2012)

Costelloe, B., Finn, D.: Thermal effectiveness characteristics of low approach indirect evaporative cooling systems in buildings. Energy Build. 39(12), 1235–1243 (2007)

Maheshwari, G.P., Al-Ragom, F., Suri, R.K.: Energy-saving potential of an indirect evaporative cooler. Appl. Energy 69(1), 69–76 (2001)

Rosen, M.A., Dincer, I., Kanoglu, M.: Role of exergy in increasing efficiency and sustainability and reducing environmental impact. Energy policy 36(1), 128–137 (2008)

Arora, A., Kaushik, S.C.: Theoretical analysis of a vapour compression refrigeration system with R502, R404A and R507A. Int. J. Refrig 31(6), 998–1005 (2008)

Nikolaidis, C., Probert, D.: Exergy-method analysis of a two-stage vapour-compression refrigeration-plants performance. Appl. Energy 60(4), 241–256 (1998)

Mairaj, M., Siddiqui, S.A., Hafiz, A.: Energetic and exergetic analysis of some models of vapour absorption chillers using lithium bromide and water. J. Basic Appl. Eng. Res. 2(4), 326–329 (2015)

Padilla, M., Revellin, R., Bonjour, J.: Exergy analysis of R413A as replacement of R12 in a domestic refrigeration system. Energy Convers. Manag. 51(11), 2195–2201 (2010)

Yumrutaş, R., Kunduz, M., Kanoğlu, M.: Exergy analysis of vapor compression refrigeration systems exergy. Int J 2(4), 266–272 (2002)

Park, C., Cho, H., Lee, Y., Kim, Y.: Mass flow characteristics and empirical modeling of R22 and R410A flowing through electronic expansion valves. Int. J. Refrig. 30(8) 1401–1407 (2007)

Venkataramanamurthy, V.P., Kumar Senthil, P.: Experimental Comparative energy, exergy flow and second law efficiency analysis of R22, R436b vapour compression refrigeration cycles. Int. J. Sci. Technol. 2(5), 1399–1412 (2010)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Hussain, T., Hafiz, A., Akramuddin (2020). Exergy Analysis of an Air Conditioning System Using Air-Cooled Condenser at Different Ambient Conditions with Different Volume Flow Rates of Air. In: Yadav, S., Singh, D., Arora, P., Kumar, H. (eds) Proceedings of International Conference in Mechanical and Energy Technology. Smart Innovation, Systems and Technologies, vol 174. Springer, Singapore. https://doi.org/10.1007/978-981-15-2647-3_55

Download citation

DOI: https://doi.org/10.1007/978-981-15-2647-3_55

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-2646-6

Online ISBN: 978-981-15-2647-3

eBook Packages: EngineeringEngineering (R0)