Abstract

As one of the four major materials in packaging industry, plastic packaging has been widely used in many industries. However, the traditional plastics have caused serious pollution and damaged the ecological environment. At present, the most effective method is to develop biodegradable packaging materials. In this study, using starch and gelatin as fillers and PVA as matrix, we prepared a new type of biodegradable composite films and studied their properties. When the mass fraction of starch and gelatin are 25% and 12.5% respectively, the mechanical properties, optical properties and water vapor barrier properties of the composite film are the best. The composite films exhibit excellent ability to block ultraviolet radiation and biodegradability, which can be used not only for light-sensitive food packaging, but also for green package.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

As one of the four major materials in packaging industry, plastics packaging has been widely used in various fields, and brought great convenience to people’s lives. However, the raw materials of traditional plastics are non-degradable and non-renewable, which will seriously pollute the environment and endanger sustainable development. Therefore, exploring and researching biodegradable packaging materials based on renewable animal and plant resources has became an important issue to the life and development of people [1,2,3].

Starch is a renewable, biodegradable natural macromolecule material, which polymerized from glucose molecules. The degradation products of starch, CO2 and H2O, can be recycled by photosynthesis and are environment-friendly [4, 5]. Gelatin is a protein formed by partial hydrolysis of collagen. It has a wide range of sources, low cost, good biocompatibility and biodegradability [6, 7]. However, pure starch or gelatin films have many disadvantages, such as low strength, poor toughness, and poor water resistance, which make them unable to meet the application requirements. Therefore, it is necessary to add synthetic polymer to modify them [8,9,10]. Polyvinyl alcohol (PVA) is a water-soluble polymer, and PVA films can completely degrade by microorganisms in nature. It can be used as an auxiliary film-forming material and added to natural macromolecule materials to prepare composite packaging films, thus improving the performance of natural macromolecule packaging materials [11].

In this paper, two-component and three-component composite biodegradable PVA-based composite films were prepared by solution casting method with starch and gelatin as fillers and polyvinyl alcohol as matrix. Their optical properties, mechanical properties and degradation properties were studied.

2 Experiment

2.1 Materials and Equipment

Polyvinyl alcohol (PVA), AR, is produced by Kuraray Co., Ltd., Shanghai. Soluble starch, AR, is produced by Aladdi chemical reagent Co., Ltd., Shanghai. Gelatin, CP, is produced by Yongda chemical reagent Co., Ltd., Tianjin. Ethanol, AR, is produced by Guangfu chemical reagent Co., Ltd., Tianjin.

Thickness gauge, CHY-CZA, Labthink Co., Ltd., Shandong. Intelligent electronic tension tester, XLW, Labthink Co., Ltd., Shandong. Light transmittance/ haze tester, WAT-S, Shenguang instruments Co., Ltd., Shanghai. Water vapor transmission tester, W3/031, Labthink Co., Ltd., Shandong. UV-vis spectrophotometer, TU-1901, Purkinje general instruments Co., Ltd., Beijing. FT-IR spectrometer, Nicoletis10, Thermo fisher scientific Co., Ltd., Shanghai.

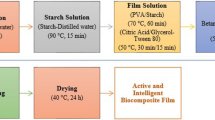

2.2 Preparation of Starch/PVA Composite Films

Six kinds of starch/PVA composite films were prepared according to the solid-liquid ratio of 1:10 and the mass fraction of soluble starch in the solid ratio of 0, 10%, 15%, 20%, 25% and 30% respectively. The mixture solution of starch and polyvinyl alcohol was heated at 90 °C for 2 h. Then the solution was coated on clean and flat glass plates. After 24 h, the films were peeled off, dried, and reserved in a drying cabinet. The thickness of the films was about 12–25 μm.

2.3 Preparation of Starch/Gelatin/PVA Composite Films

Gelatin was added to the starch and PVA solution, and the mass fraction of gelatin in total solids was 5%, 7.5%, 10%, 12.5% and 15% respectively. The mixture solution was heated and stirred at 50 °C for 2 h. After defoaming, the casting solution was coated on the glass plates. Then the films were peeled off, dried, and reserved in the drying cabinet. The thickness of the films was about 15–31 μm.

2.4 Mechanical Property Test

According to GB/T 1040-2006, the films were cut into 10 × 1.5 cm and balanced at 25 °C with relative humidity of 50% for 48 h. Tensile strength and maximum breaking elongation of the films were measured. Each sample was measured 10 times in parallel and the average value was obtained.

2.5 Optical Property Test

According to GB/T 2410-2008, the films were cut into 50 × 50 mm. The transmittance and haze were measured. Each sample was measured 5 times in parallel and the average value was obtained.

2.6 Water Vapor Permeability Test

According to GB/T 16928-1997, the films were cut into circles with diameter of about 76 mm. Under the standard mode, the experimental temperature was 38 °C, and the relative humidity difference between the two sides of the film was 90%. Each sample was measured 3 times and the average value was obtained.

2.7 FT-IR Spectroscopy

The measurement was carried out using the ATR mode with test range of 500 to 4000 cm−1 and resolution of 4 cm−1. The scanning times were 32 times.

2.8 UV-vis Spectroscopy

The thin film spline with 0.6 × 4 cm was placed into the cuvette, and light transmittance of the film was measured with air as the reference. The wavelength range was 200–700 nm, and the sampling interval was 1 nm.

2.9 Soil Degradation Test of Starch/Gelatin/PVA Composite Films

The degradation of the composite films was characterized under indoor humidity chamber and outdoor natural conditions respectively, and the degradation performance was expressed by weight loss percentage. The relative humidity of indoor was 60%, and the temperature was 25 °C. The soil was common horticultural soil, which was transferred into containers after debris removal. Outdoor conditions were natural and rainy in summer. After drying the films with 10×10 cm to constant weight (w0), they were buried in the soil below 10 cm and taken out periodically. After cleaning, the samples were dried in the oven at 65 °C to constant weight (w1). The weight loss rate (RWL) was calculated as follows.

3 Results and Discussion

In this section, we first prepared starch/PVA composite films, and determined the optimal starch and PVA mass ratio according to optical properties and mechanical properties. Then, starch/gelatin/PVA composite films were prepared, and studied their properties in order to develop new biodegradable composite materials.

3.1 Characterization of Starch/PVA Composite Films

Table 1 shows mechanical and optical properties of the starch/PVA films with different starch contents. The results shows the tensile strength and elongation of the films initially rised and then decreased gradually with the increase of starch content. This is because starch and PVA both contain much hydroxyl groups, which can interact with each other by hydrogen bonds, so that the mechanical properties of the composite films are gradually improved. When the starch content is too high, starch are cross-linked excessively with PVA, which limited’s the extension of molecular chains and increases the brittleness of the films, resulting in the decrease in tensile strength and elongation of the films. When the mass fraction of starch is 20%, the mechanical properties of the starch/PVA composite films are the best, with tensile strength of 110.96 MPa and elongation of 2.86%.

From the results of transmittance and haze of the composite films, it can be seen that with the increase of starch, the transmittance of the films decreased slightly, but all of them were above 90%, and the haze gradually increases. This indicates that the blend membranes have good compatibility with each other, but as the starch increases, the thickness of the film increases, the more light is absorbed, resulting in a decrease in transmittance. At the same time, the increase in thickness increases the scattering of light, resulting in an increase in haze.

Through synthetical consideration, the composite film with starch of 20% was selected for further research, that is, the ratio of starch to PVA in the composite film was 1:4.

3.2 Characterization of Starch/Gelatin/PVA Composite Films

3.2.1 FT-IR Spectroscopy

The FT-IR spectra of PVA, starch/PVA film and starch/gelatin/PVA composite films with different gelatin contents are shown in Fig. 1. The broad and strong absorption peaks of pure PVA film at 3342 cm−1 are O–H stretching vibration peaks, the double peaks at 2939 cm−1 and 2912 cm−1 are C–H stretching vibration peaks at –CH3 and –CH2 respectively, the peak at 1332 cm−1 is the bending vibration peak of CH–OH, the peak at 1140 cm−1 is the C–O stretching vibration peak, and the stretching vibration peaks at 1710 cm−1 of C=O bonds on the PVA branch are also observed. The stretching vibration peak of O–H in the starch/PVA film was narrowed, indicating hydrogen bonding interaction occurred between starch and PVA. After adding gelatin, the O–H stretching vibration peak narrowed further with the increase of gelatin, and a new peak appeared at 1662 cm−1, which corresponds to the stretching vibration peak of C=O in gelatin. This fully indicated gelatin entered the starch/PVA films and formed strong hydrogen bonds.

3.2.2 Tensile Strength and Elongation at Break

The tensile strength and elongation of starch/gelatin/PVA films with different gelatin contents are shown in Fig. 2. With the increase of gelatin content, the tensile strength of the composite films increases rapidly and then decreases, while the elongation increases gradually. This is because the interaction between gelatin and PVA enhanced, resulting in a denser network structure. Simultaneously, the interaction between gelatin and PVA destroys the interaction between starch and PVA, which increases the flexibility of the films. However, when the gelatin content reaches the certain value, the film-forming property of the solution is deteriorated, gelatin agglomerated and stress concentration formed, which reduces the tensile strength of the films, but has little effect on the toughness. When the percentage of gelatin was 12.5%, the tensile strength reached maximum value of 143.52 Mpa, and the elongation was 3.72%.

3.2.3 Transmittance and Haze

Figure 3 shows the optical properties of starch/gelatin/PVA films. With the increase of gelatin content, the transmittance of the films changed less, indicating that the compatibility between starch, gelatin and PVA was good. The haze of the films gradually increased, which was mainly caused by the thickness of the films. The addition of gelatin increases the thickness of the films, causes serious light scattering, and leads to an increase in haze.

3.2.4 Water Vapor Permeability Test

Figure 4 shows the effect of gelatin on water vapor permeability (WVP) of starch/gelatin/PVA films. As the gelatin content increases, the WVP of the films firstly decreased and then increased. This is because the functional groups in gelatin can interact with the hydroxyl groups in starch and PVA. This interaction reduce the exposed hydrophilic groups, thereby decrease the water absorption of the films. When the gelatin is too high, not only the network structure has been destroyed, but also the hydrophilic group has been directly introduced, and the water absorption of the film increased.

3.2.5 UV-vis Spectroscopy

Figure 5 shows the UV-vis spectra of pure PVA and starch/gelatin/PVA composite films. In the regions of 300–700 nm, the transmittance of pure PVA film is about 80%, and only partial ultraviolet absorption is exhibited below 300 nm, which indicates the ability to block ultraviolet radiation of PVA film is very poor. After adding gelatin, the transmittance of starch/gelatin/PVA composite films both decreases in the range of 300–700 nm and 200–300 nm, showing obvious ability to block ultraviolet radiation. With the increase of gelatin content, the ability to block ultraviolet radiation increases continuously. Since the composite films are effective in blocking UV radiation, they will have potential applications in light-sensitive food packaging.

3.2.6 Biodegradability Test in Soil

From the films degradation diagram (Fig. 6a) under indoor conditions, it can be seen the degradation rate of PVA film is slow in a short time. The weight loss rate (RWL) is only 7.18% in 52 days, and the degradation rate is almost zero in the first 24 days. After adding starch and gelatin, the degradability of the composite films increased rapidly. The RWL is high in the first seven days, then slowed down, and it increased with the increase of gelatin content. On the 52th day, the RWL of the composite films was all above 26%. This is because in the initial stage, the microorganisms in the soil are abundant, the starch and gelatin in the films can be used as nutrient matrix of microorganisms, the RWL of the films increased. Then the microbial nutrients in soil decrease, leading to a slower rate of RWL.

The weight loss of the films under outdoor conditions was shown in Fig. 6b. Compared with the PVA film, the degradation rate of the composite films increased significantly. The RWL was proportional to gelatin content in 52 days. The outdoor temperature is high and rainy, the humus is more, and the quantities of microorganisms increase. Starch and gelatin can be used as nutrients for microorganisms, therefore the RWL of the films is always fast, and the weight loss exceeds the weight loss of the films under indoor conditions.

4 Conclusions

In this study, biodegradable PVA-based composite films were prepared by solution casting method with starch and gelatin as fillers and PVA as matrix, and their properties were studied. (1) Using starch as the filler, the mechanical and optical properties of the composite films depended on the change in the starch content. When the starch content was 20%, the performance of the film was the best. (2) Using both starch and gelatin as the fillers, the mechanical properties and biodegradability of the composite films were significantly improved. When the mass fractions of starch and gelatin are 20% and 12.5% respectively, ultraviolet barrier and degradation properties of the film are the best. After 52 days in soil, the degradation rate of the film reached 35% indoor and 50% outdoor. Starch, gelatin and PVA have good compatibility, and adding starch and gelatin to PVA film can significantly improve the properties of PVA-based composite films, which make them suitable for light-sensitive food packaging and green package.

References

Richard AG, Bhanu K (2002) Biodegradable polymers for the environment. Science 297(5582):803–807

Khalil HPS, Tye YY, Saurabh CK, Leh CP (2017) Biodegradable polymer films from seaweed polysaccharides: A review on cellulose as a reinforcement material. Express Polym Lett 11(4):244–265

Zarina S, Ahmad I (2015) Biodegradable composite films based on κ-carrageenan reinforced by cellulose nanocrystal from kenaf fibers. BioResources 10(1):256–271

Wang S, Li C, Niu Q, Wang S (2015) Starch retrogradation: A comprehensive review. Compr Rev Food Sci Food Saf 14:1541–4337

Rahman WAWA, Sin LT, Rahmat AR (2010) Thermal behavior and interactions of cassava starch filled with glycerol plasticized polyvinyl alcohol blends. Carbohydr Polym 81(4):805–810

Russo MAL, Truss R, Halley PJ (2009) The enzymatic hydrolysis of starch-based polyvinyl alcohol plastics blends. Carbohydr Polym 77(3):442–448

Liu D, Nikoo M, Boran G, Zhou P, Regenstein JM (2015) Collagen and gelatin. Annu Rev Food Sci Technol 6:527–557

Zhao X, Lang Q, Yildirimer L (2016) Photocrosslinkable gelatin hydrogel for epidermal tissue engineering. Adv Health Mater 7:108–118

Farayde MF, Daryne C, Fábio Y (2012) Comparative study of processing methods for starch/gelatin films. Carbohydr Polym 95(2):681–689

Olga M, Julián C (2017) Influence of starch oxidation on the functionality of starch-gelatin based active films. Carbohydr Polym 178(15):147–158

Yang T (2006) Using water-soluble PVA bag packaging is solutions for the harm of pesticide packaging. Plast Packag 25(3):22–25

Acknowledgements

This study was funded by the National Natural Science Foundation of China (No. 21905079), the key scientific and technological project of Henan Province (No. 192102110159), and doctoral research start-up funds of Henan university of Animal Husbandry and Economy (No. 906/24030083).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Wang, L., Li, F. (2020). Study on Preparation and Properties of Starch/Gelatin/Polyvinyl Alcohol Biodegradable Composite Films. In: Zhao, P., Ye, Z., Xu, M., Yang, L. (eds) Advanced Graphic Communication, Printing and Packaging Technology. Lecture Notes in Electrical Engineering, vol 600. Springer, Singapore. https://doi.org/10.1007/978-981-15-1864-5_101

Download citation

DOI: https://doi.org/10.1007/978-981-15-1864-5_101

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-1863-8

Online ISBN: 978-981-15-1864-5

eBook Packages: EngineeringEngineering (R0)