Abstract

The possible sustainable technologies for waste-to-energy production are anaerobic digestion and hydrothermal carbonization. In this paper, aforementioned technologies were explored on yard waste. Yard waste was thermally pretreated to overcome inherent recalcitrant nature during anaerobic digestion to enhance biogas production. In addition, hydrothermal carbonization (HTC) of yard waste was also conducted for bio-solid fuel production. After pretreatment, the biogas production was improved from 311 ± 5 to 361 ± 11 mL/g VS. HTC of yard waste at different treatment conditions yields a higher calorific value up to 24.59 MJ/kg as compared to 15.37 MJ/kg for raw. In addition, the structural and chemical changes in biomass after pretreatment and hydrothermal carbonization were also studied. The HCT of yard waste at 200 °C for 24 h converted it into the dark lignite like coal with enhanced energy.

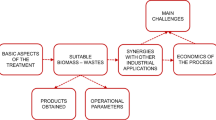

Graphical Abstract

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Industrialization and economic growth attract more and more people to a cities, and as a result, rate of urbanization is going to manifold in coming years which will also increase municipal solid waste (MSW) generation rate. Many of the Urban Local Bodies (ULBs) in India are struggling to manage MSW. This struggle is mainly due to inadequate waste managing facility, expertise and also due to lack of funds. India, a country with diverse religious groups, cultures and traditions, produces a waste composition which is unique to different cities. However, organic waste is a major fraction of MSW in ULBs which ranges between 54 and 64% (Hoornweg and Bhada-Tata 2012). Additionally, due to poor source segregation practices by urban population, wet and dry waste gets mixed which increases the overall moisture content. Thermal treatment of high moisture and low calorific waste is not suitable as wet waste has to be predried. Predrying itself is an energy-consuming process. Due to mixed nature of waste owing to poor segregation and also due to poor demand, composting is not feasible technically as well as economically.

Energy harvesting from waste is the most feasible option to handle the society transition for sustainable SWM along with the implementation of promising renewable technologies. Pertinent to Indian scenario and waste composition, anaerobic digestion (AD) and thermochemical treatment process like hydrothermal carbonization or wet torrefaction which processes a wet waste could be a reliable option. However, organic waste due to its recalcitrance nature needs to be pretreated before using it for an anaerobic digestion. Recalcitrance nature of organic waste is mainly due to lignocellulosic component like lignin, cellulose and hemicellulose. These lignocellulosic components are a complex polymer of a sugar and phenols which are not easily degraded by micro-organism and therefore yields less biogas during anaerobic digestion. To overcome such defiant nature of an organic waste for AD, due to its complex polymeric nature, it is pretreated, where polymer is broken down into simpler individual sugar or phenolic component to which micro-organism acts and yields more biogas.

Hydrothermal carbonization (HTC) is another relatively newer thermochemical treatment technique which treats wet waste or dry waste in the presence of water (Benavente et al. 2015). Waste is heated in a closed reactor at the subcritical temperature range of water generally between 200 and 260 °C for 30 min to 3 h in a auto-generated pressure. HTC takes advantage of special property of water that manifests during high temperature and pressure. During high temperature, in a subcritical range, water behaves both as acid as well as base (Funke and Ziegler 2010). Ionization of water increases during high temperature which promotes bond cleavage of complex polymeric chain of lignocellulosic component (Funke and Ziegler 2010; Kruse and Dahmen 2015). The broken glucose or phenolic molecule of lignin, cellulose and hemicellulose gets converted into coal-like material owing to series of chemical reaction like dehydration, decarboxylation, demethanation, aromatization and polymerization (Berge et al. 2011). The final solid char formed is called as a hydrochar whose value-added application is reported in a wide range of area in a literature including fuel, adsorbent, soil amender and as a precursor to a noble carbon materials.

This paper provides an insight in an AD and HTC of organic waste from MSW as a means for resource recovery, thereby contributing to a sustainable SWM transition.

2 Materials and Methods

2.1 Yard Waste Collection, Preparation and Characterization

YW [consisting of mainly dry leaves (65%), grass (33%) and fallen sticks (2%)] was collected in November 2017 from Indian Institute of Technology Kharagpur campus in West Bengal, India. Then, the feedstock was dried in an ambient temperature to reduce the moisture content, and then, it was grinded with a domestic mixture grinder (Havells Marathon, 2200 W, 230 V) to reduce its particle size and referred as prepared biomass. The prepared biomass was stored in an airtight bag.

The effluent from liquid anaerobic digester handing wastewater of Indian Institute of Technology Kharagpur was used as the inoculum. Prior to use, the collected inoculum was centrifuged to increase its total solid (TS) content. The key initial characteristics of YW and inoculum are presented in Table 1 (Fig. 1).

Heap of collected yard waste consisting of dry leaves O (65%), grasses and garden trimmings O (33%), fallen sticks and wild flower petals O (2%) (With permission from Elsevier with the license number 4703420251430 (Sharma et al., 2019))

2.2 Experimental Procedure for Pretreatment and Batch Anaerobic Digestion

Thermal pretreatment of the prepared biomass was carried out by a hot air oven (600 W, 2450 MHz). Pretreatment temperature and time were selected according to the literature reported by Ennouri et al. (2016), González-Fernández et al. (2013), Agbor et al. (2011). All pretreatments were carried out in 250 mL glass conical flask bottles contained 5 mg YW and 150 mL deionized water. After each pretreatment, the conical flasks were kept in a water bath to bring its temperature to normal temperature. One control sample was kept without any pretreatment named as untreated. Whole experiment and analysis were carried out in triplicate.

Batch AD of pretreated and untreated samples was carried out to examine the effect of pretreatment on biogas production. The batch AD process was carried out in a 1 L glass bottle under mesophilic conditions. Centrifuged inoculum was used. Food to micro-organism ratio of 2:1 was maintained in the reactor. Complete anaerobic condition inside the reactor was ensured by purging nitrogen gas into the reactor. The batch biochemical methane potential was measured by water displacement method. The batch BMP test was conducted for an approximately 30 days until biogas production was stopped.

2.3 Experimental Procedure for Hydrothermal Carbonization

The HTC was carried out in a 50 mL Teflon lined autoclave. For each experiment, 4 g of YW was mixed with 40 mL of distilled water. The autoclave was closed and placed in an electric furnace and heated to the desired temperature at a heating ramp of 13 ± 4 °C/min. The HTC was conducted as a two set of experiments. In the first set, only temperature was increased (160, 180 and 200 °C) keeping time constant (2 h). In the second set of experiment, time was increased (4, 8, 12 and 24 h) keeping temperature constant (200 °C). Calorific value of hydrochar produced at 200 °C in the first experiment was higher, so we decided to increase the temperature at it. After the desired reaction time, autoclave was immersed in a cold water bath to avoid any reaction beyond the desired residence time. Then, the dark slurry (hydrochar) was vacuum filtered and washed with distilled water for multiple times and stored in a zip lock bag for further analysis. The each sample was designated as per the reaction temperature and the time. Hydrochar prepared at the temperature and time of 160 °C and 2 h, respectively, was coded H-160-2. Similarly, rest were coded as H-180-2, H-200-2, H-200-4, H-200-8, H-200-12, H-200-24 for the hydrochar prepared at temperature–time of 180 °C–2 h, 200 °C–2 h, 200 °C–4 h, 200 °C–8 h, 200 °C–12 h and 200 °C–24 h, respectively.

2.4 Instrumentation

Physico-chemical parameters TS, volatile solid (VS), pH, alkalinity and soluble COD (sCOD) of the samples were measured using standard methods (APHA 2005). Volatile fatty acids (VFAs) were measured by the procedure described by (Lahav et al. 2002). Ultimate analysis in terms of carbon (C), hydrogen (H) and nitrogen (N) contents of YW was carried out using standard procedure of CHNS analysis by using EUROEA, fully automatic elemental analyser.

2.5 Structural Characterization

The surface structure properties of untreated and pretreated YW were analysed by SEM (Carl Zeiss SMT, Germany). The effect of thermal pretreatment on chemical composition of biomass was analysed by FTIR (NEXUS-870, Thermo Nicolet Corporation, USA).

3 Result and Discussion

3.1 Thermal Pretreatment and Anaerobic Digestion

3.1.1 Effect of Thermal Pretreatment on Organic Matter Solubilization and Subsequent Anaerobic Digestion

Thermal pretreatment of YW by hot air oven was conducted for a temperature range of 70–200 °C for a treatment duration of 45 min (Fig. 2a). A highest treatment temperature of 200 °C was selected to avoid pyrolysis reaction and formation of inhibitors. The sCOD of untreated YW was 189.35 ± 5.45 mg/L. There was an increase in sCOD to 208.6 ± 4.88 was found with increase in treatment temperature to 70 °C, with further increase in temperature to 120 °C led to decrease in sCOD to 175.6 ± 5.02 mg/L. Then, an increase in organic matter solubilization was found with increase in treatment temperature from 120 to 170 °C. The increase in sCOD with increase in temperature up to 70 °C is due to solubilization of extra polymeric substances (González-Fernández et al. 2013). However, the decrease in sCOD with further increase in temperature up to 120 °C was due to vaporization of solubilized compounds. The increase in organic matter solubilization at 170 °C was due to solubilization of structural components of YW. Hot air oven pretreatment for a treatment temperature of 200 °C led to decrease in organic matter solubilization was due to the formation of melanoidin, which was produced by the millard reactions among sugars and amino acids (Paudel et al. 2017).

a Variation in sCOD and pH of the effluent obtained after hot air oven pretreatment at different temperature for a duration of 45 min, b Cumulative methane produced from untreated and hot air oven pretreated yard waste (With permission from the Elsevier with the license number 4703421429126 (Panigrahi et al., 2019))

There was a decrease in pH was found with increase in temperature which was due to the formation of short-chain fatty acids. The pH of the liquid hydrolysate obtained after pretreatment was found to decrease from 6.15 to 5.4 with increase in temperature from 70 to 200 °C, which is due to the increase in formation of short-chain fatty acids such as VFA.

Thermal pretreatment improves the sCOD by solubilizing some part of structural constituents like hemicellulose and lignin. However, the solubilization of lignin is undesired in AD process. Solubilization of lignin may produce inhibitors like phenolicfurfural and hydroxyl methyl furfural, which affects the activity of methanogenic bacteria. In order to address the effect of pretreatment on biogas production, batch AD of untreated and hot air oven pretreated (170 °C/45 min) YW was conducted for 45 days. The cumulative biogas produced by untreated and hot air oven pretreated YW is presented in Fig. 2b. Higher cumulative biogas was produced in pretreated sample. In pretreated YW, biogas was produced after five days, whereas in untreated YW, it was nine days. The cumulative biogas produced in untreated and pretreated YW was 361 ± 11 mL/g VS and 311 ± 5 mL/g VS, respectively.

3.1.2 Effect of Thermal Pretreatment on Surface Structure of Biomass

The effect of hot air oven pretreatment (170 °C/45 min) on structural properties of biomass was mapped through SEM analysis (Fig. 3). Well ordered and smooth surface was seen in SEM micrograph of untreated biomass. After thermal pretreatment, the biomass SEM micrographs revealed cracks and void which mostly indicated the destructed cell wall of the biomass.

SEM images of yard waste. a Untreated; b hot air oven pretreated (With permission from the Elsevier with the license number 4703421429126 (Panigrahi et al., 2019))

3.2 Hydrothermal Carbonization

3.2.1 Effect of Treatment Temperature and Time on Hydrochar

The proximate, ultimate analysis of raw YW and hydrochar along with its energetic properties are presented in Table 1. Biomass has high volatile matter content, attributable to that it burns quickly (flash burn), and so, it is not appropriate for co-firing with coal because it has comparatively less volatile matter and takes time to burn (Fig. 4).

The volatile matter content in raw YW was 84.75% that got reduced to 68.99% when treatment temperature at 2 h time was increased from 160 to 200 °C. Volatile matter further decreased from 68.99 to 63.24% when treatment time was increased from 2 h to 24 h at 200 °C which makes us conclude that the treatment temperature plays major role during HTC of the YW. However, overall increase in ash content (Table 1) was observed with the increase in the reaction time and temperature. The HTC of YW improved overall carbon content, which varied between 45.70 and 60% and decreased overall oxygen content which varied between 49.9 and 32.48%. The main reaction mechanisms that lower oxygen content and increased the carbon content are dehydration and decarboxylation reaction as shown in the Van Krevelen diagram in Fig. 5. Van Krevelen diagram also helps in predicting reaction pathways during the HTC process, and it also helps in assessing quality of fuel. Basically, Van Krevelen diagram depicts coalification process and is plot of O/C and H/C atomic ratios. The yield decreased from 78.5% for the sample H-160-2 to 45.6% for the sample H-200-24 as shown in Table 2. This significant reduction in the yield was mainly due to high volatilization of organic matter in the sample during the HTC process. The energetic properties like fuel ration, calorific value, energy yield also improved after HTC. The caloric value for raw YW was 15.37 MJ/kg and that of hydrothermally treated YW at 200 °C for 24 h was 24.59 MJ/kg.

Van Krevelen diagram showing delineation of reaction pathway during hydrothermal carbonization process for raw and hydrochar sample prepared at different reaction severity (With permission from the Elsevier with the license number 4703420251430 (Sharma et al., 2019))

Dehydration and decarboxylation are the major reaction that takes place during the HTC of YW. The hydrochar H-200-24 shows the fuel properties similar to that of lignite coal, meaning HTC is effective in treating YW to produce solid coal-like fuel. The fuel ration which is a ration of fixed carbon to volatile matter also increased during HTC. Energy yield up to 82% was obtained. With HTC reaction, severity hydrochar yield decreased. The improvement in fuel quality is mainly attributed to increase in carbon content. The improvement in the carbon content is influenced both by reaction time and temperature.

4 Effect of Hydrothermal Carbonization on Surface Structure of Biomass

The HTC of YW also helps in rupture of physical structure mainly due to weakening of cell wall promoted by decomposition of lignocellulosic components in YW. The decomposed physical structure can be seen in Fig. 6(2) in comparison with smooth well-defined structure as seen in Fig. 6(1). The destruction of physical structure due to HTC promotes friability of hydrochar which makes it easy to be pelletized due to improved surface area which promotes more mechanical interlocking and liquid bridge during compression (Liu et al. 2014).

SEM image of raw yard waste (a) and Hydrochar (b) (With permission from the Elsevier with the license number 4703420251430 (Sharma et al., 2019))

5 Conclusion and Future Scope

A positive effect of thermal pretreatment on organic matter solubilization and subsequent AD was found. Thermal pretreatment for duration of 45 min at a temperature of 170 °C was best for organic matter solubilization. After thermal pretreatment, the biogas production was improved from 311 ± 5 to 361 ± 11 mL/g VS. The result of this study shows that the HTC lignocellulosic fraction of municipal solid provides us a newer technique to produce energy-dense lignite like solid fuel with a calorific value up to 24.59 MJ/kg. The hydrochar produced had higher carbon content, improved calorific value and reduced volatile matter content.

Since AD of organic waste will produce large solid residue and HTC of waste will produce organic rich water, therefore, we propose a combined HTC-AD or AD-HTC process to be more beneficial. The solid residue from AD plant can be used as a feedstock for HTC to produce bio-solid fuel or process water, rich in organic from HTC plant can be anaerobically digested to produce biogas. The hypothetical framework HTC-AD or AD-HTC is presented in a Fig. 7.

References

Agbor, V. B., Cicek, N., Sparling, R., Berlin, A., & Levin, D. B. (2011). Biomass pretreatment: Fundamentals toward application. Biotechnology Advances, 29(6), 675–685.

Apha, A. (2005). WPCF. 1989. Standard methods for the examination of water and wastewater, vol. 17, pp. 1–5.

Benavente, V., Calabuig, E., & Fullana, A. (2015). Upgrading of moist agro-industrial wastes by hydrothermal carbonization. Journal of Analytical and Applied Pyrolysis, 113, 89–98.

Berge, N. D., Ro, K. S., Mao, J., Flora, J. R., Chappell, M. A., & Bae, S. (2011). Hydrothermal carbonization of municipal waste streams. Environmental Science and Technology, 45(13), 5696–5703.

Ennouri, H., Miladi, B., Diaz, S. Z., Güelfo, L. A. F., Solera, R., Hamdi, M., et al. (2016). Effect of thermal pretreatment on the biogas production and microbial communities balance during anaerobic digestion of urban and industrial waste activated sludge. Bioresource Technology, 214, 184–191.

Funke, Axel, & Ziegler, Felix. (2010). Hydrothermal carbonization of biomass: a summary and discussion of chemical mechanisms for process engineering. Biofuels, Bioproducts and Biorefining, 4(2), 160–177.

González-Fernández, C., Sialve, B., Bernet, N., & Steyer, J. P. (2013). Effect of organic loading rate on anaerobic digestion of thermally pretreated Scenedesmus sp. biomass. Bioresource Technology, 129, 219–223.

Hoornweg, D., & Bhada-Tata, P. (2012). What a waste: a global review of solid waste management.

Kruse, A., & Dahmen, N. (2015). Water–A magic solvent for biomass conversion. The Journal of Supercritical Fluids, 96, 36–45.

Lahav, O., Morgan, B. E., & Loewenthal, R. E. (2002). Rapid, simple, and accurate method for measurement of VFA and carbonate alkalinity in anaerobic reactors. Environmental Science and Technology, 36(12), 2736–2741.

Liu, Z., Quek, A., & Balasubramanian, R. (2014). Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Applied Energy, 113, 1315–1322.

Panigrahi, S., Sharma, H. B., & Dubey, B. K. (2019). Overcoming yard waste recalcitrance through four different liquid hot water pretreatment techniques–Structural evolution, biogas production and energy balance. Biomass and Bioenergy, 127, 105268.

Paudel, S. R., Banjara, S. P., Choi, O. K., Park, K. Y., Kim, Y. M., & Lee, J. W. (2017). Pretreatment of agricultural biomass for anaerobic digestion: Current state and challenges. Bioresource Technology, 245, 1194–1205.

Sharma, H. B., Panigrahi, S., & Dubey, B. K. (2019). Hydrothermal carbonization of yard waste for solid bio-fuel production: Study on combustion kinetic, energy properties, grindability and flowability of hydrochar. Waste Management, 91, 108–119.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Sharma, H.B., Panigrahi, S., Dubey, B.K., Narra, S. (2020). Resource Recovery from Organic Fraction of Municipal Solid Waste Using Anaerobic Digestion and Hydrothermal Carbonization. In: Ghosh, S., Sen, R., Chanakya, H., Pariatamby, A. (eds) Bioresource Utilization and Bioprocess. Springer, Singapore. https://doi.org/10.1007/978-981-15-1607-8_2

Download citation

DOI: https://doi.org/10.1007/978-981-15-1607-8_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-1606-1

Online ISBN: 978-981-15-1607-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)