Abstract

Effective and efficient treatment of greywater from households and public places is an important and urgent issue to be solved in many developing countries. The higher capital investment of high-tech systems hinder the implementation, thus development of efficient yet affordable and compact wastewater treatment units for greywater treatment can solve the problem to a greater extend. This research developed a compact wastewater treatment system using commonly available construction and biomaterials. The proposed compact wastewater treatment system is consisted of three main components: up-flow anaerobic sludge blanket, charcoal granular media, and a subsurface flow constructed wetland system and is named Integrated Charcoal Filter Constructed Wetland (ICFiWet) system. In the vertical cylindrical reactor, the influent wastewater flows upward through an anaerobic chamber passes through the granular media to the subsurface flow wetland. The ICFiWet system was first tested at household scale (100 L capacity) fed with synthetic greywater. Water quality parameters such as pH, EC, TS, TSS, biological oxygen demand (BOD5), nitrate N, and phosphate removals were estimated to evaluate the reaction kinetics and performances. The BOD removal was >66% and the system reduced the nitrate (1.77 ± 0.28) concentration by 15.3%. It was also revealed that the system decomposes the complex phosphorous substances to soluble P, leaving about 3 times increase of soluble P in effluent waters. The ICFiWet system was then up-scaled to 15.0 m3 capacity to treat 5.0 m3/day of flow. The ICFiWet system was installed in a larger public washroom to treat partially digested effluents. The results showed that the treated effluent achieved the water quality standard that comply with irrigation water quality. Thus, it was concluded that the ICFiWet system could effectively use for greywater treatment in household and public places while recovering the important nutrient phosphorus.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Greywater

- Integrated

- Up-flow

- Charcoal

- Constructed wetland

- International society of waste management

- Air and water

1 Introduction

Treatment of greywater from households and public places in developing countries is an urgent issue to be solved. Techniques of greywater treatment should fulfil five main criteria: hygienic safety, esthetic appearance, environment tolerance, technical and economic feasibility, and low cost, and the ability to easily maintain by unskilled workers (Nolde 2000; Gross et al. 2007). Implementation of greywater treatment systems has subsided due to economic and technical challenges (Ammari et al. 2014). Most of the available high-tech wastewater treatment systems are not affordable by the small wastewater generators, particularly households in developing countries because of high installation and maintenance costs (El-Khateeb and El-Gohary 2003). Therefore, greywater is generally disposed to the environment without any treatment as there is no any provision for its treatment (Katukiza et al. 2014).

Releasing wastewater to the environment without any treatment can cause various problems with regard to the environment and human health. Therefore, wastewater should be treated prior to discharge into environment. Generally, natural treatment systems are used for treating greywater as it is economically feasible and environmental friendly (Li et al. 2009; Boyjoo et al. 2013). The use of conventional low-tech wastewater treatment systems such as treatment wetlands and pond systems has gained limited attention due to space limitations in urban and semi-urban communities (Parkinson and Taylor 2003).

Wetlands and pond systems have gained limited attention due to space limitations in urban and semi-urban communities (Parkinson and Tayler 2003). Consequently, there is a demand for development of appropriate and innovative technologies for wastewater treatment and reuse for small communities (Bdour et al. 2009).

Constructed wetlands and granular filtration can be identified as extended natural greywater treatment systems which use natural media for biological degradation and filtration (Albalawneh et al. 2017). Among many small scale and low-cost alternatives (Kamal et al. 2008), constructed wetland system is one that highly preferred by small communities with limited funds. Those can be identified as the systems which have the ability to remove pollutants using interactions of plants and microorganisms (Li et al. 2004). Once the constructed wetlands are designed and established, maintenance costs are less. Also, they add an esthetic value to the environment (Lorion 2001). However, larger land footprint requirement and inability of conventional constructed wetlands to handle diverse range of wastewaters hinder the effective use of this affordable system.

Granular filtration achieves wastewater treatment through three main mechanisms: physical, chemical, and biological. Physical filtration, chemical transformation, and biological treatment due to microbial growth are occurred in granular filtration (Ciuk 2015). This technology is suitable for small communities in developing countries due to the low cost of construction, operation, and maintenance (Manz and Eng 2004). Cost effective and sustainable greywater treatment systems can be achieved by selecting locally available filter materials and using them in simple treatment methods (Nansubuga et al. 2015). Charcoal can be used as an effective filter material for greywater treatment (Dalahmeh et al. 2012).

Therefore, an attempt was made to integrate an up-flow anaerobic sludge blanket; a charcoal granular media and a constructed wetland system in one physical entity and developed a new concept: Integrated Charcoal Filter Constructed Wetland (ICFiWet) system. This study presents the design concepts, pilot-scale testing of the ICFiWet for synthetic greywater treatment, and preliminary results of the up-scaled design installed in a public place for secondary treatment of sewage wastewater.

2 Methodology

2.1 Pilot-Scale Design

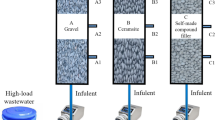

The ICFiWet system consisted of three main components: an up-flow anaerobic sludge blanket, charcoal granular media, and a subsurface flow constructed wetland system. As shown in Fig. 1, three components were assembled vertically creating an updraft movement of wastewater through successive components.

2.1.1 Fabrication of the System

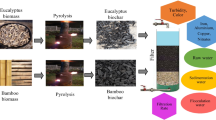

The pilot-scale reactor was established using an empty HDPE plastic barrel container having dimensions of 58 cm internal diameter and 92 cm height. A sludge removal port was fixed on the outside wall of the bottom, and 5-cm diameter perforated PVC pipes were fixed on the bottom to evenly distribute the influent. A perforated 4 mm thick plastic baffle was fixed 15 cm above the bottom, leaving the first chamber to be acting as an anaerobic reactor. A layer of softwood charcoal granules with particle sizes in between 0.5 and 3 cm was filled above the baffled up to 70 cm from bottom which acted as the charcoal granular bed. The constructed wetland media was placed above the charcoal bed, separated by a similar plastic baffle as above. Wetland media was prepared with top soil, sand, and charcoal mixture with 2:3:2 weight ratios. The wetland media was planted with Typha angustifolia plants which were collected from a microcosm previously grown in a nursery and washed with tap water to remove debris and dead parts.

Perforated stainless steel tubes (5 mm diameter) were vertically inserted into each component allowing water samples to be collected from different compartments.

2.1.2 Influent Greywater Preparation and Flow Rate

The influent for the system was a synthetic greywater solution prepared by mixing 500 g of kitchen/food waste, 8 g of laundry powder, 10 g of pulverized bar soap, 2.5 g of vegetable oils, and 100 ml of kitchen effluent in 100 L of tap water (Travis et al. 2010). A 100 L synthetic greywater solution was supplied to the system with a gravity head as shown in Fig. 1. With this arrangement, 18.3 L day−1 of influent passed through the system with a nominal residence time of 5.5 days. In order to avoid depletion of quality, the synthetic greywater solution was replaced every other day.

2.2 Upscaling of the Integrated Charcoal Filter Constructed Wetland (ICFiWet) System

The system was up-scaled and installed at a public washroom (approximately 100 users/day) as a secondary treatment system to treat the partially digested effluents. In the system, the raw sewage first collected in a septic tank and secondly, flows into a soakage pit. However, the soakage pit often overflows due to overloading, thus, the overflowing wastewater pipeline was connected to the ICFiWet system. All components of the up-scaled ICFiWet system was an up-scale of the pilot design. The system was up-scaled to capacity of 15 m3 to treat 5 m3 of daily inflow by maintaining 3 days of hydraulic retention time in ICFiWet system. The system was having 3.0 m diameter and 2.8 m depth which included 0.6 m height anaerobic compartment, 2.0 m height charcoal granular bed, and 0.2 m deep treatment wetland. The up-scaled reactor was built using masonry bricks, reinforced concrete, and finished with cement rendering. Except 0.3 m of freeboard of the wetland, entire system was constructed underground (Fig. 2).

2.3 Water Quality Monitoring

2.3.1 Pilot-Scale System Monitoring

The pilot-scale Integrated Charcoal Filter Constructed Wetland system performances were monitored for 47 days in order to evaluate grey water treatability. The treatment efficiency of the system was measured in terms of pH, electrical conductivity (EC), total solids (TS), total dissolved solids (TDS) by measuring the water quality at the inflow, outflow, and different layers; sampling point 1 (S1) in the anaerobic sludge blanket region, sampling point 2 (S2) at the top of the charcoal granular media, and sampling point 3 (S3) within the constructed wetland (Fig. 1). Water quality parameters of BOD5, nitrate and phosphate were measured for the inflow and outflow during the operational period. Greywater samples were tested for pH by probe method (Thermo Scientific, model Orion 2 star), Total Solids (TS) by oven dry method, EC and Total Dissolved Solids (TDS) by probe method (Thermo Orion, model 145A), biochemical oxygen demand (BOD5) by Winkler Titration method, nitrate nitrogen and phosphate by colorimetric method (Jenway 6305 UV/Vis Spectrophotometer).

2.3.2 Up-Scaled System Monitoring

Sampling points were established in up-scaled system, similar to the pilot-scale system and preliminary treatment efficiency was measured in terms of pH, EC, TS, and total suspended solids (TSS), Salinity, BOD5 for all five measuring points for a period of 18 days. Additionally, Nitrate Nitrogen and Phosphate were measured for inflow and outflow.

3 Results and Discussion

3.1 Performances of Pilot-Scale Integrated Charcoal Filter Constructed Wetland System

Table 1 illustrates the water quality of the inflow, outflow, and the three sampling points during the operational period. The average pH value of influent wastewater was in slightly acidic range but improved to neutral pH while flowing upward through the three consecutive treatment systems. The pH improvement was greater in first anaerobic sludge blanket indicating acidogenic and methanogenic transformations. A neutral pH of 6.69 ± 0.29 facilitates the optimum conditions for acid-producing bacteria and methane-producing bacteria. As shown in Fig. 3a, the time-dependent average pH of the outflow effluent was varied from 6.71 to 8.04 (7.3 ± 0.30) which is in the environmentally acceptable pH range (between pH 6 and 8.5 for inland surface waters) of treated wastewater before discharging into the natural environment (National Environmental Protection and Quality Regulations, No. 1 of 2008).

The EC variation of different sampling points of the reactor during the study period is shown in Fig. 3b. The artificially prepared greywater (influent) was having low EC compared to outflow waters. The EC was increased through three consecutive treatment systems because of the consumption of complex organic materials by microorganisms and their breakdown within the sludge blanket. Nevertheless, EC within the wetland is relatively high due to the solubility of different ions included in the wetland filter materials (sand, soil, and charcoal). However, with the time EC within the wetland reduced with washing away of impurities and settlement of the filter materials. EC of outflow water is gradually decreased with time from 3.5 to 0.9 mS/cm during the sampling period.

Figure 3c shows the TS variation of the inflow, outflow and within the reactor. As illustrated in Table 1, influent contains 1908 ± 384 mg/l total solids and effluent contains 1208 ± 519 mg/l with a 45.09% of removal efficiency. As shown in Fig. 3d, TDS concentrations of outflow were higher than that of the inflow due to the microbial digestion and breakdown of complex organic substances.

As shown in Fig. 4a, during the first four days of operation, BOD5 values of the outflow were greater than inflow due to the dissolution of organics in charcoal and wetland bed media substrates. A higher increase of BOD5 can be observed during 15th day. Formation of microbial flocs due to prolong storage (3 days) of synthetic greywater was the reason for sudden fluctuation of influent waters. But, effluent water quality, particularly BOD5 was maintained below 90 mg/l with a time-dependent average of 52 ± 33.11 mg/l with approximately 67% of removal efficiency. This reduction of BOD5 can occur due to the aerobic and anaerobic degradation of complex organic materials by the microorganisms grown in the filter material surface (Vymazal and Kropfelova 2008; Rani et al. 2011).

Nitrate concentration ranges between 1.31 and 2.03 ppm in the influent wastewater and 1.13–1.73 ppm in the effluent with time-dependent averages of 1.77 ± 0.28 and 1.50 ± 0.23 at influent and effluent, respectively (Table 2). The system shows a 15.3% of nitrate removal efficiency. Nitrate removal is occurred due to biological processes such as denitrification which takes place under anoxic conditions. Anoxic conditions are expected to be present at wetlands except plant root zones and near the surface (Cooper et al. 1996).

Figure 4c illustrates the phosphate concentration variation during the experiment. The influent contains of 0.58 ± 0.11 ppm phosphate concentration which increases to 1.90 ± 1.3 ppm at the outflow as shown in Table 2. This is due to the various microbial activities within the reactor, and complex organic compounds are decomposed into simple forms which release phosphate to the system and limited fixing capacity by filter media and plant.

3.2 Performances of the up-Scaled ICFiWet System

Table 3 shows the preliminary data obtained from the up-scaled ICFiWet system by water quality analysis. While flowing through the three main compartments the BOD5 of wastewater is reduced from 383 ± 23.5 mg/l to 36 ± 12.0 mg/l which is near to the standard water quality level for surface discharge.

The pH value shows a slight reduction while flowing through three consecutive compartments and it increases slightly at the outflow. However, the outflow pH is lower than the inflow pH and outflow pH is maintained at environmentally acceptable pH range to discharge to the natural environment. EC and Salinity show a similar variation like pH as shown in Table 3. Total solid content increases at S2 (charcoal granular media) region and S3 (wetland media) region due to mixing of filter material and other organic microorganism complexes with flowing wastewater. TSS is reduced gradually from inflow to the outflow through three consecutive treatment systems due to digestion of organic matter by microorganisms.

As this system was fed with a partially digested effluent from a public washroom system, the contribution of ammonia must be high; however, consequently converted to nitrate through nitrification according to data. The inflow of the up-scaled system contains high amount of phosphate (approximately 9.65 ppm) due to heavy usage of detergents for cleaning of public washroom system.

3.3 Conclusion and Recommendation

The pilot-scale Integrated Charcoal filter constructed wetland system shows 67% of BOD removal and the system reduced nitrate concentration by 15.3%. It was also revealed that the system decomposes the phosphorous complexes in influent leaving an increase in effluent phosphate, demonstrating that charcoal substrate and plants have limited capacity to fix phosphate, but recover nutrient for irrigation water use. Thus, it can be concluded that ICFiWet treated greywater can be used in irrigation and home gardening as it contains high amount of soluble phosphate; however, phosphorus adsorption substrate should be used in ICFiWet system if treated water to be discharged into natural waters. In perspective, Integrated Charcoal filter constructed wetland system can be used as a cost effective, efficient wastewater treatment system which can be constructed with locally available materials. High phosphate in outflow water gives an added advantage if the treated water to be used for irrigation/gardening, thus the system shall be coupled with home garden irrigation with treated water.

References

Albalawneh, A., Chang, T. K., & Alshawabkeh, H. (2017). Greywater treatment by granular filtration system using volcanic tuff and gravel media. Water Science and Technology, 75(10), 2331–2341.

Ammari, T. G., Al-Zu’bi, Y., Al-Balawneh, A., Tahhan, R., Al-Dabbas, M., Ta’any, R. A., & Abu-Harb, R. (2014). An evaluation of the re-circulated vertical flow bioreactor to recycle rural greywater for irrigation under arid Mediterranean bioclimate. Ecological Engineering, 70, 16–24.

Bdour, A. N., Hamdi, M. R., & Tarawneh, Z. (2009). Perspectives on sustainable wastewater treatment technologies and reuse options in the urban areas of the Mediterranean region. Desalination, 237(1–3), 162–174.

Boyjoo, Y., Pareek, V. K., & Ang, M. (2013). A review of greywater characteristics and treatment processes. Water Science Technology, 67(7), 1403–1424.

Ciuk, K. S. (2015). Simulating water and pollutant transport in bark, charcoal and sand filters for greywater treatment. Department of Energy and Technology, Swedish University of Agricultural Sciences, Uppsala, Sweden.

Cooper, P. F., Job, G. D., Green, M. B., & Shutes, R. B. E. (1996). Reed beds and constructed wetlands for wastewater treatment. Swindon, Wiltshire, UK: WRc plc.

Dalahmeh, S. S., Pell, M., Vinneras, B., Hylander, L. D., Oborn, I., & Jonsson, H. (2012). Efficiency of bark, activated charcoal, foam and sand filters in reducing pollutants from greywater. Water, Air, and Soil Pollution, 223(7), 3657–3671.

El-Khateeb, M. A., & El-Gohary, F. A. (2003). Combining UASB technology and constructed wetland for domestic wastewater reclamation and reuse. Water Science and Technology, 3(4), 201–208.

Gross, A., Shmueli, O., Ronen, Z., & Raveh, E. (2007). Recycled vertical flow constructed wetland (RVFCW)-a novel method of recycling greywater for irrigation in small communities and households. Chemosphere, 66(5), 916–923.

Kamal, A. S. M., Goyer, K., Koottatep, T., & Amin, A. T. M. N. (2008). Domestic wastewater management in South and Southeast Asia: The potential benefits of a decentralised approach. Urban Water Journal, 5(4), 345–354.

Katukiza, A. Y., Ronteltap, M., Niwagaba, C., Kansiime, F., & Lens, P. (2014). A two-step crushed lava rock filter unit for grey water treatment at household level in an urban slum. Journal of Environmental Management, 133, 258–267.

Li, F., Wichmann, K., & Otterpohl, R. (2009). Review of the technological approaches for grey water treatment and reuses. Science of the Total Environment, 407(11), 3439–3449.

Li, Z., Gulyas, H., Jahn, M., Gajurel, D. R., & Otterpohl, R. (2004). Greywater treatment by constructed wetlands in combination with TiO2-based photocatalytic oxidation for suburban and rural areas without sewer system. Water Science and Technology, 48(11–12), 101–106.

Lorion, R. (2001). Constructed wetlands: Passive systems for wastewater treatment. US EPA Technology Innovation Office: Report.

Manz, D. H., & Eng, P. (2004). New horizons for slow sand filtration. In Proceedings of the Eleventh Canadian National Conference and Second Policy Forum on Drinking Water and the Biennial Conference of the Federal-Provincial-Territorial Committee on Drinking Water, Promoting Public Health Through Safe Drinking Water (p. 6), Calgary, Alberta.

Nansubuga, I., Meerburg, F., Banadda, N., Rabaey, K., & Verstraete, W. (2015). A two-stage decentralised system combining high rate activated sludge (HRAS) with alternating charcoal filters (ACF) for treating small community sewage to reusable standards for agriculture. African Journal of Biotechnology, 14(7), 593–603.

National Environmental (Protection and Quality) Regulations, No. 1 of 2008, National environment Act No 47. of 1980.

Nolde, E. (2000). Greywater reuse systems for toilet flushing in multi-storey buildings. Urb Water J, 1(2000), 275–284.

Parkinson, J., & Tayler, K. (2003). Decentralized wastewater management in peri-urban areas in low-income countries. Environment and Urbanization, 15(1), 75–90.

Rani, S. H. C., Din, M., Md, F., Yusof, M., Mohd, B., & Chelliapan, S. (2011). Overview of subsurface constructed wetlands application in tropical climates. Universal Journal of Environmental Research & Technology, 1, 103–114.

Travis, M. J., Shafran, A. W., Weisbrod, N., Adar, E., & Gross, A. (2010). Greywater reuse for irrigation: Effect on soil properties. Science of the Total Environment, 408(12), 2501–2508.

Vymazal, J., & Kropfelova, L. (2008). Wastewater treatment in constructed wetlands with horizontal sub-surface flow. Dordrecht, The Netherlands: Springer Science & Business Media.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Vidanage, V.V.D.N.G., Karunarathna, A.K., Alahakoon, A.M.Y.W., Jayawardene, S.M.N. (2020). Development of an Effective and Efficient Integrated Charcoal Filter Constructed Wetland System for Wastewater Treatment. In: Ghosh, S., Saha, P., Francesco Di, M. (eds) Recent Trends in Waste Water Treatment and Water Resource Management. Springer, Singapore. https://doi.org/10.1007/978-981-15-0706-9_5

Download citation

DOI: https://doi.org/10.1007/978-981-15-0706-9_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0705-2

Online ISBN: 978-981-15-0706-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)