Abstract

The ever growing interest in bioactive biopolymers originated from natural sources and advances in extraction and purification of protein have led to the development of protein-polymer based targeted drug delivery system. Among them, interpenetrating polymer network (IPN) based nanoparticles have gained great attention in the last decades, mainly due to their biomedical applications. IPN nanoparticles based drug delivery system is basically designed to deliver drugs at a predetermined rate for a desired period of time with minimum fluctuation. A number of reports on the IPN based drug delivery systems showed that these carriers have emerged as a novel drug carrier in controlled delivery system. This chapter aims to give an overview of the recent design concepts of IPN based nanoparticles, methods of synthesis, some natural polymers especially protein widely used for IPN and also covers recent advances in IPN based nanoparticles system for pharmaceutical applications as well as in anticancer drug delivery system.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

7.1 Introduction

The recent extensive advances in polymer chemistry allow the state of art design of biodegradable and biocompatible polymer based nanoparticles for targeting the drug into the desired site. The proper placing of a drug delivery system in the site of action for maximizing drug availability and minimizing the side effects and thus optimizing the effect of pharmacotherapy are the main research focus. Controlled drug delivery systems offer numerous benefits over conventional dosage forms, which include reduced adverse reaction, toxicity and frequency of dosing with improved efficacy, patient compliance and convenience (Liu et al. 2007).

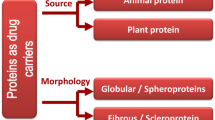

In the past few years, polymer nanoparticles evolved as a potential carrier in drug delivery system and have attracted much attention and undergone many investigations in the field of biomedical due to their wide range of applications including their surface area, size, optical and magnetic properties, and biological transport that are brought into the perspective of drug delivery. The growing demand for improved polymer properties has paved the development of the blending of polymer mixtures. The blend materials from natural and synthetic sources alone are not always able to meet the complex demands of the biomaterials. In order to improve the poor biological performance and mechanical strength, a new class of polymers has been introduced which are based on blending of either natural or synthetic polymers alone or in combinations. The use of natural polymers especially bioprotein is valuable due to their nontoxicity, low cost, biodegradability, biocompatibility and safety although their mechanical properties are often poor while, the success of synthetic polymers relies on their broad range of mechanical properties.

An interpenetrating polymer network (IPN) is a blending of two or more polymers in a network with at least one of the polymers synthesized in the presence of another (Hu 2014). This results in realization of physically crosslinked network when polymer chains of the second system are entangled with or penetrate the network formed by the first polymer. Each individual network retains its individual properties, so synergistic improvements in properties like strength or toughness can be seen (Stanciu 2003). IPN can be distinguished from the other multiple systems through their bicontinuous structure. They are usually formed by crosslinking of two polymers that are in intimate contact but without any chemical contact and yield a material with improved properties depending on the composition and degree of crosslinking (Kudela 1987). IPN offers synergistic effect by sharing the properties of both the polymers subsequently avoiding the limitations of natural as well as synthetic polymers. It is expected to have a better capability for the controlled release of drugs under physiological conditions.

IPN based drug delivery system is designed to deliver drugs in zero-order pattern with minimum fluctuation. The concept of IPN goes back at least as far as 1914 when the first interpenetrating polymer network was invented by Aylsworth (Aylsworth September 1914). For the first time, the term IPN was introduced by Miller in 1960s in a scientific report about polystyrene networks (Millar 1960). The field of IPN has expanded dramatically since that time. Advances in polymer science have led to the development of several novel drug delivery systems. Among them, IPNs have shown superior performances over the conventional individual polymers and, consequently, the ranges of applications have grown rapidly for such class of materials. The advanced properties of IPNs have attracted considerable attention in pharmaceutical field especially in the area of drug delivery. These biocompatible, nontoxic, and biodegradable polymer networks are now acquiring unique place in delivering bioactive molecules, particularly in controlled and targeted drug delivery applications. Various research investigations have shown that a variety of drugs can be delivered effectively via IPN based delivery systems. The idea of IPN nanoparticles as drug carriers may be employed to modify or to control the drug distribution at the tissue, cellular, or subcellular levels. IPN nanoparticles can be either nanospheres or nanocapsules depending on the method of preparation. Nanospheres are polymeric matrix systems in which the drug is dispersed within the polymer throughout the particle. On the contrary, nanocapsules are vesicular systems, which are formed by a drug-containing liquid core (aqueous or lipophilic) surrounded by polymeric; thus nanocapsules may be considered a reservoir system.

IPNs are prepared by some most commonly used bioproteins, which has been reported to be suitable for drug delivery system. Bioproteins available in nature are inherently biocompatible and nontoxic. Most commonly utilized proteins are gelatin, silk fibroin, silk sericin, and soy protein. Interestingly, our blood plasma can easily adapt them, which made them suitable for many pharmacological applications. Drugs loaded in the scaffolds, nanoparticles or IPNs are being used extensively in biomedical nowadays. The low mechanical properties of bioproteins can be resolved by either incorporating or by being incorporated in another synthetic or natural polymer such as starch, chitosan, alginate, polyacrylonitrile, etc. which can provide higher mechanical strength.

In this chapter, we will discuss the advances in fabrication technology of bioprotein based IPN nanoparticles and drug delivery system; particularly in the treatment of cancer patients. In the first part of this chapter, we will discuss the major challenges in anticancer drug delivery system. Then we will discuss about common bioprotein based IPN system in the second part. In the third part, the major fabrication techniques and application of IPN nanoparticles will be discussed.

7.1.1 Classification of IPN

IPN can be classified in several ways. Depending on their chemical bond, they can be divided in three groups as (a) covalent semi-IPN; when two separate polymer systems that are crosslinked form a single polymer network, it is called covalent semi-IPN. (b) Noncovalent semi-IPN; in noncovalent semi-IPNs only one of the polymer systems is crosslinked. (c) Noncovalent full IPN. A noncovalent full IPN is one in which two separate polymers are crosslinked independently.

7.2 Major Challenges in Anticancer Drug Delivery

In addition to the numerous approaches of treatment, cancer chemotherapy is considered as one of the major therapeutic methods to fight cancer. The objective of the ideal cancer chemotherapy is to deliver the precise amount of drug with anticipated controlled rate and sufficient long duration of time to the site of action (cancer cells) while preventing the normal cells to obtain the desired therapeutic response. To achieve this goal, drug delivery systems must hold enough amount of drug and root out the problems like drug resistance based on cellular or noncellular mechanism, reformed biodistribution, biotransformation as well as secretion of anticancer drugs from the body. The delivery systems should meet the requirements like sustained circulation (which can be obtained by PEGylation), sufficient tumour accumulation (by considering enhanced permeability and retention (EPR) effect), uptake by tumor cells (by active targeting) and organized drug release (by optimizing delivery system) with a profile matching the pharmacodynamics of the drug.

7.2.1 Biodistribution of Drug

While administrating conventional anticancer therapeutics through intravenous systems, drugs are distributed properly all over the body via the bloodstream, and affects both malignant and rapidly dividing normal cells of the bone marrow, gut, lymphoid tissue, spermatogenic cells, fetus, and hair follicles (Brown and Links 1999). Nevertheless, prominent limitations like severe side effects, high patient risks, repeated treatments, altered biodistribution of drug, and the acquisition of multidrug resistance (MDR) by the cancer cells were observed in such treatments (Brigger et al. 2012).

7.2.2 Multidrug Resistance (MDR)

Acquisition of drug resistance by cancer cells, considered as one of the potential factors influencing the success of cancer chemotherapy, could be attained following the noncellular as well as cellular mechanisms. The noncellular resistance, caused by poorly vascularized tumor regions, can effectively reduce drug access to the tumor thereby protecting cancerous cells from cytotoxicity. In addition to this, tumors in acidic environment can also possess a resistance mechanism against basic drugs enabling them to get ionized preventing their diffusion across the cellular membrane where high interstitial pressure and low microvascular pressure are also responsible for retarding or impeding extravasation of molecules. On the contrary, cellular mechanism involves a decrease in sensitivity and intracellular accumulation of drugs by overexpression of the plasma membrane P-glycoprotein (P-gp) which repels drugs from the cell. While entering into cell, such drugs combine with P-glycoprotein to form transmembrane channel which further uses the energy of adenosine triphosphate (ATP) hydrolysis to pump drugs out of the cells. To overcome the limitations, Krishna and Mayer (2000) administrated P-gp inhibitors along with encapsulated anticancer drugs in nanoparticles preventing P-gp-mediated multidrug resistance.

7.2.3 Clearance by Reticuloendothelial System (RES)

Rapid blood clearance by the reticuloendothelial system (RES), composed of monocytes and macrophages located in reticular connective tissue, is also considered as one of the major problems in cancer therapy. Such cells usually remove pathogens, cellular debris as well as foreign substances from the bloodstream. However, the particle size, hydrophobicity, surface charge and composition of system also influence the clearance profile of the delivery system (Juliano 1976). Addressing the problems, Blume and co-workers (1990) proposed a coating of synthetic PEG (polyethylene glycol) to increase the surface hydrophilicity of liposome inhibiting protein adsorption and liposomes opsonization (Klibanov et al. 1990).

7.2.4 Hydrophobicity of Anticancer Drugs

Hydrophobicity of anticancer drugs is another most promising problem in cancer chemotherapy. Due to limited water solubility along with the unavailability of effective biocompatible delivery system, the use of various potential anticancer drugs as chemotherapeutic agents gets restricted. In addition to the problems associated with solubility, toxicity of anticancer drugs towards cancer as well as normal cells leads to the development of an intravenous (i.v.) formulation rather than oral design, however, the i.v. formulation must hold the drug within the system providing sustained release to reduce the contact of anticancer drugs to those of normal cells. In order to obtain such objectives ascribed above, the i.v. formulation should be soluble in aqueous media which is mostly rare in case of anticancer drugs. For instance, paclitaxel, one of the most successful anticancer drugs, is highly hydrophobic with a limited water solubility (less than 0.5 mg/L). For the solubilization of paclitaxel an approach by Si-Shen et al. (Feng and Chien 2003) reported the use of adjuvants like Cremophor EL (polyoxyethylated castor oil) and dehydrated alcohol which were much more effective in solubilizing process though another prominent study by Weiss and co-workers (1990) found limitations regarding severe side effects including hypersensitivity reactions, nephrotoxicity, neurotoxicity and cardiotoxicity, hyperlipidemia, abnormal lipoprotein patterns, erythrocyte aggregation, and peripheral neuropathy while using such additives. Development of novel delivery systems for these molecules without using organic solvents and adjuvants would be one of the major approaches to overcome the obstacles stated above. Considering these, Farokhzad et al. (2006) and Cuenca et al. (2006) reported the use of porous materials in nanoscale offering a great potential and prominent approach to deliver targeted drug together with controlled releasing technology. Lu et al. (2007), working with mesoporous nanoparticles as a drug delivery system for camptothecin (a hydrophobic anticancer drug to overcome poor water solubility), utilized camptothecin (CPT) into the pores of fluorescent mesoporous silica nanoparticles (FMSNs) and delivered the drug into a variety of human cancer cells to induce cell death, a route suggesting that the mesoporous silica nanoparticles might be used as a carrier overcoming the insolubility problem of many chemotherapeutic drugs. Prior to that, the use of CPT derivatives (modification of CPT with chemical modification to develop water solubility) were limited due to loss of their effectiveness towards stomach (Litvak et al. 1999), colon (Takiguchi et al. 1994), neck (Abigerges 1995), bladder (Keane et al. 1998) as well as breast (Miller et al. 2004) owing to chemical modification.

7.2.5 Nano-Carriers in Cancer Chemotherapy

Problems associated with cancer chemotherapy can be avoided through the proper implementation of nanotechnology based targeted cancer chemotherapy including nanocapsules, nanoparticles, nanorods, nanofibers, nanocrystals, nanotubes, stealth nanoparticles, liposomes, stealth liposomes, pH sensitive liposomes, temperature sensitive liposomes, etc. A study by Du and co-workers found (Du et al. 2011) the use of nanocarriers effective for cancer affected tissues due to enhanced permeability and retention (EPR) effect (Peer et al. 2007; Torchilin 2007; Farokhzad and Langer 2009). Such delivery provides selective and effective localization of pharmacological active moiety at pre-identified target in therapeutic concentration while restricting its access to nontarget sites therefore minimizing toxicity, maximizing therapeutic index together with developing the biodistribution of drug which is the foremost concern in success of cancer chemotherapy. Targeting to only cancer cells by nanodevices can successfully be attained by surface engineering where as the characteristics of both, i.e., the cancer including highly disordered leaky vasculature, high hydrostatic pressure, high requirements for nutrition, angiogenesis, Arg-Gly-Asp tripeptide (RGD) based strategy, EPR effect and the presence of over-expressed receptors also affect the selective targeting procedure. For example, in a study by Stella et al. (2000) folate grafted to PEGylated cyanoacrylate nanoparticles showed ten-fold better affinity for the folate binding protein (FBP) than free folate. Similar results were found when poly (ε-caprolactone) nanocarrier loaded with tamoxifen was administrated to mice (Kakde et al. 2011). Congruent to previous studies, nanocarriers loaded with anticancer drugs also showed greater retention time within the affected areas (Shenoy et al. 2004). In addition, several studies on nanovehicle system found nanoparticles to conglomerate all the advantages of other innovative carriers while reducing the associated problems. Prominent research works by Pinto and Müller (1999), Dingler et al. (1999) and Demirel et al. (2001) reported the development of Solid Lipid Nanoparticles (SLN) formulations for various application routes (i.e., parenteral, oral, dermal, ocular, pulmonary, rectal) and thoroughly characterized in vitro and in vivo. Among the various routes, better results were obtained in case of parenteral applications regarding excellent physical properties, protection of incorporated drugs from degradation, controlled drug release, and site-specific targeting.

7.3 Bioprotein Based IPN Nanoparticles

Some of the proteins founds in nature, such as gelatin, silk fibroin, silk sericin, soy protein, are inherently biocompatible and nontoxic. They are easily adapted by our blood plasma which made them suitable for many biomedical applications. Drugs loaded in the scaffolds, nanoparticles or IPNs of these bioproteins are being used extensively in biomedical field nowadays. Though bioproteins are biocompatible but most of them have low mechanical properties which doesn’t allow its full utilization in drug delivery. This problem can be resolved by either incorporating or by being incorporated in another synthetic or natural polymer which can provide higher mechanical strength such as alginate, polyacrylonitrile, etc. This section describes about the IPNs prepared by some most commonly used bioproteins which has been reported to be suitable for drug delivery system.

7.3.1 Gelatin

Gelatin is produced by partial hydrolysis of native collagen. It is an important hydro-colloidal polypeptide and has widespread application in food, photographic and pharmaceutical industries by fulfilling various roles as a stabilizer, thickener, texturizer, etc. (Hasan et al. 2018). Hydrophilic chelating groups contain an acrylamide polymer poly(acrylamidoglycolic acid) (PAGA) used extensively in biomedical and separation fields (Nagaraj et al. 1987). In a recent study, curcumin encapsulated pH sensitive gelatin–acrylamidoglycolic acid (AGA) IPN-nanogels were studied for anticancer drug delivery purpose (Rao et al. 2015). IPN-nanogels were synthesized by free radical emulsion polymerization. N, N′-Methylenebisacrylamide (BIS) and glutaraldehyde crosslinkers were used for the crosslinking of AGA and gelatin, respectively, leading to the fabrication of nanogels (Fig. 7.1). Curcumin is a yellow bioactive compound of the Indian spices, turmeric, has antiproliferative activity against many different types of cancer cells, including cancers of the colon, prostate, and breast (Chen and Huang 1998; Aggarwal et al. 2007). But the poor solubility, bioavailability, and rapid degradation in physiological pH hinders its application as anticancer drug. In this study, the hydrophobic curcumin was encapsulated successfully into hydrophilic IPN-nanogels. Normal fibroblast cell line and HCT-116 human colon cancer cells were studied for finding the biocompatibility of the pristine and curcumin encapsulated nanogels. It has been found that encapsulation enhanced the bioavailability and dispersion of the curcumin due to the complex network of IPN of gelatin and AGA. The encapsulation efficiency of these IPN-nanogels drug formulations ranged from 42% to 48%. Curcumin encapsulated nanogels showed negative and positive cytotoxicity towards normal fibroblast and HCT-116 cancer cell line. Because of the enhancement of dispersion encapsulated curcumin showed higher anti-cancer cell activity compared to pristine curcumin. The results suggest that these new type of IPN-nanogels are a good carrier for colorectal cancer drug delivery.

Schematic representation of formation of IPN-nanogels; reaction represents crosslinking of BIS with AGA via covalent bond in gelatin, then glutaraldehyde (GA) are crosslinked with gelatin via imine linkages (Rao et al. 2015)

In an another study (Jain et al. 2009), moderately hydrophobic polyacrylonitrile and hydrophilic gelatin cryogel-IPN was prepared at subzero temperature by a combination of free radical crosslinking polymerization of acrylonitrile (AN) and simultaneous gelation in presence of N,N′-methylenebis(acrylamide) (MBAAm) and covalent crosslinking of gelatin with glutaraldehyde as crosslinkers, respectively. The interpenetrating cryogel was formed by single step freezing of both the precursors simultaneously. It was possible to achieve a supermacroporous and rigid scaffold of interpenetrating network with both high porosity and high mechanical strength due to the application of lyophilization and resulted in dense pore walls formed by cyroconcentration of polymers (Lozinsky et al. 2001). As the concentration of gelatin was varied, surface smoothness and the structure of pores present in the pore walls also varied. Cryogel-IPNs became more spongey and elastic with the increase of gelatin concentration by the virtue of hydrophilic nature of gelatin. Interconnected pores of cyrogel-IPNs allowed fast transportation of solvent and low resistance to flow of water. Total monomer concentration, crosslinking density, pore wall thickness, temperature at which the gels are prepared affect the rapidity of solvent transportation. Rapidity was also affected by the thickness of the gel, i.e., the distance between the outer boundaries to central parts of cryogel, larger the distance slower the rate of swelling and shrinkage due to slow rate of mass and heat exchange due to increased distance (Lozinsky et al. 2001; Plieva et al. 2005).To ensure the biocompatibility Chinese hamster ovary (CHO) cells were allowed to grow for a period of 7 days over the polyacrylonitrile (PAN)–gelatin cryogel-IPN scaffolds. CHO cells adhered well over the surface of the cryogel-IPN scaffolds and secreted extracellular matrix which was spread all over the matrix (Lozinsky et al. 2001; Xue et al. 2002; Plieva et al. 2005; Srivastava et al. 2007).

7.3.2 Silk Proteins

Silk fibroin (SF), a hydrophobic protein biopolymer obtained from Bombyx mori (silkworm) (Altman et al. 2003), has been extensively categorized as noninflammatory and highly biocompatible for various cell types (Hakimi et al. 2007). This biopolymer has been intensively used in the preparation of IPN hydrogels. It is a fibrous protein of silk fiber and consists of heavy (350 kDa) and light (25 kDa) chain polypeptides, connected by a disulfide link (Zhou et al. 2000). The regenerated fiber has been considered as a candidate for biomaterials owing to its good mechanical strength in the wet state, biocompatibility for the growth of cells, and high resistance against enzymatic degradation (Gotoh et al. 1997; Ha et al. 2003; Jin and Kaplan 2003; Nazarov et al. 2004). Various polymers have been used for making IPNs with silk fibroins. Synthesis of multicomponent materials like IPNs of Poly(N-isopropylacrylamide) (PNIPAAm) and SF was developed by Gil and Hudson (2007) to improve the deswelling kinetics by suppressing the skin layer formation.

Polymers of acrylamide (AAm) and its derivatives are well known for their hydrophilic and inert nature that makes them suitable for applications in medical and pharmacy (Rosiak et al. 1983). Semi-IPNs of poly acrylamide (PAAm) and SF were prepared by simultaneous free radical polymerization method (Mandal et al. 2009). In this study, semi-IPN was prepared by mixing organic fibroin protein and aqueous AAm solution in different ratios in presence of N,N,N′,N′-tetramethylethylenediamine (TEMED) activator and ammonium persulfate initiator. The solutions turned to gel during incubation at 37°C due to N,N′-Methylenebisacrylamide crosslinker. Resulted crosslinked semi-IPNs were semi-transparent yellowish color due to fibroin content. They were soft and elastic and had a smooth slippery surface. Fourier-transform Infrared (FTIR) results indicated the intermolecular interactions between silk fibroin and polyacrylamide during gelation and hydrogel formation (Haider et al. 1993). Prepared semi-IPNs had higher mechanical strength which overcame the disadvantages of silk fibroins. It was because of the formation of intense fibroin bonding and well entrapment of it within 3D network of polyacrylamide, resulting in matrix stability and minimal release of fibroin protein into the medium. Biocompatibility of the IPNs was evaluated against AH927 feline embryo fibroblast cells and positive results indicated the compatibility of the semi-IPNS.

In an another study, poly(vinyl alcohol) (PVA) a particularly advantageous polymer for attaching cell signaling molecules or drugs via numerous hydroxyl groups present on the backbone (Bryant et al. 2004) has been used with silk fibroins to produce semi-IPNs by photopolymerization of precursor and blend solutions. Different weight ratios were selected to study the optimal composition of semi-IPNs for biomedical purpose. The vinyl groups react to generate an insoluble, but water-swellable, crosslinked network via a photopolymerization process, in the presence of a Irgacure-2959 photoinitiator and UV irradiation light source (Martens and Anseth 2000). Due to irradiation PVA chains containing multiple vinyl groups are chemically crosslinked and the fibroin chains interdiffuse and become physically entangled within the PVA 3D network (Mandal et al. 2009; Liu and Chan-Park 2010). Incorporation of silk fibroin resulted in colored and brittle IPNs compared to pristine PVA. These were found biocompatible while tested against human fibroblast and Human keratinocytes (HaCaT) cell lines. Release of model compound proved the potential of semi-IPNs for drug release purpose. It was also reported that drug loading and release rate could be moderately controlled by varying the PVA and SF concentrations.

Silk sericin, another natural protein derived from silkworm, is a water soluble globular protein. It has been used by Wu et al. in the preparation of IPN hydrogels with PNIPAAm (Wu et al. 2006) and Polymethyl methacrylate (PMMA) (Wu et al. 2010), the last one being a fast pH-responsive hydrogel.

7.3.3 Fibrin

Fibrin is a polymerized form of a soluble 340 kDa protein named fibrinogen. Fibrinogen polymerized into fibrin through the action of thrombin in the presence of calcium. Fibrinogen can be isolated from a patient’s own blood, making possible the formation of an autologous scaffold (Ye et al. 2000). Fibrin-based gels produced from blood molecules are biodegradable and biocompatible (Ariëns et al. 2002). They also support cell adhesion, proliferation, stem cell differentiation and, importantly, capillary formation (angiogenesis) (Ahmed et al. 2008; Janmey et al. 2008). But poor mechanical properties of fibrin gels render its applicability in biomedical purposes. Lower mechanical strength makes them susceptible to contraction/compaction by cells and rapid degradation by proteases. Consequently, cell-seeded fibrin gels often shrink during in vitro culture (Syedain et al. 2009) and/or degrade prematurely prior to or soon after transplantation (Meinhart et al. 1999). One way to eliminate the limitations of fibrin is to make IPNs of it with other biocompatible natural or synthetic polymers. Recent studies suggested that incorporation of another polymer into fibrin gels leads to better shape stability and mechanical strength. Studies on IPN hydrogels composed of fibrin and polyethylene oxide (PEO) demonstrated improved mechanical properties while maintaining cell growth (Akpalo et al. 2011). The PEO network was synthesized in an aqueous buffer medium, and the fibrin gelation was carried out upon UV irradiation so that PEO/Fibrin IPNs were obtained. Another study reported a fibrin–alginate IPN as a dynamic matrix for the growth of ovarian follicle cells (Shikanov et al. 2009). Follicle growth was facilitated by the degradation of fibrin and alginate phase remained to provide structural support. The follicles cultured were meiotically more competent than in alginate alone. In another study IPN hydrogels composed of fibrin and hyaluronic acid (HA) for tissue engineering applications were reported. HA is a non-sulfated glycosaminoglycan found primarily in the extracellular matrix (ECM). Due to its low immunogenic, biodegradable properties, and their versatility in chemical modification, it has been widely used as tissue engineering scaffolds (Masters et al. 2005; Prestwich 2011). In this study fibrin–HA IPN was prepared by chemically crosslinking HA network and entangling fibrin in the matrix. Human umbilical vein endothelial cells (HUVECs) were cultured for biocompatibility analysis. Result showed that IPN had improved mechanical properties of fibrin gels while retaining the ability to promote cell proliferation but cell proliferation decreased with the degree of crosslinking.

7.3.4 Soy Protein

Renewable plant protein soy protein is 60–70% of the total soybean protein (Shewry et al. 1995). It is naturally abundant and regarded as an ideal biomaterial for biomedical, tissue engineering scaffold and drug delivery applications due to its good biodegradability and biocompatibility, ready availability, high thermal stability and noncytotoxicity (Vaz et al. 2003; Zheng et al. 2007; Liu et al. 2008). Recently, soy protein composites blended with environmentally sensitive polymers have been developed for cell cultures, drug carriers and wound dressing materials (Vaz et al. 2004; Snyders et al. 2007). Addition of stimuli sensitive polymers endow the composites with intelligent features and resulted in new potential applications in the biomedical and pharmaceutical fields (Liu et al. 2009). Novel temperature-sensitive interpenetrating polymer network of soy protein/Poly(N-isopropylacrylamide) (PNIPAAm) was prepared (Liu and Cui 2011). PNIPAAm is a typical temperature sensitive hydrogel which has been used with many other natural polymers for biomedical applications (Zhang et al. 2005; Mallikarjuna Reddy and Ramesh 2008). In this study, Glutaraldehyde and N,N′-methylenebisacrylamide as crosslinking agents and ammonium persulfate as initiator was used and properties such as network structure, miscibility dynamic swelling and deswelling kinetics and temperature sensitivity of IPNs were investigated. IPNs have shown good miscibility and thermal stability. Soy protein and BIS contents were the crucial parameters to obtain the expected properties such as swelling ratio, water retention capacity, network structure and temperature sensitivity. The release behavior and the release mechanism of a model protein, bovine serum albumin (BSA), were also investigated in detail (Liu and Cui 2011). The results indicated that the release behavior of BSA had strong temperature dependence and the release percentage of BSA could be controlled by modulating the amount of soy protein or crosslinking agent. The results indicate that the hydrogels may have potential applications in the field of biomedical materials such as in the controlled release of drugs.

7.4 Fabrication Techniques

Several methods have been reported to prepare IPNs from protein polymers. Fundamental free radical crosslinking reaction of polymers behind all these processes occurs either by chemical or irradiation in presence of an initiator. Though irradiation can mitigate the use of chemical crosslinkers but loaded drug may degrade in contact with radiation. In this section several methods have been described by which IPNs of protein have been produced and isolated.

7.4.1 Desolvation or Coacervation

Coacervation/desolvation is the most commonly used method for the preparation of protein nanoparticles (Lohcharoenkal et al. 2014; Cheng et al. 2016). In addition to conformation changes in protein structure, the desolvation process reduces the solubility of the protein leading to phase separation. The size of nanoparticles in the coacervate can be controlled by controlling processing variables. After nanoparticles are formed, they are crosslinked by agents such as glutaraldehyde and glyoxal which leads to the formation of IPN nanoparticles (Langer et al. 2003). This desolvation is based on the differential solubility of proteins in different solvents as a function of solvent polarity, pH, ionic strength, and presence of electrolytes (Thiering et al. 2001; Lohcharoenkal et al. 2014). In case of albumin, antisolvent acetone produced smaller nanoparticles compared to ethanol. Moreover, the increase in antisolvent/solvent ratio results in rapid extraction or diffusion of the solvent into the antisolvent phase. This limits the growth of particles and smaller nanoparticles are formed (Wang et al. 2008).

Langer et al. (2003) studied processing parameters that influence the formation of Human serum albumin (HAS) nanoparticles. Furthermore, the pH value of the protein solution prior to desolvation has an impact on the resulting particle size and yield due to higher probability of protein coacervation at net-zero surface charge at the isoelectric point (Fuchs et al. 2010). It was found that by changing the initial pH, prior to desolvation step, nanoparticles ranging from 100 to 300 nm can be produced and higher pH leads to formation of smaller particles (Ko and Gunasekaran 2006).

Gelatin nanoparticles can be prepared by dissolving gelatin in an aqueous solution (pH 7), followed by changing the solvent composition of water and alcohol, and gradual addition of ethanol (Coester et al. 2000; Kaul and Amiji 2004; Jain et al. 2008). Denaturation and hydrophobicity of protein molecules also control the size of nanoparticle. Although β-lactoglobulin (BLG) and bovine serum albumin (BSA) have same pI but due to lower hydrophobicity BLG produces smaller nanoparticles (∼130 nm) than BSA (Ko and Gunasekaran 2006) and denaturation of BLG prior to phase separation further reduced the particle size of BLG nanoparticles to approximately 60 nm (Chen et al. 1994). In desolvation process rigidity of the nanoparticles can be increased by increasing the degree of crosslinking agent. Lysine residues in the protein involve in crosslinking. This crosslinking causes the stabilization of the protein nanoparticles, reduces enzymatic degradation, drug release from the nanoparticles (Langer et al. 2008; Nahar et al. 2008) and leads to the formation of denser but smaller particles (Nahar et al. 2008). But due to their toxic nature, it is essential to remove the crosslinkers as completely as possible thereafter (Wang and Uludag 2008). To stabilize the hydrophobic proteins such as gliadin and legumin during phase separation surfactants are required. Addition of surfactant in this case increases product yield without alternating the particle size (Irache et al. 1995). Recently radiation has been used for crosslinking of some elastin-derived nanoparticles where α-elastin aggregates were generated by increasing the temperature and then irradiated with 60Co gamma rays (Neradovic et al. 2004). Drugs can be loaded into particles by various processes such as surface adsorption and entrapment method during desolvation process. Efficiency of the method of loading varies from protein to protein and it also depends on drug properties as well as other factors such as drug/polymer ratio (Merodio et al. 2001). Casting evaporation has been used to form crosslinking polymers to synthesize IPN. For example, IPNs of gelatin and dextran have been prepared by this method in presence of glutaraldehyde as a crosslinker agent. In this process gelatin was added to crosslinker solution of glutaraldehyde and dextran was added.

7.4.2 Emulsion or Solvent Extraction

The emulsification and solvent extraction methods for production of nanoparticle proteins required an aqueous buffer solution. Emulsification of an aqueous solution of protein particle is done in oil by a high-speed homogenizer or ultrasonic shear and nanoparticles are formed at the water/oil interface (Fig. 7.2). Surfactants such as phosphatidylcholine and Span 80 are added as stabilizers to produce nanoparticles (Sussman et al. 2007; Yang et al. 2007). A nanosuspension is obtained after solvent evaporation and particles can be stored after freeze-drying (Xiao et al. 2009). This method has been used for the production of various protein nanoparticles including albumin, gelatin, and whey protein. Both chemical, by glutaraldehyde, and thermal crosslinking can be done in emulsion process. IPN-nanogels of gelatin and PAGA have also been prepared by using emulsion polymerizations. A double emulsion technique involving w/o/w emulsions allows encapsulation of proteins and hydrophilic drugs (Mayer et al. 2005).

Preparation of protein IPN particles by coacervation or desolvation method (Lohcharoenkal et al. 2014)

Though single emulsion crosslinking technique based on w/o emulsion is used extensively but recently w/w emulsion method has also been developed to form IPN (Bhattacharya et al. 2013). The main advantage of w/w emulsion method is that there is no use of organic solvents which might leave toxic residue that is incompatible with IPN biomaterials. Difference between these two methods is how they are prepared. In w/o emulsification method an aqueous phase is added to oil phase to prepare w/o emulsion after dissolving the water soluble materials in aqueous phase by stirring until a homogenous solution is made at specific temperature (Banerjee et al. 2010). But in the case of w/w emulsion technique an aqueous solution of water soluble polymers is emulsified as a dispersed phase in an aqueous solution of another polymer that acts as continuous phase. Then the dispersed polymer phase is crosslinked to form IPN network (Bhattacharya et al. 2013). Miniemulsion and inverse miniemulsion techniques are also used for the preparation of semi- or full IPNs. In this technique small stable droplets are prepared in a continuous phase by the application of high shear stress (Landfester 2006). First constituent polymers are obtained by sonication using specific initiator then one of the polymers is crosslinked with crosslinking agent which produces a semi-IPN and finally another crosslinking agent for another polymer is added to form full IPN. High shear stress applied during the process may cause degradation of miniemulsion through coalescence. To prevent this degradation a surfactant and a costablizer are added that are soluble in dispersed phase but insoluble in continuous phase. Koul et al. (2011) synthesized novel IPN nanogels composed of poly(acrylic acid) and gelatin by inverse miniemulsion technique. Acrylic acid monomer stabilized around the gelatin macromolecules in each droplet was polymerized using ammonium persulfate and tetramethylethylene diamine and crosslinked with N,N′-methylenebisacrylamide to form semi-IPN nanogels, which were sequentially crosslinked using glutaraldehyde to form IPNs (Fig. 7.3).

Synthesis of IPN particles by miniemulsion polymerization (Lohani et al. 2014)

7.4.3 Electrospray

A relatively new technique called electrospray has been used in the preparation of nanoparticles. This method is dependent upon the surface tension force that arises due to the application of high voltage current in a polymer solution. Aerosolized liquid droplets are formed after applying high voltage followed by passing through an emitter. The aerosolized droplets contain protein nanoparticles of colloidal size which are collected. Many researches have been done with this method to produce nanofiber, nanoparticles, and spray coating. Size of the particle formed through this method depends on many variables such as applied potential, working distance, nozzle diameter, polymer type, etc. (Zhou et al. 2007; Fathollahipour et al. 2015). It has been used largely for the preparation of gliadin and elastin-like peptide nanoparticles (Wu et al. 2008; Gulfam et al. 2012). Therapeutic drugs and nucleic acids can be well loaded by the protein nanoparticles with high efficacy through this pathway.

7.4.4 Irradiation Technique

This process is based on exposing the polymer under the radiation to facilitate the crosslinking of polymers in IPNs. Crosslinking of protein polymer such as gelatin by gamma irradiation has been reported in the literature (Kojima et al. 2004). IPNs based on N-vinyl pyrrolidone (NVP):gelatin, and a copolymer of NVP – acrylic acid:gelatin were prepared and studied (Singh et al. 2007). N,N′-methylenebisacrylamide (BIS) for NVP and/or acrylic acid and glutaraldehyde for gelatin were used as crosslinkers, respectively. BIS crosslinker was placed in NVP or copolymeric solution of NVP and acrylic acid before gamma irradiation and glutaraldehyde was applied after the irradiation for crosslinking the gelatin polymer. Irradiation was found beneficial in a sense that higher amount of crosslinker results in brittle and very longer degradation time product (Anderson et al. 1979) which is minimized in irradiation. Dose, composition, time, and pH of immersion medium played important role in controlling the swelling degree of prepared IPNs. Incorporation of acrylic acid leads to form IPNs with rigid as well as elastic structures that may find applications in wound dressing and drug delivery systems.

7.5 Conclusions

Interpenetrating polymer network nanoparticles can be realized for controlled delivery of anticancer drugs. The controlled delivery of anticancer drug in proper place is prime consideration in designing anticancer drug delivery system. IPN offers various advantages like specificity, excellent swelling capacity and mechanical strength, which play an important role in targeted drug delivery. Bioprotein based IPN nanoparticles are mainly designed to deliver drugs to a specific site of action with minimum fluctuation at a predetermined rate for maximizing drug availability and minimizing the dose related side effects and thus the effects of pharmacotherapy can be optimized. IPN based nanoparticle system using various polymers has the opportunity of obtaining desire materials with a range of properties that will improve drug carrier and eliminate the disadvantages of individual polymer system.

References

Abigerges D (1995) Irinotecan (CPT-11) high-dose escalation using intensive high-dose loperamide to control diarrhea. J Clin Oncol 13:210

Aggarwal BB, Banerjee S et al (2007) RETRACTED: curcumin induces the degradation of cyclin E expression through ubiquitin-dependent pathway and up-regulates cyclin-dependent kinase inhibitors p21 and p27 in multiple human tumor cell lines. Biochem Pharmacol 73:1024–1032. Elsevier

Ahmed TA, Dare EV et al (2008) Fibrin: a versatile scaffold for tissue engineering applications. Tissue Eng Part B Rev 14(2):199–215

Akpalo E, Bidault L et al (2011) Fibrin–polyethylene oxide interpenetrating polymer networks: new self-supported biomaterials combining the properties of both protein gel and synthetic polymer. Acta Biomater 7(6):2418–2427

Altman GH, Diaz F et al (2003) Silk-based biomaterials. Biomaterials 24(3):401–416

Anderson C, Rodriguez F et al (1979) Crosslinking aqueous poly (vinyl pyrrolidone) solutions by persulfate. J Appl Polym Sci 23(8):2453–2462

Ariëns RA, Lai T-S et al (2002) Role of factor XIII in fibrin clot formation and effects of genetic polymorphisms. Blood 100(3):743–754

Aylsworth JW (1914, September) Plastic composition. US. US Patent 1111284

Banerjee S, Chaurasia G et al (2010) Investigation on crosslinking density for development of novel interpenetrating polymer network (IPN) based formulation. J Sci Ind Res 69(10):777–784

Bhattacharya SS, Shukla S et al (2013) Tailored IPN hydrogel bead of sodium carboxymethyl cellulose and sodium carboxymethyl xanthan gum for controlled delivery of diclofenac sodium. Polym-Plast Technol Eng 52(8):795–805

Blume G, Cevc G (1990) Liposomes for the sustained drug release in vivo. Biochim Biophys Acta 1029(1):91–97

Brigger I, Dubernet C et al (2012) Nanoparticles in cancer therapy and diagnosis. Adv Drug Deliv Rev 64:24–36

Brown R, Links M (1999) Clinical relevance of the molecular mechanisms of resistance to anti-cancer drugs. Expert Rev Mol Med 1(15):1–21

Bryant SJ, Davis-Arehart KA et al (2004) Synthesis and characterization of photopolymerized multifunctional hydrogels: water-soluble poly (vinyl alcohol) and chondroitin sulfate macromers for chondrocyte encapsulation. Macromolecules 37(18):6726–6733

Chen HW, Huang HC (1998) Effect of curcumin on cell cycle progression and apoptosis in vascular smooth muscle cells. Br J Pharmacol 124(6):1029–1040

Chen G, Lin W et al (1994) Preparation of human serum albumin microspheres by a novel acetone-heat denaturation method. J Microencapsul 11(4):395–407

Cheng D, Yong X et al (2016) Synthesis of protein nanoparticles for drug delivery. Eur J BioMed Res 2(2):8–11

Coester C, Langer K et al (2000) Gelatin nanoparticles by two step desolvation a new preparation method, surface modifications and cell uptake. J Microencapsul 17(2):187–193

Cuenca AG, Jiang H et al (2006) Emerging implications of nanotechnology on cancer diagnostics and therapeutics. Cancer 107(3):459–466

Demirel M, Yazan Y et al (2001) Formulation and in vitro-in vivo evaluation of piribedil solid lipid micro-and nanoparticles. J Microencapsul 18(3):359–371

Dingler A, Blum R et al (1999) Solid lipid nanoparticles (SLNTM/LipopearlsTM) a pharmaceutical and cosmetic carrier for the application of vitamin E in dermal products. J Microencapsul 16(6):751–767

Du J-Z, Du X-J et al (2011) Tailor-made dual pH-sensitive polymer–doxorubicin nanoparticles for efficient anticancer drug delivery. J Am Chem Soc 133(44):17560–17563

Farokhzad OC, Langer R (2009) Impact of nanotechnology on drug delivery. ACS Nano 3(1):16–20

Farokhzad OC, Karp JM et al (2006) Nanoparticle–aptamer bioconjugates for cancer targeting. Expert Opin Drug Deliv 3(3):311–324

Fathollahipour S, Abouei Mehrizi A et al (2015) Electrospinning of PVA/chitosan nanocomposite nanofibers containing gelatin nanoparticles as a dual drug delivery system. J Biomed Mater Res A 103(12):3852–3862

Feng S-S, Chien S (2003) Chemotherapeutic engineering: application and further development of chemical engineering principles for chemotherapy of cancer and other diseases. Chem Eng Sci 58(18):4087–4114

Fuchs S, Coester C et al (2010) Protein-based nanoparticles as a drug delivery system: chances, risks, perspectives. J Drug Deliv Sci Technol 20(5):331–342

Gil ES, Hudson SMJB (2007) Effect of silk fibroin interpenetrating networks on swelling/deswelling kinetics and rheological properties of poly (N-isopropylacrylamide) hydrogels. Biomacromolecules 8(1):258–264

Gotoh Y, Tsukada M et al (1997) Synthesis of poly (ethylene glycol)-silk fibroin conjugates and surface interaction between L-929 cells and the conjugates. Biomaterials 18(3):267–271

Gulfam M, Kim J-e et al (2012) Anticancer drug-loaded gliadin nanoparticles induce apoptosis in breast cancer cells. Langmuir 28(21):8216–8223

Ha S-W, Park YH et al (2003) Dissolution of Bombyx m ori silk fibroin in the calcium nitrate tetrahydrate− methanol system and aspects of wet spinning of fibroin solution. Biomacromolecules 4(3):488–496

Haider ZA, Arai M et al (1993) Mechanism of the gelation of fibroin solution. Biosci Biotechnol Biochem 57(11):1910–1912

Hakimi O, Knight DP et al (2007) Spider and mulberry silkworm silks as compatible biomaterials. Compos Part B 38(3):324–337

Hasan MM, Khan MN et al (2018) Novel alginate-di-aldehyde cross-linked gelatin/nano-hydroxyapatite bioscaffolds for soft tissue regeneration. Int J Biol Macromol 117:1110–1117

Hu LHSR (2014) Interpenetrating polymer networks. In: Leszek CW, Utracki A (eds) Polymer blends handbook. Springer, Dordrecht, pp 417–447

Irache JM, Bergougnoux L et al (1995) Optimization and in vitro stability of legumin nanoparticles obtained by a coacervation method. Int J Pharm 126(1–2):103–109

Jain SK, Gupta Y et al (2008) Mannosylated gelatin nanoparticles bearing an anti-HIV drug didanosine for site-specific delivery. Nanomedicine 4(1):41–48

Jain E, Srivastava A et al (2009) Macroporous interpenetrating cryogel network of poly (acrylonitrile) and gelatin for biomedical applications. J Mater Sci 20(1):173

Janmey PA, Winer JP et al (2008) Fibrin gels and their clinical and bioengineering applications. J R Soc Interface 6(30):1–10

Jin H-J, Kaplan DLJN (2003) Mechanism of silk processing in insects and spiders. Nature 424(6952):1057

Juliano R (1976) The role of drug delivery systems in cancer chemotherapy. Prog Clin Biol Res 9:21–32

Kakde D, Jain D et al (2011) Cancer therapeutics-opportunities, challenges and advances in drug delivery. J Appl Pharm Sci 1(9):1–10

Kaul G, Amiji M (2004) Biodistribution and targeting potential of poly (ethylene glycol)-modified gelatin nanoparticles in subcutaneous murine tumor model. J Drug Target 12(9–10):585–591

Keane TE, El-galley RE et al (1998) Camptothecin analogues/cisplastin: an effective treatment of advanced bladder cancer in a preclinical in vivo model system. J Urol 160(1):252–256

Klibanov AL, Maruyama K et al (1990) Amphipathic polyethyleneglycols effectively prolong the circulation time of liposomes. FEBS Lett 268(1):235–237

Ko S, Gunasekaran S (2006) Preparation of sub-100-nm β-lactoglobulin (BLG) nanoparticles. J Microencapsul 23(8):887–898

Kojima T, Bessho M et al (2004) Characterization of biopolymer hydrogels produced by γ-ray irradiation. Radiat Phys Chem 71(1–2):235–238

Koul V, Mohamed R et al (2011) Interpenetrating polymer network (IPN) nanogels based on gelatin and poly (acrylic acid) by inverse miniemulsion technique: synthesis and characterization. Colloids Surf B 83(2):204–213

Krishna R, Mayer LD (2000) Multidrug resistance (MDR) in cancer: mechanisms, reversal using modulators of MDR and the role of MDR modulators in influencing the pharmacokinetics of anticancer drugs. Eur J Pharm Sci 11(4):265–283

Kudela V (1987) Hydrogels. In: Kroschwitz JI (ed) Encyclopedia of polymer science and engineering. Wiley, NewYork, pp 783–807

Landfester K (2006) Synthesis of colloidal particles in miniemulsions. Annu Rev Mater Res 36:231–279

Langer K, Balthasar S et al (2003) Optimization of the preparation process for human serum albumin (HSA) nanoparticles. Int J Pharm 257(1–2):169–180

Langer K, Anhorn M et al (2008) Human serum albumin (HSA) nanoparticles: reproducibility of preparation process and kinetics of enzymatic degradation. Int J Pharm 347(1–2):109–117

Litvak DA, Papaconstantinou HT et al (1999) Inhibition of gastric cancer by camptothecin involves apoptosis and multiple cellular pathways. Surgery 126(2):223–230

Liu Y, Chan-Park MB (2010) A biomimetic hydrogel based on methacrylated dextran-graft-lysine and gelatin for 3D smooth muscle cell culture. Biomaterials 31(6):1158–1170

Liu Y, Cui Y (2011) Thermosensitive soy protein/poly (n-isopropylacrylamide) interpenetrating polymer network hydrogels for drug controlled release. J Appl Polym Sci 120(6):3613–3620

Liu Y-F, Huang K-L et al (2007) Preparation and characterization of glutaraldehyde cross-linked O-carboxymethylchitosan microspheres for controlled delivery of pazufloxacin mesilate. Int J Biol Macromol 41(1):87–93

Liu D, Tian H et al (2008) Effects of calcium carbonate polymorph on the structure and properties of soy protein-based nanocomposites. Macromol Biosci 8(5):401–409

Liu Y, Cui Y et al (2009) Synthesis, characterization, and drug release behaviour of novel soy protein/poly (acrylic acid) ipn hy-drogels. Iran Polym J 18:339–348

Lohani A, Singh G et al (2014) Interpenetrating polymer networks as innovative drug delivery systems. J Drug Deliv 2014:1–11

Lohcharoenkal W, Wang L et al (2014) Protein nanoparticles as drug delivery carriers for cancer therapy. Biomed Res Int 2014:1–12

Lozinsky VI, Plieva FM et al (2001) The potential of polymeric cryogels in bioseparation. Bioseparation 10(4–5):163–188

Lu J, Liong M et al (2007) Mesoporous silica nanoparticles as a delivery system for hydrophobic anticancer drugs. Small 3(8):1341–1346

Mallikarjuna Reddy K, Ramesh Babu V et al (2008) Temperature sensitive semi-IPN microspheres from sodium alginate and N-isopropylacrylamide for controlled release of 5-fluorouracil. J Appl Polym Sci 107(5):2820–2829

Mandal BB, Kapoor S et al (2009) Silk fibroin/polyacrylamide semi-interpenetrating network hydrogels for controlled drug release. Biomaterials 30(14):2826–2836

Martens P, Anseth KJP (2000) Characterization of hydrogels formed from acrylate modified poly (vinyl alcohol) macromers. Polymer 41(21):7715–7722

Masters KS, Shah DN et al (2005) Crosslinked hyaluronan scaffolds as a biologically active carrier for valvular interstitial cells. Biomaterials 26(15):2517–2525

Mayer G, Vogel V et al (2005) Oligonucleotide-protamine-albumin nanoparticles: protamine sulfate causes drastic size reduction. J Control Release 106(1–2):181–187

Meinhart J, Fussenegger M et al (1999) Stabilization of fibrin-chondrocyte constructs for cartilage reconstruction. Ann Plast Surg 42(6):673–678

Merodio M, Arnedo A et al (2001) Ganciclovir-loaded albumin nanoparticles: characterization and in vitro release properties. Eur J Pharm Sci 12(3):251–259

Millar JR (1960) Interpenetrating polymer networks. Styrene–divinylbenzene copolymers with two and three interpenetrating networks, and their sulphonates. J Chem Soc 1:1311–1317

Miller KD, Soule SE et al (2004) A phase II study of 9-nitro-camptothecin in patients with previously treated metastatic breast cancer. Investig New Drugs 22(1):69–73

Nagaraj D, Rothenberg A et al (1987) Low molecular weight polyacrylamide-based polymers as modifiers in phosphate beneficiation. Int J Miner Process 20(3–4):291–308

Nahar M, Mishra D et al (2008) Development, characterization, and toxicity evaluation of amphotericin B–loaded gelatin nanoparticles. Nanomedicine 4(3):252–261

Nazarov R, Jin H-J et al (2004) Porous 3-D scaffolds from regenerated silk fibroin. Biomacromolecules 5(3):718–726

Neradovic D, Soga O et al (2004) The effect of the processing and formulation parameters on the size of nanoparticles based on block copolymers of poly (ethylene glycol) and poly (N-isopropylacrylamide) with and without hydrolytically sensitive groups. Biomaterials 25(12):2409–2418

Peer D, Karp JM et al (2007) Nanocarriers as an emerging platform for cancer therapy. Nat Nanotechnol 2(12):751

Pinto J, Müller R (1999) Pellets as carriers of solid lipid nanoparticles (SLN) for oral administration of drugs. Pharmazie 54(7):506–509

Plieva FM, Karlsson M et al (2005) Pore structure in supermacroporous polyacrylamide based cryogels. Soft Matter 1(4):303–309

Prestwich GD (2011) Hyaluronic acid-based clinical biomaterials derived for cell and molecule delivery in regenerative medicine. J Control Release 155(2):193–199

Rao KM, Rao KK et al (2015) Curcumin encapsulated pH sensitive gelatin based interpenetrating polymeric network nanogels for anti cancer drug delivery. Int J Pharm 478(2):788–795

Rosiak J, Burozak K et al (1983) Polyacrylamide hydrogels as sustained release drug delivery dressing materials. Radiat Phys Chem 22(3–5):907–915

Shenoy DB, Chawla JS et al (2004) Biodegradable polymeric nanoparticles for tumor-selective tamoxifen delivery: in vitro and in vivo studies. MRS Online Proc Libr Arch 845:369–374

Shewry PR, Napier JA et al (1995) Seed storage proteins: structures and biosynthesis. Plant Cell 7(0):945

Shikanov A, Xu M et al (2009) Interpenetrating fibrin–alginate matrices for in vitro ovarian follicle development. Biomaterials 30(29):5476–5485

Singh D, Choudhary V et al (2007) Radiation synthesis of interpenetrating polymer networks based on N-vinyl pyrrolidone–acrylic acid copolymer and gelatin. I. Swelling, morphology, and thermal characterization for biomedical applications. J Mater Sci 104(3):1456–1463

Snyders R, Shingel KI et al (2007) Mechanical and microstructural properties of hybrid poly (ethylene glycol)–soy protein hydrogels for wound dressing applications. J Biomed Mater Res A 83(1):88–97

Srivastava A, Jain E et al (2007) The physical characterization of supermacroporous poly (N-isopropylacrylamide) cryogel: mechanical strength and swelling/de-swelling kinetics. Mater Sci Eng A 464(1–2):93–100

Stanciu LIA (2003) Advanced polymers: interpenetrating polymer networks. In: Vasile C (ed) Handbook of polymer blends and composites, vol 3. Rapra Technology, Shrewsbury, pp 275–280

Stella B, Arpicco S et al (2000) Design of folic acid-conjugated nanoparticles for drug targeting. J Pharm Sci 89(11):1452–1464

Sussman EM, Clarke MB et al (2007) Single-step process to produce surface-functionalized polymeric nanoparticles. Langmuir 23(24):12275–12279

Syedain ZH, Bjork J et al (2009) Controlled compaction with ruthenium-catalyzed photochemical cross-linking of fibrin-based engineered connective tissue. Biomaterials 30(35):6695–6701

Takiguchi S, Shimazoe T et al (1994) Antitumor effect of camptothecin analog on liver metastatic model of human colon cancer in nude mice. Gan To Kagaku Ryoho 21(5):705

Thiering R, Dehghani F et al (2001) Current issues relating to anti-solvent micronisation techniques and their extension to industrial scales. J Supercrit Fluids 21(2):159–177

Torchilin VP (2007) Micellar nanocarriers: pharmaceutical perspectives. Pharm Res 24(1):1

Vaz CM, Van Doeveren P et al (2003) Development and design of double-layer co-injection moulded soy protein based drug delivery devices. Polymer 44(19):5983–5992

Vaz CM, de Graaf LA et al (2004) pH-sensitive soy protein films for the controlled release of an anti-inflammatory drug. Mater Res Innov 8(3):149–150

Wang G, Uludag H (2008) Recent developments in nanoparticle-based drug delivery and targeting systems with emphasis on protein-based nanoparticles. Expert Opin Drug Deliv 5(5):499–515

Wang G, Siggers K et al (2008) Preparation of BMP-2 containing bovine serum albumin (BSA) nanoparticles stabilized by polymer coating. Pharm Res 25(12):2896–2909

Weiss RB, Donehower R et al (1990) Hypersensitivity reactions from taxol. J Clin Oncol 8(7):1263–1268

Wu W, Li W et al (2006) Synthesis and characterization of pH-and temperature-sensitive silk sericin/poly (N-isopropylacrylamide) interpenetrating polymer networks. Polym Int 55(5):513–519

Wu Y, MacKay JA et al (2008) Fabrication of elastin-like polypeptide nanoparticles for drug delivery by electrospraying. Biomacromolecules 10(1):19–24

Wu W, Wang D-S et al (2010) A fast pH-responsive IPN hydrogel: synthesis and controlled drug delivery. React Funct Polym 70(9):684–691

Xiao K, Luo J et al (2009) A self-assembling nanoparticle for paclitaxel delivery in ovarian cancer. Biomaterials 30(30):6006–6016

Xue W, Hamley IW et al (2002) Rapid swelling and deswelling of thermoreversible hydrophobically modified poly (N-isopropylacrylamide) hydrogels prepared by freezing polymerisation. Polymer 43(19):5181–5186

Yang L, Cui F et al (2007) Preparation, characterization and biodistribution of the lactone form of 10-hydroxycamptothecin (HCPT)-loaded bovine serum albumin (BSA) nanoparticles. Int J Pharm 340(1–2):163–172

Ye Q, Zünd G et al (2000) Fibrin gel as a three dimensional matrix in cardiovascular tissue engineering. Eur J Cardiothorac Surg 17(5):587–591

Zhang GQ, Zha LS et al (2005) Preparation and characterization of pH-and temperature-responsive semi–interpenetrating polymer network hydrogels based on linear sodium alginate and crosslinked poly (N-isopropylacrylamide). J Appl Polym Sci 97(5):1931–1940

Zheng H, Zhou Z et al (2007) pH-sensitive alginate/soy protein microspheres as drug transporter. J Appl Polym Sci 106(2):1034–1041

Zhou C-Z, Confalonieri F et al (2000) Fine organization of Bombyx mori fibroin heavy chain gene. Nucleic Acids Res 28(12):2413–2419

Zhou Y, Yang D et al (2007) Electrospun water-soluble carboxyethyl chitosan/poly (vinyl alcohol) nanofibrous membrane as potential wound dressing for skin regeneration. Biomacromolecules 9(1):349–354

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Hasan, M.M., Chisty, A.H., Rahman, M.M., Khan, M.N. (2020). Bioprotein Based IPN Nanoparticles as Potential Vehicles for Anticancer Drug Delivery: Fabrication Technology. In: Jana, S., Jana, S. (eds) Interpenetrating Polymer Network: Biomedical Applications. Springer, Singapore. https://doi.org/10.1007/978-981-15-0283-5_7

Download citation

DOI: https://doi.org/10.1007/978-981-15-0283-5_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0282-8

Online ISBN: 978-981-15-0283-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)