Abstract

Global environmental concerns and the advancements in power electronics technology leading the application of Photovoltaic Systems (PVS) in the distribution generation (DG). For generating electric power through the energy received from the Sun, solar PVS is an emerging technology. It is playing a key role to consume solar energy as much as possible. Electric power is generated by the PV array in form of DC. This DC power before utilization for domestic or industrial uses must be converted into AC. If the PVS is grid-connected then the inverter requires high efficiency, maximum power point tracking, total harmonic distortion of currents injected into the grid must have low and the power injected into the grid must be controlled. The employed control schemes decide the performance of the inverter which is connected to the grid. In this paper, all aspects related to grid-connected inverter are presented that includes historical evolution of the inverter topologies, standards and specifications, summary of inverter types, and classification of inverter topologies. Also, a discussion has been presented based on the number of power processing stages required in the system to fed electrical power into the grid.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The increasing power demand throughout the world and environmental benefits of using PVS are gaining more visibility toward PVS to supply electrical power directly to the utility grid [1]. The main drawback why PVS have not so far been installed into the grid is its cost. It has relatively high cost, if compared to the conventional energy sources. However, solid-state inverter is the key technology for placing PVS into the grid. The cost of PV modules in now decreasing these days due to rise in production capacity of PV modules which has the major component in the high cost of PVS in the past. In order to get reduced overall cost of the system, the most challenging issue these days is the cost of the inverter which is connected to the grid. To make PVS more attractive, it becomes necessary to reduce the cost per watt of grid-connected inverter [2].

A DC/DC converter is required to connect PVS to the electric utility grid together with a DC/AC inverter. Typically used inverters are either Voltage Source Inverter (VSI) or a Current Source Inverter (CSI). The application of VSI is gaining interest throughout the world day by day in grid-connected PVS. Therefore, the main constraint in these inverters is high efficiency, also it is the serious constraint for the effective application of these inverters in the grid-connected PVS [3]. The design of VSI control system must be fast and accurate in order to ensure the proper operation of the PVS in the grid-connected mode. As a result, in order to achieve appropriate performance of the grid-connected PVS and for the actual tracking as per the anticipated command, an appropriate VSI control system is needed. In a grid-connected PVS, grid-connected inverter controls the current injected to the grid as a result DC-link voltage is maintained to its reference value also, active and reactive powers are regulated which is to be delivered to the grid [4].

Therefore, main focus in this paper has been placed on inverter solutions which are new, innovative as well as cheap. It has been found in the high diversity within the inverter itself and some new configurations of the system. Further, the study follows an overview of historical as well as some new inverter topologies for interfacing modules connected in PVS to the electric utility grid. Various approaches are discussed to recognize the most appropriate topology for PV inverters, and, finally, a conclusion is given.

2 Evolution of Grid-Connected Inverter Topologies for PVS

An inverter is used to convert the DC output power received from solar PV array into AC power of 50 Hz or 60 Hz. It may be high-frequency switching based or transformer based, also, it can be operated in stand-alone, by directly connecting to the utility or a combination of both [5]. In order to have safe and reliable grid interconnection operation of solar PVS, the inverter is the key technology. The generation of high-quality AC power is required for the electric utility system at reasonable cost, for which inverter is essential. The high-frequency power electronics-based switching devices with PWM are used to meet these requirements [6]. There are five possible topologies of inverter family in grid-connected PVS as shown in Fig. 1, viz., (a) centralized inverters, (b) string, (c) multi-string, (d) AC-module inverters, and (e) cascaded inverters [7].

The advantages and disadvantages based on the comparative study of the various publications [8,9,10,11,12,13,14] are presented in Table 1.

2.1 Centralized Inverters

The centralized inverters were the first topology as illustrated in Fig. 1a with that a large number of PV modules interfaced to the grid [15]. Each PV module generating a sufficiently high voltage and is divided into series to form string as a result further amplification of the voltage is avoided. Further, these strings were then connected in parallel along with string diode to achieve high power levels.

The PV modules and inverter were tied with the high-voltage DC cables in this centralized inverter, which is considered as the limitation related to this topology. Also, the increased power losses in centralized MPPT, increased mismatch loss between inverter and PV modules, nonflexible design, and increased losses in the string diodes are the severe limitations of this topology. The benefits of mass production could not be achieved due to these factors. The grid-connected stage comprising poor power quality and many current harmonics as it was ordinarily line commutated. This was the occasion to evolve a new inverter topology as to overcome the large amount of harmonics and comprises the evolving standards which also overcome power quality issue.

2.2 String Inverters and AC-Modules

The string inverters and the AC-module are the two technologies which are widely used in recent days also termed as present technology [15]. The string inverter is nothing but the reduced version of the centralized inverter as illustrated in Fig. 1b, where the inverter is connected to a single string of the PV modules [16]. The voltage amplification here can be avoided because of enough high input voltage. For European system, it requires only 16 PV modules approximate and the total open-circuit voltage of whole system may reach 720 V for 16 PV modules. However, the voltage in normal operation is as low as 450–510 V. If for voltage amplification, a line frequency transformer or a DC–DC converter is used then there is also the possibility to connect some PV modules in series also. Individual MPPTs can be applied for each string and there would be no losses accompanying with string diodes. As a result increased overall efficiency could be achieved as compared to the centralized inverter with reduced cost because of mass production.

On the other hand as illustrated in Fig. 1d, in the AC module, PV module and the inverter are integrated into one electrical equipment [16]. As there is only one PV module so, it maintains optimal adjustment between the inverter and the PV module and removes the mismatch losses. Also, there is a possibility of an easy enlarging of the system because of modular structure. The inherent feature of this topology is that it can become a “plug and play” device so that anyone can use it without any knowledge regarding electrical installation.

On the other hand, increased complexity in the topology may lead to reduced overall efficiency along with increase in price per watt due to the necessity of high voltage amplification. However, to keep low manufacturing cost as well as retail prices, the AC-module is proposed to be mass produced.

2.3 Multi-string Inverters and Cascaded Inverters

The multi-string is the further development of the string inverter as illustrated in Fig. 1c, in which several strings are interfaced to a single DC–AC inverter with their own DC–DC converter [16, 17]. Since every string can be controlled separately therefore, this is beneficial over centralized system, since every string can be controlled individually. Hence, with few modules, an operator may start his/her own PVS connected to the grid. With the possibility of plugging a new string into the existing platform with a DC–DC converter, further developments can be easily achieved as a result a flexible design is hereby achieved with high efficiency [18,19,20]. To develop an inverter which is capable to amplify very low voltage, 0.5–1.0 V and 100 W per meter square, up to required voltage level for the grid is the main challenge for the designers. Also, at the same time, it should reach high efficiency, that is why the new converter technology is required these days. The cascaded inverter depicted in Fig. 1e in which several converters have been connected in series to achieve high power or high voltage from the combination of several modules. These parameters would have supported this topology in medium and large grid-connected PVS.

3 Power Processing Stages-Based Inverters

There are broadly two categories of the inverters according to their power processing stages: single-stage inverters (SSI) and multiple-stage inverters (MSI).

3.1 SSI: Single-Stage Inverter

Multiple functions are to be performed by the single-stage inverter, such as voltage amplification function, controlling of currents to be injected into the grid, and the maximum power point tracking process. The double peak power is also handled by the design of single-stage inverter as per the below equation

where Pgrid denotes peak grid power and ωgrid denotes grid frequency.

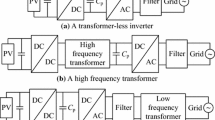

A huge weight is added to the inverter by the application of low-frequency transformer in single-stage inverter (operating at low frequency), also, the peak efficiency losses of 2% are introduced [21]. On the other hand, the most efficient, light in weight and cost-effective converter design is transformer-less or high-frequency transformer based converter design. The line frequency transformers are increasingly replacing by these transformers.

3.2 MSI: Multiple-Stage Inverter

There are more than one power processing stages involved in multistage inverter. The function of DC–AC conversion is executed by the last stage of power processing while the voltage amplification function is performed the first and intermediate stages, the galvanic isolation function is also performed by the intermediate stages in some of the inverters. In [22] a multiple-stage inverter with buck-boost converter is presented. As there is no transformer implemented so it is an example of non-isolated type with input DC voltage of very low range [22]. Another isolated topology is presented in [22] with multiple-stage buck-boost converter, in which transformer is implemented of very high frequency which works on a very low DC voltage. The sine wave of rectified current in both the aforesaid topologies received in the first stage and at the line frequency is transformed into the full sine wave which is switched by the second stage CSI. In both SSI and MSI, the power decoupling process is essential in order to filter out the voltage spikes and to allow the DC component of the input PV source. This decoupling is accomplished by the high capacitance which is offered by a bulky electrolytic capacitor.

4 Conclusion

To adopt PV inverter technology interconnected with the grid in domestic as well as industrial application, the most severe issues are their cost and efficiency. The cost is not only determined by the rated power of the inverter. The variation in technology is found from manufacturer to manufacturer which ultimately leads efficiency differences, variations in size, reliability, weight, etc. These factors have also the same impact on the costing of an inverter. The emerging topologies these days are advanced topologies like energy storing and harmonic filtering devices, power switching which also leads lower cost and higher overall efficiency of power conversion, also, with reduced number of devices. Some standards have been covered in this review which is essential for an inverter to fulfill before implementing in grid-connected PVS. This includes focussing on detection of islanding as well as injection of DC currents into the grid and power quality. The next part focuses on the large areas of PV modules which are connected to the grid through centralized inverters to present historical summary used in the past. In this part many shortcomings are included due to which string inverters came into picture as an emerging technology. Naturally, it was developed by adding more strings, individual DC–DC converter and MPPT connected to each string and a common DC–AC inverter is connected to them. Thus, the multi-string inverters were highlighted. This has been believed as one of the possible solutions from future perspective. Development of the AC-module was the trend which has been seen in this field, where each PV module along with its own DC–AC inverter is interfaced to the grid.

References

Benner JP, Kazmerski L (1999) Photovoltaics gaining greater visibility-IEEE. Spectrum 36(9)

Standard I (2004) 61000-3-2: 2004, limits for harmonic current emissions. International Electromechanical Commission, Geneva

Libo W, Zhengming Z, Jianzheng L (2007) A single-stage three-phase grid-connected photovoltaic system with modified MPPT method and reactive power compensation. IEEE Trans Energy Convers 22(4):881–886

Engel S, Rigbers K, De Doncker RW (2009) Digital repetitive control of a three-phase at-top-modulated grid tie solar inverter. In: 13th European conference on power electronics and applications, 2009. EPE’09. IEEE, pp 1–10

Chinnaiyan VK, Jerome J, Karpagam J (2013) An experimental investigation on a multilevel inverter for solar energy applications. Int J Electr Power Energy Syst 47:157–167

Eltawil MA, Zhao Z (2010) Grid-connected photovoltaic power systems: technical and potential problems: a review. Renew Sustain Energy Rev 14(1):112–129

Xiao B, Hang L, Mei J, Riley C, Tolbert LM, Ozpineci B (2015) Modular cascaded H-bridge multilevel PV inverter with distributed MPPT for grid-connected applications. IEEE Trans Ind Appl 51(2):1722–1731

AbdEl-Gawad H, Sood VK (2014) Overview of connection topologies for grid-connected pv systems. In: 2014 IEEE 27th Canadian conference on electrical and computer engineering (CCECE). IEEE, pp 1–8

Mahela OP, Shaik AG (2017) Comprehensive overview of grid interfaced solar photovoltaic systems. Renew Sustain Energy Rev 68:316–332

Chowdhury ASK, Razzak MA (2013) Single phase grid-connected photovoltaic inverter for residential application with maximum power point tracking. In: 2013 2nd international conference on informatics, electronics and vision (ICIEV 2013). IEEE, pp 1–6

Sastry J, Bakas P, Kim H, Wang L, Marinopoulos A (2014) Evaluation of cascaded H-bridge inverter for utility-scale photovoltaic systems. Renew Energy 69:208–218

Islam M, Mekhilef S, Hasan M (2015) Single phase transformerless inverter topologies for grid-tied photovoltaic system: a review. Renew Sustain Energy Rev 45:69–86

Latran MB, Teke A (2015) Investigation of multilevel multifunctional grid connected inverter topologies and control strategies used in photovoltaic systems. Renew Sustain Energy Rev 42:361–376

Chong B, Zhang L (2013) Controller design for integrated PV-converter modules under partial shading conditions. Sol Energy 92:123–138

Calais M, Myrzik J, Spooner T, Agelidis VG (2002) Inverters for single-phase grid-connected photovoltaic systems-an overview. In: 2002 IEEE 33rd annual power electronics specialists conference, 2002. PESC’02, vol 4. IEEE, pp 1995–2000

Lysen E, Vigotti R (1998) The international energy agency photovoltaic power systems implementing agreement. Renew Energy 15(1–4):60–65

Meinhardt M, Cramer G (2000) Past, present and future of grid connected photovoltaic-and hybrid-power-systems. In: IEEE power engineering society summer meeting, 2000, vol 2. IEEE, pp 1283–1288

Wilk H, Ruoss D, Toggweiler P (2002) Innovative electrical concepts. International Energy Agency Photovoltaic Power Systems, IEA PVPS, pp 7–07

Wuest M, Toggweiler P, Riatsch J (1994) Single cell converter system (SCCS). In: IEEE photovoltaic specialists conference-1994, 1994 IEEE first world conference on photovoltaic energy conversion, 1994, conference record of the twenty fourth, vol 1. IEEE, pp 813–815

Riatsch J, Stemmler H, Schmidt R (1997) Single cell module integrated converter system for photovoltaic energy generation. In: European conference on power electronics and applications, vol 1. Proceedings Published by Various Publishers, pp 1–071

Attanasio R, Cacciato M, Gennaro F, Scarcella G (2008) Review on single-phase PV inverters for grid-connected applications. In: 4th IASME/WSEAS, international conference on energy, environment, ecosystems and sustainable development (EEESD’08). Algarve, Portugal

Saha S, Sundarsingh V (1996) Novel grid-connected photovoltaic inverter. IEEE Proc Gener Trans Distrib 143(2):219–224

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Singh, B.P., Goyal, S.K., Siddiqui, S.A., Kumar, P. (2020). A Study and Comprehensive Overview of Inverter Topologies for Grid-Connected Photovoltaic Systems (PVS). In: Kalam, A., Niazi, K., Soni, A., Siddiqui, S., Mundra, A. (eds) Intelligent Computing Techniques for Smart Energy Systems. Lecture Notes in Electrical Engineering, vol 607. Springer, Singapore. https://doi.org/10.1007/978-981-15-0214-9_107

Download citation

DOI: https://doi.org/10.1007/978-981-15-0214-9_107

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0213-2

Online ISBN: 978-981-15-0214-9

eBook Packages: EngineeringEngineering (R0)