Abstract

Organic-inorganic hybrid materials have developed rapidly to become an established part of ceramic science and technology. In this chapter, among preparation methods of organic-inorganic hybrid materials, the sol-gel process, intercalation, and surface modification, which have a close relationship with ceramic materials, are described with an emphasis on their synthetic aspects and their applications. To begin with, classification of organic-inorganic hybrid materials based on the type of their interfacial chemical bonds is introduced. Following a brief definition of the sol-gel process, the basic chemistry of the sol-gel process is explained. Various preparation methods for sol-gel-derived organic-inorganic hybrid materials, including bridged silsesquioxane and mesostructured materials, are then described, and representative applications of sol-gel-derived organic-inorganic hybrid materials are briefly discussed. For intercalation, which is characteristic of layered materials, the basic concept is introduced first, after which the applicable reaction mechanisms for intercalation are demonstrated with the grafting reaction, which is related to intercalation. Representative applications of intercalation compounds are then exhibited with applications of nanosheets obtained via the exfoliation of layered materials. The process of surface modification of metal oxide nanoparticles and the application of the resulting surface-modified metal oxide nanoparticles are then demonstrated.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Organic-inorganic hybrid materials

- Metal oxide nanomaterials

- Polymers

- Sol-gel process

- Intercalation

- Surface modification

10.1 Organic-Inorganic Hybrid Materials: Introduction [1, 2]

Organic-inorganic hybrid materials have been attracting increasing attention as next-generation materials, since they could exhibit the advantages of both inorganic and organic components. To optimize the properties of organic-inorganic hybrid materials, it is important to control the domain sizes and shapes of the components and chemical bonds at their interfaces, in addition to their compositions and structures. The selection of starting materials and processes is thus important for obtaining desirable macroscopic structures. In this chapter, the sol-gel process, intercalation, and surface modification are selected among various processes for preparing organic-inorganic hybrid materials, since they can provide organic-inorganic hybrid materials where ceramic materials play an important role. Their characteristics and some examples are presented in the following sections.

Among various classifications of organic-inorganic hybrid materials, the classification using interfacial bonds is frequently employed [3]. The advantage of this classification is that it can be applied to organic-inorganic hybrid materials prepared through all the processes.

-

Class I: Organic-inorganic hybrid materials bearing relatively weak chemical bonds, such as the van der Waals force, hydrogen bonds, and ionic bonds.

-

Class II: Organic-inorganic hybrid materials bearing relatively strong chemical bonds, covalent and ion o-covalent bonds.

In this chapter, typical processes for producing organic-inorganic hybrid materials in which ceramic materials play key roles are presented: the sol-gel process, inorganic network formation process materials; intercalation compounds and nanosheet-related materials, intercalation reactions, which are host-guest reactions, and related reactions, grafting reactions and exfoliation; and surface modification of nanoparticles are all described.

10.2 Sol-Gel Process [4,5,6,7,8]

10.2.1 Overview of the Sol-Gel Process

The definition of the sol-gel process by IUPAC is as follows: “a process through which a network is formed from solution by a progressive change of liquid precursor(s) into a sol, to a gel, and in most cases finally to a dry network.” [9] The term “sol-gel process” has actually been employed for processes which proceed via formation of no clear sol and gel. Thus, this term has been employed for the conversion of precursors into solid materials, and the precursors are commonly metal alkoxides. Recently developed non-hydrolytic sol-gel process provides typical examples of processes which proceed without the formation of sol and gel [10, 11].

Metal alkoxides are generally expressed as M(OR)n, where M is metal or metalloid, and R is an alkyl or alkenyl group. In extended usage, R could be an organic group with atoms other than hydrogen and carbon, such as oxygen. A large number of metals and metalloids are known to form metal alkoxides.

Some metal alkoxides can form oligomeric or polymeric structures in solvents, and in some cases the alkoxides are insoluble in common organic solvents. The introduction of a bulky group as an R group is known to be an effective means of increasing their solubility. Since metal oxides can be prepared from metal alkoxides, they can be regarded as monomers of metal oxides. Metal alkoxides are not classified as organometallic compounds but as metalorganic compounds. There are a few exceptions, such as organoalkoxysilanes, R′xSi(OR)4−x, where Si-C covalent bonds are present. Since metal alkoxides are hydrolysable molecules, their handling is similar to that of organometallic compounds, which are frequently moisture-sensitive. A typical organometallic-chemistry-type handling procedure involves purification by vacuum distillation.

Although various organic solvents can be employed for dissolving metal alkoxides, alcohols, in particular parent alcohols (alcohols whose alkyl group is the same as the R group in M(OR)n), are utilized. When alcohols other than the parent alcohol are used, reactions called “alcohol-exchange reactions” proceed:

In a hydrolytic sol-gel process, which is commonly employed, hydrolysis of an alkoxy group leads to the formation of a hydroxyl group and triggers a condensation reaction. Such reactions can be expressed as follows for tetraalkoxysilane, Si(OR)4:

-

[hydrolysis]

-

[condensation]

Since tetraalkoxysilanes are relatively less reactive toward hydrolysis, a catalyst, generally an acid or a base, is added to the system. In an acid-catalyzed hydrolysis, the hydrolysis is initiated by the addition of a proton to an oxygen atom in tetraalkoxysilane, while a direct nucleophilic attack by an OH− ion triggers the reaction in a base-catalyzed hydrolysis. The hydrolysis rate depends on various factors, including the catalyst concentration and the size of R group. On the other hand, the reactivities of organoalkoxysilanes, R′xSi(OR)4−x, depend on both the R and R′ groups. The inductive effects of R′ groups influence their hydrolysis rates, since they affect the electron density of silicon. Thus, with an increase in x, the hydrolysis rate increases in an acidic system, while the hydrolysis rate decreases in a basic system. The steric effects of both R and R′ groups also change their hydrolysis rates.

The hydrolysis rates of transition metal alkoxides are much faster compared to those of the tetraalkoxysilanes and organoalkoxysilanes [12]. And the hydrolysis rate strongly depends on the metal. One factor is lower electronegativities of the transition metals (the electronegativity of silicon is 2.5 and those of many transition metals are less than 2). Another important factor is larger coordination numbers of the transition metals, coordination numbers larger than four. The coordinative unsaturation of monomeric metal alkoxides also causes additional intermolecular coordination of oxygen atoms to form oligomeric or polymeric structures (Fig. 10.1).

To reduce the reactivities of transition metal alkoxides, modification of transition metal alkoxides is frequently applied. A typical example is modification with β-diketones (HZ). Since β-diketones undergo keto-enol tautomerism, their enol forms react to form β-diketonates:

In the resulting molecule, the oxygen atom in the carbonyl group (C=O) coordinates to the metal additionally to reduce the reactivity of the molecule, leading to suppression of the formation of precipitation during the sol-gel process (Fig. 10.2).

Non-hydrolytic processes have been developed in recent decades [10, 11]. Since the presence of water favors a hydrolytic sol-gel process, a non-hydrolytic process is conducted in non-aqueous systems. These reactions contain a condensation step, which involves functional groups containing oxygen. Non-hydrolytic processes are particularly suitable for the preparation of organic-inorganic hybrid materials in systems containing moisture-sensitive compounds and those for which controllable condensation is advantageous [13].

10.2.2 Preparation of Organic-Inorganic Hybrid Materials via the Sol-Gel Process

Since thermal treatment at high temperatures is not required for the sol-gel process, the sol-gel process is highly suitable for the preparation of organic-inorganic hybrid materials. Various approaches have therefore been reported to date, with a large number of combination of organic and inorganic components. Typical examples are presented below.

-

(a)

Organic-inorganic hybrid materials prepared via incorporation of organic ions or molecules upon hydrolysis and condensation of metal alkoxides [14, 15]

It is possible to prepare organic-inorganic hybrids containing organic ions or molecules upon hydrolysis and condensation of metal alkoxides. An organic species soluble in a system can be easily incorporated into a final xerogel. Since the resulting organic-inorganic hybrids are class-I hybrid materials, durability can be a problem.

-

(b)

Organic-inorganic hybrids prepared via co-hydrolysis of organoalkoxysilane and tetra-functional alkylalkoxysilane [15, 16]

Since the Si-C bonds are stable with respect to hydrolysis, organoalkoxysilanes are suitable starting materials for class-II hybrid materials. It should be noted that most other metal-carbon bonds are not stable with respect to hydrolysis. It should also be noted that current organosilicon chemistry can provide a variety of commercially available organoalkoxysilanes and also allow us to prepare target organoalkoxysilanes.

Co-hydrolysis of a di-functional or tri-functional organoalkoxysilane (R′xSi(OR)4−x, x = 1,2) with tetraalkoxysilane (Si(OR)4) is generally employed to prepare organic-inorganic hybrid materials, which have been called ORMOCERs (organically modified ceramics) or ORMOSILs (organically modified silicate). The hydrolysis and condensation rates of organoalkoxysilanes are different from those of tetraalkoxysilanes, and the hydrolysis and condensation rates of organoalkoxysilanes depend strongly on the R and R′ groups in R′xSi(OR)4−x, as discussed above. Thus, when R is a small organic group such as a methyl group, a relatively homogeneous structure can be obtained (Fig. 10.3), while a segregated structure can be obtained with a bulky R group.

By employing an organoalkoxysilane with a polymerizable group, another organic polymeric network can be formed in addition to an inorganic siloxane network, leading to a relatively homogeneous structure. Structures of this type in which an organic network and a metaloxane network are penetrating each other are classified to so-called “interpenetrating polymer networks” (IPNs). Typical organoalkoxysilanes are methacryloxymethyltrialkoxysilane and (3-glycidoxypropyl)trialkoxysilane (Fig. 10.4).

-

(c)

Organic-inorganic hybrids prepared from organic polymers and metal alkoxides [17]

When an organic-inorganic hybrid is prepared from an organic polymer and a metal alkoxide via the sol-gel process, the affinity between the organic polymer and a metaloxane network formed from the metal alkoxide plays a crucial role, and the two components could be easily segregated. Thus, preparation should be carefully designed to achieve preparation of homogeneous organic-inorganic hybrids.

A homogeneous organic-inorganic hybrid material can be obtained by selecting an appropriate polymer structure. Various hydroxyl-terminated and trialkoxysilyl-functionalized polymers have been employed with a metal alkoxide or tetraalkoxysilane to prepare homogeneous organic-inorganic hybrid materials [18]. Polymeric structures employed for homogeneous organic-inorganic hybrid materials include polydimethylsiloxane (PDMS), poly(tetramethylene oxide) (PMTO), poly(methyl methacrylate) (PMMA), and polyoxazoline. When tetraalkoxysilane and silanol-terminated PDMS are used, the resulting organic-inorganic hybrids are also called ORMOSILs. For a homogeneous silica-polyoxazoline hybrid material, a structural model in which hydrogen bonding between polyoxazoline and a siloxane network plays an important role was proposed (Fig. 10.5) [19].

Another approach involves a polymerizable molecule released upon hydrolysis of tetraalkoxysilane. Typical metal alkoxides are shown in Fig. 10.6 [20]. In a standard sol-gel process, alcohol is released upon hydrolysis of a metal alkoxide, and the released alcohol molecules, which are normally in the form of a volatile liquid, cause shrinkage upon drying. The molecules released from this type of tetraalkoxysilane, on the other hand, can be polymerized to form a polymeric matrix.

-

(d)

Bridged-silsesquioxane-type organic-inorganic hybrids prepared from precursors bearing multiple trialkoxysilyl groups [18, 21,22,23,24,25]

Another type of organic-inorganic hybrids, bridged-silsesquioxanes, has been developed. Bridged-silsesquioxanes are prepared via the sol-gel process from precursors bearing multiple trialkoxysilyl groups, R[Si(OR)3]n typically with n = 2 (Fig. 10.7). The advantage of this type of precursor is facile gelation without the addition of another metal alkoxide, and relatively homogeneous organic-inorganic hybrids can be obtained. Thus, enormous effort has been directed to developing bridged silsesquioxanes in recent years.

A combination of the sol-gel process with colloid chemistry has been applied to the preparation of nanomaterials in confined media and biomimetic silica-based membranes [30, 31]. Another outcome is the formation of microscale helical organic-inorganic hybrid materials using bridged-type precursors with two trialkoxysilyl groups, R[Si(OR)3]2 [32, 33].

A robust new research direction, however, appeared following the discovery of the ability of the liquid crystal templating process [34,35,36] (Fig. 10.8) to provide mesostructured materials, which can be converted into mesoporous materials via the removal of templates [37, 38]. In the standard preparation of mesoporous silica, which is typical materials prepared via the liquid crystal templating process, the electrostatic interaction between positively charged templates, which is formed by the self-assembly of cationic surfactant, and anionic silicate species plays a crucial role in the formation of mesostructured class-I hybrid materials. Hydrolysis of precursors bearing Si-C bonds in the presence of liquid crystal templates leads to the formation of mesostructured class-II hybrid materials [39, 40]. The use of bridged-type precursors, R[Si(OR)3]2, in the liquid crystal templating process provides class-II mesoporous hybrid materials called periodic mesoporous organosilica (PMO) [41].

Sol-gel-derived silica-based mesoporous materials (mesoporous silicas) are capable of surface modification using the reactivity of surface silanols by silylation, where surface silanol groups react with silylation reagents, typically XSiR3, where X = Cl or OR′, and the overall reaction can be expressed as shown below [42]:

10.2.3 Applications of Organic-Inorganic Hybrid Materials via the Sol-Gel Process [15, 43]

A variety of applications have been proposed and studied for sol-gel-derived materials. A few notable applications are described below.

Since transparent and robust materials can be prepared by the sol-gel process, various photofunctional organic-inorganic hybrids have been prepared. When a functional dye or a luminescent metal complex is added to the sol-gel system, for example, these guest species can be immobilized.

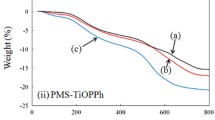

Organically modified siloxane networks obtained by the co-hydrolysis process can also be employed as hosts for encapsulating functional molecules and ions. For hydrophobic dyes, in particular, standard sol-gel matrices derived through hydrolysis of tetraalkoxysilanes are not appropriate matrices. In addition, since some functional molecules and ions are sensitive to their environments, their photochemical and photophysical behavior might depend on the compositions of organic-inorganic hybrids [48]. Thus, organically modified siloxane networks are attractive matrices. Typical example is spyrooxazine in sol-gel matrices derived from a vinyltriethoxysilane-tetraethoxysilane (VTEOS-TEOS) system. Spyrooxazine was present in a gel derived from vinyltriethoxysilane alone, while merocyanine was present in a gel prepared from a TEOS-rich system (Fig. 10.9) [49].

Coupling reactions and condensation reactions can be employed for binding organic functional groups covalently to silicon to prepare functional organoalkoxysilanes. A typical example is second harmonic generation (SHG) materials, since simple encapsulation of SHG dyes results in instability of dye alignment caused by poling. Thus, SHG dyes with trialkoxysilyl groups were synthesized and employed to prepare class-II SHG hybrid materials via a co-hydrolysis process [50].

Surface modification of sol-gel-derived mesoporous silica with surface modification agents bearing photofunctional groups led to class-II hybrid materials [51,52,53]. The use of photofunctional groups as spacers for the bridged precursors leads to the formation of various photofunctional PMOs as Class-II hybrid materials [29].

Another topic is immobilization of luminescent metal complexes, especially lanthanide complexes, which exhibit excellent luminescent properties [54]. When a soluble metal complex is added to a sol-gel system, a lanthanide complex can be easily encapsulated in a sol-gel matrix. Introducing trialkoxysilyl groups to a ligand enables a lanthanide complex with multiple trialkoxysilyl groups to be prepared, and a bridged-silsesquioxane-type material can be obtained by the sol-gel process.

Since the sol-gel process is suitable for the immobilization of biological materials, a large number of studies have been reported on immobilized biological materials ranging from enzymes to whole protozoa.

Among biological materials, encapsulation of enzymes is attracting a particularly enormous amount of attention; encapsulation of enzymes is important for the development of biocatalytic processes, and additional advantages such as better thermal stability are expected. In a typical example, activities of phosphatases encapsulated in sol-gel matrices were maintained at a pH where bare phosphatases lost their activities [60].

10.3 Intercalation [61,62,63,64,65,66,67]

10.3.1 Overview of Intercalation

For layered materials, intercalation is defined as an insertion reaction of a guest ion or molecule between layers. A standard intercalation reaction can be expressed by the following equation:

where [H] is the host substance, G is the guest species, and ⃞ represents an interlayer vacant site which can accommodate the guest species. The product, Gx[H], is called an intercalation compound. It should be noted that intercalation reactions are reversible.

In this section, intercalation reactions of metal oxide-based layered materials are described, and grafting reactions and exfoliation, the latter of which is currently attracting increasing attention, are also briefly described. Brief descriptions of other typical layered materials such as graphite and iron oxychloride are also included.

10.3.2 Intercalation Mechanism

-

(a)

Ion exchange

Figure 10.10 shows the concept of intercalation via ion exchange. When inorganic ions are present in the interlayer space, organic ions can be introduced by ion exchange. Typical host substances for cation exchange are montmorillonite, a typical aluminosilicate clay, layered transition metal oxometalates, such as layered titanates and niobates, and layered zirconium phosphates; n-alkylammonium ions are typical guest species. Anion-exchangeable layered materials are limited; a typical example is layered double hydroxides (LDHs).

-

(b)

Hydrogen bonding

In some neutral layered materials bearing surface hydroxyls, guest species can be present between the layers due to the formation of hydrogen bonds (Fig. 10.10). A typical example is kaolinite, a layered aluminosilicate clay. In addition to polar organic molecules such as dimethyl sulfoxide, carboxylate salts, such as potassium acetate, can be present between the layers of kaolinite.

-

(c)

Redox reaction

When a host substance is capable for redox reactions, intercalation involving a redox reaction could proceed (Fig. 10.10). A typical example is layered transition metal dichalcogenides and graphite.

-

(d)

Interaction with interlayer ions

Some layered materials bearing interlayer cations accommodate water molecules in their interlayer space because of the polarity of water molecules. Similar interactions with interlayer cations cause intercalation of polar organic molecules, such as alcohols and acrylonitrile (Fig. 10.10). When a proton is present as an interlayer cation, on the contrary, organic bases, such as n-alkylamines, can be accommodated in the interlayer space by acid-base reactions. When relatively hydrophobic cations such as tetramethyammonium ions are incorporated, moreover, the resulting organically pillared relatively hydrophobic interlayer space can accommodate small organic molecules.

-

(e)

Grafting reaction

If reactive groups are present on the interlayer surfaces, grafting reactions could proceed. It should be noted that these grafting reactions are not truly categorized as intercalation reactions, which should be reversible. A well-known host is iron oxychloride, FeOCl, where surface Fe-Cl bonds undergo grafting reactions with alcohols and sodium alkoxides:

Among metal oxide-based layered materials, layered crystalline silicic acids, such as magadiite and kenyaite, are well-known examples [68, 69]. The standard technique for grafting reactions is silylation (Fig. 10.11) [70, 71]. For transition metal oxometalates, silylation can also be applied [72]. Phosphorous coupling agents can be applied as well, moreover, to form stable M-O-P bonds [73].

Oxidized graphite, graphite oxide, also possesses reactive groups and undergoes grafting reactions [74].

10.3.3 Preparation of Organic-Inorganic Hybrid Materials via Intercalation Reactions and Exfoliation

A variety of combinations of host substances and guest species have been employed for intercalation reactions, and appropriate synthesis strategies have been applied according to the combination and target application. Exfoliation has been employed, on the contrary, to prepare nanosheets. Typical examples of intercalation reactions and exfoliation are shown below.

Intercalation of functional organic molecules and ions leads to organic-inorganic hybrid materials in which organic molecules or ions are homogeneously dispersed in the interlayer space. Cationic functional organic compounds such as rhodamine 6G can be immobilized especially easily in the interlayer space [77]. One strategy for neutral functional organic compounds is their accommodation in porous structures prepared by the intercalation of organic cations: the vapor-phase intercalation of p-nitroaniline, a typical second harmonic generation dye, under an electric field to achieve its noncentrosymmetric alignment [78]. The alignment of p-nitroaniline was also achieved by intercalation in kaolinite, whose interlayer environment was asymmetrical with a silicate layer and an aluminol layer facing each other (Fig. 10.12) [79].

The immobilization of metal complexes, which act as homogeneous catalysts, in the interlayer space provides unique solid catalysts. For example, immobilization of a Ziegler–Natta polymerization catalyst in fluorinated mica-type silicate and swelled synthetic hectorite gave solid catalysts active for polymerization of propylene with a narrow molecular mass distribution [80].

Encapsulation of enzymes can be achieved by intercalation, and the resulting materials can be employed as biocatalysts [81]. A typical study involved the intercalation of several enzymes in the interlayer space of α-zirconium phosphate, and the resulting intercalation compounds exhibit catalytic activities [82].

Since host substances are generally crystalline, the reactive sites are expected to be ordered on the interlayer surfaces. Such regularity can be utilized for constructing interlayer environments for selective adsorption. Selective adsorption by layered materials was first reported for vanadyl alkylphosphonates [85] and was also achieved by magadiite modified with octyl groups via a surface grafting reaction. Unique interlayer environments can be achieved by immobilizing optically active iron(II) tris(1,10-phenanthroline); montmorillonite bearing a single enantiomer in the interlayer space can resolve the racemic mixture of optically active metal complexes, and such properties can be employed in clay column chromatography for optical resolution [86].

The interactions between clay and organic polymers have been investigated over a long period of time, and various intercalation compounds have been prepared [90,91,92,93,94]. Their synthesis is mainly achieved by one of two different methods: direct intercalation of polymers form their solutions or their melts and intercalation of monomers and their subsequent polymerization in the interlayer space. One of the targets is electroconductive organic-inorganic hybrids. A typical example is the intercalation of poly(ethylene oxide), PEO, into a host substance bearing interlayer monovalent cations, such as Li+ and Na+. The intercalated PEO solvates interlayer cations and facilitates the transportation of Li+ and Na+, leading to ionic conductivity. The proposed structures of PEO-Li+-montmorillonite is shown in Fig. 10.13. This strategy is attractive, since crystallization of PEO chains, occurring below 60 °C and reducing Li+ ion conductivity significantly, can be suppressed in the interlayer space [88, 95, 96]. Another well-known example is oxidative polymerization of aniline in the interlayer space of layered substances containing appropriate transition metals. The resulting intercalation compounds exhibit electroconductivity [97,98,99,100].

-

(d)

Preparation of nanosheets by exfoliation and their applications for polymer-based organic-inorganic hybrids [92, 93, 101,102,103,104,105,106]

Nanosheets can be prepared from layered materials via exfoliation. One of the common approaches to layered materials with negatively charged layers is intercalation of bulky ammonium ions, such as tetrabutylammonium ions, and subsequent treatment, such as ultrasonication and stirring, and the resulting nanosheets can be dispersed in water. The use of n-alkylammonium ions with long alkyl chains also causes exfoliation in organic solvents.

Grafting reactions can be employed for both neutral and negatively charged layered materials. In the case of layered materials with negatively charged layers, protonated forms can be employed. In addition, intercalation compounds with polar organic solvents and organic ions can be employed as intermediates. Since covalent bonds are formed via grafting reactions, interlayer surface modification by grafting reaction is appropriate for exfoliation. The introduction of polymer chains can be achieved by several techniques, including the surface-initiated atom transfer radical polymerization (SI-ATRP) process [107].

Exfoliation of graphite requires another process for completion [108]. The typical process involves the oxidation of graphite to form graphite oxide and subsequent ultrasonication leading to the formation of graphene oxide, which can be reduced to form graphene or modified with organic compounds using functional groups, such as epoxy groups or carboxyl groups, on the surfaces or at the edges.

Exfoliated nanosheets can be dispersed in polymer matrices to form nanosheet/polymer hybrids. Pioneering work has been reported for clay-nylon systems (clay-nylon hybrids) [109]. Mechanical and gas barrier properties were dramatically improved by the addition of relatively small amount of clay nanosheets. A large number of studies have been reported for polymer-based hybrids with clay nanosheets and other types of metal oxide nanosheets. To date, considerable attention has been paid to graphene-nanosheet-containing polymer-based hybrids [110,111,112]. Different approaches have been applied to improve their affinity to polymer matrices: binding previously prepared polymer chains to graphene nanosheets (grafting to method); growth of polymer chains from surfaces, typically by the SI-ATRP technique (grafting from method); and grafting functional groups that react with monomers during polymerization for matrix formation.

The combination of nanosheets and polymers can provide different types of organic-inorganic hybrid materials. Organic-inorganic hybrid films with layered structures can be obtained by sequential adsorption of cationic polymers and negatively charged nanosheets [113, 114]. Another type of organic-inorganic hybrid material are hydrogels, which exhibit unique mechanical properties [115, 116].

10.4 Surface Modification of Nanoparticles and the Application of Modified Nanoparticles to Polymer-Based Organic-Inorganic Hybrids [117,118,119,120]

Ceramic nanoparticles, especially metal oxide nanoparticles, are attracting increasing attention. The origin of this interest includes possible modification of the band structures of semiconductors and superparamagnetism of magnetic nanoparticles, such as magnetite nanoparticles, by downsizing.

Surface modification of metal oxide nanoparticles has been developed for several purposes depending on the objectives, and two issues can generally be pointed out. One is the suppression of aggregation. Nanoparticles tend to aggregate, and it is generally accepted that breakdown of the resulting aggregates into individual nanoparticles is difficult. Thus, surface modification is required to suppress the aggregation of metal oxide nanoparticles. Another issue is tuning of the surface properties to obtain sufficient affinity to media or matrices. In any application of nanoparticles, affinity to the surrounding environment is a key factor. Thus, an appropriate interface should be designed via surface modification.

-

(a)

Surface modification process

Surface modification techniques were developed for modification of silica, and silylation has been applied [70, 71]. Thus, silylation reactions are also applied to other metal oxide nanoparticles. On the other hand, phosphorous coupling reagents are suitable for the modification of transition metal oxide nanoparticles and alumina nanoparticles, since M-O-P bonds formed are stable [121,122,123]. Phosphorous coupling reagents include organophosphonic acids (RPO(OH)2) and phosphate ester (generally in the form of a mixture of monoester, PO(OR)(OH)2, and diester, PO(OR)2(OH)). POH groups can react with surface hydroxyls to form M-O-P bonds. Since phosphoryl groups act as Lewis base sites, moreover, their coordination to surface Lewis acid sites is possible. Thus, upon modification of an organophosphonic acid, for example, a bidentate or tridentate environment is expected to form on the surface, leading to stable modification (Fig. 10.14).

Carboxylic acids can also be employed for transition metal oxide nanoparticles. As in the case of the surface modification of organophosphonic acids, the formation of a bidentate environment is expected upon modification with a carboxylic acid.

-

(b)

Application of surface-modified metal oxide nanoparticles [124,125,126,127,128,129,130,131,132,133,134]

Incorporation of metal oxide nanoparticles into organic polymers is currently one of the common strategies for improving polymer properties. Typical targets are high or low refractive index materials. By incorporating high refractive index nanoparticles, such as titania and zirconia nanoparticles [135, 136], or relatively low refractive index nanoparticles, such as silica [137], the refractive indices of organic-inorganic hybrid materials based on conventional polymers such as epoxy resins can be controlled.

Superparamagnetic nanoparticles are also attracting enormous attention because of their possible use in biomedical applications such as hyperthermia, drug delivery system, and magnetic resonance imaging [138, 139]. For these applications, surface modification is extremely important [139, 140]. Figure 10.15 shows surface-modified magnetic nanoparticles with multi functions [128]. Since magnetite is attractive for use in these applications, various approaches to surface modification of magnetite have been developed.

Recently developed applications for sol-gel-derived mesoporous silica nanoparticles include their use in drug delivery systems [141, 142]. The advantages of mesoporous silica nanoparticles include their large and controllable pore volume, facile inner and outer surface modification, facile particle size control, and high biocompatibility. The introduction of molecular valves that can react to stimuli provides further control of the release of drugs.

10.5 Summary and Outlook

In this chapter, the preparation and some applications for organic-inorganic hybrid materials in which ceramic materials play key roles are described: sol-gel materials including mesoscaled materials, intercalation compounds and nanosheet-related materials, and organically modified nanoparticles. Preparation techniques have been developed for these materials and new types of materials have been revealed in recent decades. It is clear from society’s demands for materials that the development of organic-inorganic hybrid materials is another major direction in ceramic material research, and one of the keys is the development of the precise preparation of inorganic component employed in organic-inorganic hybrid materials.

References

P. Judeinstein, C. Sanchez, J. Mater. Chem. 6, 511 (1996)

E. Ruiz-Hitzky, Chem. Rec. 3, 88 (2003)

C. Sanchez, P. Belleville, M. Popall, L. Nicole, Chem. Soc. Rev. 40, 696 (2011)

C.J. Brinker, G.W. Scherer, Sol-Gel Science. The Physics and Chemistry of Sol-Gel Processing (Academic Press, Boston, 1990)

A.C. Pierre, Introduction to sol-Gel Processing (Kluwer Academic Publishers, Boston, 1998)

D.C. Bradley, R.C. Mehrotra, I.P. Rothwell, A. Singh, Alkoxo and Aryloxo Derivatives of Metals (Academic Press, London, 2001)

N.Y. Turova, E.P. Turevskaya, V.G. Kessler, M.I. Yanovskaya, The Chemistry of Metal Alkoxides (Kluwer Academic Publishers, Boston, 2002)

S. Sakka, Handbook of sol-Gel Science and Technology, vol I–III (Kluwer, Boston, 2005)

J. V. Alemán, A. V. Chadwick, J. He, M. Hess, K. Horie, R. G. Jones, P. Kratochvíl, I. Meisel, I. Mita, G. Moad, S. Penczek, R. F. T. Stepto, Pure Appl. Chem. 79, 1801 (2007)

N. Pinna, M. Niederberger, Angew. Chem. Int. Ed. Eng. 47, 5292 (2008)

P.H. Mutin, A. Vioux, Chem. Mater. 21, 582 (2009)

J. Livage, C. Sanchez, J. Non-Cryst. Solids 145, 11 (1992)

J.N. Hay, H.M. Raval, Chem. Mater. 13, 3396 (2001)

R.C. Mehrotra, Struct. Bond. 77, 1 (1992)

J.D. Mackenzie, E.P. Bescher, Acc. Chem. Res. 40, 810 (2007)

H. Schmidt, ACS Symp. Ser. 360, 333 (1988)

J. Wen, G.L. Wilkes, Chem. Mater. 8, 1667 (1996)

D.A. Loy, K.J. Shea, Chem. Rev. 95, 1431 (1995)

Y. Chujo, E. Ihara, S. Kure, T. Saegusa, Macromolecules 26, 5681 (1993)

B.M. Novak, Adv. Mater. 5, 422 (1993)

R.J.P. Corriu, Angew. Chem. Int. Ed. 39, 1376 (2000)

K.J. Shea, D.A. Loy, Chem. Mater. 13, 3306 (2001)

K.J. Shea, D.A. Loy, Acc. Chem. Res. 34, 707 (2001)

B. Boury, R. Corriu, Chem. Rec. 3, 120 (2003)

L.-C. Hu, K.J. Shea, Chem. Soc. Rev. 40, 688 (2011)

P.F.W. Simon, R. Ulrich, H.W. Spiess, U. Wiesner, Chem. Mater. 13, 3464 (2001)

M.E. Davis, Nature 417, 813 (2002)

F. Hoffmann, M. Cornelius, J. Morell, M. Fröba, Angew. Chem. Int. Ed. 45, 3216 (2006)

N. Mizoshita, T. Tani, S. Inagaki, Chem. Soc. Rev. 40, 789 (2011)

R. Muñoz-Espí, C.K. Weiss, K. Landfester, Curr. Opin. Colloid Interface Sci. 17, 212 (2012)

K. Ariga, Chem. Rec. 3, 297 (2004)

J.J.E. Moreau, L. Vellutini, M.W.C. Man, C. Bied, J. Am. Chem. Soc. 123, 1509 (2001)

J.J.E. Moreau, L. Vellutini, M.W.C. Man, C. Bied, J.L. Bantignies, P. Dieudonné, J.L. Sauvajol, J. Am. Chem. Soc. 123, 7957 (2001)

N.K. Raman, M.T. Anderson, C.J. Brinker, Chem. Mater. 8, 1682 (1996)

J.Y. Ying, C.P. Mehnert, M.S. Wong, Angew. Chem. Int. Ed. 38, 56 (1999)

F. Schüth, Chem. Mater. 13, 3184 (2001)

C.T. Kresge, M.E. Leonowicz, W.J. Roth, J.C. Vartuli, J.S. Beck, Nature 359, 710 (1992)

J.S. Beck, J.C. Vartuli, W.J. Roth, M.E. Leonowicz, C.T. Kresge, K.D. Schmitt, C.T.W. Chu, D.H. Olson, E.W. Sheppard, S.B. McCullen, J.B. Higgins, J.L. Schlenker, J. Am. Chem. Soc. 114, 10834 (1992)

A. Shimojima, Y. Sugahara, K. Kuroda, J. Am. Chem. Soc. 120, 4528 (1998)

A. Shimojima, K. Kuroda, Angew. Chem. Int. Ed. 42, 4057 (2003)

S. Inagaki, S. Guan, T. Ohsuna, O. Terasaki, Nature 416, 304 (2002)

G.E. Fryxell, Inorg. Chem. Commun. 9, 1141 (2006)

C. Sanchez, B. Julián, P. Belleville, M. Popall, J. Mater. Chem. 15, 3559 (2005)

P.N. Prasad, F.V. Bright, U. Narang, R. Wang, R.A. Dunbar, J.D. Jordan, R. Gvishi, ACS Symp. Ser. 585, 317 (1995)

C. Sanchez, F. Ribot, B. Lebeau, J. Mater. Chem. 9, 35 (1999)

B. Lebeau, C. Sanchez, Curr. Opin. Solid State Mater. Sci. 4, 11 (1999)

C. Sanchez, B. Lebeau, F. Chaput, J.P. Boilot, Adv. Mater. 15, 1969 (2003)

B. Dunn, J.I. Zink, Chem. Mater. 9, 2280 (1997)

J. Biteau, F. Chaput, J.-P. Boilot, J. Phys. Chem. 100, 9024 (1996)

B. Lebeau, S. Brasselet, J. Zyss, C. Sanchez, Chem. Mater. 9, 1012 (1997)

K. Moller, T. Bein, Chem. Mater. 10, 2950 (1998)

B.J. Scott, G. Wirnsberger, G.D. Stucky, Chem. Mater. 13, 3140 (2001)

G. Schulz-Ekloff, D. Wöhrle, B. van Duffel, R.A. Schoonheydt, Microporous Mesoporous Mater. 51, 91 (2002)

J. Feng, H. Zhang, Chem. Soc. Rev. 42, 387 (2013)

I. Gill, A. Ballesteros, Trends Biotechnol. 18, 282 (2000)

J. Livage, T. Coradin, C. Roux, J. Phys. Condens. Matter 13, R673 (2001)

I. Gill, Chem. Mater. 13, 3404 (2001)

A.C. Pierre, Biocatal. Biotransform. 22, 145 (2004)

G.J. Owens, R.K. Singh, F. Foroutan, M. Alqaysi, C.-M. Han, C. Mahapatra, H.-W. Kim, J.C. Knowles, Prog. Mater. Sci. 77, 1 (2016)

H. Frenkel-Mullerad, D. Avnir, J. Am. Chem. Soc. 127, 8077 (2005)

B.K.G. Theng, The Chemistry of Clay-Organic Reactions (Adam Hilger, London, 1974)

M.S. Whittingham, A.J. Jacobson, Intercalatioin Chemistry (Academic Press, New York, 1982)

G. Lagaly, Solid State Ionics 22, 43 (1986)

G. Lagaly, K. Beneke, Colloid Polym. Sci. 269, 1198 (1991)

A.J. Jacobson, in Solid State Chemistry: Compounds, ed. by A. K. Cheetham, P. Day, (Oxford University Press, Oxford, 1992), p. 182

P. O’Brien, in Inorganic Materials, 2nd edn. ed. by D. W. Bruce, D. O’Hare, (John Wiley & Sons, Chichester, 1997), p. 171

M. Ogawa, K. Kuroda, Bull. Chem. Soc. Jpn. 70, 2593 (1997)

E. Ruiz-Hitzky, J.M. Rojo, Nature 287, 28 (1980)

N. Takahashi, K. Kuroda, J. Mater. Chem. 21, 14336 (2011)

E.P. Plueddemann, Silane Coupling Agents, 2nd edn. (Springer Science + Business Media, New York, 1991)

P. Van Der Voort, E.F. Vansant, J. Liq. Chromatogr. Relat. Technol. 19, 2723 (1996)

Y. Ide, M. Ogawa, Angew. Chem. Int. Ed. 46, 8449 (2007)

N. Kimura, Y. Kato, R. Suzuki, A. Shimada, S. Tahara, T. Nakato, K. Matsukawa, P.H. Mutin, Y. Sugahara, Langmuir 30, 1169 (2014)

A.B. Bourlinos, D. Gournis, D. Petridis, T. Szabó, A. Szeri, I. Dékány, Langmuir 19, 6050 (2003)

M. Ogawa, K. Kuroda, Chem. Rev. 95, 399 (1995)

T.J. Pinnavaia, Science, 220, 365 (1983)

R. Sasai, N. Iyi, T. Fujita, F.L. Arbeloa, K. Takagi, H. Itoh, Langmuir 20, 4715 (2004)

M. Ogawa, M. Takahashi, K. Kuroda, Chem. Mater. 6, 715 (1994)

R. Takenawa, Y. Komori, S. Hayashi, J. Kawamata, K. Kuroda, Chem. Mater. 13, 3741 (2001)

J. Tudor, L. Willington, D. O’Hare, B. Royan, Chem. Commun., 2031 (1996)

T. Baskaran, J. Christopher, A. Sakthivel, RSC Adv. 5, 98853 (2015)

C.V. Kumar, A. Chaudhari, J. Am. Chem. Soc. 122, 830 (2000)

A. Yamagishi, J. Coord. Chem. 16, 131 (1987)

M. Ogawa, S. Okutomo, K. Kuroda, J. Am. Chem. Soc. 120, 7361 (1998)

J.W. Johnson, A.J. Jacobson, W.M. Butler, S.E. Rosenthal, J.F. Brody, J.T. Lewandowski, J. Am. Chem. Soc. 111, 381 (1989)

A. Yamagishi, M. Taniguchi, Y. Imamura, H. Sato, Appl. Clay Sci. 11, 1 (1996)

E. Ruiz-Hitzky, Adv. Mater. 5, 334 (1993)

E. Ruiz-Hitzky, P. Aranda, B. Casal, J.C. Galván, Adv. Mater. 7, 180 (1995)

E. Ruiz-Hitzky, B. Casal, P. Aranda, J.C. Galván, Rev. Inorg. Chem. 21, 125 (2001)

B.K.G. Theng, Formation and Properties of Clay-Polymer Complexes, 2nd edn. (Elsevier, Amsterdam, 2012)

E.P. Giannelis, Appl. Organomet. Chem. 12, 675 (1998)

M. Alexandre, P. Dubois, Mater. Sci. Eng. R 28, 1 (2000)

S.S. Ray, M. Okamoto, Prog. Polym. Sci. 28, 1539 (2003)

S. Pavlidou, C.D. Papaspyrides, Prog. Polym. Sci. 33, 1119 (2008)

P. Aranda, E. Ruiz-Hitzky, Chem. Mater. 4, 1395 (1992)

R.A. Vaia, S. Vasudevan, W. Krawiec, L.G. Scanlon, E.P. Giannelis, Adv. Mater. 7, 154 (1995)

M.G. Kanatzidis, C.G. Wu, H.O. Marcy, C.R. Kannewurf, J. Am. Chem. Soc. 111, 4139 (1989)

M.G. Kanatzidis, C.-G. Wu, H.O. Marcy, D.C. DeGroot, C.R. Kannewurf, A. Kostikas, V. Papaefthymiou, Adv. Mater. 2, 364 (1990)

M.G. Kanatzidis, R. Bissessur, D.C. Degroot, J.L. Schindler, C.R. Kannewurf, Chem. Mater. 5, 595 (1993)

L. Wang, P. Brazis, M. Rocci, C.R. Kannewurf, M.G. Kanatzidis, Chem. Mater. 10, 3298 (1998)

A. Okada, A. Usuki, Mater. Sci. Eng. C 3, 109 (1995)

C. Tan, H. Zhang, Chem. Soc. Rev. 44, 2713 (2015)

V. Nicolosi, M. Chhowalla, M.G. Kanatzidis, M.S. Strano, J.N. Coleman, Science 340, 1226419 (2013)

J.N. Coleman, M. Lotya, A. O’neill, S.D. Bergin, P.J. King, U. Khan, K. Young, A. Gaucher, S. De, R.J. Smith, I.V. Shvets, S.K. Arora, G. Stanton, H.-Y. Kim, K. Lee, G.T. Kim, G.S. Duesberg, T. Hallam, J.J. Boland, J.J. Wang, J.F. Donegan, J.C. Grunlan, G. Moriarty, A. Shmeliov, R.J. Nicholls, J.M. Perkins, E.M. Grieveson, K. Theuwissen, D.W. McComb, P.D. Nellist, V. Nicolosi, Science 331, 568 (2011)

R. Ma, T. Sasaki, Adv. Mater. 22, 5082 (2010)

M. Osada, T. Sasaki, Adv. Mater. 24, 210 (2012)

N. Idota, S. Fukuda, T. Tsukahara, Y. Sugahara, Chem. Lett. 44, 203 (2015)

S. Mao, H. Pu, J. Chen, RSC Adv. 2, 2643 (2012)

A. Usuki, Y. Kojima, M. Kawasumi, A. Okada, Y. Fukushima, T. Kurauchi, O. Kamigaito, J. Mater. Res. 8, 1179 (1993)

S. Stankovich, D.A. Dikin, G.H.B. Dommett, K.M. Kohlhaas, E.J. Zimney, E.A. Stach, R.D. Piner, S.T. Nguyen, R.S. Ruoff, Nature 442, 282 (2006)

T. Kuilla, S. Bhadra, D. Yao, N.H. Kim, S. Bose, J.H. Lee, Prog. Polym. Sci. 35, 1350 (2010)

T. Kuila, S. Bose, A.K. Mishra, P. Khanra, N.H. Kim, J.H. Lee, Prog. Mater. Sci. 57, 1061 (2012)

E.R. Kleinfeld, G.S. Ferguson, Science 265, 370 (1994)

S.W. Keller, H.-N. Kim, T.E. Mallouk, J. Am. Chem. Soc. 116, 8817 (1994)

S. Tamesue, M. Ohtani, K. Yamada, Y. Ishida, J.M. Spruell, N.A. Lynd, C.J. Hawker, T. Aida, J. Am. Chem. Soc. 135, 15650 (2013)

M. Liu, Y. Ishida, Y. Ebina, T. Sasaki, T. Hikima, M. Takata, T. Aida, Nature 517, 68 (2015)

F. Caruso, Adv. Mater. 13, 11 (2001)

M.Z. Rong, M.Q. Zhang, W.H. Ruan, Mater. Sci. Technol. 22, 787 (2006)

M.-A. Neouze, U. Schubert, Monatsh. Chem. 139, 183 (2008)

S. Kango, S. Kalia, A. Celli, J. Njuguna, Y. Habibi, R. Kumar, Prog. Polym. Sci. 38, 1232 (2013)

C. Queffélec, M. Petit, P. Janvier, D.A. Knight, B. Bujoli, Chem. Rev. 112, 3777 (2012)

G. Guerrero, J.G. Alauzun, M. Granier, D. Laurencin, P.H. Mutin, Dalton Trans. 42, 12569 (2013)

R. Boissezon, J. Muller, V. Beaugeard, S. Monge, J.-J. Robin, RSC Adv. 4, 35690 (2014)

W. Caseri, Macromol. Rapid Commun. 21, 705 (2000)

R.J. Nussbaumer, W.R. Caseri, P. Smith, T. Tervoort, Macromol. Mater. Eng. 288, 44 (2003)

A.K. Gupta, M. Gupta, Biomaterials 26, 3995 (2005)

I.I. Slowing, J.L. Vivero-Escoto, C.-W. Wu, V.S.-Y. Lin, Adv. Drug Deliv. Rev. 60, 1278 (2008)

C. Sun, J.S.H. Lee, M. Zhang, Adv. Drug Deliv. Rev. 60, 1252 (2008)

K.K. Coti, M.E. Belowich, M. Liong, M.W. Ambrogio, Y.A. Lau, H.A. Khatib, J.I. Zink, N.M. Khashab, J.F. Stoddart, Nanoscale 1, 16 (2009)

J.H. Jang, H.B. Lim, Microchem. J. 94, 148 (2010)

R.A. Sperling, W.J. Parak, Philos. Trans. R. Soc. A 368, 1333 (2010)

S. Laurent, S. Dutz, U.O. Häfeli, M. Mahmoudi, Adv. Colloid Interf. Sci. 166, 8 (2011)

N. Lee, D. Yoo, D. Ling, M.H. Cho, T. Hyeon, J. Cheon, Chem. Rev. 115, 10637 (2015)

A. Watermann, J. Brieger, Nanomater. 7, 189 (2017)

W.-C. Chen, S.-J. Lee, L.-H. Lee, J.-L. Lin, J. Mater. Chem. 9, 2999 (1999)

K. Luo, S. Zhou, L. Wu, Thin Solid Films 517, 5974 (2009)

K.C Krogman, T. Druffel, M.K Sunkara, Nanotechnology 16, S338 (2005)

A. Jordan, R. Scholz, P. Wust, H. Fähling, R. Felix, J. Magn. Magn. Mater. 201, 413 (1999)

C. Wilhelm, C. Billotey, J. Roger, J.N. Pons, J.C. Bacri, F. Gazeau, Biomaterials 24, 1001 (2003)

Y. Zhang, N. Kohler, M. Zhang, Biomaterials 23, 1553 (2002)

J. Lu, M. Liong, J.I. Zink, F. Tamanoi, Small 3, 1341 (2007)

Y. Zhao, B.G. Trewyn, I.I. Slowing, V.S.-Y. Lin, J. Am. Chem. Soc. 131, 8398 (2009)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Sugahara, Y. (2019). Organic-Inorganic Hybrid Materials. In: Hojo, J. (eds) Materials Chemistry of Ceramics. Springer, Singapore. https://doi.org/10.1007/978-981-13-9935-0_10

Download citation

DOI: https://doi.org/10.1007/978-981-13-9935-0_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-9934-3

Online ISBN: 978-981-13-9935-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)