Abstract

Considering that air source heat pumps have the advantages of fast heat supply response, high heat supply efficiency and environmental protection, air source heat pumps can quickly follow the change of wind power when wind power changes rapidly, and timely eliminate wind power. Air source heat pumps are considered in the day-ahead dispatch model of integrated electricity-heating system in this paper. The model regards generation cost for traditional units and combined heating power (CHP) units, operation cost for air source heat pumps and electric boilers and curtailment cost of wind power as its optimization target. The response speed of air source heat pumps and electric boilers are first considered in the constraint conditions. The wind power can be converted into heat energy by air source heat pumps so that improve the consumption of wind power when the wind curtailment is serious. The heat generated is used to provide system heat. The excess of heat can be stored in the thermal storage energy devices, which released to provide system heat at low troughs. Finally, the comparison between the examples shows that air source heat pumps not only can quickly respond to the change of wind power, but also have low operation cost and reduce system power generation cost .

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Integrated electricity-heating systems

- Wind power consumption

- Air source heat pump (ASHP)

- Speed of response

1 Introduction

In recent years, with the rapid development of renewable energy represented by wind power, it not only has alleviated the energy crisis, but also reduced environmental pollution. However, the phenomenon of wind curtailment is serious [1] due to the randomness, the volatility and anti-peaking characteristics of wind power output, which bringing huge losses to the economy. Determining-power-by-heat operation mode of the combined heating power (CHP) units gradually becomes a main reason for the curtailment of wind in “Three North” region of china [2], and limits the adjustment capacity of the CHP units, which does not provide enough space for wind power consumption. The coupling devices such as electric boilers, heat pumps and thermal storage energy devices can promote the direct conversion between electric energy and thermal energy [3] and decouple the CHP units from ‘heat set’ constraint, thus they can provide upside space for wind power consumption. The excess of wind power can be converted into heat energy by electric boilers and heat pumps so that improve the consumption of wind power. Therefore, it is of practical significance to study the optimized dispatch of the integrated electricity-heating system under wind power consumption.

Scholars have made some research on the integrated electricity-heating system under wind power consumption at present. In the literature [4], the use of thermal storage energy devices to improve the capacity of wind power consumption was studied. In Ref. [5], the authors quantified the regulation capacity of thermal storage energy devices to CHP units during heating period. The authors in Refs. [6, 7] introduced the scheme of eliminating the wind curtailment after the electric power plant was configured with electric boilers. Some scholars have jointly considered thermal storage energy devices and electric boilers, and proposed a combined arrangement of thermal storage energy devices and electric boilers [8, 9] and the application of regenerative electric boilers [10, 11] after analyzing the CHP units alone to configure thermal storage energy devices or electric boilers. In Ref. [8], the authors compared the economy considering thermal storage energy devices worked alone or did not work. In Ref. [9], the multi-agent of electricity-heat model based on electric boilers and thermal storage energy devices was introduced, which considered the scheduling difficulty of the thermal storage energy device and electric boilers. In Ref. [10], the authors proposed the wind power accommodation dispatch model based on the regenerative electric boilers and thermal storage energy devices and proved that they had less operation cost. In Ref. [11], the authors did research on the effect of power of electric boilers regulated by electromechanical components and proposed the model aiming at the minimum number of electrode adjustments of regenerative electric boilers and the maximum amount of wind power consumption. In Ref. [12], a comprehensive coordination model of thermal storage energy devices and heat release rate of ultimate wind power consumption and the electric power of electric boiler was established. In Ref. [13], a distributional robust coordinated dispatch model for integrated electricity-heating system considering uncertainty of wind power was proposed in this paper. In Ref. [14], the electric heating characteristics of heat pumps was gradually considered and they were applied to wind power consumption in electricity-heating integrated systems. In the electricity-heating system with wind power, the difference in wind power variation above was only considered, but they did not take into account the rate of wind power variation. Electric boilers, heat pumps and thermal storage energy devices may not be able to absorb wind power in time due to the limitation of their own regulation rate in actual dispatching. However, the clean heating devices represented by air source heat pumps attract extensive attention due to their fast heat supply response, high heat supply efficiency and environmental protection [15,16,17,18,19,20], which had been applied in the field of clean heating [15,16,17] and intelligent building heat storage [19, 20] and achieve good results. But air source heat pumps are not considered in the rate of wind power change [21,22,23]. This paper will consider the influence of air source heat pumps to adjust the power speed, and pay attention to the influence of equipment characteristics of air source heat pumps on the amount of wind curtailment and system cost when wind power changes.

In this paper, air source heat pump are added to the coordinated optimization scheduling model of integrated electricity-heating system with traditional units, CHP units and thermal storage energy devices based on the existing paper. The effect of different response when wind power varies quickly on the total operating cost and the amount of wind curtailment in the electric boilers and air source heat pumps is compared. Finally, the comparison between the examples shows that air source heat pumps not only can quickly respond to wind power changes, reduce the amount of abandoned wind, but also have low operating costs and reduce system power generation costs.

2 Integrated Electricity-Heating System Structure with Air Source Heat Pump

2.1 Air Source Heat Pump

The working principle of air source heat pumps is shown in Fig. 1. An air source heat pump is mainly composed of a compressor, an evaporator, an expansion valve and a condenser. Based on the principle of reverse Carnot cycle, the air source heat pump obtains the external air low temperature heat source (QA) through the evaporator, vaporizes into low temperature and low pressure steam. Then it consumes a small amount of electric energy (QB) to drive the compressor, and the compressor converts the inhaled low temperature and low pressure steam into high temperature and high pressure steam. Therefore, the high pressure gaseous refrigerant enters. The condenser exchanges heat with the outside environment (QC). The condensate becomes a high-pressure liquid after the heat is released, and then the pressure of the throttle machine drops to a low-pressure and low-temperature liquid. Thereby liquid continues thermal cycle of evaporating, compressing, condensing, throttling, and re-evaporating in the evaporator. The conversion efficiency of the air source heat pump is generally between 3 and 5.

2.2 Integrated Electricity-Heating System

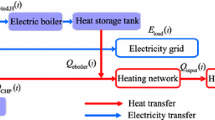

The structure of the integrated electricity-heating system in this paper is shown in Fig. 2. The system includes CHP units, traditional units, wind units, electric boilers (EB), air source heat pumps (ASHP), and thermal storage energy devices.

Air source heat pumps can configure with thermal storage energy devices in the electricity-heating system, which can promote the direct conversion between electric energy and thermal energy and decouple the CHP units from ‘heat set’ constraint, thus they can provide upside space for wind power consumption. The excess of wind power can be converted into heat energy by air source heat pumps so that improve the consumption of wind power when the wind curtailment is serious.

Considering that air source heat pumps have the advantages of fast heat supply response, high heat supply efficiency and environmental protection, air source heat pumps can quickly follow the change of wind power when wind power changes rapidly, and timely eliminate wind power. There is great prospect in the future efficient use of renewable energy and low carbon operation.

3 Model of the Integrated Electricity-Heating System

3.1 Objective Functions

The operating cost of CHP units, the power generation cost of traditional units, the operating cost of air source heat pumps, the operating cost of electric boilers and curtailment cost of wind power are the objective functions in this paper when the economical optimization of electricity-heating system with wind power is carried out. The formula can be given as follows:

where: \( {\text{C}}_{NC} \) is the operating cost function of combined heat and power (CHP) units; \( {\text{C}}_{NG} \) is the function of the generating power of traditional units; \( {\text{C}}_{EB} \) is the operating cost function of electric boilers; \( {\text{C}}_{ASHP} \) is the operating cost function of air source heat pumps; \( {\text{C}}_{loss} \) is the function of the curtailment cost of wind power.

-

(1)

Operating costs of CHP units. The CHP units set up in this paper set to normally open state, and only their operating cost is considered, the formula can be given as follows:

$$ {\text{C}}_{NC} = \sum\limits_{t \in T} {\sum\limits_{i \in NC} {\left\{ {a_{i}^{chp} \left( {P_{i,t}^{chp} } \right)^{2} + b_{i}^{chp} P_{i,t}^{chp} + c_{i}^{chp} } \right\}} } $$(3)where: T is the scheduling period, NC is the number of CHP units, and \( P_{i,t}^{chp} \) is the electric power of the ith CHP unit at time t, \( a_{i}^{chp} \), \( b_{i}^{chp} \), \( c_{i}^{chp} \) is expressed as the cost coefficient of the ith CHP unit.

-

(2)

The cost of power generation for traditional units. The power generation cost of a traditional unit consists of the unit start-up cost and operating cost. The formula can be given as follows:

$$ {\text{C}}_{NG} = {\text{C}}_{NG1} + {\text{C}}_{NG2} $$(4)$$ {\text{C}}_{NG1} = \sum\limits_{t \in T} {\sum\limits_{i \in NG} {CS_{i,t} \left( {1 - U_{i,t - 1} } \right)U_{i,t} } } $$(5)$$ {\text{C}}_{NG2} = \sum\limits_{t \in T} {\sum\limits_{i \in NG} {\left\{ {a_{i} P_{i,t}^{2} + b_{i} P_{i,t} + U_{i,t} c_{i} } \right\}} } $$(6)where: \( {\text{C}}_{NG1} \) is the start-up cost of the traditional units, \( {\text{C}}_{NG2} \) is the operating cost of the traditional units, NG is the number of traditional units, and \( CS_{i,t} \) is the cost coefficient of the start-up of the ith traditional unit at time t. \( U_{i,t} \) is expressed as the ith traditional unit start-stop state at time t, 0 is the unit shutdown state, 1 is the unit start-up state, and \( P_{i,t} \) is expressed as the ith traditional unit at the time t, and \( a_{i} \), \( b_{i} \), and \( c_{i} \) are expressed as the power cost coefficient of the ith traditional unit.

-

(3)

Operating costs of electric boilers. The cost of electric boilers is regarded as the electric cost of electricity consumed by electric boilers, and the cost of electric boilers is linearized in this paper. The formula can be given as follows:

$$ {\text{C}}_{EB} = \sum\limits_{t \in T} {\sum\limits_{i \in EB} {a_{EB} P_{i,t}^{EB} } } $$(7)where: \( a_{EB} \) is expressed as the operating cost coefficient of electric boilers, and \( P_{i,t}^{EB} \) is the electric power consumed by the ith electric boiler at time t.

-

(4)

Operating costs of air source heat pumps. The cost of air source heat pumps is regarded as the electricity cost of air source heat pumps, and the cost of air source heat pumps is linearized in this paper. The formula can be given as follows:

$$ {\text{C}}_{ASHP} = \sum\limits_{t \in T} {\sum\limits_{i \in ASHP} {a_{ASHP} P_{i,t}^{ASHP} } } $$(8)where: \( a_{ASHP} \) is expressed as the operating cost coefficient of air source heat pumps, and \( P_{i,t}^{ASHP} \) is the electric power consumed by the ith air source heat pump at time t.

-

(5)

Curtailment cost of wind power. In the integrated electricity-heating system, in order to improve wind power consumption, the cost of abandoning wind is added to the objective function. The formula can be given as follows:

$$ {\text{C}}_{loss} = \sum\limits_{t \in T} {\sum\limits_{i \in NW} {\delta \left( {P_{i,t}^{W0} - P_{i,t}^{W} } \right)} } $$(9)where: NW is expressed as the number of wind farms, δ is expressed as the cost coefficient of discarding wind, \( P_{i,t}^{W0} \) is expressed as the predicted output of the ith wind farm at time t, \( P_{i,t}^{W} \) For the ith wind farm, the active output is actually dispatched at time t.

3.2 Constraints of the Model

-

(1)

Electric power balance constraints

$$ \sum\limits_{i \in NC} {P_{i,t}^{chp} } + \sum\limits_{i \in NG} {P_{i,t} } + \sum\limits_{i \in NW} {P_{i,t}^{w} } = P_{t}^{L} + \sum\limits_{i \in EB} {P_{i,t}^{EB} } + \sum\limits_{i \in ASHP} {P_{i,t}^{ASHP} } $$(10)where: \( P_{t}^{L} \) represents the total electrical load power at time t.

-

(2)

Thermal power balance constraints

$$ \sum\limits_{i \in NC} {Q_{i,t}^{chp} } + \sum\limits_{i \in EB} {Q_{i,t}^{EB} } + \sum\limits_{i \in ASHP} {Q_{i,t}^{ASHP} } + \sum\limits_{i \in Ehs} {Q_{i,t}^{Ehs} } = Q_{t}^{L} $$(11)where: \( Q_{i,t}^{chp} \) is the thermal power generated by the ith CHP unit in the t period, and \( Q_{i,t}^{EB} \) is expressed as the thermal power generated by the ith electric boiler in the t period, \( Q_{i,t}^{ASHP} \) indicates the thermal power generated by the ith air source heat pump in the t period. \( Q_{i,t}^{Ehs} \) is expressed as the storage and release of thermal power of the ith thermal storage energy device in the t period, and \( Q_{i,t}^{Ehs} > 0 \) indicates heat storage, \( Q_{i,t}^{Ehs} < 0 \) indicates exotherm, and \( Q_{t}^{L} \) indicates total heat load power at time t,

-

(3)

Electric boiler constraints

$$ Q_{i,t}^{EB} = \eta_{EB} P_{i,t}^{EB} $$(12)$$ P_{i,t}^{EB} - P_{i,t - 1}^{EB} \le R_{U,i}^{EB} $$(13)$$ P_{i,t - 1}^{EB} - P_{i,t}^{EB} \le R_{D,i}^{EB} $$(14)where: \( \eta_{EB} \) represents the thermal efficiency of the electric boiler. \( \eta_{EB} = 0.98 \), \( R_{U,i}^{EB} \) and \( R_{D,i}^{EB} \) represent the upper limit of the electric power up and down slope of the ith electric boiler in this paper, respectively.

-

(4)

Air source heat pump constraints

$$ Q_{i,t}^{ASHP} = \eta_{ASHP} P_{i,t}^{ASHP} $$(15)$$ P_{i,t}^{ASHP} - P_{i,t - 1}^{ASHP} \le R_{U,i}^{ASHP} $$(16)$$ P_{i,t - 1}^{ASHP} - P_{i,t}^{ASHP} \le R_{D,i}^{ASHP} $$(17)where: \( \eta_{ASHP} \) represents the thermal efficiency of air source heat pumps. \( \eta_{EB} = 3.25 \), \( R_{U,i}^{EB} \) 和 and \( R_{D,i}^{EB} \) represent the upper limit of the up-down slope of the electric power of the ith air source heat pump in this paper, respectively.

Unit upper and lower limits and upper and lower ramping rate constraints, wind power output constraint, electricity-thermal coupling of CHP constraints and thermal storage energy device constraints are shown in Ref. [13].

4 Case Study

4.1 Composition of Case Study System

This case selects the modified IEEE-39 node system for verification. The air source heat pump is connected to node 8. The location of the remaining equipment nodes is shown in Ref. [13]. The case diagram is shown in Fig. 3. The predicted values of electric/heat load and wind power output in the integrated electricity-heating system of this example, the data of CHP units, traditional units and thermal storage energy devices are shown in Ref. [13]. The values of electric boilers and air source heat pumps parameters are shown in Table 1. The entire study was solved by using the commercial solver CPLEX on a computer with Intel Core 2.60 GHz and 4G RAM.

In Table 1, \( \varvec{R}_{{\varvec{U},\varvec{i}}}^{{\varvec{EB}}} = 100\,{\text{MW}}/{\text{h}} \) and \( \varvec{R}_{{\varvec{D},\varvec{i}}}^{{\varvec{EB}}} = 100\,{\text{MW}}/{\text{h}} \) means that the electric boiler can rise or fall 100 MW in one hour, \( \varvec{R}_{{\varvec{U},\varvec{i}}}^{{\varvec{ASHP}}} = 200\,{\text{MW}}/{\text{h}} \) and \( \varvec{R}_{{\varvec{D},\varvec{i}}}^{{\varvec{ASHP}}} = 200\,{\text{MW}}/{\text{h}} \) means that the air source heat pump can rise or fall 200 MW in one hour.

4.2 Analysis of Wind Curtailment Power and System Cost in the Electricity-Heating System

4.2.1 Case Analysis

In order to compare the effects of air source heat pumps configuration thermal storage energy devices, the normal operation of the system without them, the system configuration thermal storage energy devices, and electric boilers configuration thermal storage energy devices for the amount of wind curtailment power and cost of system operation, this paper sets 4 scenarios as following:

-

Scenario 1: The electricity-heating system is not configured with thermal storage energy devices, electric boilers and air source heat pumps. The system operates in the traditional mode.

-

Scenario 2: The electricity-heating system is configured with thermal storage energy devices, and electric boilers and air source heat pumps are not configured.

-

Scenario 3: The electricity-heating system is configured with thermal storage energy devices and electric boilers. Air source heat pumps are not configured.

-

Scenario 4: The electricity-heating system is configured with thermal storage energy devices and air source heat pumps, and no electric boiler is configured.

This paper firstly discusses the scenario 1 and scenario 2, compares the influence of the system configuration thermal storage energy devices on the amount of wind curtailment power, and then discusses scenario 3 and scenario 4, compares the response speed of air source heat pumps with the response speed of electric boilers to analyze the effect of response speed on the amount of wind curtailment power. Finally, the differences between the four scenarios and the amount of wind curtailment power are analyzed.

4.2.2 Scenario 1 and Scenario 2

With comparing scenario 1 and scenario 2, this paper does research on the influence of the system configuration thermal storage energy devices on the amount of wind curtailment power. The amount of wind curtailment power is shown in Fig. 4. The initial heat storage of the two thermal storage energy devices are 1500 and 1000 MW in scenario 2 of this paper, respectively. The heat storage and heat release of the thermal storage energy devices is shown in Fig. 4.

As shown in Fig. 4, the wind curtailment power is reduced from 12,511 to 11,714 MWh after thermal storage energy devices are added, and the wind power consumption is increased by 797 MWh. It can be seen from Fig. 3 that the serious phenomenon of wind curtailment mainly occurs in 1–8 h and 22–24 h. It can be seen from Fig. 4 that the thermal storage energy devices mainly release heat in the 1–9 h and 16–24 h to meet the demand of heat load, they reduce the output of the CHP units, and provide the rising space for the wind power consumption. It can be seen that the amount of wind curtailment power can be reduced to some extent by adding thermal storage energy devices to the system. It is possible to make the wind curtailment power completely consumed during the period when the amount of wind curtailment power is small.

4.2.3 Scenario 3 and Scenario 4

With comparing scenario 3 and scenario 4, this paper does research on the effects of electric boilers and air source heat pumps on the amount of wind curtailment power and system operating cost. The amount of wind curtailment power is shown in Fig. 5. The output of electric boilers, the air source heat pumps and CHP units is shown in Fig. 6. In scenario 3 and scenario 4 of this paper. The initial heat storage of the two thermal storage energy devices are 200 and 200 MW respectively, and the storage and release heat changes of the thermal storage energy devices in scenario 3 and 4 are as Fig. 7.

In scenario 3 and scenario 4, the wind curtailment power in Scenario 3 is 5222 MWh as shown in Fig. 5. The wind curtailment power is 1071 MWh in Scenario 4, and the amount of wind curtailment power is reduced by 4151 MWh, which is reduced by 76.5%. It can be seen from Fig. 6 that when the wind power changes, air source heat pumps can absorb wind power more quickly and can adjust power more quickly. The adjustment time of electric boilers output is 6 h and the adjustment time of air source heat pumps output is 4.245 h in Fig. 6. The output of the CHP units can be reduced more quickly since air source heat pumps adjust the power faster and generate more heat in a short time. Therefore, the wind power can be completely absorbed in the 0–1 h period and the 6–8 h period in Fig. 5, and the electric boilers cannot absorb the same amount of wind curtailment power completely. At the same time, Fig. 6 show the different effects of electric boilers and air source heat pumps on the output of the CHP units. In Fig. 6, the output of the CHP units in Scenario 3 in the period of 1–9 h is around 1200 MWh. And, the output of the CHP units in Scenario 4 is about 500 MW during the period of 1–9 h of wind curtailment power, and the system with the air source heat pumps is compared with the CHP units in the system of electric boilers. The output of CHP units is significantly reduced, reduced by about 700 MWh, and reduced by about 58.3%.

The advantages of high heat supply efficiency of air source heat pumps through the variation of the thermal storage energy devices are shown in Fig. 7. During the 1–7 h period, the air source heat pumps store 3466 MW more heat than the electric boilers. During the 8–14 h period, the thermal storage energy devices in the system of air source heat pumps releases 2506 MW more than that in the system of electric boilers. The air source heat pump can produce more heat than heat produced by the electric boils during the serious period of wind curtailment and allow the thermal storage energy devices to release more heat during periods of low wind power.

Only the output of traditional units in scenario 4 is shown in Fig. 8. And the output of traditional units in other scenarios is not shown because of the space limitations.

4.2.4 Scenarios 1–4

The air source heat pumps and the electric boilers are respectively arranged with thermal storage energy devices of 400 MW in the initial heat distribution of the thermal storage energy device compared with scenarios 1–4. The initial heat of the thermal storage energy devices is separately set to 2500 MW. The air source heat pumps and the electric boilers reduce the requirements for initial heat of the thermal storage energy devices significantly. If the initial heat is too low, the wind curtailment power will not be absorbed.

In order to visually see the difference between the operation of system in the traditional mode, the thermal storage energy devices, the electric boilers configuration thermal storage energy devices and the air source heat pumps configuration thermal storage energy devices, the wind curtailment power in the scenarios 1–4 is drawn in Fig. 9. Table 2 shows the amount of wind curtailment power in scenarios 1–4.

Compared with scenario 2, the amount of wind curtailment power in scenario 3 is reduced by 6492 MWh, which was reduced by 55.4%. In Scenario 4, the electric boilers of Scenario 3 are replaced with the air source heat pumps, and the amount of wind curtailment power is reduced to 1071 MWh, and the amount of wind curtailment power became less. Combined with scenarios 1–4, it can be seen that the coupling effect of the electricity-heating system can greatly reduce the output of the CHP units and eliminate the wind curtailment power.

The total operating cost of the system in scenarios 1–4 in order to compare the total cost of system operation is shown in Table 3.

It can be seen that the total costs of system operation decrease after thermal storage energy devices, electric boilers configuration thermal storage energy devices and air source heat pumps configuration thermal storage energy devices are added. The system’s operating cost of the scenario 2 is reduced by 209,200 compared with the system’s operating cost of the scenario 1, which is reduced by 13.8%. The system’s operating cost of the scenario 3 is reduced by 261,500 compared with the system’s operating cost of the scenario 1, which is reduced by 17.3%. The system’s operating cost of the scenario 4 is reduced by 432,500 compared with the system’s operating cost of the scenario 1, which is reduced by 28.6%.

In terms of the amount of wind curtailment power, air source heat pump configuration thermal storage energy devices can completely eliminate the wind in the period of 1–2 h and 6–8 h, and the other methods can not completely eliminate the wind in this period. In terms of the cost of system operation, air source heat pumps have the lowest cost of system operation. It can be seen that air source heat pumps configuration thermal storage energy devices not only can absorb more wind curtailment power, but also can reduce the total operating cost of the system.

5 Conclusion

A model of integrated electricity-heating system for wind power consumption is proposed in this paper in order to eliminate the wind curtailment in time. The coupling unit based on air source heat pumps can absorb wind power timely in the electricity-heating system with wind power, and can also reduce the operating cost of the system. Through the analysis of the example, the following conclusions are obtained:

-

(1)

Air source heat pumps configuration thermal storage energy devices can consume the excess of wind curtailment power more quickly and provide more heat. And reduce the output of the CHP units more quickly and the cost of system.

-

(2)

The initial heat of the separated heat storage devices is reduced after the system is configured with electric boilers and air source heat pumps. It can reduce the cost of thermal storage energy devices.

-

(3)

The thermal storage energy device, the electric boiler and the air source heat pump have a certain degree of promoting effect on the wind power consumption. Air source heat pumps configuration thermal storage energy devices can completely eliminate the wind curtailment power during certain periods of time.

References

China’s National Energy Administration (2019) Wind power grid operation in 2018 [EB/OL]. China’s National Energy Administration, Beijing, 2019. http://www.nea.gov.cn/2019-01/28c_137780779.htm

Yang JI, Zhang N, Wang Y, Kang C (2018) Multi-energy system towards renewable energy accommodation: review and prospect. Autom Electr Power Syst 42(4):11–24

Wang W, Wang D, Jia H et al (2016) Review of steady-state analysis of typical regional integrated energy system under the background of energy internet. Proc CSEE 36(12):3292–3305

Xu F, Min Y, Chen L et al (2014) Combined electricity-heat operation system containing large-capacity thermal energy storage. Proc CSEE 34(29):5063–5072

Ge W, Wang S, Luo H, Ge Y, Zhou G, Cui D (2018) The leverage effect of large capacity centralized heat storage for wind power consumption. In: 2018 2nd IEEE conference on energy internet and energy system integration (EI2), Beijing, 2018, pp 1–6. https://doi.org/10.1109/ei2.2018.8582549

Guo F, Hu L, Zhou S (2018) Dispatching model of wind power accommodation based on heat storage electric boiler for peak-load regulation in secondary heat supply network. Autom Electr Power Syst 42(19):50–56

Li Y, Wang X, W. Zhang W (2018) Heat and power combined dispatching model with renewable energy, electrical heat pumps, and electrical boilers. In: 2018 IEEE power & energy society general meeting (PESGM), Portland, OR, 2018, pp 1–5. https://doi.org/10.1109/pesgm.2018.8586465

Yang C, Zhi C, Gangui Y et al (2016) Coordinated wind power accommodating dispatch model based on electric boiler and CHP with thermal energy storage. Proc CSEE 36(15):4072–4081

Yang L, Zhang X, Gao P (2018) Research on heat and electricity coordinated dispatch model for better integration of wind power based on electric boiler with thermal storage. In: IET generation, transmission & distribution, vol 12 no 15. 28 8 2018. pp 3736–3743. https://doi.org/10.1049/iet-gtd.2017.2032

Yang C, Zhuang Y, Chen Z et al (2019) Economic analysis of wind power accommodation schemes with the electric-thermal time shift characteristics of regenerative electric boiler. Thermal Power Gener 1–9

Li G, Zhuang G, Tian C et al (2018) Multi-objective optimization control of wind power consumption based on regenerative electric boiler system integrated with large-scale energy storage. Electr Power Autom Equipment 38(10):1006–6047. https://doi.org/10.16081/j.issn

Lu Z, Yang Y, Geng L et al (2018) Low-carbon economic dispatch of the integrated electrical and heating systems based on benders decomposition. Proc CSEE 38(7):1922–1934

Yue S, Liu J, Gao H et al (2018) A distributionally robust coordinated dispatch model for integrated electricity and heating systems considering uncertainty of wind power. Proc CSEE, 2018 38(24):7235–7247, 7450

Wang W, Yang L, Wang L, Zhang P, Huang J, Wang K (2018) Optimal dispatch of integrated electricity-heat energy system considering heat storage characteristics of heating network. Autom Electr Power Syst 42(21):45–52

Wu D, Hu B, WANG RZ et al (2017) Present situation, technology and policy of air source heat pump heating in China. Refrig Technol 37(5):1–7

Min J, Xu J et al (2019) Analysis on the principle and application of solar coupled air source heat pump technology. Shandong Chem Ind 48(02):115–118

Longfei MA et al (2017) Research on influence of large-scale air-source heat pump start-up characteristics to power grid. In: 2017 IEEE conference on energy internet and energy system integration (EI2), Beijing, 2017, pp 1–4. https://doi.org/10.1109/ei2.2017.8245377

Song D (2018) Study on compound energy supply system of gas-fired distributed combined heating and power cogeneration unit with air-sourced heat pump. Shanghai Energy Conserv (10):785–790

Chen X, Zhang X, Zhao X (2016) Air source heat pump energy storage heating system for smart building. In: 2016 Chinese control and decision conference (CCDC), Yinchuan, 2016, pp 3635–3639.https://doi.org/10.1109/ccdc.2016.753161

Craciun VS, Trifa V, Bojesen C, Andreasen SJ (2012) Air source heat pump a key role in the development of smart buildings in future energy systems: Low cost and flexible experimental setup for air source heat pumps. In: 2012 international conference and exposition on electrical and power engineering, Iasi, 2012, pp. 984–989.https://doi.org/10.1109/icepe.2012.6463805 (2012)

Zhou W, Z Jng, Sun H, Li G, Kong J, Zhang F (2018) An interval rolling estimation method for daily wind power forecast errors based on hidden Markov model. Autom Electr Power Syst 42(21):90–95

Zhu J, Liu Y, Xu L, Jiang Z, Ma C (2019) Robust day-ahead economic dispatch of microgrid with combined heat and power system considering wind power accommodation. Autom Electr Power Syst 43(4):40–48

Gan W, Guo J, Ai X, Yao W, Yang B, Yao L, Wen J (2019) Multi-scale multi-index sizing of energy storage applied to fluctuation mitigation of wind farm. Autom Electr Power Syst 43:01–07

Funding

This research was funded by National Natural Science Foundation of China (61703404).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gao, Z., Han, L., Jin, H. (2020). Day-Ahead Optimized Economic Dispatch of Integrated Electricity-Heating Systems Considering Wind Power Consumption. In: Xue, Y., Zheng, Y., Rahman, S. (eds) Proceedings of PURPLE MOUNTAIN FORUM 2019-International Forum on Smart Grid Protection and Control. Lecture Notes in Electrical Engineering, vol 585. Springer, Singapore. https://doi.org/10.1007/978-981-13-9783-7_8

Download citation

DOI: https://doi.org/10.1007/978-981-13-9783-7_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-9782-0

Online ISBN: 978-981-13-9783-7

eBook Packages: EnergyEnergy (R0)