Abstract

Low driving voltage, high luminance, and high efficiency are the important parameters of organic light-emitting diodes (OLEDs) for their application of display and lighting. Usually, synthesis of new materials, doping technique and designing suitable device structures were the main methods to use for realizing the aim of the wide application of OLEDs. In this paper, we try to obtain a high efficiency and low driving voltage tandem OLED with ultrathin films through optimizing the thickness of hole transporting layer (HTL), electron transport layer (ETL), emission layer (EML), and charge generation layer (CGL). As a result, we got the ultrathin tandem OLED with a very low driving voltage of 7.44 V, the luminance of 16,080 cd/m2, the current efficiency of 16.08 cd/A, and power efficiency of 6.28 lm/W, respectively. This research not only saves the cost and improves the power efficiency, which may supply a theoretical basis for the development of OLEDs in the lighting field.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In tandem organic light-emitting diodes (OLEDs), the luminance and current efficiency are multi-fold growth with the increasing number of electroluminescence (EL) unit, but also the multi-fold growth of driving voltage, which means that the power efficiency of tandem OLED is not improved, and not conducive to its practical application, especially in lighting field. So, reduction in the driving voltage of OLEDs is a key issue to improve the power efficiency in the application of flat panel displays and solid-state lighting [1]. Usually, there are several methods to reduce the driving voltage of OLEDs. One of the most powerful solutions is to use doping concept in the carrier transporting or injection layer [1,2,3,4,5,6,7,8,9,10,11]. From the electrical doping mechanism of organic semiconductor, the doping process can be regarded as a charge transfer process, which is the host material to obtain hole or electron from acceptor or donor, and realize p- or n-doped. For example, p-doped occurs through the charge transfer from the highest occupied molecular orbital (HOMO) of the host material to the lowest unoccupied molecular orbital (LUMO) of the dopant material [12], while n-doped occurs through the charge transfer from the HOMO of the dopant material to the LUMO of the host material. As we know, p- and n-type doping is widely used to improve or change the device electrical characteristics. If using the proper doped systems, it can be increased the conductivity of film with several orders of magnitude and can also realize ohmic contact between the electrode and the organic layer, reduce the injection barrier at the electrode/organic interface, and provide excellent hole or electron injection from electrode to organic layer [13]. Inserting a buffer layer with suitable thickness like MoOx [14], SiO2 [15], CFx [16], LiF [17], Ag2O [18], TCNQ [19] can improve balance of the hole and electron injections. And synthesis of organic materials with high mobility and proper energy level [20,21,22,23,24] can conducive to achieve good charge balance and confine excitons in the EML [23,24,25,26].

In this work, we try to realize an ultrathin tandem OLED with low driving voltage, high brightness, and high efficiency through optimizing the thickness of organic layers. Basing on our early works [10, 27, 28], we firstly design several single devices (given in Table 1) and then fabricate serial tandem devices with different thickness of function layers. As a result, we obtained the ultrathin tandem OLED with a very low driving voltage of 7.44 V and high power efficiency of 6.28 lm/W.

2 Experimental Methods

In this work, all organic devices were fabricated on the indium-tin-oxide (ITO) coated glass with a sheet resistance of 20 Ω/sq by evaporation method without breaking the vacuum (<2 × 10−6 Torr). The ITO surface was cleaned with ultrapurified water and organic solvents, dry-cleaned for 30 min, and treated by UV–ozone for 15 min before put into high-vacuum thermal evaporation system. A shadow mask was used to define the Al cathode to form an emissive area of 10 mm2. The evaporation rates of all organic layers were 2 Å/s, LiF layer was 0.1 Å/s, and Al cathode was 5 Å/s, respectively.

The fabricated devices were encapsulated immediately by using epoxy resin and glass lids prior to the measurement. The current density–voltage–luminance, current efficiency–current density–power efficiency characteristics, and EL spectra were recorded on a computer-controlled programmable Keithley model 2400 power source with a Photo Research 655 spectrometer.

3 Results and Discussion

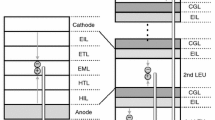

To get the low driving voltage of tandem OLEDs, firstly, four single-unit OLEDs with different thickness of organic layers were fabricated. The structures of single-unit devices are listed in Table 1, the corresponding performance is displayed in Fig. 1, and more detailed performance parameters are shown in Table 2. It is known that the driving voltage and luminance increased with the thickness of organic layers, which appears that the thinnest device A has the lowest driving voltage, and the thickest device D has the best luminance. With the aim to realize the device with low driving voltage and high efficiency, we chose the thinner EL unit for further research and designed a serial structure of tandem devices based on these kinds of EL unit through changing the thickness of hole transporting layers (HTL), electron transporting layers (ETL), emission layers (EML), and charge generation layer (CGL), respectively.

a Current density–voltage–luminance and b current efficiency–current density–power characteristics of devices listed in Table 1

3.1 Optimizing the Thickness of HTL

First of all, we try to changing the thickness of HTL on the second EL unit with the structure of ITO/NPB(20 nm)/C545T:Alq3(1 wt%, 10 nm)/BPhen(20 nm)/Mg:BPhen(10 wt%, 10 nm)/MoO3(5 nm)/NPB(x nm)/C545T:Alq3(1 wt%, 20 nm)/BPhen(40 nm)/LiF(0.5 nm)/Al(100 nm). Here, x is 20 nm for device E and 40 nm for device F. The current density–voltage–luminance and current efficiency–current density–power efficiency characteristics of devices E–F are shown in Fig. 2. According to Fig. 2, we can know that the thickness of HTL on the second EL unit plays an important role in driving voltage and device efficiencies. With a thickness difference of 20 nm in NPB layer, the device performance exhibits a large difference. The driving voltage of devices E and F is 7.44 and 8.09 V at J = 1 mA/cm2, and their luminance is 14,950 and 16,340 cd/m2 at the current density of 100 mA/cm2. But the driving voltage is still very high, and the efficiency is not as perfect as we anticipated.

3.2 Optimizing the Thickness of EML

In this part, we modify the thickness of EML for further research and design this kind of device: ITO/NPB(20 nm)/C545T:Alq3(1 wt%, y nm)/BPhen(20 nm)/Mg:BPhen(10 wt%, 10 nm)/MoO3(3 nm)/NPB(20 nm)/C545T:Alq3(1 wt%, z nm)/BPhen(20 nm)/LiF(0.5 nm)/Al(100 nm), y and z are 10 and 10 nm for device G, 10 and 20 nm for device H, and 20 and 20 nm for device I, respectively. It is shown in Fig. 3 that device H has the largest luminance and efficiency, which are 15230 cd/m2 and 15.23 cd/A at J = 100 mA/cm2, while the driving voltage is a bit higher than device G, which are 7.10 and 6.71 V at J = 1 mA/cm2.

3.3 Optimizing the Thickness of ETL

Then, we attempt to get the device with low driving voltage by optimizing the thickness of ETL, and use device structure: ITO/NPB(20 nm)/C545T:Alq3(1 wt%, 10 nm)/BPhen(m nm)/Mg:BPhen(10 wt%, 10 nm)/MoO3(3 nm)/NPB(20 nm)/C545T:Alq3(1 wt%, 20 nm)/BPhen(n nm)/LiF(0.5 nm)/Al(100 nm). Here, m and n are 20 and 20 nm for device H, 20 and 30 nm for device J, 30 and 30 nm for device K, respectively. Figure 4 compares the electrical and luminescent properties of devices H, J, and K, they show the same variation trend as a comparison of devices G–I, the thinnest device has the lowest driving voltage, and the device with middle thickness has the highest current efficiency and power efficiency, and a bit higher driving voltage than the thinnest device. This phenomenon may be due to the suitable energy level of this kind of organic layers and its adjacent layers, which is convenient for carriers transporting and promote the effective combination of charge within the device.

3.4 Optimizing the Thickness of CGL

It is reported that the device performance may be affected by the thickness of the charge generation layer [29]. And how the thickness of CGL affects the device performance still needs study. In this part, several devices were designed to make clear of this problem, which are: (H) ITO/NPB(20 nm)/C545T:Alq3(1 wt%, 10 nm)/BPhen(20 nm)/Mg:BPhen(10 wt%, 10 nm)/MoO3(3 nm)/NPB(20 nm)/C545T:Alq3(1 wt%, 20 nm)/BPhen(20 nm)/LiF(0.5 nm)/Al(100 nm); (L)ITO/NPB(20 nm)/C545T:Alq3 (1 wt%, 10 nm)/BPhen(20 nm)/Mg:BPhen(10 wt%, 5 nm)/MoO3(1 nm)/NPB(20 nm)/C545T:Alq3(1 wt%, 20 nm)/BPhen(20 nm)/LiF(0.5 nm)/Al(100 nm); (M) ITO/NPB(20 nm)/C545T:Alq3(1 wt%, 10 nm)/BPhen(20 nm)/Mg:BPhen(10 wt%, 5 nm)/MoO3(3 nm)/NPB(20 nm)/C545T:Alq3(1 wt%, 20 nm)/BPhen(20 nm)/LiF(0.5 nm)/Al(100 nm); (N) ITO/NPB(20 nm)/C545T:Alq3(1 wt%, 10 nm)/BPhen(20 nm)/Mg:BPhen(10 wt%, 10 nm)/MoO3(1 nm)/NPB(20 nm)/C545T:Alq3(1 wt%, 20 nm)/BPhen(20 nm)/LiF(0.5 nm)/Al(100 nm). As shown in Fig. 5, device H shows the largest efficiencies and the lowest driving voltage. Comparing the devices H and N, which is different in thickness of MoO3, the thicker of MoO3, the better of device performance, the same phenomenon can be seen in the comparison of devices L and M. It seems like that 5-nm and 10-nm-thick Mg:BPhen layer displays very little effect on the luminance and current efficiency, but large effect on the driving voltage and power efficiency of devices H and M. There appears the same worse performances of devices L and N, though they are different in thickness of Mg:BPhen layer, which may be due to 1-nm-thick MoO3 film is very thin, its evaporation is too little and cannot form a continuous film, and finally exhibit a great impact on the generation and transmission capacity of carriers.

3.5 Comparison of Two Tandem OLEDs

Figure 6 compares the performances of the optimized device J and reference device O. Here, the thickness and structure of the reference device are we usually used, which is ITO/NPB(40 nm)/C545T:Alq3(1 wt%, 20 nm)/BPhen(40 nm)/Mg:BPhen(10 wt%, 10 nm)/MoO3(5 nm)/NPB(40 nm)/C545T:Alq3(1 wt%, 20 nm)/BPhen(40 nm)/LiF(0.5 nm)/Al(100 nm). From Fig. 6, we can know that with a total difference of 80 nm thick in organic layers, the driving voltage of devices J and O is 7.44 and 10.21 V at the current density of 1 mA/cm2, the maxim current efficiency is 16.08 and 19.64 cd/A, and the maxim power efficiency is 6.28 and 5.28 lm/W. It is obvious that the driving voltage is reduced and the power efficiency is increased after optimizing, this is a good phenomenon that we see, but there is still a long way to realize a lower driving voltage and higher power efficiency device, and need that we make more efforts.

4 Summary

We fabricated an ultrathin tandem device with a driving voltage of 7.44 V and power efficiency of 6.28 lm/W. This is implemented to reduce cost and enhance the efficiency of the device. We believe that further optimization of device parameters will more ascension the device performance, and hope this study can provide a train of thought for the OLED application.

References

Pfeiffer, M., Forrest, S.R., Leo, K., Thompson, M. E.: Electrophosphorescent p-i-n organic light emitting devices for Very-High-Efficiency Flat-Panel displays. Adv. Mater. (Weinheim, Ger.) 14, 1633 (2002)

Zhou, X., Blochwitz, J., Pfeiffer, M., Nollau, A., Fritz, T., Leo, K.: Enhanced hole injection into amorphous hole-transport layers of organic light emitting diodes using controlled p-type doping. Adv. Funct. Mater. 11, 310 (2001)

Qasim, K., Wang, B.P., Zhang, Y.P., Li, P.F., Wang, Y.S., Li, S.J., Lee, S. T., Liao, L.S., Lei, W., Bao, Q.L.: Solution-processed extremely efficient multicolor perovskite light emitting diodes utilizing doped electron transport layer. Adv. Funct. Mater. 27(21), 1606874(2017)

Huang, J., Pfeiffer, M., Werner, A., Blochwitz, J., Leo, K., Liu, S.: Low-voltage organic electroluminescent devices using pin structures. Appl. Phys. Lett. 80, 139 (2002)

Soman, A., Manuraj, M., Unni, K.N.N.: Addressing the efficiency roll-off in a fluorescent OLED by facile electron transport layer doping and carrier confinement. Opt. Mater. 79, 413–419 (2018)

Walzer, K., Maenning, B., Pfeiffer, M., Leo, K.: Highly efficient organic devices based on electrically doped transport layers. Chem. Rev. 107, 1233 (2007)

Chang, C.C., Hsieh, M.T., Chen, J.F., Hwang, S.W., Chen, C.H.: Highly power efficient organic light emitting diodes with a doping layer. Appl. Phys. Lett. 89, 253504 (2006)

Ikeda, H., Sakata, J., Hayakawa, M., Aoyama, T., Kawakami, T., Kamata, K., Iwaki, Y., Seo, S., Noda, Y., Nomura, R., Yamazaki, S.: Low-Drive-Voltage OLEDs with a buffer layer having molybdenum oxide. SID Int. Symp. Digest Tech. Papers 37, 923 (2006)

Chen, D.C., Liu, K.K., Gan, L., Liu, M., Gao, K., Xie, G.Z., Ma, Y.G., Shi, Y.C., Su, J.: Modulation of exciton generation in organic active planar p-n heterojunction: toward low driving voltage and high-efficiency OLEDs employing conventional and thermally activated delayed fluorescent emitters. Adv. Mater. 28(31), 6758–6765 (2016)

Deng, Y.H., Li, Y.Q., Ou, Q.D., Wang, Q.K., Sun, F.Z., Chen, X.Y., Tang, J.X.: The doping effect of cesium-based compounds on carrier transport and operational stability in organic light-emitting diodes. Org. Electron. 15, 1215–1221 (2014)

Chiba, T., Pu, Y.J., Ide, T., Ohisa, S., Fukuda, H., Hikichi, T., Takashima, D., Takahashi, T., Kawata, S., Kido, J.: Addition of Lithium 8-Quinolate into polyethylenimine electron-injection layer in OLEDs: not only reducing driving voltage but also improving device lifetime. ACS Appl. Mater. Interfaces. 9(21), 18113–18119 (2017)

Gao, W., Kahn, A.: Controlled p-doping of zinc phthalocyanine by coevaporation with tetrafluorotetracyanoquinodimethane: a direct and inverse photoemission study. Appl. Phys. Lett. 79, 4040 (2001)

Walzer, K., Maennig, B., Pfeiffer, M., Leo, K.: Highly efficient organic devices based on electrically doped transport layers. Chem. Rev. 107(4), 1233 (2007)

Zhou, Y., Fuentes-Hernandez, C., Shim, J., Meyer, J., Giordano, A.J., Li, H., Winget, P., Papadopoulos, T., Cheun, H., Kim, J., Fenoll, M., Dindar, A., Haske, W., Najafabadi, E., Khan, T.M., Sojoudi, H., Barlow, S., Graham, S., Brédas, J. L., Marder, S.R., Kahn, A., Kippelen, B.: A universal method to produce low-work function electrodes for organic electronics. Science 336, 327 (2012)

Deng, Z.B., Ding, X.M., Lee, S.T., Gambling, W.A.: Enhanced brightness and efficiency in organic electroluminescent devices using SiO2 buffer layers. Appl. Phys. Lett. 74, 2227 (1999)

Tong, S.W., Lee, C.S., Lifshitz, Y., Gao, D.Q., Lee, S.T.: Conducting fluorocarbon coatings for organic light-emitting diodes. Appl. Phys. Lett. 84, 4032 (2004)

Zhao, J.M., Zhang, S.T., Wang, X.J., Zhang, Y.Q., Wang, X.Z., Zhong, G.Y., Wang, Z.J., Ding, W., Huang, X.M., Hou, X.Y.: Dual role of LiF as a hole-injection buffer in organic light-emitting diodes. Appl. Phys. Lett. 84, 2913 (2003)

Wang, C.T., Ting, C.C., Kao, P.C., Li, S.R., Chu, S.Y.: Improvement of OLED performance by tuning of silver oxide buffer layer composition on silver grid surface using UV-ozone treatment. Appl. Phys. Lett. 113, 051602 (2018)

Zhang, J., Xin, L.W., Gao, J., Liu, Y., Rui, H.S., Lin, X., Hua, Y.L., Wu, X.M., Yin, S.G.: Improving the performance of organic light-emitting devices by incorporating non-doped TCNQ as electron buffer layer. J. Mater. Sci.: Mater. Electron. 28(17), 12761–12767 (2017)

Han, C., Xie, G., Xu, H., Zhang, Z., Yu, D., Zhao, Y., Yan, P., Deng, Z., Li, Q., Liu, S.: Towards highly efficient blue-phosphorescent organic light-emitting diodes with low operating voltage and excellent efficiency stability. Chem. Eur. J. 17, 445 (2011)

Gong, S., Chang, Y.L., Wu, K., White, R., Lu, Z.H., Song, D., Yang, C.: High-power-efficiency blue electrophosphorescence enabled by the synergistic combination of phosphine-oxide-based host and electron-transporting materials. Chem. Mater. 26, 1463 (2014)

Sasabe, H., Gonmori, E., Chiba, T., Li, Y.J., Tanaka, D., Su, S.J., Takeda, T., Pu, Y.J., Nakayama, K.I., Kido, J.: Wide-energy-gap electron-transport materials containing 3, 5-dipyridylphenyl moieties for an ultra high efficiency blue organic light-emitting device. Chem. Mater. 20, 5951 (2008)

Xiao, L., Su, S.J., Agata, Y., Lan, H., Kido, J.: Nearly 100% internal quantum efficiency in an organic Blue-Light electrophosphorescent device using a weak electron transporting material with a wide energy gap. Adv. Mater. 21, 1271 (2009)

Ye, H., Chen, D., Liu, M., Su, S.J., Wang, Y.F., Lo, C.C., Lien, A., Kido, J.: Pyridine-Containing Electron-Transport materials for highly efficient blue phosphorescent OLEDs with ultralow operating voltage and reduced efficiency roll-off. Adv. Funct. Mater. 24, 3268 (2014)

Jeon, S.O., Jang, S.E., Son, H.S., Lee, J.Y.: External quantum efficiency above 20% in deep blue phosphorescent organic light-emitting diodes. Adv. Mater. 23, 1436 (2011)

Kim, C.Y., Ha, D.G., Kang, H.H., Yun, H.J., Kwon, S.K., Kim, J.J., Kim, Y.H.: Synthesis and characterization of new blue light emitting iridium complexes containing a trimethylsilyl group. J. Mater. Chem. 22, 22721 (2012)

Deng, Y.H., Ou, Q.D., Wang, Q.K., Wei, H.X., Li, Y.Q., Lee, S.T., Tang, J.X.: The role of charge generation layers in the operational stability of tandem organic light-emitting diodes. J. Mater. Chem. C 2, 1982–1989 (2014)

Deng, Y.H., Wang, J.J., Ou, Q.D., Zhang, D.Y., Chen, L.Z., Li, Y.Q., Tang, J.X.: The electro-optic performance and photovoltaic effect of organic devices based on cesium carbonate/Al/molybdenum trioxide intermediate connector. Org. Electron. 51, 452–457 (2017)

Fung, M.K., Li, Y.Q., Liao, L.S.: Lead-free inverted planar Formamidinium Tin Triiodide Perovskite solar cells achieving power conversion efficiencies up to 6.22%. Adv. Mater. 28(42), 1–28 (2016)

Acknowledgements

The authors gratefully acknowledge the Hunan Provincial Natural Science Foundation of China (No. 2018JJ3010, 2017JJ2009), Scientific Research Fund of Hunan Provincial Education Department (No. 15B033), the Hunan Provincial Applied Basic Research Base of Optoelectronic Information Technology (GD18K05), Science and Technology Plan Project of Hunan Province (No. 2016TP1020), Open fund project of Hunan Provincial Key Laboratory of Intelligent Information Processing and Application for Hengyang normal university (No. 2017IIPAYB02), the Science and Technology Development Plan Project in Hengyang City (No. 2017KJ159), the Excellent Talents Program of HYNU, and the college students inquiry learning and innovative experimental project of Hengyang Normal University (No. CX1754).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Deng, Y. et al. (2020). An Ultrathin Tandem Organic Light-Emitting Diodes with Very Low Driving Voltage and High Efficiency. In: Peng, Y., Dong, X. (eds) Proceedings of 2018 International Conference on Optoelectronics and Measurement. Lecture Notes in Electrical Engineering, vol 567. Springer, Singapore. https://doi.org/10.1007/978-981-13-8595-7_15

Download citation

DOI: https://doi.org/10.1007/978-981-13-8595-7_15

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-8594-0

Online ISBN: 978-981-13-8595-7

eBook Packages: EngineeringEngineering (R0)