Abstract

The increasing demand for crude oil makes it necessary to consider factors that increase the productivity of the reservoirs. One of these factors is fracture that is found naturally or produced hydraulically, where the fracture improves reservoir flow and connectivity. The most common characteristics of naturally fractured reservoirs (NFRs) are the fractures directionality. In this review, the most important characteristics and parameters that affect the fracture have been explained. In addition, the simulations of the fracture phenomena have been cleared. The difference among the models that solved the fracture problems are; discrete fracture model (DFM), dual porosity model (DPM), embedded discrete fracture model (EDFM), and hybrid models DP and EDFM (DP + EDFM) are shown with characteristics of each model. The present study focused on the shape factor and the direction of the fracture to show their effects on the performance of the petroleum reservoir. In addition, the review of general important parameters for the fractured reservoirs has been presented.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

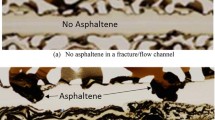

All petroleum reservoirs contain natural fractures due to the earth layers stress. The man-made fractures result from drilling activities and increase in pore pressure during the injection operations. The naturally fractured reservoir (NFR) is a randomly located fracture networks in earth layers. The injection and production practices caused a redistribution of the earth stresses [1, 2]. Characteristics of fracture networks such as shape, dimensions, orientations, rocks properties of fracture matrix, etc. They are important in order to enhance the productivity of the reservoir. For fractured reservoirs, obtaining the right data and forecasting the reservoir performance is much more difficult than for the conventional reservoir. Naturally fractured reservoirs (NFRs) characterized are difficult for the engineers to predict because of the constructions of the fractures and nature of rocks and fluid (phases, wettability, capillary, etc.). It is important to establish some basic criteria for recognizing the fractures, since the fractures are an important element in performance of NFR. Fractures occur in preferential directions, determined by the direction of regional stress [3]. This is usually parallel to the direction of nearby faults or folds. Nevertheless, in the case of faults, they may be perpendicular to the fault or there may be two orthogonal directions. This study summarizes the main characteristics and parameters that effect on the fluid flow within the fractured reservoirs. It also includes a thorough review of the fractured reservoir simulation modeling, and models that deal and solve the fracture problems.

2 Reservoir Fracture Parameters

The researchers show that natural fracture permeability and density are the most common parameters [4]. The fractures have high permeability than the matrix. Therefore, they provide a quick flow. Many parameters are considered to characterize the fractured reservoir [5]. Some of these parameters related to the properties of rock and some others related to the fractures. The properties of fracture (porosity, relative permeability, intensity, conductivity, orientation, and size of fractures) can be estimated directly from core analysis or by well logging methods [6, 7].

In 1986, a new method for modeling NFR was developed to describe the effect of capillary pressure and gravity forces in fractured reservoirs [8].

In addition, many papers studied the effect of interporosity function and shape factors [9,10,11]. The shape factor is one of the important parameters in a dual porosity system, which describes the fluid transportation between matrix blocks and fractures [12]. Nevertheless, this parameter is not used in a single porosity matrix block as it is a single piece of rock [13]. This factor is proposed by Warren [14], and Kazemi [15] in double porosity concept. In 1976, Kazemi et al. extended the Warren and Root’s shape factor to be used for two phases and three dimensional NFR [16]. However, in 1989, they proposed that Kazemi’s shape factor is not accurate, and the most accurate pressure distribution has been obtained if they multiplied this parameter with some factors [17, 18]. In 1985, it was concluded that by increasing the surface area, the imbibitions recovery rate increases [19]. Since that time, the shape factor has been discussed stormily for modeling fractured reservoir [20,21,22,23,24]. In 2012, it was explained that the hydraulic conductivity in the fracture has been affected by the fracture toughness [25]. They proposed a new method to simulate the flow in a real fracture.

Fracture porosity and fracture permeability have a major effect on fluid flow in many NFR [26]. These properties can be estimated by using a well test analysis [27]. Hydraulic fracturing in some low-permeability reservoirs is instrumental to increase and achieve an economic production rate. Modeling complex coupled with transient and dynamic processes found in geo-systems require increasingly high-resolution models for a more precise and qualified validation and evaluation [28].

Recently, in 2012, the fractured permeability have been estimated with more reliability if image log data and well test analysis were integrated together [26]. The resistance of the material against fracture can be measured in the lab or in the field [29]. There is a significant complexity in numerical simulation fracturing and multiple phases flow. A significant number of researches during the last 50 years described the fracturing in laboratories [30].

In 2016, [31] a study has noted that dual porosity-dual permeability simulation of the water-flood process is inaccurate if all fractures have been taken in calculate shape factor. Therefore, they suggested that the shape factor used in dual porosity-dual permeability water-flood or enhanced oil recovery simulations or in homogenization should be based only on the sub-network that carries almost all the injected fluid.

In 2017, a new analytical solution was developed for interporosity flow functions and shape factors between the fracture and matrix block in the NFR [32]. Their new method is able to provide more accurate parameters for compressible fluid productivity prediction and the more reasonable theoretical basis for the correct interpretation of well testing has been introduced.

3 Fractured Reservoir Simulation

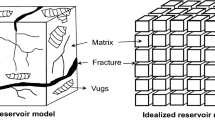

Fractures have a great effect on the fluid within the reservoir. To simulate the flow in the fractured reservoir, the dual porosity models have been used widely [4, 33,34,35,36,37,38]. At that time, they stated that the dual porosity model gave a sufficient precision for a practical purpose [37]. The porosity and permeability are high in the fractured reservoir. Therefore, the single porosity model cannot be used in such cases.

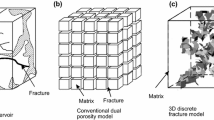

In 1960, dual porosity was established [39]. In former time, the dual continuum modeling was the conventional method for simulating fractured reservoir [40]. None of them, neither dual continuum nor dual porosity could provide an accurate solution [41]. Discrete fracture methods were better than dual continuum and others because it models the fluid flow in individual fracture [41]. Nevertheless, the disadvantaged, and limitations due to the time consuming and high computational cost for the above numerical methods have been stated in Ref. [4].

Several studies assumed transient interporosity flow for modeling [42,43,44]. The fracture of the basement reservoir was introduced by Lefranc et al. [45], Suardana et al. [46] and Gupta et al. [47].

In 2014, Huang et al. [48] used the mimetic finite difference method to develop a new numerical scheme for the discrete-fracture model. They explained that their new method provides a highly accurate approximation of the velocity field. In addition, a robust and efficient numerical approach has been implemented for the two-phase flow simulation in discrete-fractured media, if the mimetic finite difference and finite volume methods were combined. Their approach is applicable for both 2D and 3D discrete-fracture systems.

However, in 2017, it has been proposed that the results are not as accurate as compared with discrete fracture models [41]. The most accurate results have been obtained if a discrete fracture model with dual porosity and dual permeability (DPDP) were integrated together [41]. The exemplary results are presented in Fig. 1. Obviously, different models have been used to simulate the oil production in a low-permeability oil reservoir. Their workflow contained fives vertical wells. Four of these wells hold at the corners of the reservoir, while the water injection from one well holds at the center. As shown in this Fig. 1, the dual porosity method gives a less accuracy among all other considered models, while high accuracy was achieved when embedded discrete fracture method was applied.

Comparison between different models: a well “Prod_1” oil rate, b well “Prod_2” oil rate, c well “Prod_3” oil rate, d well “Prod_4” oil rate, and, e field cumulative oil [41]

The fracture networks were simulated also by extended FEM (XFEM) method based on the stress intensity factor (SIF) [49]. This approach is criticized as it is time consuming. Therefore, the crack propagation based on energy criterion was used instead [49].

Simulation of fractures in rocks and reservoirs like in metals can be done in terms of the SIF and fracture mechanics approach. This approach is essential, and can be used to understand the behavior of the reservoir. Simulating the fracturing process in rock using Franc2D was carried out [50, 51]. Fracture mechanics and SIF calculations for metal structures can be found [50,51,52].

SIFs were calculated using a Franc2D program from Cornell University Fracture Group [53], which needs less effort than a 3D model. The fracture propagation in 2-D requires a series of fracture analysis. The author published few works using Franc2D that can be considered as the extended case studies [54,55,56,57].

The flow model through the naturally fractured was presented in Ref. [58]. Hence, streamlines and contour have been shown. The flow is controlled between the matrix (crack networks) and fracture by hydraulic conductivity [58].

Finally, the fracture in reservoir with both categories (naturally and hydraulic) needed more attention and investigation.

4 Conclusions

In the above-mentioned reviews, it has been concluded that the models and simulation of the fractured reservoir are still developing. However, discrete fracture model gives a more accurate simulation when comparing with dual-continuum models. Moreover, for a large scale and for a complex fracture network in shale oil reservoirs, high accuracy simulation can be achieved when it is integrated with embedded discrete fracture model and dual continuum models. Finally, to get an integrated model for any fractured reservoir, all parameters may affect on the fluid flow in the fracture zone or affect on the porous zone as well, and these must be considered. In this issue, we discussed some important parameters of the unconventional reservoir. Moreover, importantly many parameters that affect on the performance of fractured petroleum reservoirs such as shape, dimensions, orientations of fracture, etc., were detected and discussed.

References

Abushaikha AS, Gosselin, OR (2008) Matrix-fracture transfer function in dual-media flow simulation: REVIEW, comparison and validation. In: Europec/EAGE conference and exhibition

Bratton T et al (2006) The nature of naturally fractured reservoirs. Oilfield Rev 4–23

Ouenes A, Richardson S, Weiss WW (1995) Fractured reservoir characterization and performance forecasting using geomechanics and artificial intelligence. In: SPE annual technical conference and exhibition

Han X et al (2013) The optimal design of hydraulic fracture parameters in fractured gas reservoirs with low porosity. In: Proceedings of the 2nd international conference on computer science and electronics engineering

Golf-Racht TD (1982) Fundamentals of fractured reservoir engineering

Cinco-Ley H (1996) Well-test analysis for naturally fractured reservoirs. J Pet Technol 48(01):51–54

Mavor MJ, Cinco-Ley H (1979) Transient pressure behavior of naturally fractured reservoirs. In: SPE California regional meeting

Litvak BL (1986) Simulation and characterization of naturally fractured reservoirs. In: Reservoir characterization, Elsevier, pp 561–584

Matthews CS, Russell DG (1967) Pressure buildup and flow tests in wells. Soc Pet Eng AIME 130–133

Sarma P, Aziz K (2004) New transfer functions for simulation of naturally fractured reservoirs with dual porosity models. In: SPE annual technical conference and exhibition

Bourbiaux B, Granet S, Landereau P, Noetinger B, Sarda S, Sabathier JC (1999) Scaling up matrix-fracture transfers in dual-porosity models: theory and application. In: SPE annual technical conference and exhibition

Dershowitz B, LaPointe P, Eiben T, Wei L (1998) Integration of discrete feature network methods with conventional simulator approaches. In: SPE annual technical conference and exhibition

Firoozabadi A, Thomas LK (1990) Sixth SPE comparative solution project: dual-porosity simulators. J Pet Technol 42(06):710–763

Warren PRJE (1963) The behavior of naturally fractured reservoirs. Trans Soc Pet Eng AIME 228:245–255

Kazemi H (1969) Pressure transient analysis of naturally fractured reservoirs with uniform fracture distribution. Soc Pet Eng J 9(04):451–462

Kazemi H, Merrill LS Jr, Porterfield KL, Zeman PR (1976) Numerical simulation of water-oil flow in naturally fractured reservoirs. Soc Pet Eng J 16(06):317–326

Ueda Y, Murata S, Watanabe Y, Funatsu K (1989) Investigation of the shape factor used in the dual-porosity reservoir simulator. In: SPE Asia-Pacific conference

Coats KH (1989) Implicit compositional simulation of single-porosity and dual-porosity reservoirs. In: SPE symposium on reservoir simulation

Torsaeter O, Silseth JK (1985) The effects of sample shape and boundary conditions on capillary imbibition. In: North Sea Chalk symposium, Stavanger

Panek LA (1985) Estimating fracture trace length from censored measurements on multiple scanlines. In: Proceedings of the international symposium on fundamentals of rock joints, Björkliden, pp 15–20

Rouleau A, Gale JE (1985) Statistical characterization of the fracture system in the Stripa granite, Sweden. Int J Rock Mech Mining Sci Geomech Abstr 22(6):353–367

Rives T, Razack M, Petit J-P, Rawnsley KD (1992) Joint spacing: analogue and numerical simulations. J Struct Geol 14(8–9):925–937

Lee SH, Lough MF, Jensen CL (2001) Hierarchical modeling of flow in naturally fractured formations with multiple length scales conventional finite difference on the basis of their length (l f) relative to the finite difference grid size (/g), fractures are classified as belonging to on. Water Resour Res 37(3):443–455

Pirker B (2008) A new approach for modeling dual porosity reservoirs using recovery curves (na)

Liu QQ, Fan HG (2012) The characteristics and estimation of flow through a single rough-walled fracture. J Hydrodyn 24(3):315–322

Bahrami H, Rezaee R, Hossain M (2012) Characterizing natural fractures productivity in tight gas reservoirs. J Pet Explor Prod Technol 2(2):107–115

Saidi AM (1987) Reservoir engineering of fractured reservoirs: fundamental and practical aspects. Total Edition Presse, Paris. Total

Kemmler D, Adamidis P, Wang W, Bauer S, Kolditz O (2005) Solving coupled geoscience problems on high performance computing platforms. In: International conference on computational science, pp 1064–1071

Malin SC (2005) In situ stress determination in unsaturated soils using hydraulic fractures. Clemson University

Murdoch LC, Richardson JR, Tan Q, Malin SC, Fairbanks C (2007) Reply to the discussion by Au and Yeung on ‘forms and sand transport in shallow hydraulic fractures in residual soil’ Can Geotech J 44(12) :1474–1475, 1476–1478

Gong J, Rossen WR (2016) Shape factor for dual-permeability fractured reservoir simulation: effect of non-uniform flow in 2D fracture network. Fuel 184:81–88

He Y, Chen X, Zhang Y, Yu W (2017) Modeling interporosity flow functions and shape factors in low-permeability naturally fractured reservoir. J Pet Sci Eng 156(March):110–117

Douglas J, Hensley JL, Arbogast T (1991) A dual-porosity model for water flooding in naturally fractured reservoirs. Comput Meth Appl Mech Eng 87(2):157–174

Dykhuizen R (1990) A new coupling term for dual-porosity models. Water Resour Res 26(2):351–356

Zimmerman RW, Chen G, Hadgu T, Bodvarsson GS (1993) A numerical dual-porosity model with semianalytical treatment of fracture/matrix flow. Water Resour Res 29(7):2127–2137

Gerke HH, Van Genuchten MT (1993) A dual-porosity model for simulating the preferential movement of water and solutes in structured porous media. Water Resour Res 29(2):305–319

Douglas Jr V, Arbogast T ( 1990) Dual porosity models for flow in naturally fractured reservoirs. Dyn Fluids Hierarchical Porous Media 177–221

Li W, Dong Z, Lei G (2017) Integrating embedded discrete fracture and dual-porosity, dual-permeability methods to simulate fluid flow in shale oil reservoirs

Barenblatt G, Zheltov I, Kochina I (1960) Basic concepts in the theory of seepage of homogeneous liquids in fissured rocks [strata]. J Appl Math Mech 24(5):1286–1303

Moinfar A, Varavei A, Sepehrnoori K, Johns RT (2013) Development of a novel and computationally-efficient discrete-fracture model to study IOR processes in naturally fractured reservoirs. In: SPE improved oil recovery symposium, pp 1–17

Li W, Dong Z, Lei G (2017) Integrating EDFM and dual porosity method to simulate fluid flow in shale oil reservoir. In: SPE/IATMI Asia Pacific oil & gas conference and exhibition

Pruess K, Narasimhan TN (1982) Practical method for modeling fluid and heat flow in fractured porous media. Lawrence Berkeley Lab, CA, USA

Serra K, Reynolds AC, Raghavan R (1983) New pressure transient analysis methods for naturally fractured reservoirs (includes associated papers 12940 and 13014). J Pet Technol 35(12):2–271

Streltsova TD (1983) Well pressure behavior of a naturally fractured reservoir. Soc Pet Eng J 23(05):769–780

Lefranc M, Farag S, Souche L, Dubois A (2012) Fractured basement reservoir characterization for fracture distribution, porosity and permeability prediction. Aapg 41106:#41106

Suardana M, Samodra A, Wahidin A, Sule MR (2013) Identification of fractured basement reservoir using intregated well data and seismic attributes: case study at Ruby Field, North West Java Basin. In: Proceedings of AAPG annual convention and exhibition, Pennsylvania, Pittsburg

Gupta SD, Chatterjee R, Farooqui MY (2012) Formation evaluation of fractured basement, Cambay Basin, India. J Geophys Eng 9(2):162–175

Huang Z, Yan X, Yao J (2014) A two-phase flow simulation of discrete-fractured media using mimetic finite difference method. Commun Comput Phys 16(3):799–816

Zhao H, Wang X, Wang W, Mu E (2018) A simulation method based on energy criterion for network fracturing in shale gas reservoirs. J Nat Gas Sci Eng 52:295–303

Al-Mukhtar AM, Merkel B (2015) Simulation of the crack propagation in rocks using fracture mechanics approach. J Fail Anal Prev 15(1):90–100

Al-Mukhtar AM (2017) Fracturing in HDR geothermal system. Adv Eng Forum 20:57–60

Al-Mukhtar AM (2014) Performance of the subsurface hydraulics in a doublet system using the ThermoGIS calculator. J Geogr Geol 6(3):90

Cornell Fracture Group (2010) “FRANC2D Version 3.2 [Online]. Available http://www.cfg.cornell.edu/software/franc2d_casca.htm. Accessed 07 July 2013

Al-Mukhtar AM (2011) Fracture mechanics method of welded components under cyclic loads: Fatigue life calculations and simulation. Südwestdeutscher Verlag für Hochschulschriften

Al-Mukhtar A, Biermann H, Hübner P, Henkel S (2009) Fatigue crack propagation life calculation in welded joints. In: CP2009, pp 391–397

Al-Mukhtar A, Biermann H, Henkel S, Hübner P (2010) Comparison of the stress intensity factor of load-carrying cruciform welded joints with different geometries. J Mater Eng Perform 19(6):802–809

Al-Mukhtar AM, Biermann H, Hübner P, Henkel S (2010) Determination of some parameters for fatigue life in welded joints using fracture mechanics method. J Mater Eng Perform 19(9):1225–1234

van Harmelen A, Weijermars R (2018) Complex analytical solutions for flow in hydraulically fractured hydrocarbon reservoirs with and without natural fractures. Appl Math Model 56:137–157

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Majeed, A.J., Alshara, A.K., Al-Mukhtar, A.M., Abood, F.A. (2020). Fracturing Parameters in Petroleum Reservoirs and Simulation. In: Awang, M., Emamian, S., Yusof, F. (eds) Advances in Material Sciences and Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-8297-0_51

Download citation

DOI: https://doi.org/10.1007/978-981-13-8297-0_51

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-8296-3

Online ISBN: 978-981-13-8297-0

eBook Packages: EngineeringEngineering (R0)