Abstract

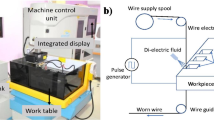

The current work focuses on multi-objective wire electrical discharge machining (WEDM) parameters optimization of Inconel 750 alloy. Taguchi L18 orthogonal array (OA) was used to carry the experiments in various WEDM parameters such as wire feed rate, pulse-on-time, pulse-off-time and water pressure. The output responses estimated are machining speed (cutting) and machined surface roughness of the part. Optimum machining parameters estimation is difficult in Taguchi process; a multi-objective optimization (MOO) technique known as TOPSIS is embedded with grey wolf optimizer (GWO). Initially, the multi-responses are converted to the relative closeness value, and then the heuristic approach is applied. Based on the optimal parametric setting value from GWO, a confirmation test has been conducted and compared with the fitness value.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Williams, R.E., Rajurkar, K.P.: Study of wire electrical discharge machined surface characteristics. J. Mater. Process. Technol. 28(1–2), 127–138 (1991)

Bewlay, BP., Weimer, M., Kelly, T., Suzuki, A., Subramanian, PR., Baker, I., Heilmaier, M., Kumer, S., Yashimi, K. (eds.) Inter Metallic Based Alloys-Science, Technology and Applications, Mrs Symposium Proceedings, vol. 1, no. 516, p. 49 (2013)

Anurag, S.: Wire-EDM: a potential manufacturing process for gamma titanium aluminides in future aero engines. Int. J. Adv. Manuf. Technol. 94(1–4), 351–356 (2018)

Mirjalili, S., Mirjalili, S.M., Lewis, A.: Grey wolf optimizer. Adv. Eng. Softw. 69, 46–61 (2014)

Lai, Y.J., Liu, T.Y., Hwang, C.L.: Topsis for MODM. Eur. J. Oper. Res. 76(3), 486–500 (1994)

Chakraborty, S., Mitra, A.: Parametric optimization of abrasive water-jet machining processes using grey wolf optimizer. Mater. Manuf. Process. 1–12 (2018)

Nain, S.S., Garg, D., Kumar, S.: Investigation for obtaining the optimal solution for improving the performance of WEDM of super alloy Udimet-L605 using particle swarm optimization. Eng. Sci. Technol. Int. J. 21(2), 261–273 (2018)

Yuvaraj, N., Pradeep Kumar, M.: Multiresponse optimization of abrasive water jet cutting process parameters using TOPSIS approach. Mater. Manuf. Process. 30(7), 882–889 (2015)

Rao, R.V.: Advanced Modeling and Optimization of Manufacturing Processes : International Research and Development (2010)

Garg, M.P., Kumar, A., Sahu, C.K.: Mathematical modeling and analysis of WEDM machining parameters of nickel-based super alloy using response surface methodology. Sādhanā 42(6), 981–1005 (2017)

Selvam, M.P., Kumar, P.R.: Optimization Kerf width and surface roughness in wire cut electrical discharge machining using brass wire. Mech Mech Eng 21(1), 37–55 (2017)

Ashok, R., Poovazhagan, L., Srinath Ramkumar, S., Vignesh Kumar, S.: Optimization of material removal rate in wire-edm using fuzzy logic and artificial neural network. In: Applied Mechanics and Materials, vol. 867, pp. 73–80. Trans Tech Publications (2017)

Kumar, P., Meenu, M., Kumar, V.: Optimization of process parameters for WEDM of Inconel 825 using grey relational analysis. Decis. Sci. Lett. 7(4), 405–416 (2018)

Huang, Y., Ming, W., Guo, J., Zhang, Z., Liu, G., Li, M., Zhang, G.: Optimization of cutting conditions of YG15 on rough and finish cutting in WEDM based on statistical analyses. Int. J. Adv. Manuf. Technol. 69(5–8), 993–1008 (2013)

Majumder, H., Maity, K.: Prediction and optimization of surface roughness and micro-hardness using grnn and MOORA-fuzzy-a MCDM approach for nitinol in WEDM. Measurement 118, 1–13 (2018)

Rajyalakshmi, G., Ramaiah, P.V.: Multiple process parameter optimization of wire electrical discharge machining on Inconel 825 using Taguchi grey relational analysis. Int. J. Adv. Manuf. Technol. 69(5–8), 1249–1262 (2013)

Varun, A., Venkaiah, N.: Simultaneous optimization of WEDM responses using grey relational analysis coupled with genetic algorithm while machining EN 353. Int. J. Adv. Manuf. Technol. 76(1–4), 675–690 (2015)

Rao, R.V., Pawar, P.J.: Modelling and optimization of process parameters of wire electrical discharge machining. Proc. Inst. Mech. Eng. Part B J Eng. Manuf. 223(11), 1431–1440 (2009)

Nayak, B.B., Mahapatra, S.S., Chatterjee, S., Abhishek, K.: Parametric appraisal of WEDM using harmony search algorithm. Mater. Today Proc. 2(4–5), 2562–2568 (2015)

Yoon, K.P., Hwang, C.L.: Multiple Attribute Decision Making: An Introduction, vol. 104. Sage publications (1995)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kumar, G.V.A., Narasimhamu, K.L. (2020). Multi-objective Optimization in WEDM of Inconel 750 Alloy: Application of TOPSIS Embedded Grey Wolf Optimizer. In: Venkata Rao, R., Taler, J. (eds) Advanced Engineering Optimization Through Intelligent Techniques. Advances in Intelligent Systems and Computing, vol 949. Springer, Singapore. https://doi.org/10.1007/978-981-13-8196-6_22

Download citation

DOI: https://doi.org/10.1007/978-981-13-8196-6_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-8195-9

Online ISBN: 978-981-13-8196-6

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)