Abstract

Design and analysis of tunnels and underground structures are challenging areas of Geotechnical Engineering. The soil/rock in tunnelling areas is often strengthened by grouting. This improves the properties of soil/rock and enhances the stability. In the present study, a two-dimensional analysis that explains the properties of soil/rock strengthened by grouting is carried out. Initially, the settlement behaviour of grouted soil mass with different curing periods of 7, 14 and 28 days was studied by the plate load laboratory model test, and the settlement behaviour of grouted soil mass was compared with ungrouted soil mass. The experimental results reveal that the settlement of the grouted soil mass is comparatively reduced with respect to increase in curing period. The analysis was carried out using PLAXIS 2D software, a two-dimensional indirect finite element programme which facilitates elastic/elasto-plastic analysis of underground excavations. The distribution of stress and deformation under different loading conditions is visualized from the analysis. Based on the results, critical locations for failure were identified. Then, the grouting was applied to the soil mass. Comparison of the mechanical properties of the grouted and ungrouted soil mass brings out the effectiveness of the grouting in improving the stability of the tunnel.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Poor-quality soils, because of their low bearing capacity, need to be improved by implementing ground improvement techniques (GIT). Especially in granular soils, the ground improvement technique is essentially needed to improve the shear strength of the soil (Daykar et al. 2012). It can be achieved through various methods and techniques like vibro-flotation, grouting, etc. Selection of right method is based on various factors like condition of the soil, degree of the compaction, type of structures need to be supported, depth of compaction, as well as site considerations like sensitivity of adjacent structures. For many of the foundation problems, compaction of the soil is the effective solution, and it is useful for reducing the settlement. However, up to 20 m depth only, the dynamic compaction will be effective if any water is present at shallow depth (Yilmaz et al. 2008). But the grouting will improve the bonding and cohesive capacity of the soil (Anagnostopous 2005). Nowadays the grouting process is carried out widely to strengthen the soil mass and to improve the bearing capacity of the soil mass (Daykar et al. 2012). Grouting is an effective method to improve the physical and mechanical properties of the soil (Sayaehv and Kalantari 2012). The improved properties give rise to better load bearing capacity and stability of the soil (Kumar et al. 2011). The application of grouting will reduce the liquefaction process during periods of dynamic loading (Sayaehv and Kalantari 2012), and the resistance of the soil can be improved without altering the physical structure. The application of grouting will reduce the void space and increase the density of the soil mass which alters the engineering properties such as strength, stiffness, etc. (Kumar et al. 2011). A brief overview of significant literature is presented. Different kinds of grouting material are described. Stepwise procedure for grouting by making use of various equipments is prescribed (Lowe and Standford 1982; Schwarz and Krizek 1992; Lovly 1998). Permeation grouting is an effective method to enhance the bearing capacity of the soil and to decrease the void ratio of the soil mass without disturbing the structure of the soil; in this way, the permeability of the soil can be reduced to a great extent, and the groundwater movement can be controlled (Daykar et al. 2012). This study describes the improvement attained in the strength of unconsolidated sand bed after permeation cement grouting. The permeation grouting method is employed to disperse the grouting material uniformly into the soil mass (Glory and Abraham 2001). Today, the grouting operations are carried out based on empirical rules only. A proper finite element modelling will give appropriate ideas for the implementation of grouting. But to identify the behaviour of the soil after grouting at the earliest, a proper numerical analysis should be carried out before implementation of the grouting. The numerical analysis tool of PLAXIS 2D software facilitates to carry out the elastic/elasto-plastic analysis. This analysis is very much helpful to identify the behaviour of the soil with respect to the load in elastic and elasto-plastic states.

2 Materials Used

As per the ASTM and BIS classifications, river sand was used. It was graded into fine particles (74–425 µm), medium (425–2 µm) and coarse (2–4.75 mm).

Ordinary Portland cement-43 grade was used as grouting material. The properties of the cement are tabulated in Table 1 (Table 2).

Soil sample was analysed, and their physical properties are presented in Table 2.

3 Experimental Set-up

3.1 Plate Load Test

As per IS: 1904-1978, the plate load test was carried out to assess the strength improvement of the grouted soil mass. It was carried out in grouted as well as ungrouted soil masses.

3.1.1 Plate Load Test for Ungrouted Sand

In the first stage, the soil was taken in a box of dimensions 25 cm × 25 cm × 25 cm. A steel plate of one-fifth size of the box was placed over the surface of the soil sample. Then, the load was applied at gradual increments on the plate. The density and void ratio of the sand in a loose state were 17.8 and 0.69 kN/m3, respectively. On applying the load, the soil began to settle down. This setting was measured using a dial gauge. The test arrangement is shown in Fig. 1.

3.1.2 Plate Load Test for Sand in with Grout State

Initially, cement was mixed with water, and the consistent cement slurry was prepared. Pipes with micro-holes on the surface were inserted into the soil at four corners. The mixed cement slurry was injected through the pipes into the soil by applying pressure. It gushed out the holes and dispersed into the soil. This type of grouting is known as permeation grouting. After completion of grouting the model was cured for 7, 14 and 28 days. Plate load test was conducted for the grouted sample after 7, 14 and 28 days of curing. The applied loads and corresponding settlement were noted in each trial (Fig. 2).

Arora stated Eq. 1 to calculate the settlement of sandy soil

Arora stated Eq. 2 to calculate the ultimate bearing capacity of sandy soil

where qu(p) = ultimate bearing capacity of plate, qu(f) = ultimate bearing capacity of foundation, Bf = width of foundation, Sf = settlement of foundation, Sp = settlement of plate, Bp = width of plate.

3.2 Permeability Test

Permeability test was carried out by using the permeability test apparatus. It was conducted in two states; the permeability values for grouted and ungrouted soil samples were determined and compared.

4 Elasto-Plastic Analysis

Generally, when a load is applied, soil undergoes three kinds of phase, namely elastic, elasto-plastic and plastic. Elastic state can be identified from a plot of stress–strain values obtained from laboratory tests. Elasto-plastic state denotes a condition/zone lying between elastic and plastic zones. This is known as yield line Huang (2013). In the present study, the PLAXIS 2D software was used to identify the elasto-plastic behaviour of the soil (grouted and ungrouted) under different loading conditions. Initial experiments were conducted in the laboratory, and the properties of the sand were determined. Then, a model was created using the PLAXIS 2D software for both cases of grouted and ungrouted states, and then, the analysis process was carried out.

4.1 Model Generation

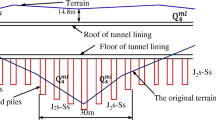

A Mohr–Coulomb model was derived from the PLAXIS 2D software which functions on the principles of finite element analysis. Initially, the boundary conditions were created based on the requirement, and then, the geometry of the NATM tunnel was introduced into the boundary conditions. Then, the soil parameters were entered into the boundary, and a real field condition was generated within the boundary.

4.1.1 Ungrouted and Grouted Soil Model generation

Initially, the model was tested in ungrouted state, and the deformation and stress distribution behaviour were studied. From the plate load test, the stress–strain behaviour of the soil during the grouted and ungrouted state was constantly monitored with respect to the loading. From the stress–strain behaviour, the Young’s modulus value of the soil was identified in both cases. Keeping the same model, the change of E value, permeability value of the soil was entered in grouted soil model, and the behaviour of the soil with respect to the load was analysed in both cases. The maximum deformation with respect to the loading was recorded. The critical point was identified from the stress–strain distribution pattern. The deformation and stress distribution patterns in respect of ungrouted and grouted models were compared. The strength improvement due to grouting was determined. Figure 3 shows the generated model for with and without grouting.

5 Results and Discussion

The results of the above conducted tests (plate load test, permeability test and elasto-plastic analysis output) are discussed below.

5.1 Plate Load Test Results

Plate load test was carried out to determine the strength improvement in the sandy soil after grouting. Grouted soil sample after different periods of curing of 7, 14 and 28 days was tested. The settlement of the soil was relatively reduced in the case of grouted soil sample with increasing periods of curing. Figure 4 shows the load versus the settlement behaviour of the grouted and ungrouted sand for different periods of curing. The increased Young’s modulus was observed after curing of grouted sample.

5.2 Permeability Test Result

The permeability of grouted and ungrouted soil mass was 0.0083 and 0.0169 cm/s, respectively. From the observed results, it is found that the permeability of the soil after the grouting stage is comparatively reduced.

5.3 Elasto-Plastic Analysis Output

The Mohr–Coulomb model was generated. The numerical finite element analysis was carried for the generated model, and the stress distribution and deformation behaviour of the soil mass were predicted. The critical locations in the stress distribution were recorded. Figure 5 shows the stress distribution and maximum deformation rate in ungrouted soil state. In Fig. 5, the stress distribution critical locations are located on the sloped corner, the surface of the soil mass and the right side face of the tunnel section. As such, it is necessary to strengthen and improve the stability of these areas.

After introducing the Young’s modulus value of grouted soil mass, due to the increase in E value and decrease in permeability value after the grout state, the critical locations in the soil mass were reduced, and uniform stress distribution was attained. By the process of grouting, the deformation of the soil mass was comparatively reduced (Fig. 6).

6 Conclusions

From the experimental results of plate load test, it is observed that the settlement of the grouted soil was reduced with respect to the load as compared to the ungrouted soil sample. Especially an increase in curing period reduced the settlement. After 28 days of curing, the settlement was highly reduced as compared with the ungrouted sample. From the permeability test, it is found that the permeability value of the soil was comparatively reduced due to grouting; it is possible that this reduction in permeability will restrict the movement of groundwater. From the numerical analysis, it is summarized that deformation of the soil mass can be reduced, and uniform stress distribution of the soil mass can be realized by eliminating the critical points in the ungrouted state by means of grouting. By using Eq. 1, the settlement of the soil was calculated in both grouted and ungrouted stage. The 40–48% of settlement is reduced in after grout stage. From Eq. 2, the bearing capacity of the soil was calculated in both cases, it was observed that the 12.5–20% of bearing capacity was increased in grouted stage. After the cement grouting for proper curing the settlement is decreases gradually with respect to curing period. From the plate load test, the Young’s modulus of the grouted sample was increased in after grouted stage. The cement grouting in sandy soil with increasing curing period is reducing the settlement of soil. The novelty of this study is the NATM tunnel section which was introduced in the sandy soil strata and analysed stress distribution, deformation in grouted and ungrouted states. This study is carried out to overcome the difficulty during the process of tunnel construction because in some areas, the sandy soil layer may be interrupted during the process of tunnel construction.

References

Anagnostopous CA (2005) Laboratory study of an injected granular soil with polymer grouts. Tunn Undergr Space Tech 20:525–533

Daykar P, Venkat Raman K, Raju KV (2012) Study on permeation grouting using cement grout in sandy soil. IOSR J Mech Civil Eng 4:5–10

Glory J, Abraham BM (2001) Improvement of bearing capacity of sandy soils by grouting. In: IGC 2001, The New Millennium conference, Indore, pp 14–16

Huang F (2013) The effect of weak interlayer on the failure pattern of rock mass around the tunnel-scaled model test and numerical analysis. Tunn Undergr Space Technol 35:207–218

Kumar TGS, Abraham BM, Sridharan A (2011) Bearing capacity improvement of loose sandy foundation soils through grouting. Int J Eng Res Appl 2248–2296

Lovly KM (1998) Effect of admixture on cement grout. In: Indian geotechnical conference, New Delhi

Lowe J, Standford TC (1982) Special grouting at Tarbela dam project. In: Proceedings of conference on grouting, New Orleans, ASCE, New York, pp 152–172

Sayaehv S, Kalantari B (2012) Use of grouting method to improve soil stability against liquefaction—a review. EJGE 17:1559–1566

Schwarz LG, Krizek RJ (1992) Effect of mixing on rheological properties of micro fine cement. In: Proceedings of the conference on grouting, soil improvement and geosynthetics, New Orleans, ASCE, New York, pp 512–525

Yilmaz D, Babuccu F, Batmaz S, Kavruk F (2008) Liquefaction analysis and soil improvement in beydagdam. Geotech Geol Eng 26(2):211–224

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Vinothkumar, M., Malathy, R. (2019). Elasto-Plastic Analysis of a Tunnel Strengthened by Grouting. In: Sundaram, R., Shahu, J., Havanagi, V. (eds) Geotechnics for Transportation Infrastructure. Lecture Notes in Civil Engineering , vol 29. Springer, Singapore. https://doi.org/10.1007/978-981-13-6713-7_35

Download citation

DOI: https://doi.org/10.1007/978-981-13-6713-7_35

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-6712-0

Online ISBN: 978-981-13-6713-7

eBook Packages: EngineeringEngineering (R0)