Abstract

The worldwide increase in population, industrialization, and urbanization results in the increase of Municipal Solid Waste (MSW). Most of the countries have adopted sanitary landfilling as the best method for disposal of their MSW. One of the major pollution problems caused by the sanitary landfill is landfill leachate, which is generated as consequences of infiltration of water into landfills and squeezing of the waste due to self-weight. Landfill leachate contains variety of compounds such as organic matter, heavy metals, and inorganic salts. The treating of these recalcitrant compounds by conventional ways makes it quite difficult, because of its high chemical stability and low biodegradability. In recent years, semiconductor photocatalysis has gained focus on treatment of heavy metals, organic, and inorganic matter by nanosized ZnS, ZnO, CdS, TiO2, and Fe2O3. Among all these semiconductor nanomaterials, TiO2 has received more popularity because of its low-cost, nontoxic, chemical stability, and photostable properties. In the present study, the degradation of lead in aqueous solution was investigated by using photocatalytic TiO2 under natural sunlight. The parabolic trough collector is used as solar photoreactor, which brings chemical reagents and solar photons into contact with the photocatalyst. The characterization of TiO2 is conducted by Scanning Electron Microscope (SEM) and X-Ray Diffraction (XRD). The influencing parameters (pH, contact time, photocatalytic dosage, and concentration of an aqueous solution) on lead removal efficiency was studied and optimized by Response Surface methodology (RSM). The results indicated that at pH 7, with adsorbent dosage 0.35 g/l, with initial concentration 27.5 mg/l, and irradiation time 42.5 min can successfully remove lead up to 99.3%. The characterization study of TiO2 confirms that the selected photocatalytic TiO2 is anatase which is spherical in shape. The crystallite size is approximately 19 nm and specific surface area of 120.32 m2/gm.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Developing countries are the highest Municipal Solid Waste (MSW) producers, due to the growing urbanization and industrilization. In India, it is estimated that about 115000 MT of Municipal Solid Waste (MSW) is generated daily in the country [1]. The social and environmental effects caused by MSW have received great attention in recent decades. The policies, plans, strategies, and techniques have been developed in the field of MSW management for waste recovery, reuse, recycling, and energy generation by incineration and sanitary landfilling for the final rejects [2]. Most of the developed and developing countries have adopted sanitary landfilling as the general technique for their MSW disposal because of its low-cost and well-established methods [3]. Major pollutants emerge from sanitary landfill sites are biogas and leachate. The environmental problems experienced by the leachate is evading of leachate from the site and the subsequent contamination of surrounding land and water [4]. The difficulty associated with treating MSW landfill leachate involves highly variable composition and high concentration of recalcitrant organic compounds, ammonia, and heavy metals [5].

Heavy metals are one of the major concerns in the sanitary landfill leachate. Heavy metals enter in the landfill by electroplating waste, painting waste, used batteries, etc., when these wastes degradation takes place in acidic condition leads to a high metal concentration in the leachate [6]. Heavy metals disturb the natural biological balance and inhibit self-purification process [7]. Heavy metal ions, for example, Pb2+, Cd2+, Cr6+, Zn2+, and Hg2+ have toxic and nonbiodegradable properties, can cause serious health issues in human being and animals [8].

Heavy metal lead (Pb2+) can cause harmful effects such as anemia, abdominal pain, irritability, as well as it disturbs functioning of the brain resulting in memory loss and headache.

In recent years, various techniques have been developed for effective removal of heavy metal from water and wastewater, those are adsorption, reverse osmosis, membrane filtration, ion exchange, and electrochemical technologies. Among these techniques, adsorption offers flexibility in design and operation, which produces high-quality-treated effluent [9].

In recent years, nanomaterials are used for treating heavy metals, organic, and inorganic compounds from water and wastewater. These nanomaterials are used as an adsorbent and photocatalyst. Photocatalytic nanomaterials are metal oxides which includes ferric oxide, aluminum oxides, titanium oxides, manganese oxides, and magnesium oxides.

In nanosized metal oxides, semiconductor photocatalysis has gained more attention because of its outstanding efficiency in environmental purification. TiO2 is one of the broadly used semiconductor photocatalysts [3]. One of the widely used semiconductor photocatalysts is TiO2. TiO2 gained a prominent place in research due to its nontoxicity, cost-effective, high chemical stability, and has highly oxidizing power, which makes it a competitive candidate for many photocatalytic applications [10]. Heterogeneous photocatalysis uses artificial or natural solar UV rays for degradation most of the heavy metals in water and wastewater. The reduction of Cr6+ under visible light is studied by using TiO2 photocatalytic. Methanol, methanal, and formic acid are used as electron donors in photocatalysis process and quickest rate of chromium reduction was found in formic acid [11]. The photocatalytic reduction of Cu2+, Ni2+, Pb2+, and Zn2+, is studied under solar energy with the parabolic trough and TiO2 as a photocatalyst. Citric acid is used as a hole scavenger and results show that 97% reduction of copper and other metals reduction is significantly low compared to nickel 36.4%, zinc 22.2%, and lead 41.4% [12, 13]. Photocatalytic reduction of nickel and zinc is more in alkaline pH and acidic pH is favorable for chromium reduction [12, 13]. Photocatalytic degradation of phenol by titanium dioxide was investigated with varying pH, irradiation time, and dosage of TiO2. A total of 94.5% degradation of phenol is achieved in 150 min of irradiation time [14].

In the present work, the UV/TiO2 photocatalyst is used for the degradation of lead (Pb2+) in the aqueous solution. TiO2 characterization study is performed on particle size, specific surface area, and surface morphology. The parabolic trough collector is used as solar photoreactor. This photoreactor brings efficiently solar photons and chemical reagents in contact with TiO2 photocatalyst. Factors affecting the performance of TiO2 photocatalysis are considered as pH, contact time, dosage, and different lead concentrations in Design of Experiments (DOE).

2 Materials and Methods

2.1 Chemicals

A stock lead solution is prepared by dissolving 1.599 gm of lead nitrate Pb(NO3)2 in deionized distilled water. When the solution is completely acidified, 10 ml redistilled HNO3 and diluted to 1 L with deionized distilled water. 1 ml = 1 mg (1000 mg/l). Different concentrations of lead solutions are obtained by using stock lead solution.

The pH is varied as 4, 7, and 10 in aqueous solution, buffer solutions are prepared with reagents such as Disodium Hydrogen Phosphate (Na2HPO4). The Disodium Tetra borate (Na2B4O7) is commonly known as borax and Boric acid or Hydrogen Borate (H3BO3). The titanium dioxide (TiO2) used for the work is Sisco Research Laboratories Private limited.

2.2 Design of Experiments (DOE)

Various factors are influencing the degradation of lead under photocatalytic process. To know the key factors and their interaction effects in the photocatalytic process, a statistical tool DOE was used. Four influencing factors were considered for the study which is pH, initial concentration of aqueous solution, adsorbent dosage, and irradiation time. Design Expert Software version 7.0 is used with two-level factorial design. It is used in most of the experiments because of its simplicity, versatility and can be used for many factors. A total of 30 runs were obtained with Design expert software 7.0 for adsorbent dosage (A), pH (B), initial concentration of aqueous solution (C), and the irradiation time (D) in randomized fashion.

2.3 Experiments

The experiments were carried out in a batch sequence under natural sunlight at Vijayapur, (16.83°N 75.71°E) Karnataka state, India. The parabolic trough (Fig. 1) is used with an angle of 45° to receive the maximum sunrays. A 100 ml glass tube is used as a container for experimental work. For proper circulation of TiO2 with aqueous lead solution air is supplied. At the end of each experiment, the filter paper is used for the separation of TiO2 particles. The lead analysis was done by using Atomic Absorption Spectroscopy (Varian 240). The lead removal efficiency is calculated according to

where Cin and Cout are initial and residual concentrations of the metal ion, respectively.

3 Results and Discussion

3.1 Characterization of TiO2

3.1.1 X-Ray Diffraction (XRD)

3.1.1.1 Crystal Structure and Crystallite Size

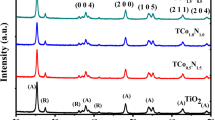

The X-ray diffraction of photocatalytic TiO2 is carried out to determine the crystal structure and crystallite size. The XRD pattern of TiO2 is shown in Fig. 2. The results show six peaks at 25.29, 37.92, 48.09, 53.86, 55.12, and 62.7. The 2θ peaks at 25.29° and 48.09° confirm the TiO2 used for the study is anatase form according to JCPDS Card No. 21-1272. The TiO2 nanomaterials are available in the crystallographic structures to form as anatase, rutile, and brookite. Among these three structures, anatase exhibits higher photocatalytic activity compared to the others, because of its indirect band gap semiconductor. Rutile exhibits direct band gap semiconductor. Anatase having band gap of 3.2 eV which is larger than of rutile 3.0 eV.

Average crystallite size is calculated by considering the 2θ peak values. The average crystallite size is estimated from the Full Width Half Maximum (FWHM) of diffraction peak using Debye-Scherer formula. This Debye-Scherer formula is the simplest and widely used one.

where λ—wavelength of X-ray (0.1540 nm), β—FWHM, θ—diffraction angle, and D—crystallite size. The average crystallite size obtained by the above equation is 19 nm. The samples intensity of the XRD peaks reflects that the smaller the crystal size, the broader the peak and confirming small size crystallite.

3.1.1.2 Specific Surface Area (SSA)

SSA is a surface area per unit mass, and this property is important for adsorption, heterogeneous catalysis, and reactions on surfaces. As the size of material decreases, the specific surface area and surface-to-volume ratio increases. The SSA can be calculated as per the Eqs. 2 and 3. The results obtained by both the equations are same. The observed results are tabulated in Table 1.

where SSA and S = specific surface area, VPart = particle volume, SApart = surface area, Dp = the size (Spherical Shaped), and ρ = density of the material.

The results show that 120.32 m2/gm SSA is responsible for the enhanced photocatalytic degradation of lead. The high specific surface area of TiO2 nanoparticles facilitates reaction/interaction between the TiO2 as the interacting media, which mainly occurs on the surface or at the interface and strongly depends on the surface area of the material.

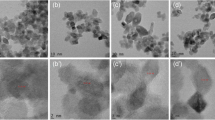

3.1.2 Scanning Electron Microscope (SEM)

The surface morphology is studied by Scanning Electron Microscopy (SEM) in the physical Instrumentation Facility Centre (PIFC), Department of Physics, Shivaji University, Kolhapur, Maharashtra. The SEM images of TiO2 at different magnifications are shown in Fig. 3a, b, which confirms that the TiO2 used for the study is spherical in shape.

3.2 Response Surface Methodology (RSM)

RSM application helps in optimizing the critical factors and provides a useful data about the response nature. Figure 4 indicates the relevant fitted response surfaces for the design. It shows % removal of Pb2+ versus variables in the response surface plots. The interaction among variables and removal efficiency can be observed at the curvature of the plots. The response surface plots as shown in Fig. 4 indicate the dependency of variables such as dosage, pH, irradiation time, and lead concentration with respect to percentage removal of lead from the aqueous solution.

The effect of initial concentration of lead and pH values is shown in Fig. 4a with percentage removal of lead. The results obtained from the graph show that increasing in pH as well as concentration of lead leads to remove maximum percentage of lead from aqueous solution. At higher pH, the movement of holes and electrons in photocatalyst is faster compared to acidic media.

Figure 4b demonstrates the change in the lead as a function of pH and irradiation time. As the irradiation time increases, the percentage removal of lead increases. This is because of longer irradiation time accelerates mixing and dispersion of adsorbent into the solution and provides more vacant sites in the metal ions. Furthermore, an increase of irradiation time leads to precipitation of the adsorbed lead back to the solution.

Figure 4c represents the lead removal in terms of pH and dosage variables. As the dosage increases, the lead removal efficiency increases. The increase in lead removal efficiency is due to the density of increased dosage particles in the area of illumination. This density will help in increasing availability of catalyst sites for the adsorption. Further, an increase of dosage levels reduces the light absorption coefficient which in turn reduces the lead removal efficiency. Lower adsorbent dosage with alkaline pH causes a higher adsorption capacity, due to deprotonation of the more adsorption sites.

Figure 4d represents variation of the initial concentration and irradiation time. From the results, it is seen that the initial concentration of lead with 27.50 mg/l and 35 min contact time will help in maximum percentage removal of lead. It indicates that high adsorption capacities of ions were observed at initial irradiation time, due to probable saturation of the adsorbent surface as a result of air-assisted mixing and dispersion of adsorbent and metal ions in solution.

3.3 Optimization of Parameters

The surface profiles (Fig. 4) obtained by the study are utilized for optimizing the process of lead removal. The overall response provided by the plots with different variables are studied individually and found that maximum percentage removal of the lead was 99.38% at optimum conditions of 42.5 min = contact time, 0.35 g/l = adsorbent dose, initial lead concentration = 27.5 mg/l, and pH = 7.

4 Conclusions

In this study, the TiO2 photocatalytic nanomaterial is used for the removal of lead from aqueous solution. The TiO2 characteristics study such as XRD and SEM results confirm that the selected photocatalytic TiO2 is an anatase with spherical in shape. The crystallite size is approximately 19 nm and specific surface area of 120.32 m2/gm. It is observed that the TiO2 is having small crystal size and high SSA which proves to be an efficient photocatalyst for the removal of lead from leachate. Central Composite Design (CCD) and RSM are used to find the effects of different factors, interactions among the various operating parameters and optimizing the process. With the results, we can conclude that the optimum operating variables are 42.5 min = irradiation time, 0.35 g/l = dosage, 27.5 mg/l = lead concentration, and pH = 7 is required to achieve maximum percentage removal of lead. The said photocatalyst and the operating conditions can help in the study of lead removal from sanitary landfill leachate.

References

Position paper on the solid waste management sector in India (2009) Department of economic affairs, Ministry of Finance, Government of India

El-Salam MMAbd, Abu-Zuid GI (2015) Impact of landfill leachate on the groundwater quality: a case study in Egypt. J Adv Res 6:579–586

Hassan M, Zhao Y, Xie B (2016) Employing TiO2 photocatalysis to deal with landfill leachate: Current status and development. Chem Eng J 285:264–275

Mahmud K, Hossain MD, Shams S (2012) Different treatment strategies for highly polluted landfill leachate in developing countries. Waste Manag 32(11):2096–2105

Meeroff DE, Bloetscher F, Reddy DV, Gasnier F, Jain S, McBarnette A, Hamaguchi H (2012) Application of photochemical technologies for treatment of landfill leachate. J Hazard Mater 299–307

Esakku S, Palanivelu K, Joseph K (2003) Assessment of heavy metals in a municipal solid waste dumpsite. Workshop on Sustainable Landfill Management, 3–5 Dec 2003, pp 139–145

Talalaj IA (2015) Release of heavy metals from waste into leachate in active solid waste landfill. Environ Prot Eng 41:83–89

Wang X, Guo Y, Yang L, Han M, Zhao J, Cheng X (2012) Nanomaterials as sorbents to remove heavy metal ions in wastewater treatment. Environ Anal Toxicol, ISSN: 2161-0525

Hua M, Zhang S, Pan B, Zhang LW, Lv QZ (2012) Heavy metal removal from water/wastewater by nanosized metal oxides: a review. J Hazard Mater 211–212:317–331

Castellote M, Bengtsson N (2011) Principal of TiO2 photocatalysis. Applications of titanium dioxide photocatalysis to construction materials. Springer, Dordrecht. ISBN 978-94-007-1296-6

Zhang X, Song L, Zeng X, Li M (2012) Effects of electron donors on the TiO2 photocatalytic reduction of heavy metal ions under visible light. Energy Procedia 17(Part A):422–428

Kabra K, Chaudhary R, Sawhney RL (2008) Solar photocatalytic removal of metal ions from industrial waste water. AIChE Environ Prog 27(4):487–495

Kabra K, Chaudhary R, Sawhney RL (2008) Solar photocatalytic removal of Cu(II), Ni(II), Zn(II) and Pb(II): speciation modeling of metal–citric acid complexes. J Hazard Mater 155:424–432

Alalm MG, Tawfik A (2014) Solar photocatalytic degradation of phenol in aqueous solutions using titanium dioxide. Int J Chem Mol Nucl Mater Metall Eng 8(2):136–139

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Desai, N.N., Soraganvi, V.S. (2019). Performance of TiO2 Photocatalytic Nanomaterial in Removal of Lead from Sanitary Landfill Leachate Using Sunlight. In: Ghosh, S. (eds) Waste Valorisation and Recycling. Springer, Singapore. https://doi.org/10.1007/978-981-13-2784-1_44

Download citation

DOI: https://doi.org/10.1007/978-981-13-2784-1_44

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-2783-4

Online ISBN: 978-981-13-2784-1

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)